#Cryogenic Equipment Industry

Text

3 Key Insights on US$ 15 Bn Opportunity in the Global Stem Cell Banking Market - Ken Research

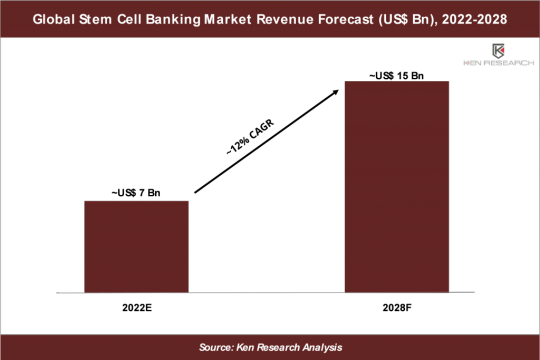

Driven By the increasing prevalence of infectious diseases and rising individuals’ awareness regarding the therapeutic potentials of stem cells, the Global Stem Cell Banking Market is forecasted to Cross US$ 15 Bn by 2028 says Ken Research Study.

Stem Cell Banking is the collection and cryogenic storage of stem cells from a newborn infant's umbilical cord blood and tissue which can be further used in cell treatments or clinical trials. It has the potential to treat a wide range of diseases, as well as the ability to mortgage stem cells from multiple family members and use an individual’s own stem cells (autologous transplant). Furthermore, individuals with spinal cord injuries, type 1 diabetes, Parkinson's disease, amyotrophic lateral sclerosis, Alzheimer's disease, heart disease, stroke, burns, cancer, and osteoarthritis may also benefit from stem cell therapies.

“Ken Research shares 3 key insights on this high opportunity market from its latest research study”

Stem Cell Banking Market Continues to Grow Owing to The Growing Newborn Population Worldwide.

The Global Stem Cell Banking Market is expected to witness stable growth during the forecast period, owing to the increasing newborn population, and rising individuals’ awareness regarding the therapeutic potentials of stem cells. The global stem cell banking market was valued at ~US$ 4 billion in 2017, it is estimated to be ~US$ 7 billion in 2022 and is expected to reach a market size of ~US$ 15 billion by 2028 growing with a CAGR of ~12%.

North America is the dominating region in the Global Stem Cell Banking Market due to the increasing incidence rates of diseases, such as cancer, neurological disorders, and diabetes. Furthermore, the growing government initiatives and investments in stem cell therapies are contributing to the region's growth in stem cell banking.

To learn more about this report Download A Free Sample Report

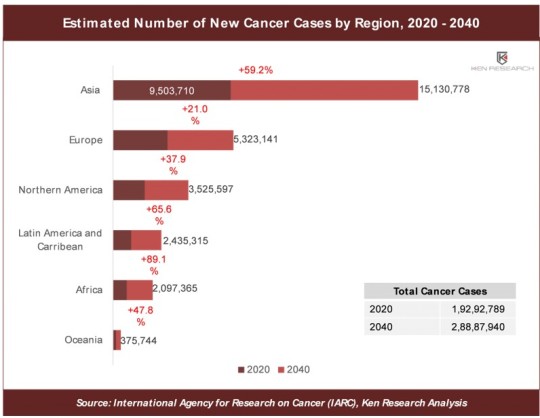

The Rising Prevalence of fatal Chronic Diseases, Such as Cancer, Cardiovascular Diseases, Neurological Disorders, Immunological Disorders, and Other Rare Metabolic Diseases is Propelling the Market Growth of Stem Cell Banking.

The growing geriatric population worldwide, who are more exposed to chronic and infectious diseases, including immunological disorders is propelling the stem cell banking market. In addition, the increasing prevalence of cancer, cardiovascular diseases, and autoimmune diseases, such as type 1 diabetes, and nephrological diseases is widening the use of stem cells as a potential treatment option.

For instance, according to Scientific American, an American science magazine that covers science, health, and social justice issues, several autoimmune diseases affected nearly 4.5% of the world's population in 2021.

According to the World Health Organization (WHO), a United Nations agency responsible for global public health, nearly 18 million people die every year as a result of cardiovascular diseases.

Visit This Link: - Request For Custom Report

High Operational Cost Associated with Stem Cell Banking, along with the stringent regulatory Frameworks May Impede the Market Growth of Stem Cell Banking.

Stem cell therapies have grown in popularity in recent years as individuals seek out alternative treatments for a variety of chronic diseases. Every day, new types of therapies are introduced, and individuals from all over the world are turning to them in place of traditional drug treatments and hospital visits. Despite the significant increase in demand for stem cell therapies, they remain prohibitively expensive to pursue. Simple joint injections cost close to US$ 5000, and more advanced treatments cost up to US$ 100,000, depending on the condition.

Furthermore, the stem cell field remains highly specialized and has yet to be adopted by citizens or insurance companies. Additionally, the field is further limited by older laws in some countries, most notably the United States. That means that there are relatively few sources for stem cells, and labs equipped to perform stem cells.

Request Free 30 Minutes Analyst Call

Key Topics Covered in the Report

Snapshot of the Global Stem Cell Banking Market

Industry Value Chain and Ecosystem Analysis

Market size and Segmentation of the Global Stem Cell Banking Market

Historic Growth of the Overall Global Stem Cell Banking Market and Segments

Competition Scenario of the Market and Key Developments of Competitors

Porter’s 5 Forces Analysis of the Global Stem Cell Banking Industry

Overview, Product Offerings, and Strengths & Weaknesses of Key Competitors

Covid-19 Impact on the Overall Global Stem Cell Banking Market

Future Market Forecast and Growth Rates of the Total Global Stem Cell Banking Market and by Segments

Market Size of Source, Service Type, Application, Cell Type Segments with Historical CAGR and Future Forecasts

Analysis of the Global Stem Cell Banking Market

Major Production/Supply and Consumption/Demand Hubs within Each Region

Major Country-wise Historic and Future Market Growth Rates of the Total Market and Segments

Overview of Notable Emerging Competitor Companies within Each Region

Notable Key Players Mentioned in the Report

CBR Systems, Inc.

Cryo-Cell International, Inc.

ViaCord

Sartorius AG

StemCyte, Inc.

Smart Cells International Limited

Global Cord Blood Corporation

Vita 34

LifeCell International Pvt. Ltd

Cordlife Group Limited

Notable Emerging Companies Mentioned in the Report

CyroHoldco

Generate Life Sciences Inc.

Hope Biosciences

Cell Care

ReeLabs Pvt. Ltd.

BrainStorm Cell Therapeutics, Inc.

CellSave a CSG-BIO Company, Inc.

