#FretureTechno

Text

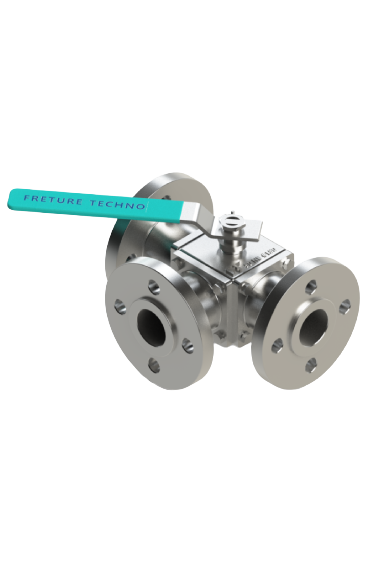

Floating Ball Valve: A Comprehensive Guide to Optimal Fluid Control

Floating Ball Valves are essential components in fluid control systems, offering reliable shut-off and excellent sealing capabilities. In this comprehensive guide, we will explore the features, benefits, and applications of floating ball valves, providing valuable insights to help you make informed decisions for your fluid control needs.

Section 1: Understanding Floating Ball Valves

Floating ball valves are designed with a Floating Ball that is not fixed to the valve stem. This unique design allows the Ball to float and move with the fluid pressure, ensuring optimal sealing and minimizing the risk of leakage. These valves are commonly used in various industries for their versatility and reliable performance.

Section 2: Advantages of Floating Ball Valves

Excellent Sealing: Floating ball valves provide exceptional sealing performance due to the pressure exerted on the ball by the fluid, ensuring tight shut-off and preventing leakage.

Wide Range of Applications: Floating Ball Valves are suitable for a wide range of applications, including oil and gas, petrochemicals, chemical processing, water treatment, and many more. Their versatility makes them a popular choice in various industries.

Easy Operation and Maintenance: Floating Ball Valves are designed for ease of operation and maintenance. The simple structure and fewer components contribute to quick and efficient maintenance, reducing downtime and overall costs.

Section 3: Types of Floating Ball Valves

Two-Piece Design: This type of floating ball valve consists of two main parts—the body and the Ball. It offers ease of maintenance and is commonly used in low-pressure applications.

Three-Piece Design: Three-piece floating ball valves feature a detachable body, allowing easy access to the internals for maintenance. They are suitable for high-pressure and high-temperature applications.

Section 4: Selecting the Right Floating Ball Valve

Consider the following factors when choosing a Floating Ball Valve:

Material Compatibility: Ensure that the valve materials are compatible with the fluid being handled, considering factors such as corrosion resistance and temperature limitations.

Pressure and Temperature Rating: Select a valve with the appropriate pressure and temperature ratings to ensure optimal performance and safety.

End Connection Type: Choose the correct end connections (flanged, threaded, or welded) based on your piping system requirements.

Section 5: Maintenance and Safety Tips

Proper maintenance and safety practices are crucial for the optimal performance and longevity of floating ball valves. Regular inspection, lubrication, and adherence to safety guidelines are essential to ensuring reliable and safe operation.

Floating Ball Valves are reliable and versatile components for fluid control applications. Their excellent sealing capabilities, a wide range of applications, and ease of operation make them a popular choice in various industries. By understanding the advantages, types, and selection criteria for floating ball valves, you can make informed decisions and optimize your fluid control systems for efficient and reliable performance.

2 notes

·

View notes

Text

Ball Valve FAQ: Everything You Need to Know

Ball valves are indispensable components in various industrial applications, offering reliable fluid control and shut-off capabilities. Here's a comprehensive guide to frequently asked questions about ball valves, tailored for professionals across industries.

What is a ball valve, and how does it work?

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluids. When the handle is turned 90 degrees, the ball's bore aligns with the flow path, allowing fluid to pass through, or it blocks the flow when turned perpendicular.

What are the main advantages of using ball valves?

Ball valves offer several advantages, including:

Quick and easy operation with a quarter-turn handle.

Excellent sealing capabilities, ensuring leak-proof performance.

Minimal pressure drop across the valve, enhancing efficiency.

Versatility to handle a wide range of fluids, including corrosive and abrasive media.

In which industrial applications are ball valves commonly used?

Ball valves find extensive use across various industries, including:

Oil and gas: Pipeline control, wellheads, and refining processes.

Petrochemical: Chemical processing, gas distribution, and storage.

Water and wastewater: Treatment plants, distribution networks, and pumping stations.

Power generation: Boiler systems, cooling towers, and steam lines.

Pharmaceuticals: Process control, sterile environments, and cleanroom applications.

What types of ball valves are available, and how do they differ?

There are several types of ball valves, including:

Floating ball valves: The ball is free to move within the valve body, allowing it to seat against the downstream seal under pressure.

Trunnion-mounted ball valves: The ball is supported by trunnions to handle higher pressure and larger sizes.

Multi-port ball valves: Designed with multiple ports for diverting, mixing, or isolating flows in complex systems.

V-port ball valves: Featuring a V-shaped ball orifice for precise flow control in throttling applications.

How can I select the right ball valve for my application?

Choosing the appropriate ball valve depends on factors such as fluid type, pressure, temperature, flow rate, and environmental conditions. Consulting with a knowledgeable supplier or engineer can help ensure the selection of the most suitable valve for your specific needs.

