#FabricationTechnology

Text

#FabricationServices#MetalFabrication#StructuralSteel#SheetMetal#CustomFabrication#SteelFabrication#Welding#PrecisionFabrication#FabricationExpertise#QualityFabrication#FabricationTechnology#IndustrialFabrication#FabricationSolutions#FabricationProjects#FabricationWorkshop#FabricationSkills#FabricationProcesses

1 note

·

View note

Text

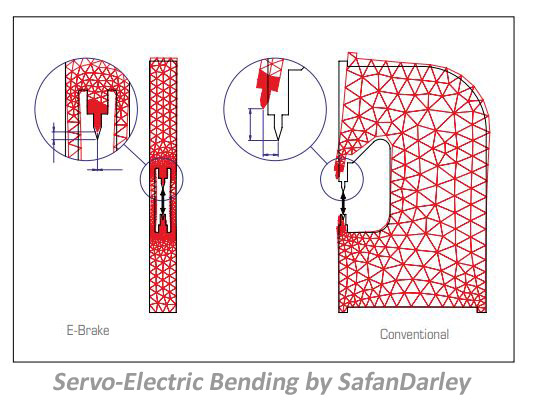

4 Things You Need to Know About Electric Brake Technology

Double your bending productivity,increase accuracy, and save money

1. Well-Vetted Technology

Electric brakes have come of age. Hesitations about moving from hydraulic brakes to electric are disappearing as e-brakes become the chosen technology to increase bending capacity in high mix, low-volume shops, as well as large run production.

Draw 50% less power during idle time than a hydraulic brake

Uses less power than hydraulics with energy-efficient servo drives

2. High Accuracy with Less Effort: belt and pulley system

When using hydraulic cylinders an operator must compensate for limited tonnage in the center and correct with crowning. The belt and pulley system virtually eliminates crowning and self- adjusts for tonnage. This is the #1 difference between electric and hydraulic brakes, saving power and time.

"The pulleys are spaced across the length of the beam, allowing an equal distribution of the bending force, which eliminates the need for a crowning table in 95 percent of jobs," said Mauricio Matta from SafanDarley. "The 5% exception is when a user wants to bend with an extreme load, for example, when V-width is less than eight times the sheet thickness."

3. 30% Faster

Cycle times of the SafanDarley E-Brake are far shorter than conventional press brakes due to the active integrated safety system and the acceleration of the servo motors. The SafanDarley E-Brake only uses energy when the top beam is actually moving. This equals an energy saving of up to 50% compared with conventional hydraulic press brakes.

4. More Than a Safety Tool: SafanDarley Integrated Safety System

The integrated safety system can be programmed to allow the upper beam to move within 1mm above the sheet in milliseconds prior to bending allowing the E-Brake to be automatically ready for the next step.

0 notes