Bristol-Myers Squibb Company

Key Target Audience – Organizations and Entities Who Can Benefit by Subscribing This Report

Stem Cell Banking Companies

Biopharmaceuticals Companies

Cord Blood Banks

Machinery and Equipment Suppliers for Stem Cell Banking

Cryogenic Healthcare Equipment Manufacturers

Biotechnology - Therapeutics and Diagnostics Companies

Pharmaceutical Companies

World Marrow Donor Association

Cord Blood Association

The International Stem Cell Banking Initiative (ISCBI) – PubMed

Healthcare Research Institutes

Healthcare Technology Research Institutes

Healthcare Technology Regulatory Authorities

Government Ministries and Departments of Healthcare

Period Captured in the Report

Historical Period: 2017-2021

Forecast Period: 2022E-2028F

For more insights on the market intelligence, refer to the link below: -

Global Stem Cell Banking Market

Related Reports By Ken Research: -

Global Stem Cell Banking Market Outlook to 2028

#Adipose Tissue-Derived Stem Cells Market#Africa Stem Cell Banking Market#Asia Pacific Stem Cell Banking Market#Biopharmaceuticals Companies#Biotechnology - Therapeutics and Diagnostics Companies#Bone Marrow-Derived Stem Cells Market#CBR Systems Stem Cell Banking Market#Challenges in Stem Cell Banking Industry#Cordlife Stem Cell Banking Market#Cryogenic Healthcare Equipment Manufacturers#Dental Pulp-Derived Stem Cells Market#Emerging Companies in Stem Cell Banking Market#Europe stem cell banking market#Global Players in Stem Cell Banking Market#Global Stem Cell Banking Application#Global Stem Cell Banking Industry#Global Stem Cell Banking Industry Outlook#Global Stem Cell Banking Market#Human Embryo-Derived Stem Cells Market#Key Competitors in Stem Cell Banking Market#Latin America Stem Cell Banking Market#Leading Players in Stem Cell Banking Industry#LifeCell Stem Cell Banking Market#Machinery and Equipment Suppliers for Stem Cell Banking#Major Companies in Stem Cell Banking Market#Middle East Stem Cell Banking Market#North America Stem Cell Banking Market#Opportunities in the Stem Cell Banking Market#Placental Stem Cells (PSCS) Banking Market#Sartorius Stem Cell Banking Market

0 notes

Text

Did you know that NASA engineers considered the failure rate of some critical shuttle parts to be about 1 in 100 (significantly greater than what NASA upper-management considered the failure rate to be, and what was considered at all acceptable by the certification process)?

Do you know that NASA engineers currently have no idea how many rocket launches the next mission in the Artemis program (in 2 years!) is meant to involve, because the mission plan relies on SpaceX being contracted to deliver a supply of cryogenic fuel to the crewed Orion (™ Lockheed-Martin) capsule in orbit - a procedure that 1: has never been attempted before on any spacecraft, let alone the Orion™ capsule, not even in uncrewed technology demonstration flights; and 2: would require an as-of-yet unknown number of SpaceX 'Starship' launches, because said vehicle does not actually exist at time of writing?

Did you know they're planning on using this 'starship' as the crewed lander? A design for a lunar ascent vehicle, that is, that does not use hypergolic fuel, that relies on a swing-out crane as the only entry and egress point? During the original moon landings, the LEM had so many redundant methods to make sure it got astronauts off the surface of the moon, that in the most absurd, extreme case, where every single mechanism fails, there's a procedure trained into the astronauts to climb around the outside of the capsule, take a pair of bolt-cutters from the equipment box, physically cut the couplings holding the capsule to the lander stage, and take off to get home. Artemis' proposed lander, on the other hand, is planned to be a vehicle whose design didn't even include heatshields until it was realised it would obviously need heatshields, which are ceramic tiles bolted after-the-fact directly through the steel hull, because SpaceX had decided to mass-produce the original-design hull sections all at once for all the 'starships' first, before doing any integrated testing.

We're seeing the exact attitude that led to the shuttle disasters not being prevented now expressing itself in (and even through) the Artemis program, a project pushed harder and faster through the gates than it should be, by a government (and NASA administration thereby) desperate to advance the eponymous Artemis Accords (that goes unsigned by China, Russia, and much of the world) and reneg on all previous space charters that onsidered ownership, commercial exploitation, and military usage of space forbidden. Something bad is going to happen, and it's going to happen for the sake of SpaceX and the military-industrial complex at large.

2K notes

·

View notes

Text

Get Med Online: Your One-Stop Shop for Medical and Lab Equipment

Looking for a way to make sure your baby's bottles are always clean and sterile? An automatic sterilizer is the answer! These handy devices can be a real lifesaver for busy parents. Here's everything you need to know about automatic sterilizers, including how they work, the different types available, and the pros and cons of using one.

Get Med Online is your one stop shop for all your medical equipment needs. We carry a wide range of products from leading brands such as Automatic Sterilizer, ECG Equipment & Supplies, Electrosurgical Smoke Evacuators, and Sterilizer Equipment. With our huge selection, you're sure to find the perfect product for your needs.

An automatic sterilizer is a machine that uses either steam or dry heat to sterilize equipment and supplies. Automatic sterilizers are commonly used in hospitals, clinics, and other healthcare settings to sterilize items such as instruments, dressings, and other materials.

There are several different types of automatic sterilizers available, including tabletop sterilizers, floor-standing sterilizers, and portable sterilizers. Tabletop sterilizers are small and can be placed on a countertop or other surface. Floor-standing sterilizers are larger and must be placed on the floor. Portable sterilizers are small and can be carried from one location to another.

There are several factors to consider when choosing an automatic sterilizer, including the type of sterilizer, the size of the unit, the number of items to be sterilized, the frequency of use, and the budget.

If you're looking for a top-of-the-line autoclave sterilizer, look no further than the Automatic Sterilizer from ECG Equipment & Supplies. This advanced sterilizer uses the latest in autoclave technology to quickly and effectively sterilize your surgical tools and instruments. Additionally, the Automatic Sterilizer features a built-in smoke evacuator that quickly and efficiently removes any surgical smoke from the operating room, keeping your OR clean and safe for both you and your patients.

You can visit our website https://www.getmedonline.com/ or call us at 631-803 2694 to seek our website today.

#Cryogenic Equipment & Supplies#Electrosurgical Generators and Supplies#Clinical and Industrial Lighting Fixtures

0 notes

Text

Factors to Consider When Choosing Dewars and Cryogenic Vessels

When selecting Dewars and cryogenic vessels for your business needs, it's important to consider several factors to ensure that you choose the right equipment. Here are some key factors to keep in mind:

Purpose and Application: Determine the specific purpose and application of the vessels you need. Consider the type of materials you will be storing or transporting, their temperature requirements, and any specific handling or safety considerations.

Capacity and Size: Assess your storage or transportation needs in terms of capacity and size. Consider the volume of materials you need to store or transport and choose vessels that can accommodate your requirements. Keep in mind that larger vessels may offer more storage capacity but may also be more challenging to handle and transport.

Material and Construction: Pay attention to the material and construction of the Dewars and cryogenic vessels. Stainless steel and aluminum are commonly used materials as they offer durability and resistance to low temperatures. Glass vessels may be suitable for certain applications but can be more fragile. Choose vessels that are designed to withstand the temperatures and conditions specific to your application.

Insulation: Consider the insulation capabilities of the vessels. Effective insulation is crucial for maintaining the low temperatures required for cryogenic storage. Look for vessels with high-quality insulation materials and designs that minimize heat transfer and provide efficient temperature control.