What maintenance is required for ball valves?

Ball valves generally require minimal maintenance due to their robust design. Periodic inspection for leaks, corrosion, and proper operation is recommended. Lubricating the valve stem and replacing seals as needed will help ensure long-term reliability.

In Conclusion

Ball valves are essential components in industrial fluid control systems, offering efficiency, reliability, and versatility across various applications. Understanding their features, types, and proper selection criteria is crucial for ensuring optimal performance and system integrity in diverse industrial settings.

#ball valves manufacturers#ball valve suppliers#freturetechno#industrial valves#manufactuers#mumbai#india

0 notes

Text

Enhancing Safety and Efficiency with Instrumentation Double Block and Bleed Valves

In the complex world of industrial processes, where safety and efficiency are paramount, the role of instrumentation valves cannot be overstated. Among these, Instrumentation Double Block and Bleed (DBB) Valves stand out as crucial components for ensuring safety, reliability, and performance in critical applications.

Understanding Instrumentation Double Block and Bleed Valves

Instrumentation DBB valves are engineered to provide an additional layer of safety and efficiency in fluid control systems. As the name suggests, these valves offer two separate isolation barriers (the "double block") along with a third valve for bleeding pressure (the "bleed"), all integrated into a single compact unit.

Enhanced Safety

One of the primary advantages of DBB valves is their ability to isolate fluids in both upstream and downstream directions simultaneously. This feature is particularly valuable in industries where fluid containment is critical, such as oil and gas, chemical processing, and power generation.

By providing two independent sealing mechanisms, DBB valves minimize the risk of leakage and cross-contamination, thereby enhancing operational safety and environmental protection. In scenarios where maintenance or repair is necessary, these valves allow for isolation of equipment without shutting down the entire system, reducing downtime and improving overall productivity.

Improved Efficiency

In addition to their safety benefits, DBB valves contribute to operational efficiency by streamlining fluid control processes. With integrated bleed functionality, these valves enable efficient purging of trapped fluid or pressure between the isolation barriers, facilitating smoother operation and maintenance.

Applications

Instrumentation DBB valves find applications across a wide range of industries and processes, including:

Oil and Gas Production and Transmission

Petrochemical and Chemical Processing

Power Generation

Pharmaceutical Manufacturing

Water and Wastewater Treatment

Aerospace and Defense

Types of Instrumentation DBB Valves

There are various configurations of DBB valves to suit different application requirements:

Single Piston Design: Ideal for applications with limited space, this design features a single piston that provides both the primary and secondary isolation.

Dual Piston Design: Offering enhanced reliability, this design incorporates two separate pistons for primary and secondary isolation, providing redundancy.

Slab Gate Design: Commonly used in high-pressure applications, slab gate DBB valves utilize a gate mechanism for sealing, ensuring tight shut-off even in extreme conditions.

Conclusion

Instrumentation Double Block and Bleed Valves play a crucial role in ensuring safety, reliability, and efficiency in fluid control systems across various industries. By providing dual isolation barriers and bleed functionality in a single compact unit, these valves offer an effective solution for critical applications where fluid containment is paramount. As industries continue to prioritize safety and operational excellence, the demand for high-quality DBB valves is expected to remain strong, driving innovation and advancement in fluid control technology.

Freture Techno

#dbb valves#instrumentation valves#doubleblockandbleedvalves#freturetechno#instrumentationvalves#manufactuers#mumbai#india

0 notes

Text

The Application and Importance of Bellow Seal Gate Valves in Critical Industries

In industries where safety and containment are of paramount importance, bellow seal gate valves serve as a vital component that provides reliable and leak-proof sealing. These valves offer unique features and capabilities that make them indispensable in critical applications. In this article, we will explore the diverse applications and highlight the significance of bellow seal gate valves in ensuring operational efficiency and safety across various industries.

1. Petrochemical and Oil Refineries:\

Petrochemical plants and oil refineries deal with highly volatile and corrosive media. Bellow seal gate valves are extensively used in these industries to control the flow of aggressive hydrocarbons, ensuring safe and efficient operations. The bellow design acts as a dynamic seal, effectively preventing any leakage even under high pressures, thus safeguarding the environment and minimizing the risk of accidents.

2. Chemical Processing Plants:\

Chemical processing plants handle a wide range of aggressive chemicals, acids, and alkalis. Bellow seal gate valves are particularly well-suited to these environments due to their corrosion resistance and leak-proof sealing capabilities. These valves play a crucial role in maintaining the integrity of containment systems, protecting workers, and preventing environmental contamination.

3. Power Generation Facilities:\

Power plants, including those in the thermal, nuclear, and renewable sectors, rely on bellow seal gate valves to regulate the flow of steam and other media. The ability of these valves to withstand high temperatures and provide reliable sealing ensures the safe and efficient operation of turbines, boilers, and heat exchangers. By maintaining tight containment, bellow seal gate valves contribute to the overall performance and longevity of power generation facilities.

4. Pharmaceutical and Food Industries:\

In industries where sterility and purity are of utmost importance, such as pharmaceutical and food processing, bellow seal gate valves find extensive use. These valves are designed to meet stringent hygienic standards and prevent any potential contamination. With their smooth and seamless operation, bellow seal gate valves facilitate precise control over the flow of fluids, ensuring the integrity and quality of the final products.

5. Water Treatment and Desalination Plants:\

Water treatment facilities and desalination plants rely on bellow seal gate valves to optimize water flow control. These valves play a crucial role in regulating the movement of water, chemicals, and wastewater. By providing effective sealing and preventing any leakage or loss, bellow seal gate valves contribute to efficient resource utilization, minimizing water waste, and ensuring clean and safe water supply.

In critical industries, where containment, leak prevention, and reliable sealing are of utmost importance, bellow seal gate valves emerge as a reliable and indispensable solution. Their unique design, incorporating metallic bellows as dynamic seals, offers numerous advantages such as corrosion resistance, longevity, and secondary containment. The application of these valves in petrochemical plants, oil refineries, chemical processing plants, power generation facilities, pharmaceutical and food industries, as well as water treatment plants, serves as a testament to their significance in ensuring operational efficiency and safety.

In conclusion, bellow seal gate valves play a vital role in critical industries by providing leak-proof sealing and reliable containment. Their application not only enhances operational efficiency but also contributes to the protection of the environment, the safety of workers, and the optimization of resource utilization. With their remarkable capabilities, bellow seal gate valves continue to be a crucial component in ensuring the smooth and secure functioning of critical industrial processes.

0 notes

Text

Beyond Petrochemicals: The Curious Case of Control Valves in Unexpected Industries

In the industrial world, control valves often conjure images of towering petrochemical refineries, pulsating with volatile fluids and echoing with the roar of machinery. But their reign of flow control extends far beyond the realm of hydrocarbons, venturing into surprising corners of human endeavor. So, buckle up, fellow curious adventurers, as we embark on a journey to uncover the unconventional uses of control valves in unexpected industries.

First Stop: The Culinary Symphony: Imagine a perfectly poached egg, the delicate dance of white and yolk suspended in pristine water. Behind this culinary masterpiece lies a hidden maestro – the control valve. In sophisticated kitchens, these unsung heroes regulate the flow of water in sous vide baths, ensuring precise temperature control for consistent, restaurant-worthy results. From simmering broths to temperamental chocolate fountains, control valves orchestrate the culinary symphony, guaranteeing impeccable taste and texture.

Next Step: The Brewing Bonanza: Forget the industrial giants; some control valves thrive in the cozy confines of microbreweries. They meticulously meter precise amounts of hops and grains into kettles, ensuring the perfect balance of bitterness and flavor in your favorite craft beer. Whether it's a hoppy IPA or a smooth stout, these micro-regulators play a crucial role in crafting the magic in every pint.

A Dive into the Deep: The Ocean Symphony: Beyond the surface, in the silent world of underwater explorations, control valves play a vital role in submersibles and research vessels. They manage the flow of hydraulic fluids that power robotic arms, manipulate delicate sampling equipment, and maintain crucial pressure levels in diving chambers. Their silent dedication ensures the safety and success of oceanographic missions, unveiling the secrets of the deep.

A Musical Interlude: The Sound of Silence: Even the world of music owes a debt of gratitude to these flow guardians. In concert halls and recording studios, control valves regulate the flow of compressed air in pneumatic instruments, like organs and harmoniums. Their precise modulation ensures the smooth, uninterrupted flow of melodies that captivate audiences and fill concert halls with the magic of sound.

The Grand Finale: The Dance of Life: Our journey culminates in the most sacred realm of all – healthcare. In hospitals and research labs, control valves contribute to life-saving advancements. They precisely calibrate the flow of fluids in dialysis machines, ensuring the delicate balance of electrolytes in patients' blood. They regulate the oxygen and medications delivered through ventilators, sustaining fragile lives. In this noble cause, the silent symphony of control valves becomes a symphony of life itself.

So, the next time you savor a gourmet dish, raise a toast to your favorite craft beer, or marvel at the mysteries of the deep, remember the unsung heroes who orchestrate these unexpected wonders – the control valves. Their dedication to precise flow control lies at the heart of diverse industries, shaping our world in ways we often don't realize. Now, go forth, curious adventurers, and let the hunt for unexpected uses of control valves begin! You might just be surprised at what you uncover.

0 notes

Text

Advanced Features of Bellow Seal Valves

Superior Sealing: The distinctive bellows element ensures an impeccable gland seal, eradicating any potential leak paths and prioritizing safety in fluid control systems.

Minimal Maintenance: Engineered with a bellows design that minimizes friction and wear, these valves exhibit an extended lifespan and demand minimal maintenance, reducing operational downtime.

High-Temperature Resistance: Purpose-built to endure extreme temperatures and thermal cycling, Bellow Seal Valves prove ideal for demanding applications where consistent performance under challenging conditions is essential.

Corrosion Resistant: Crafted from premium materials like stainless steel, these valves showcase exceptional resistance to corrosion, ensuring compatibility with a diverse range of fluids and enhancing longevity.

Applications Across Industries:

The versatility of Bellow Seal Valves makes them indispensable across various industries:

Chemical and Petrochemical Industry: Essential in processes involving aggressive chemicals, high-pressure systems, and hazardous materials.

Pharmaceutical Industry: Maintaining sterile environments, preventing contamination, and ensuring product purity in pharmaceutical manufacturing.

Oil and Gas Industry: Crucial in controlling flow, preventing leakage, and maintaining safety in oil and gas production, refining, and transportation.