Safety Features: Ensure that the vessels you choose have appropriate safety features. This may include pressure relief valves, emergency venting systems, and secure closures to prevent leaks or spills. Safety should be a top priority when dealing with cryogenic materials.

Supplier Reputation and Support: Research and choose reputable suppliers or manufacturers with experience in producing high-quality Dewars and cryogenic vessels. Consider factors such as product warranties, technical support, and after-sales service. A reliable supplier will be able to provide guidance and assistance throughout the lifespan of the equipment.

Compliance with Regulations: Verify that the Dewars and cryogenic vessels you choose comply with relevant regulations and standards in your industry. This ensures that the equipment meets safety and performance requirements and can be used legally and responsibly.

Conclusion

Choosing the right Dewars and cryogenic vessels is essential for businesses that require storage or transportation of materials at extremely low temperatures. By considering factors such as purpose, capacity, materials, insulation, safety features, supplier reputation, and compliance with regulations, you can make an informed decision that suits your business needs.

It's recommended to consult with industry experts or suppliers who specialize in cryogenic equipment to get personalized recommendations based on your specific requirements. They can provide valuable insights and guidance to help you choose the most suitable Dewars and cryogenic vessels for your business.

#Liquid nitrogen dewar#cryogenic nitrogen dewars#cryogenic nitrogen tank#cro storage dewars#nitrogen dewar flask

2 notes

·

View notes

Text

Cryogenic Equipment: Revolutionizing the Field of Cold Temperature Applications

In recent years, cryogenic equipment has gained significant recognition and importance in various industries that rely on low-temperature applications. From medical research and space exploration to food preservation and industrial processes, cryogenic equipment enables advancements and enhances efficiency.

Cryogenic Equipment Overview

Many industries rely on low-temperature applications; thus, cryogenic equipment is vital. Cryogenic equipment is essential in various sectors that depend on low-temperature applications. Cryogenic equipment comprises specialized devices and components designed to work under severe cold environments. These include storage tanks, pumps, valves, and refrigeration systems that allow cryogenic chemicals to be handled, stored, and transported.

Cryogenic Applications in Medical Research

Medicine is one of the most renowned sectors where cryogenic equipment has revolutionized study. Cryopreservation techniques have considerably aided the success of organ transplantation, fertility preservation, and regenerative medicine breakthroughs.

Cryogenics in Space Exploration

Space exploration relies heavily on cryogenic equipment for its various missions and operations. Cryogenic fuels such as liquid oxygen and liquid hydrogen are used in rocket propulsion systems, offering high energy efficiency and greater thrust.

These fuels are stored and handled using specialized cryogenic equipment to maintain low temperatures and prevent vaporization. By utilizing cryogenics, space agencies can propel spacecraft more efficiently, enabling more extended missions and exploration of distant celestial bodies.

Conclusion

Cryogenic equipment has unquestionably altered many businesses by enabling novel applications and increasing operating efficiency. The potential for further breakthroughs in cryogenic equipment is tremendous as technology continues to evolve. We can unlock new frontiers and design a future where cold temperature applications are effortlessly incorporated into our daily lives by harnessing the potential of ultra-low temperatures.

2 notes

·

View notes

Text

Setting Blurb: Non-Imperial Polities

· The Cordons Sanitare: It is misleading to assume that the coalition of warlords and their nascent League was accepted by all the world’s population. A dozen or so city-states located in the Americas, Europe, and Asia remained nominally independent from the League. These independent cities were then used by neighbors in the League to “dump” their political and social undesirables. This practice continued well into the final stages of the Crystalline War, halted only by those cities’ destruction during the war.

· Fugitive Clans: Throughout Imperial territory, Serviles in large enough numbers overpower their captors and flee into areas that are difficult to pursue. In orbital habitats these bands are short lived, but on Mars and other terrestrial colonies fugitive communities can survive for decades before being discovered by Imperial forces.

· Hoppe City: Founded on the planetoid Ceres in the Solar asteroid belt, Hoppe City is home to the largest settlements of the anarcho-capitalist “Covenanter” movement. Hoppe City is also home to a large number of industries deemed too “sinful” for Imperial citizens to pursue (such as the ones that brought about the “Catgirl Incident” during the Transhuman Wars).

· Libertania: Originally a decommissioned Space Force mothership stolen by Belter insurgents during the Mining Wars of the 2600s, the mobile free port became a haven for economic dissidents and others wishing to not live under the Imperial System. Despite abandoning piracy to escape Imperial reprisal, Libertania's denizens maintain some aspects of the "buccaneer lifestyle".

· The Sedna Soviet: During the Martian War for Independence, Imperial military intelligence discovered discrepancies in the projected and actual manpower and equipment used by the disparate rebel groups on Mars. A lengthy investigation revealed that many revolutionary organizations within the Cordons Sanitaire had sent materiel and personnel in support of the rebels. Fearing retribution from the Imperial Military, rebel sympathizer that could fled to the Trans-Neptunian Object Sedna. Over the years, more and more immigrants arrived at the cold planetoid as the Cordons Sanitaire were purged of their more volatile denizens.

· Free Centauri Movement: Many denizens of the Cordons Sanitaire by the dawn of the 29th Century were desperate to escape their dilapidated living conditions on Earth. So desperate in fact, that they were willing to indenture themselves to the Imperial firms responsible for the construction and maintenance of colonial spacecraft. Following the arrival at Alpha Centauri, through manumission or mutiny, many of those laborers (and a few former Imperial sympathizers) made their way to Alpha Centauri A’s asteroid belt and established their own polities there.

· Xorta Conglomerate: As the Imperial League constructed their colonial spacecraft, many independent “Adventurers, Contractors, and Security” hired themselves onto the project. Cryogenically freezing themselves, these independents broke off once the expedition reached Proxima Centauri and seized Proxima Centauri C for themselves.

· The Spartacus Republic/State of Atlas: Like a majority of the extrasolar colonial expeditions launched by the League, the Procyon colonists were sent back in time by the extradimensional Fay during their voyage. Once it became apparent that they were cut off from the League for a time much longer than originally planned, the Servile population revolted and took over the vessel. In the centuries that followed, the rebel government fragmented along ideological lines. Currently, a tense peace exists between the communist Spartacus Republic and capitalist State of Atlas, though they may put aside their differences once Imperial forces arrive and return them to the fold.

· Trappist Refugees: While many displaced peoples fled to the Outer Solar System during the conflicts of the Second and Third Dynasties, those that fled the wars of the Fourth Dynasty wanted nothing to do with what the Solar System was becoming. Braving forty-odd years of interstellar void and the machinations of the Fay, wave after wave of refugees arrived at the three habitable worlds of the Trappist-1 System prior to the Fourth Servile Revolt. The different waves of refugees fought one another over the worlds until the arrival of military deserters and mutineers.

· The Persianate: As the Fourth Dynasty was growing more and more in unpopularity, more and more Imperial subjects expressed their dislike by any means possible. The usual response to these protestations came in the form of the Fourth Dynasty dispatching the military and crush dissent. When the men of the 213rd Mechanized Infantry Division were given orders to make an example out of their fellow countrymen in the Iranic Habitat Cluster of Viceroyalty Ummah, they overpowered their mothership’s crew and made the two-generation long journey to the Trappist-1 system. The mutineers easily conquered the settlements of Trappist-1 f and established themselves as the world’s ruling class.

· The Zouavians: During the Martian phase of the Transhuman Wars the 128th Specialist Infantry Division, also known as the Zouaves Division, were among the few loyalist units to evacuate the planet intact. Fearing punishment for their refusal to fight to the last on the Red World, the Zouaves fled to the Trappist-1 system as so many had done before. Unlike the founders of the Persianate on Trappist-1 f, the Zouaves had a more difficult time subjugating Trappist-1 g, as the original settlers there wizened up following the first major invader to their refuge. The Zoauves broke up into tribal groups that still compete among each other and the locals over territory to this day.

10 notes

·

View notes

Text

A516 Grade 65 Steel Plates Dealers in India

INTRODUCTION:-

Vandan Steel & Engg. co. depended on the hypothesis of persistently seeing the necessities of its customers and understanding that quality, on-time movement, cost and customer advantage are imperative to it accomplishment. It is depended on the hypothesis of persistently seeing the necessities of its customers and understanding that quality, on-time movement, cost and customer advantage are imperative to it accomplishment.

Vandan Steel & Engg. co. Can redraw Plates for customers that require phenomenal plate sizes or specific tempers for their application. It is one of the apparent maker and intermediary of SA 516 GR.65 PLATES far and wide. The courses of action given by the association are satisfactory to withstand sodium chloride conditions with extraordinary dangerous fruitful properties. The to some degree higher purposeful worth of plates can withstand zones including high chloride presentation especially in enthusiastically salt and waterfront zones.

DESCRIPTION:-

The GR.65 PLATES are the most outstanding or typical sort of steel that got utilized generally in light of splendid utilization impediment properties similarly as included characteristics. The carbon steel plates contain around 24 percent chromium and 16 present chromium what's more with 35 percent nickel. It in like manner contains little traces of manganese and carbon.

The strength of Grade 65 Pressure Vessel plates makes it less difficult to decontaminate therefore making it ideal for sustenance similarly as kitchen applications. It might be used routinely in elaborate design, building, or else products. A metallurgical trademark makes the plates set up through the extension of 8 percent nickel that extends disintegration hindrance through the decline of manufactured mixes.

The plates are offered well wherever all through the globe in different width, surface, length, points of interest, finishing, structure, and benchmarks. A bit of the known endeavors where it got utilized are substance equipment, seawater apparatus, condensers, and gas planning.

The SA 516 carbon steel plates are made using the most momentous nature of unrefined material similarly as another assessment. The features that make it top notch thing are high control, particular to utilization, disintegration hindrance pliability, hardness, and long utilitarian life, The GR.65 plates can suffer successfully in over the top temperature, and condition thus contributing best results.

SPECIFICATION:-

Grade: ASME SA 516 GR.65 Boiler and Pressure Vessel Steel Plates

Width: 1500mm-3000mm

Thickness: 3 - 200 mm/ dimensions up to 4.000 mm

Length: 3000mm-11000mm.

Production: Hot-Rolled (HR)

Heat Treatment: Rolled/Normalised/N+T/QT

BENEFIS OF A516 GRADE 65 STEEL PLATES:-

Excellent Toughness: These plates exhibit excellent toughness, even at low temperatures, making them suitable for cryogenic applications and environments with stringent toughness requirements.

Good Weldability: Like Grade 60, Grade 65 plates offer good weldability, facilitating ease of fabrication and construction of pressure vessels and boilers.

Corrosion Resistance: A516 Grade 65 plates demonstrate good resistance to corrosion and oxidation, ensuring durability and longevity in corrosive environments.

Normalized Heat Treatment: Similar to Grade 60, Grade 65 plates are often normalized to enhance their mechanical properties, including toughness and ductility, ensuring reliable performance under various operating conditions.

Compliance with Standards: A516 Grade 65 steel plates are manufactured in compliance with ASTM/ASME standards, guaranteeing consistent quality and adherence to industry specifications.

CONCLUSION:-

In conclusion, A516 Grade 65 steel plates offer a robust solution for demanding pressure vessel and boiler applications. With their higher yield strength, excellent toughness, good weldability, corrosion resistance, and compliance with industry standards, these plates are well-suited for critical environments in various sectors, including oil and gas, petrochemical, power generation, and chemical processing. Whether facing high-pressure conditions, extreme temperatures, or corrosive atmospheres, A516 Grade 65 plates provide reliability and performance, making them a preferred choice for engineers and manufacturers seeking high-quality materials for their projects.

CONTACT US:-

Phone : 022-23893665

Phone : +91-8828813630

E-mail : [email protected]

#A516 GRADE 65 Steel Plates#A516 GRADE 65 Steel Plates Suppliers#A516 GRADE 65 Steel Plates Exporters#A516 GRADE 65 Steel Plates Importers#A516 GRADE 65 Steel Plates Authorized Distributer#A516 GRADE 65 Steel Plates Dealers

0 notes

Text

Inconel 625 Flanges

In the realm of industrial applications where extreme temperatures, corrosive environments, and high pressures are the norm, the choice of materials becomes paramount. Among the arsenal of materials designed to withstand such conditions, Inconel 625 stands out as a formidable alloy. When it comes to connecting pipes or valves in critical systems, Inconel 625 flanges offer an indispensable solution, combining resilience, durability, and versatility.

Understanding Inconel 625: Inconel 625 is a nickel-based superalloy renowned for its exceptional resistance to corrosion and high temperatures. Composed primarily of nickel, chromium, and molybdenum, with additions of niobium, tantalum, and other elements, Inconel 625 exhibits superb mechanical properties even in harsh environments. Its resistance to chloride-ion stress-corrosion cracking makes it a top choice for applications in marine and chemical processing industries.

Strengths of Inconel 625 Flanges:

Corrosion Resistance: One of the most prominent features of Inconel 625 flanges is their remarkable resistance to corrosion. Whether it's exposure to acidic solutions, seawater, or high-temperature steam, these flanges remain steadfast, ensuring the integrity of the connected components over extended periods.

High-Temperature Stability: Inconel 625 retains its strength and structural integrity even at elevated temperatures, making it ideal for applications involving heat exchangers, boilers, and exhaust systems. The alloy's ability to withstand oxidation and creep deformation at high temperatures ensures reliable performance in demanding conditions.

Mechanical Strength: With its excellent tensile strength, fatigue resistance, and toughness, Inconel 625 ensures that flanged connections can withstand the rigors of industrial operations. This strength is particularly crucial in applications where high pressures and mechanical stresses are commonplace.

Versatility: Inconel 625 flanges find applications across a wide spectrum of industries, including aerospace, chemical processing, marine engineering, and oil and gas. Their versatility stems from the alloy's ability to maintain performance across diverse environments, from cryogenic temperatures to extreme heat.

Weldability: Inconel 625 is readily weldable using conventional welding techniques, enabling the fabrication of complex structures and assemblies. This weldability ensures ease of installation and maintenance for flanged connections, reducing downtime and enhancing operational efficiency.