Thermic Fluid / Hot Oil: Exceptional thermal resistance allows reliable operation under extreme temperatures, making them ideal for regulating the flow of heat transfer oils.

Power Generation: Excelling in power plants, handling steam, gas, and other media at high temperatures and pressures.

Food and Beverage Industry: Deployed to ensure hygiene and prevent contamination in various processes within the food and beverage sector.

Water and Wastewater Treatment: Instrumental in water treatment plants and wastewater management systems, regulating flow and preventing leakage.

Widely used in industries that prioritize reliable sealing, corrosion resistance, high-temperature capabilities, and pressure containment, Bellow Seal Valves offer unmatched performance.

For inquiries or additional information, contact us. Your fluid control solution awaits. 🌐💼

0 notes

Text

Today, we honor the memory of Dr. B.R. Ambedkar, a icon of social justice and the chief architect of our Constitution. His enduring legacy inspires us to champion equality and inclusivity in every facet of our society. 🙏

0 notes

Text

Zero Leakage Valves in the Oil and Gas Industry: Enhancing Safety and Efficiency

The oil and gas industry is no stranger to high stakes and rigorous demands. With complex operations, volatile substances, and often remote locations, safety and efficiency are paramount. Enter zero leakage valves, a revolutionary technology that has transformed the way the industry approaches these critical aspects. In this article, we will delve into how zero leakage valves are playing a pivotal role in enhancing safety and efficiency within the oil and gas sector.

The Imperative of Safety

Safety is not a mere buzzword in the oil and gas industry; it is a solemn commitment that influences every decision made. Accidental leaks, spills, and equipment failures can lead to catastrophic consequences, both for the environment and human lives. Zero leakage valves, as the name suggests, are designed to eliminate any possibility of leaks, making them an invaluable addition to the industry's safety measures.

The Zero Leakage Difference

Zero leakage valves differ from conventional valves in one fundamental way—they are engineered to prevent even the tiniest escape of fluids or gases. Traditional valves may have minuscule leaks over time, but zero leakage valves maintain an airtight seal, ensuring that no product or emissions escape. This singular advantage can spell the difference between a routine operation and a major disaster.

Enhancing Efficiency

Efficiency is another crucial aspect of oil and gas operations. When every drop of valuable resource counts, zero leakage valves shine. They help in the precise control and management of fluids, minimizing waste and optimizing production. Additionally, the reduced need for maintenance and replacement due to leak prevention results in cost savings and enhanced operational efficiency.

Applications in Oil and Gas

Zero leakage valves find their applications in various facets of the oil and gas industry:

Drilling and Wellhead Operations: Zero leakage valves are used in wellhead and drilling equipment to control the flow of oil, gas, and other fluids. By ensuring a leak-free environment, they contribute to the safety of these critical operations.

Pipelines and Transportation: In the vast network of pipelines used to transport oil and gas over long distances, zero leakage valves prevent environmental contamination and loss of resources.

Refineries and Petrochemical Plants: Within refineries and petrochemical facilities, these valves help manage the flow of highly volatile substances while reducing the risk of accidents.

Tank Farms and Storage: Zero leakage valves are crucial in storage facilities, where containment is essential. They maintain the integrity of tanks and vessels, preventing leaks and spills.

Offshore Platforms: In the challenging and remote environment of offshore platforms, zero leakage valves play a vital role in ensuring safety and preventing environmental harm.

The Environmental Impact

Beyond safety and efficiency, zero leakage valves also have a positive environmental impact. By preventing leaks and spills, these valves significantly reduce the risk of soil and water contamination, which can have long-lasting ecological consequences. This aligns with the industry's growing commitment to environmental responsibility and sustainability.

Challenges and Innovation

While zero leakage valves offer a myriad of benefits, they are not without challenges. High upfront costs and the need for precision maintenance can be barriers for some operators. However, ongoing research and development in valve technology are continually addressing these concerns, making zero leakage valves increasingly accessible and cost-effective.

Zero leakage valves have emerged as a game-changer in the oil and gas industry. Their ability to enhance safety, optimize efficiency, and minimize environmental risks makes them an indispensable asset for a sector known for its demanding conditions. As the industry continues to evolve, zero leakage valves will remain a cornerstone of responsible and efficient oil and gas operations, setting a higher standard for safety and sustainability.

0 notes

Text

Ball Valve Selection for Chemical Processing: Corrosion Resistance and Compatibility

Ball valves are a crucial component in various industries, especially in chemical processing plants, where the safe and efficient handling of corrosive fluids is paramount. Selecting the right ball valve for chemical applications involves a deep understanding of materials and sealing mechanisms. In this article, we will delve into the complexities of choosing ball valves that offer optimal corrosion resistance and compatibility with chemicals, ensuring the reliability and safety of your operations.

The Challenge of Corrosive Chemicals: Chemical processing environments often deal with aggressive and corrosive substances that can wreak havoc on standard valves. Corrosion can compromise the integrity of the valve, leading to leaks, safety hazards, and costly downtime. Therefore, when it comes to ball valve selection for chemical applications, several key considerations must be taken into account.

Material Selection: One of the most critical factors in choosing a ball valve for chemical processing is the material used in its construction. The right material can withstand the corrosive effects of chemicals and extend the valve's service life. Common materials used for ball valves in chemical applications include:

Stainless Steel (316 or 316L): Known for its excellent resistance to a wide range of chemicals, stainless steel is a popular choice in chemical processing.