Applications of Inconel 625 Flanges:

Oil and Gas Industry: Inconel 625 flanges are widely used in oil refineries, offshore platforms, and petrochemical plants, where they provide reliable connections in corrosive environments and high-pressure systems.

Chemical Processing: From reactor vessels to pipelines, chemical processing facilities rely on Inconel 625 flanges to maintain the integrity of critical connections exposed to corrosive chemicals and high temperatures.

Aerospace Engineering: In aerospace applications, where lightweight yet durable materials are essential, Inconel 625 flanges find use in propulsion systems, exhaust ducts, and turbine engines, ensuring performance under extreme conditions.

Marine Engineering: The marine industry benefits from the corrosion-resistant properties of Inconel 625 flanges, employing them in seawater piping systems, desalination plants, and shipboard equipment where durability is paramount.

Conclusion: Inconel 625 flanges represent a pinnacle of engineering excellence, offering unparalleled corrosion resistance, high-temperature stability, and mechanical strength. As a vital component in critical systems across various industries, these flanges exemplify the resilience and versatility of Inconel 625 alloy, ensuring the integrity and longevity of interconnected components in the face of demanding operating conditions.

0 notes

Text

0 notes

Text

Lox lin lar cryogenic centrifugal pump

Brightway centrifugal pumps are typically used in air separation plants to pressurize cryogenic liquids (LOX, LIN, LAR, LNG) and circulate them in the system.

Cryogenic centrifugal pumps are used to pump liquefied gases from storage tanks and subsequently to deliver low temperature liquids from tanks to the consumer (for example, filling of cryogenic semi-trailers of tanks). The multistage design of the pump significantly increases its head as compared to the single-stage design.

Company Name:Huzhou Baihui Cryogenic Equipment Co., Ltd

Web:https://www.brightwaycryogenic.com/products/cryogenic-centrifugal-pump/lox-lin-lar-cryogenic-centrifugal-pump.html

ADD:Building A38, China Energy Conservation and Environmental Protection Industrial Park, No. 1506, Yishan Road, Wuxing District, Huzhou City, Zhejiang Province, China

Phone:86-18257285710

Email:[email protected]

Tip:313000

Profile:With long working life, low maintenance cost and high cost performance, our cryogenic liquid pumps are sold well both locally and internationally. Our cryogenic liquid pumps have reached globally such as Southeast Asia、Central Asia、Middle East 、Latin America and African Region.

0 notes

Text

Lifesigns from Plug Power - Footprint with Major Agreements

Lifesigns from Plug Power. Plug Power continues to make significant strides in the renewable energy sector, with recent announcements highlighting its ongoing commitment to innovation and expansion. On Tuesday, May 2, 2024, Plug Power unveiled several key developments that underscore its growing influence in the global clean energy landscape.

Plug Power to supply 3 gigawatts (GW) for Australian.

One of the most notable announcements is Plug Power's preliminary agreement to supply 3 gigawatts (GW) of electrolysers for an Australian green hydrogen and ammonia project. This landmark deal, established through a memorandum of understanding (MOU) with Allied Green Ammonia, demonstrates Plug Power's dedication to advancing sustainable energy solutions on a global scale. The collaboration aims to support AGA's upcoming hydrogen to ammonia facility in the Northern Territory of Australia, marking a significant milestone in the transition towards a greener future.

Plug Power is also making significant strides in North America

In addition to its international expansion efforts, Plug Power is also making significant strides in North America. The company has successfully secured multiple contracts in the region, further solidifying its position as a leader in the hydrogen industry. Among these contracts is the delivery of eight low-temperature trailers for the US and Canadian markets. With delivery scheduled for the second half of 2025, Plug Power is poised to meet the growing demand for hydrogen infrastructure and transportation solutions in North America.

Plug Power services with the certification of liquid hydrogen storage in Korea.

Furthermore, Plug Power is enhancing its cryogenic equipment services with the certification of liquid hydrogen storage tanks and transport trailers in Korea. This strategic initiative underscores Plug Power's commitment to offering comprehensive solutions for the storage, transportation, and utilization of hydrogen across various industries.

Lifesigns from Plug Power again since months

As Plug Power continues to expand its global footprint and forge strategic partnerships worldwide, the company remains at the forefront of driving the transition towards a sustainable energy future. With a portfolio of cutting-edge technologies and a relentless focus on innovation, Plug Power is poised to shape the future of renewable energy and accelerate the adoption of clean hydrogen solutions on a global scale. Readmore on Plug Power

Plug Power Stock under 3usd, the right time to buy?

Read the full article

0 notes

Text

low temperature circulating bath

A low-temperature circulating bath is a specialized piece of equipment used in laboratories and industrial settings

for precise temperature control of samples and experiments at temperatures below ambient. It consists of a thermostatic

bath filled with a heat transfer fluid, typically a mixture of water and a cryogenic agent like ethylene glycol or

propylene glycol, which allows the bath to achieve temperatures well below 0°C.

0 notes

Text

Elevate Your Research with the Best Physics Lab Equipment Manufacturers

Are you looking to push the boundaries of scientific discovery? To unlock the mysteries of the universe? The quality of your research depends heavily on the tools at your disposal. When it comes to physics, precision, reliability, and innovation are paramount. That's why partnering with the best lab equipment manufacturer is crucial.

Why Quality Lab Equipment Matters

In the realm of physics, where experiments often hinge on minute details and intricate measurements, the significance of high-quality lab equipment cannot be overstated. Whether you're studying quantum mechanics, electromagnetism, or astrophysics, the accuracy and reliability of your instruments directly impact the validity and reproducibility of your results.

Key Considerations in Choosing a Manufacturer

1. Precision Engineering: Look for manufacturers known for their precision engineering. Instruments must be built to exacting standards to ensure accurate measurements and dependable performance.

2. Durability and Reliability: Physics experiments can be rigorous, subjecting equipment to extreme conditions. Choose equipment known for its durability and reliability to withstand the demands of your research.

3. Innovation and Technology: Advancements in physics often stem from breakthroughs in instrumentation. Partner with manufacturers at the forefront of technological innovation to access cutting-edge equipment that can propel your research forward.

4. Customization Options: Every research project is unique, with its own set of requirements. Opt for manufacturers who offer customization options, allowing you to tailor equipment to your specific needs.

5. Support and Service: Beyond the initial purchase, consider the level of support and service offered by the manufacturer. Timely maintenance, technical support, and readily available spare parts are essential for uninterrupted research.

Leading Physics Lab Equipment Manufacturers

1. Keysight Technologies: Renowned for its precision measurement solutions, Keysight Technologies offers a comprehensive range of instruments for fundamental research in physics, including signal analyzers, oscilloscopes, and spectrum analyzers.

2. Thorlabs: Specialising in photonics and optomechanics, Thorlabs provides high-quality equipment for applications ranging from quantum optics to laser spectroscopy.

3. Newport Corporation: With a focus on precision motion control and optical technologies, Newport Corporation offers a diverse portfolio of products ideal for experimental setups in atomic, molecular, and optical physics.

4. Bruker Corporation: Known for its advanced analytical instrumentation, Bruker Corporation provides cutting-edge solutions for materials research and nanotechnology, including atomic force microscopes and scanning electron microscopes.