Hastelloy: This high-performance alloy offers superior resistance to highly corrosive chemicals, making it suitable for extreme conditions.

Teflon (PTFE): PTFE-lined ball valves are ideal for applications involving strong acids and bases, as they provide a non-reactive, chemically resistant surface.

Alloy 20: Often used in applications involving sulfuric acid and other aggressive chemicals due to its excellent corrosion resistance.

Duplex Stainless Steel: Combines the benefits of stainless steel and increased strength, making it suitable for challenging chemical environments.

Sealing Mechanisms: The choice of sealing mechanism is equally crucial. Ball valves can have soft-seated or metal-seated designs, each with its advantages:

Soft-Seated Valves: These ball valves use resilient materials such as PTFE to create a tight seal. They are well-suited for applications involving moderate pressures and a wide range of chemicals.

Metal-Seated Valves: Metal-seated ball valves are designed for high-pressure and high-temperature applications. They offer increased durability and resistance to abrasive chemicals but may require more precise alignment.

Considerations for Compatibility: Selecting the appropriate material and sealing mechanism also depends on the specific chemicals being handled. Before choosing a ball valve, consider the following compatibility factors:

Chemical Resistance: Review the chemical resistance chart for the chosen material to ensure it is compatible with the chemicals in your process.

Temperature and Pressure: Take into account the operating temperature and pressure conditions, as some materials may perform differently under extreme conditions.

Flow Control Requirements: Determine if your application requires precise flow control or if on/off functionality is sufficient.

Conclusion: In the world of chemical processing, the selection of ball valves is not a one-size-fits-all endeavor. It requires a deep understanding of the corrosive nature of the chemicals involved, as well as the materials and sealing mechanisms that offer optimal resistance. Choosing the right ball valve can prevent safety hazards, reduce maintenance costs, and ensure the smooth operation of your chemical processes. By emphasizing corrosion resistance and compatibility, you can make an informed decision that will benefit your operations in the long run.

#ball valves#ball valves manufacturers#ball valve suppliers#freture techno#freturetechno#valve muanufacturers#india

0 notes

Text

Enhancing Industrial Efficiency with Bellow Sealed Controlled Valves

In the ever-evolving landscape of industrial processes, optimizing efficiency is a perpetual goal. One integral element in achieving this goal is the deployment of Bellow Sealed Controlled Valves. These innovative devices play a pivotal role in enhancing industrial efficiency, ensuring precise control of fluids, and minimizing maintenance demands. In this article, we will delve into the world of Bellow Sealed Controlled Valves and how they contribute to improved efficiency across a variety of industries.

The Importance of Precise Flow Control

In industries ranging from chemical processing to pharmaceuticals, the ability to control fluid flow with precision is indispensable. Bellow Sealed Controlled Valves, or BSCVs, excel in this regard. These valves offer unmatched control, enabling operators to regulate the flow of fluids, gases, and steam with pinpoint accuracy. This precision translates into improved process efficiency, reduced energy consumption, and ultimately, cost savings. When it comes to maintaining consistency and quality in production, these valves are indispensable.

Sealing the Deal with Bellows

The heart of Bellow Sealed Controlled Valves lies in their distinctive bellows. These accordion-like structures, typically constructed from metal or elastomers, provide a hermetic seal around the valve stem. This unique sealing mechanism ensures zero-leakage, safeguarding against fluid or gas escaping into the external environment. The bellows' flexibility and resilience enable them to adapt to extreme temperatures and corrosive environments, making BSCVs a dependable choice for demanding applications.

Minimal Maintenance, Maximum Uptime

One of the key advantages of Bellow Sealed Controlled Valves is their ability to minimize maintenance requirements. The robust construction and advanced sealing mechanism reduce wear and tear, extending the valve's lifespan. This longevity translates to less downtime for maintenance and fewer replacements, resulting in increased uptime for industrial processes. Reduced maintenance not only saves time and resources but also contributes to the overall efficiency of operations.

Applications Across Industries

Bellow Sealed Controlled Valves find applications across a diverse range of industries. In the chemical sector, where the handling of volatile substances is commonplace, these valves provide a critical safeguard against leaks and spills. In the pharmaceutical field, where precision is paramount, BSCVs play a role in maintaining stringent quality standards. The petrochemical and power generation industries benefit from their durability and reliability. Their adaptability and ability to function in extreme conditions make them a versatile choice in various applications.

Looking Ahead

As industries continue to evolve, the role of Bellow Sealed Controlled Valves in enhancing efficiency remains as crucial as ever. The combination of precision control, minimal maintenance, and reliability positions these valves as a linchpin in achieving operational excellence. Whether it's optimizing production, reducing environmental impact, or ensuring product quality, BSCVs are leading the way in the pursuit of industrial efficiency.

In conclusion, the deployment of Bellow Sealed Controlled Valves is not just a choice; it's a strategic move towards operational excellence. With their precise control, resilient bellows, and minimal maintenance requirements, these valves are at the forefront of enhancing industrial efficiency. They offer a solution that not only meets the demands of modern industries but also propels them toward a future marked by sustainability, precision, and reliability.