5. Lake Shore Cryotronics: For researchers exploring low-temperature phenomena, Lake Shore Cryotronics offers a range of cryogenic and temperature measurement instruments crucial for condensed matter physics and quantum computing.

Conclusion

In the pursuit of scientific discovery, the right tools can make all the difference. By partnering with the best physics lab equipment manufacturers, you can elevate your research to new heights, unlocking the mysteries of the universe and driving innovation in the field of physics. Choose wisely, invest in quality, and embark on a journey of exploration and discovery that knows no bounds.

For more information visit us : https://supertekedu.com/physics/

Mail us: [email protected]

Call us: (+91-171-2699537 / 2699297)

Location:23, Industrial Estate, Ambala Cantt-133006

0 notes

Text

Egg Freezing Cost in Bangkok

In recent years, egg freezing has emerged as a revolutionary reproductive technology, offering women the opportunity to preserve their fertility for various reasons such as medical conditions, career pursuits, or personal choice. Bangkok, the bustling capital city of Thailand, has become a prominent destination for individuals seeking affordable and high-quality egg freezing services. However, understanding the egg freezing cost in Bangkok requires a nuanced exploration of various factors that influence pricing and overall expenses.

Egg freezing, also known as oocyte cryopreservation, involves the retrieval and freezing of a woman’s eggs for future use. The process typically begins with ovarian stimulation, where fertility medications are administered to stimulate the ovaries to produce multiple eggs. These eggs are then retrieved through a minor surgical procedure performed under sedation. After retrieval, the eggs are carefully frozen using a process called vitrification, which preserves them at extremely low temperatures until they are needed.

When considering the cost of egg freezing in Bangkok, several key factors come into play:

1. Medical Consultation and Evaluation: The initial consultation with a fertility specialist is essential to assess the individual’s medical history, conduct fertility tests, and discuss treatment options. This consultation fee may vary depending on the clinic and the expertise of the physician.

2. Ovarian Stimulation Medications: The cost of fertility medications used for ovarian stimulation can significantly impact the overall expenses. The dosage and duration of medication vary depending on the individual’s ovarian reserve and response to treatment.

3. Egg Retrieval Procedure: The surgical procedure to retrieve the eggs is typically performed in an outpatient setting. The cost includes anesthesia, medical equipment, and the expertise of the fertility specialist and supporting staff.

4. Laboratory Fees: After retrieval, the eggs undergo various laboratory processes, including evaluation, grading, and vitrification. Laboratory fees cover these services and the maintenance of frozen eggs in storage.

5. Storage Fees: Once frozen, the eggs are stored in specialized cryogenic tanks at the fertility clinic’s storage facility. Storage fees are charged annually or monthly, depending on the clinic’s policies.

6. Additional Services and Ancillary Costs: Some clinics may offer additional services such as genetic testing (preimplantation genetic screening or diagnosis) or optional procedures like sperm freezing for future fertility treatments. These services incur additional costs beyond the basic egg freezing procedure.

7. Travel and Accommodation: For individuals traveling to Bangkok for egg freezing, expenses such as transportation, accommodation, and meals should be considered in the overall budget.

While Bangkok is known for its competitive pricing in the medical tourism industry, the cost of egg freezing may vary from one clinic to another. It is essential for individuals to research and compare multiple clinics, considering not only the cost but also the reputation, success rates, and quality of services provided.

Moreover, many fertility clinics in Bangkok offer package deals or financing options to help make egg freezing more accessible to a broader range of individuals. These packages may bundle multiple services together at a discounted rate or offer flexible payment plans to ease the financial burden.

In conclusion, the egg freezing cost in Bangkok can be influenced by various factors, including medical consultation, ovarian stimulation medications, procedural fees, laboratory services, storage, and additional services. By understanding these factors and exploring available options, individuals can make informed decisions regarding their fertility preservation journey in Bangkok, ultimately empowering them to take control of their reproductive futures.

0 notes

Text

Technical Insulation Market: Trends, Growth, and Forecast

Introduction

The Technical Insulation Market plays a vital role in various industries by providing thermal, acoustic, and fire protection solutions. From residential buildings to industrial facilities, technical insulation is essential for optimizing energy efficiency, enhancing occupant comfort, and ensuring the safety and longevity of infrastructure. In this comprehensive analysis, we delve into the key trends, growth drivers, and future forecasts shaping the Technical Insulation Market.

According to the study by Next Move Strategy Consulting, the global Technical Insulation Market size is predicted to reach USD 11.82 billion with a CAGR of 4.0% by 2030.

Request for a sample, here: https://www.nextmsc.com/technical-insulation-market/request-sample

Trends Shaping the Technical Insulation Market

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency across industries is a primary driver fueling the demand for technical insulation solutions. As organizations strive to reduce energy consumption and minimize environmental impact, there is a growing preference for insulation materials that offer superior thermal performance. Technical insulation plays a crucial role in minimizing heat loss or gain in buildings, industrial equipment, and pipelines, thereby contributing to energy conservation efforts.

Advancements in insulation materials, such as aerogels, vacuum insulation panels, and eco-friendly foams, are enabling improved thermal insulation properties while ensuring sustainability. These innovative materials offer high thermal resistance and durability, making them ideal for applications where energy efficiency is paramount.

Advancements in Insulation Materials

Technological innovations have revolutionized the technical insulation industry, leading to the development of advanced materials with superior performance characteristics. Traditional insulation materials such as fiberglass and mineral wool are being augmented with newer options that offer enhanced thermal conductivity, moisture resistance, and fire retardancy.

Aerogels, for instance, are lightweight, highly porous materials with exceptional thermal insulating properties. These silica-based materials possess low thermal conductivity, making them effective insulators for a wide range of applications, including building envelopes, cryogenic systems, and aerospace components.

Vacuum insulation panels (VIPs) represent another breakthrough in insulation technology. Consisting of a rigid core encased in a gas-tight envelope, VIPs achieve extremely low thermal conductivity by minimizing convective and conductive heat transfer. These panels are increasingly being used in refrigeration, cold chain logistics, and building insulation applications.

Furthermore, eco-friendly insulation materials derived from renewable sources, such as soybean oil-based foams and cellulose insulation made from recycled paper, are gaining traction due to their sustainability credentials. These bio-based materials offer comparable thermal performance to traditional insulation options while reducing environmental impact.

Focus on Green Building Standards

The construction industry is undergoing a paradigm shift towards sustainable building practices, driven by increasing awareness of environmental conservation and energy efficiency. Green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), are becoming increasingly prevalent, influencing design and construction decisions worldwide.

Technical insulation plays a pivotal role in achieving green building certifications by enhancing energy efficiency and thermal comfort within buildings. By minimizing heat transfer through walls, roofs, and floors, insulation helps reduce heating and cooling loads, thereby lowering energy consumption and operational costs. Additionally, insulation materials with high recycled content and low embodied energy contribute to the overall sustainability of building projects.

Expansion in Industrial Infrastructure

The rapid expansion of industrial infrastructure, particularly in emerging economies, is driving significant demand for technical insulation solutions. Industries such as power generation, oil and gas, petrochemicals, and manufacturing rely heavily on insulation to maintain optimal operating temperatures, protect personnel and equipment, and ensure process efficiency.

In power generation facilities, for example, thermal insulation is critical for steam turbines, boilers, and piping systems to minimize heat losses and maximize energy conversion efficiency. Similarly, in the oil and gas sector, insulation is utilized in pipelines, storage tanks, and processing equipment to prevent heat transfer, reduce energy consumption, and mitigate the risk of corrosion under insulation (CUI).

The petrochemical industry also relies on technical insulation for maintaining process temperatures and ensuring product quality and safety. Insulation materials with excellent chemical resistance and thermal stability are essential for withstanding harsh operating conditions in chemical processing plants and refineries.

Growth Drivers of the Technical Insulation Market

Regulatory Mandates

Stringent regulations and building codes mandating the use of energy-efficient insulation materials are driving market growth across regions. Governments worldwide are implementing measures to reduce greenhouse gas emissions, combat climate change, and promote sustainable development. As a result, building energy codes are being updated to include requirements for enhanced thermal performance and insulation levels.

In Europe, for instance, the Energy Performance of Buildings Directive (EPBD) sets minimum energy performance standards for new and existing buildings, including requirements for thermal insulation. Similarly, in the United States, the International Energy Conservation Code (IECC) establishes criteria for building envelope insulation, HVAC systems, and lighting efficiency to improve overall energy efficiency.

Compliance with these regulatory mandates necessitates the adoption of advanced insulation materials and construction techniques to achieve the prescribed energy performance targets. As a result, manufacturers and suppliers of technical insulation products are witnessing increased demand for their solutions, particularly those that offer high thermal resistance, durability, and environmental sustainability.

Urbanization and Industrialization

The ongoing trends of urbanization and industrialization are driving the demand for technical insulation solutions globally. As populations migrate to urban centers in search of employment opportunities and better living standards, there is a corresponding need for infrastructure development to accommodate growing urban populations.

Residential and commercial construction projects in urban areas require effective insulation solutions to ensure thermal comfort, indoor air quality, and energy efficiency. Proper insulation of buildings helps reduce heating and cooling loads, thereby lowering energy consumption and utility bills for occupants.

In addition to urban construction, industrial infrastructure projects are also driving demand for technical insulation products. The expansion of manufacturing facilities, power plants, refineries, and chemical processing plants necessitates the installation of insulation systems to maintain process temperatures, protect equipment, and ensure operational reliability.

Focus on Renewable Energy

The global transition towards renewable energy sources, such as solar, wind, and geothermal power, is creating new opportunities for the technical insulation market. Renewable energy technologies rely on efficient insulation systems to maximize energy capture, storage, and distribution while minimizing heat losses and environmental impact.

Solar photovoltaic (PV) systems, for example, require insulation materials to protect electrical components, minimize thermal losses, and optimize performance under varying weather conditions. Insulated piping and storage tanks are essential for solar thermal systems used for heating water or generating steam for industrial processes.

Similarly, wind turbines utilize insulation to protect critical components such as gearboxes, generators, and control systems from temperature extremes, moisture ingress, and mechanical wear. Insulated enclosures and thermal barriers help maintain stable operating conditions within turbine nacelles, ensuring reliable performance and longevity.

Geothermal heating and cooling systems also rely on effective insulation to enhance energy efficiency and thermal stability. Underground piping networks, heat exchangers, and thermal storage tanks are insulated to minimize heat loss during heat transfer processes, thereby improving system efficiency and reducing operating costs.

Forecast for the Technical Insulation Market

The outlook for the technical insulation market remains promising, with sustained growth expected in the coming years. Factors such as increasing investments in infrastructure development, regulatory support for energy efficiency initiatives, and the expansion of end-use industries will drive market expansion across regions.

Furthermore, advancements in insulation materials, manufacturing processes, and installation techniques will continue to drive innovation and product development in the technical insulation sector. Manufacturers are investing in research and development to enhance the performance, sustainability, and cost-effectiveness of their insulation products, thereby addressing evolving customer needs and market demands.

Regional Insights and Market Dynamics

North America

North America is a significant market for technical insulation products, driven by robust construction activity, industrial expansion, and regulatory mandates for energy efficiency. The United States and Canada are witnessing increased adoption of insulation solutions in residential, commercial, and industrial applications to meet stringent building codes and sustainability goals.

In the United States, initiatives such as the Department of Energy's Better Buildings Challenge and the Environmental Protection Agency's ENERGY STAR program are driving demand for energy-efficient building solutions, including insulation upgrades and retrofits. Building owners and facility managers are investing in insulation improvements to reduce energy consumption, lower operating costs, and enhance occupant comfort.

Inquire before buying, here: https://www.nextmsc.com/technical-insulation-market/inquire-before-buying

Europe

Europe leads the global technical insulation market, supported by stringent energy efficiency regulations, green building standards, and sustainability initiatives. Countries such as Germany, the United Kingdom, France, and Scandinavia are at the forefront of sustainable construction practices, driving demand for high-performance insulation materials and systems.

The European Union's Energy Efficiency Directive (EED) sets ambitious targets for reducing energy consumption and greenhouse gas emissions, spurring investments in energy-efficient building envelopes and HVAC systems. The nearly-zero energy building (NZEB) concept, which aims to minimize energy demand and maximize renewable energy use in new construction, is driving the adoption of advanced insulation solutions across Europe.

Asia Pacific

Asia Pacific is emerging as a lucrative market for technical insulation products, fueled by rapid urbanization, industrialization, and infrastructure development. Countries such as China, India, Japan, South Korea, and Australia are witnessing significant investments in residential, commercial, and industrial construction projects, driving demand for insulation materials and systems.

In China, the government's focus on sustainable development and green building initiatives is driving the adoption of energy-efficient building materials, including insulation products. The implementation of building energy codes and certification programs, such as Three-Star and Green Building Label, incentivizes developers and building owners to invest in insulation upgrades and energy-saving measures.

In India, the construction of smart cities, industrial corridors, and infrastructure projects is driving demand for technical insulation solutions to enhance energy efficiency, occupant comfort, and environmental sustainability. Insulation manufacturers are partnering with developers, architects, and contractors to promote the use of advanced insulation materials and construction techniques in building projects.

Latin America

Latin America is experiencing steady growth in the technical insulation market, driven by infrastructure investments, urban development, and regulatory measures to promote energy efficiency. Countries such as Brazil, Mexico, Argentina, and Chile are witnessing increased demand for insulation products in residential, commercial, and industrial applications.

In Brazil, the construction of new residential complexes, commercial buildings, and industrial facilities is driving demand for thermal insulation materials to improve energy efficiency and indoor comfort. The government's My House My Life program, aimed at providing affordable housing to low-income families, includes provisions for energy-efficient building design and insulation installation.

In Mexico, the implementation of building energy codes and standards is driving the adoption of insulation solutions in new construction and retrofit projects. The National Housing Commission (CONAVI) promotes sustainable building practices and energy-efficient technologies, encouraging developers to incorporate insulation upgrades and energy-saving measures in housing projects.