#bellow sealed controlled valves#bellow seal valves#bellow seal gate valves#bellow seal eurochlor valves#FretureTechno#India

0 notes

Text

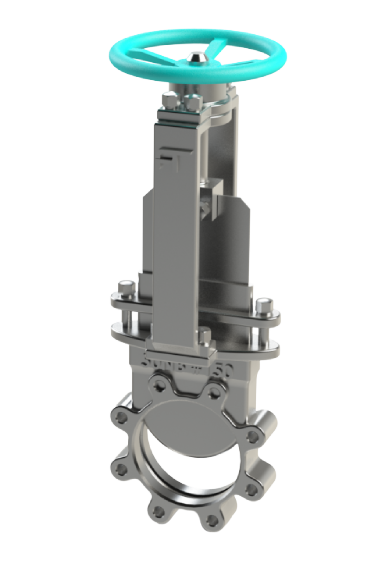

Knife Gate Valve vs. Traditional Gate Valve: Which Is Right for You?

In the realm of flow control solutions, gate valves play a pivotal role in regulating the movement of fluids through pipelines. When it comes to selecting the right valve for your application, one common dilemma arises: Knife Gate Valve or Traditional Gate Valve? Each has its unique features and advantages, and choosing the right one can significantly impact the efficiency and reliability of your operations. In this article, we'll explore the differences between these two types of gate valves to help you make an informed decision.

Traditional Gate Valve:

Traditional gate valves, also known as wedge gate valves, are the more conventional choice. They feature a solid wedge-shaped disc that travels perpendicular to the flow direction. When fully open, the gate completely clears the flow path, allowing for minimal pressure drop. Traditional gate valves are known for their tight seal and excellent shut-off capabilities.

Pros of Traditional Gate Valves:

Excellent sealing performance.

Minimal pressure drop when fully open.

Suitable for a wide range of applications.

Long service life with proper maintenance.

Cons of Traditional Gate Valves:

Not ideal for handling thick or viscous fluids.

Prone to damage from solid particles in the flow.

Slower operation compared to Knife Gate Valves.

Knife Gate Valve:

Knife gate valves are specifically designed for applications involving thick, abrasive, or viscous media. These valves have a sharp-edged gate that cuts through the flow, providing a reliable seal even in challenging conditions. Knife gate valves are particularly popular in industries such as wastewater treatment, mining, and pulp and paper processing.

Pros of Knife Gate Valves:

Ideal for handling slurry, pulp, and thick media.

Resistant to clogging from solids.

Quick and easy operation.

Space-saving design.

Cons of Knife Gate Valves:

May have higher maintenance requirements.

Limited to applications with abrasive or viscous fluids.

Choosing the Right Valve for Your Application:

The choice between a Knife Gate Valve and a Traditional Gate Valve largely depends on your specific application requirements. Here are some key factors to consider:

Media Type: If you deal with slurry, wastewater, or viscous substances, a Knife Gate Valve is likely the better choice. For general-purpose applications with clean fluids, a Traditional Gate Valve may suffice.

Maintenance: Knife gate valves may require more frequent maintenance, especially in applications with abrasive media. Assess your maintenance capabilities and schedule when making a decision.

Space Constraints: If space is limited, knife gate valves have a compact design that can be advantageous.

Pressure Drop: Consider the pressure drop tolerance of your system. Traditional gate valves typically offer lower pressure drop when fully open.

In the choice between a Knife Gate Valve and a Traditional Gate Valve, there is no one-size-fits-all answer. It's crucial to evaluate your specific application, fluid characteristics, maintenance capabilities, and space constraints. Both types of valves have their merits, and making an informed decision will ensure optimal performance and reliability in your fluid control system. Consult with valve experts, like Feature Techno, to select the valve that best suits your needs and enjoy efficient flow control in your operations.

0 notes

Text

Nurturing Innovation and Excellence: Celebrating International Youth Day with Freture Techno Engineering Firm

Every year on August 12th, the world comes together to celebrate International Youth Day, recognizing the immense potential and contribution of young individuals to society. This occasion holds particular significance for Freture Techno, an engineering firm that values innovation, fresh perspectives, and the infusion of youthful energy into its operations. On this International Youth Day, we celebrate the role of young minds in driving excellence and shaping the future of engineering.

Empowering Tomorrow's Leaders: Freture Techno understands that the youth are not just the future but also the driving force of the present. As an engineering firm committed to delivering cutting-edge solutions, we recognize the importance of fostering an environment that encourages young professionals to flourish. Our commitment to nurturing talent goes beyond mere lip service; it's ingrained in our culture.

Innovation at the Core: Innovation is the lifeblood of the engineering world, and it's often the young minds that bring fresh ideas and unconventional approaches to the table. At Freture Techno, we encourage our young engineers to explore uncharted territories, challenge the status quo, and develop groundbreaking solutions. We firmly believe that by embracing their creativity and out-of-the-box thinking, we're not just enhancing our capabilities but also contributing to the advancement of the entire industry.

Mentoring and Collaboration: As seasoned professionals, we understand the importance of mentorship in honing the skills of young engineers. Freture Techno's mentorship programs bridge the gap between experience and enthusiasm, fostering an environment where knowledge flows freely. Through these programs, our seasoned experts guide and support the next generation, helping them navigate complex challenges and emerge as industry leaders.