Middle East and Africa

The Middle East and Africa region is witnessing increasing demand for technical insulation products, driven by infrastructure development, urbanization, and industrial expansion. Countries such as Saudi Arabia, the United Arab Emirates, South Africa, and Nigeria are investing in construction projects and energy infrastructure, driving demand for insulation materials and systems.

In the Gulf Cooperation Council (GCC) countries, the construction of residential, commercial, and industrial buildings is driving demand for insulation solutions to mitigate heat transfer and enhance energy efficiency. Insulation manufacturers are leveraging innovative materials and technologies to address the region's unique climate challenges and regulatory requirements.

In South Africa, the government's focus on sustainable development and energy efficiency is driving investments in green building initiatives and renewable energy projects. The Green Building Council of South Africa (GBCSA) promotes green building practices and certification programs, incentivizing developers to incorporate insulation upgrades and energy-saving measures in building projects.

Conclusion

In conclusion, the Technical Insulation Market is poised for significant growth driven by evolving trends, regulatory mandates, and the need for sustainable solutions. Advancements in insulation materials, technological innovations, and market dynamics will continue to shape the industry landscape, presenting opportunities for stakeholders across the value chain.

As industries strive to enhance energy efficiency, reduce environmental impact, and comply with regulatory requirements, the demand for technical insulation solutions will continue to rise. Manufacturers, suppliers, contractors, and end-users must collaborate to develop and implement cost-effective, high-performance insulation solutions that meet the evolving needs of the market.

By embracing innovation, sustainability, and collaboration, the Technical Insulation Market can play a pivotal role in advancing energy conservation, environmental stewardship, and sustainable development worldwide.

#technical insulation#materials#chemicals#metals#minerals#business insights#market research#market trends

0 notes

Text

Compressed Non-asbestos Supplies

(making it a “drop-in” gasket), nevertheless it can be more durable to clamp in place. The software will affect the gasket choice; however, correct gasket set up is equally important. Based on one hundred gaskets analyzed and material collected from the members of the Fluid Sealing Association, up to 85% of gasket failures have been due to defective user set up.

Suitable for saturated and superheated steam, oil, dilute acids and alkalis, hydrocarbons, and solvents. Durlon® 8900 has achieved the necessities of the Fire Test Certification ANSI/API 607, 6th Edition with zero leakage. Designed to resist publicity to sizzling or cold water, air, and a few delicate acids. Well suited to common industrial applications and the specific service in the chemical process, pulp/paper and power generation industries. Also generally known as press-in place gaskets, these all-elastomer gaskets are custom-shaped and are designed for purposes where there's a groove that positions the gasket between components to optimize the sealing performance within the groove.

We can custom minimize any sort gasket – inform us what sort of customized gasket you want. NeoGraf has a long history in supporting the big selection of high temperature gasketing wants, leveraging an intensive product portfolio and a world-wide distribution network. Piping, equipment, and equipment containing water, steam, petroleum based mostly liquids, gases, and delicate acids or alkalines.

When choosing a CNA gasket material for potable water, the person should ensure they use a NSF sixty one verified material to ensure that they aren't contaminating the water source. Because CNA gasket material contains a rubber part, the material nonetheless does have a shelf life. Over time, the rubber will begin to break down and deteriorate, based mostly on exposure to environmental conditions. It displays low electrical resistivity and high thermal conductivity and is appropriate for cryogenic temperatures.

Specialist metallic alloys corresponding to Inconel, which consists of nickel, chromium and iron, have properties suited to processes that bear extreme pressures or temperatures. Our state-of-the-art research and improvement facilities are geared to fulfill the ever altering demands required in today’s number of service situations. Since their inception, Durlon gasket supplies have undergone many enhancements, every incorporating the most recent expertise to raised meet the huge variety of industry’s altering wants. Garlock’s gasketing products include engineered low-load types obtainable in both sheet form or as discreet gaskets in addition to supplies to successfully seal metallic piping.

Garlock’s excessive temperature gasketing excels in the harshest conditions—intense heat and excessive strain. These excessive performance gasket supplies have been laboratory tested for fireplace security. A comprehensive technical handbook containing categorized Durlon® gasket material data; physical properties, trade applications, gasket elements & certifications.

GYLON BIO-LINE® PTFE material supplies exceptional sealing performance for all pharmaceutical and meals processing purposes and processes. Its restructured PTFE composition provides safe, durable and constant sealing performance in a range of difficult environments, together with publicity to acids, caustics, delicate media, low and high temperatures and pressures. At Gasket Resources Inc. (GRI®), we concentrate on creating top quality economical gasket solutions to supply our prospects with revolutionary fluid sealing products. To study more about our compressed sheet gaskets, or about any of our different products, contact us right now. Even polymer-based chemical substances used in wastewater treatment, together with flocculants, coagulants and defoamers, may cause deterioration in rubber-based gasket materials. Therefore, it is extremely important to test the chemical resistance of the gasket material used with every chemical and to measure the concentration.

The temperature could be topping the 260°C mark in there, however the nitrile-bonded gasket resolutely endures. Leader Gasket Technologies is a producer of metallic, semi-metallic and delicate gasket products. Originally centered on Spiral Wound know-how and Specialty Equipment gaskets similar to Double Jacked and Corrugated Metal gaskets, Leader has evolved into an entire producer of gaskets and gasket merchandise. Fittings and equipment can be found in an array of various supplies together with metal, stainless steel, brass, nylon, polypropylene and more.

non-asbestos gasket material

The anti-stick coating applied to the surface through the manufacturing process permits for improved separation from flange surfaces during removal, saving time and power. For crucial service and chemical applications, filled polytetrafluoroethylene (PTFE) gasket material is an excellent alternative due to its in-service longevity, chemical resistance and high sealability. Graphite gasketing offers a reliable seal because it seals simply under reasonable bolt load, offers superior torque retention, retains dimensional stability in excessive temperatures and seals tightly, even during strain fluctuations. Garlock® Inorganic Fiber Gasketing provides glorious thermal stability with minimal weight reduction, lowered creep relaxation and improved torque retention. The inorganic fibers have glorious thermal and oxidation resistance, withstanding a steady operating temperature of up to 550°F (290°C), and most spike of 800°F (425°C). Durlon® 8700 is a high-performance gasket material to be used in processes requiring a neoprene (CR) bonded sheet and has glorious hand and die-cutting traits.

Gallagher Fluid Seals can help advise on material, design, and different gasket questions. Our suppliers place us able to offer a big selection of materials, together with versatile graphite, PTFE, FKM, FFKM, and extra. Highly conformable 100 percent expanded PTFE (ePTFE) reliably seals irregular surfaces. Durlon merchandise are utilized in virtually every industrialized corner of the world. Our gasket supplies are manufactured to ISO 9001 quality standards and are subjected to steady testing and inflexible high quality management, making certain unvarying efficiency on the job. These features make Durlon® gasket materials simple on tooling for prime speed or hand-cut tasks.

#cna sheet gasket#compressed non-asbestos gaskets#compressed non-asbestos gasket sheet material#non asbestos gasket#non-asbestos gasket material

1 note

·

View note