Diversity in Perspectives: Diversity is a cornerstone of innovation, and the inclusion of young professionals from various backgrounds enriches our company's perspective. International Youth Day reminds us that diversity is not just about age; it's about embracing different experiences, cultures, and viewpoints. This diversity fuels dynamic discussions, drives innovation, and ensures that our solutions cater to a global audience.

Building a Sustainable Future: At Freture Techno, we're not just building engineering solutions; we're also building a sustainable future. The passion and commitment of our young engineers to environmental consciousness inspire us to create products and systems that are energy-efficient, eco-friendly, and aligned with global sustainability goals. International Youth Day serves as a reminder that the decisions we make today shape the world our youth will inherit tomorrow.

Conclusion: As we celebrate International Youth Day, Freture Techno Engineering Firm renews its commitment to nurturing and empowering young professionals who are at the heart of our journey towards excellence. Their enthusiasm, innovation, and dedication continue to fuel our growth, ensuring that we remain at the forefront of the engineering industry. This International Youth Day, let's not just acknowledge the potential of young minds, but actively invest in their growth and development. Together, we'll shape a brighter future for engineering and beyond.

#InternationalYouthDay#2023#SustainableFuture#YouthEmpowerment#InnovationForGood#EngineeringForChange#FretureTechno#engineeringfirm#Mumbai#India

0 notes

Text

Non-Return Valve: Ensuring Fluid Flow in the Right Direction

Fluid flow control is a critical aspect of various industries and systems, from plumbing and wastewater management to industrial processes. One essential component used to regulate fluid flow is the Non-Return Valve (NRV), also known as a check valve. In this article, we'll explore what a non-return valve is, how it works, its applications, and why it is crucial in ensuring the proper direction of fluid flow.

What is a Non-Return Valve?

A Non-Return Valve (NRV) is a mechanical device designed to allow fluid flow in one direction only. It automatically prevents backflow or reverse flow of the fluid, ensuring that it moves in the intended direction. The valve opens when the fluid flows in the desired direction and closes when the flow tries to reverse.

How Does a Non-Return Valve Work?

The basic design of a non-return valve consists of a movable element, typically a disc or a flap, positioned in the valve body. This element is hinged or attached in such a way that it can move freely in one direction while obstructing flow in the opposite direction. When fluid flows in the desired direction, it pushes the disc or flap, opening the valve and allowing the fluid to pass through. However, if the flow tries to reverse, the disc or flap is forced against the valve seat, blocking the flow and preventing backflow.

Applications of Non-Return Valves:

Plumbing Systems: Non-return valves are commonly used in plumbing to prevent the backflow of wastewater into the clean water supply, ensuring water quality and safety.

Pumps and Compressors: NRVs are essential components in pumps and compressors, preventing the reverse flow of fluids and protecting the equipment from damage.

Hydraulic Systems: Non-return valves are used in hydraulic systems to control the flow of hydraulic fluid, avoiding unwanted pressure fluctuations and ensuring smooth operation.

Steam and Gas Lines: In steam and gas lines, NRVs maintain the flow direction, preventing the escape of steam or gas back into the system.

Industrial Processes: Non-return valves find applications in various industrial processes where maintaining one-way flow is critical for efficiency and safety.

Types of Non-Return Valves:

There are several types of non-return valves, including:

Swing Check Valve: The disc swings open on a hinge when the fluid flows in the right direction and swings shut to block reverse flow.

Lift Check Valve: The disc lifts up from the valve seat to allow forward flow and drops back to close the valve and prevent backflow.

Ball Check Valve: A ball is used as the movable element, moving away from the valve seat to allow flow and returning to its position to block backflow.

The non-return valve is a simple yet indispensable device used to regulate fluid flow and prevent backflow in various systems and industries. By ensuring that fluids move in the right direction, these valves play a crucial role in maintaining system efficiency, safety, and reliability. Understanding the working principles and applications of non-return valves helps engineers and technicians select the appropriate type for specific requirements, ensuring the smooth and reliable operation of fluid systems.

0 notes

Text

Ball Valves for Water: Efficient Control and Reliability

Ball valves are indispensable components when it comes to controlling the flow of water in plumbing systems and various industrial applications. Their simplicity, efficiency, and reliability have made them a preferred choice for a wide range of water-related tasks.

How Ball Valves Work for Water Control:

Ball valves consist of a hollow, perforated sphere (the "ball") inside a pipe. When the valve is open, the ball's hole aligns with the pipe, allowing water to flow through. Conversely, turning the handle or lever by 90 degrees closes the valve, positioning the hole perpendicular to the pipe, obstructing the flow. This straightforward mechanism ensures quick on/off action, providing immediate control over the water flow.

Advantages of Ball Valves for Water Applications:

Fast Shut-Off: The quick 90-degree turn required to operate ball valves enables rapid shut-off, preventing water wastage and minimizing potential damage in case of emergencies.

Minimal Leakage: Ball valves provide a tight seal when closed, reducing the risk of water leakage and ensuring water conservation and cost efficiency.

Durability: Made from robust materials like brass, stainless steel, or PVC, ball valves are highly durable and can withstand harsh water conditions, making them suitable for both residential and industrial settings.

Versatility: Ball valves are versatile and can handle a wide range of water pressures, temperatures, and flow rates, making them suitable for various water-related applications.

Limitations of Ball Valves for Water:

While ball valves offer many benefits, they do have some limitations:

Throttling Control: Ball valves are not ideal for precise throttling control due to their full-open or full-closed positions. For applications requiring fine adjustments to the flow rate, other specialized valves like globe valves may be more appropriate.

Water Hammer: The quick closing action of ball valves can generate water hammer—a hydraulic shock caused by the sudden stoppage of water flow. Water hammer can potentially damage the system, so proper consideration and measures are necessary to mitigate this effect.

Applications of Ball Valves for Water:

Ball valves find extensive use in water-related applications, such as:

Residential Plumbing: They are commonly used in households for controlling water supply to sinks, toilets, and appliances.

Municipal Water Systems: Ball valves are employed in water distribution systems to control water flow, isolate sections for repairs, and manage water mains.

Water Treatment Plants: Ball valves are vital in water treatment processes to regulate the flow of water through different treatment stages.

Industrial Settings: In industrial processes involving water, ball valves play a crucial role in controlling cooling water, wastewater, and other fluids.

Maintenance and Care:

To ensure optimal performance, regular maintenance of ball valves is essential. Periodic inspections, lubrication of seals and stems, and addressing any signs of wear or leakage are recommended. Following manufacturer guidelines for maintenance will extend the life and efficiency of the ball valves in water applications.

In conclusion, Ball Valves for water provide efficient flow control, reliability, and easy operation for a wide range of applications. Their advantages outweigh their limitations, making them an indispensable component in water systems across residential, commercial, and industrial sectors. With proper maintenance, ball valves can continue to serve as reliable water flow control solutions for years to come.

0 notes

Text

Kargil Vijay Diwas: A Tribute to Valor and Sacrifice

Every year on July 26th, India commemorates Kargil Vijay Diwas to honor the supreme sacrifice and unwavering valor of its brave soldiers during the Kargil War of 1999. This day holds immense significance as it marks the successful conclusion of one of the most challenging military operations in Indian history. The Kargil conflict was not just a war fought on the battlefield but a testament to the indomitable spirit and determination of the Indian Armed Forces to protect the nation's sovereignty and uphold the values of courage and patriotism.

Background:

The Kargil War was an armed conflict between India and Pakistan that took place between May and July 1999 in the Kargil district of Jammu and Kashmir. The intrusion of Pakistani soldiers and irregular forces into Indian territory, occupying strategic positions in the high-altitude mountains, caught India off guard. The operation, code-named "Operation Vijay," was launched to recapture these infiltrated areas and drive out the aggressors.

The Valor of Indian Soldiers:

The Kargil War witnessed the exemplary bravery and determination of the Indian soldiers, who fought in some of the most treacherous and challenging terrains at altitudes as high as 18,000 feet. Facing inclement weather, rugged mountains, and an enemy who had the advantage of higher ground, the Indian Armed Forces displayed extraordinary courage and resilience.

The soldiers faced heavy artillery shelling and endured extreme conditions, including freezing temperatures and lack of oxygen, but remained steadfast in their resolve to protect the motherland. Their selflessness and willingness to make the ultimate sacrifice for the nation serve as a shining example for future generations.

The Role of Leadership:

During the Kargil conflict, leadership played a pivotal role in the success of "Operation Vijay." The strategic planning, impeccable decision-making, and astute tactical maneuvers demonstrated by the Indian military leaders were commendable. The officers led from the front, inspiring their troops to fight with valor and conviction, ensuring that every soldier felt the weight of their responsibility while defending the nation's honor.

Remembering the Martyrs:

Kargil Vijay Diwas is also an occasion to pay tribute to the brave soldiers who made the supreme sacrifice in the line of duty. Their courage and dedication to protecting the country will forever remain etched in the collective memory of the nation. Their sacrifice reminds us of the cost of freedom and the importance of preserving the hard-earned independence of our nation.

Reaffirming National Unity:

Kargil Vijay Diwas is not just a day of remembrance; it is a celebration of national unity and solidarity. It reminds us that in times of adversity, the entire nation stands united behind its armed forces, displaying unwavering support and appreciation for their sacrifices. This unity has always been and will continue to be our strength in defending the nation against any threat.

Kargil Vijay Diwas serves as a solemn reminder of the sacrifices made by our soldiers to protect our borders and preserve the spirit of democracy and freedom. It is a day of reflection, gratitude, and respect for the brave hearts who laid down their lives for the nation. As citizens, we must take this opportunity to honor their memory by fostering a sense of responsibility towards the country and contributing to its growth and progress.

On this Kargil Vijay Diwas, let us bow our heads in gratitude and pledge to uphold the values of courage, unity, and patriotism that define the spirit of our armed forces and our great nation. Jai Hind!

#KargilVijayDivas#SaluteToHeroes#ProudToBeIndian#RememberingKargil#JaiHind#FretureTechno#Valves#Flanges#Manufacturer#Mumbai#India

0 notes

Text

instagram

Like parents, they ensure a smooth flow and provide unwavering support. Happy Parents' Day!

Just like valves and flanges regulate and control the flow in industrial processes, parents play a crucial role in guiding and supporting us every step of the way. They ensure our lives operate seamlessly and securely. 💪⚙️

#ParentsDay#HappyParentsDay#LoveMyParents#FamilyFirst#ParentingGoals#BestParents#ParentalLove#MomAndDad#ThankYouParents GratefulForParents#FamilyBonding#FretureTechno#Instagram

0 notes