#Powered System Surgical Drill

Text

Unravelling the Essence of Surgical Power Tools

Surgical power tools encompass a spectrum of instruments designed for drilling, sawing, reaming, and screwing, pivotal in orthopedic surgery, traumatology, neurology, and ENT procedures. Their significance lies in elevating surgical accuracy and enabling intricate procedures with unparalleled precision.

Driving Forces Behind Market Growth

The surge in neurological disorders, as highlighted by the WHO, has spurred the demand for surgical power tools. With nervous system disorders topping the charts for disability-adjusted life years (DALYs) globally, the imperative for neurosurgeries has escalated. Concurrently, the advent of minimally invasive neurosurgeries, propelled by advanced surgical tools, has augmented market growth. Factors such as enhanced precision, reliability, and ease of use have catapulted surgical power tools to the forefront of modern surgical interventions.

Technological Advancements Paving the Way

Key market players like Johnson & Johnson and Medtronic are spearheading technological advancements in surgical power tools. Innovations such as advanced ergonomics, potent motors, and robust batteries have streamlined surgical procedures. Notably, the integration of brushless motors equipped with sophisticated sensors has elevated precision, reduced costs, and prolonged battery life, fostering widespread adoption.

Exploring Market Dynamics

The market dynamics are multifaceted, with notable trends emerging across product segments, applications, usage, and end-users. Handpieces, renowned for their optimal power flow and compatibility, dominate the product landscape, particularly in orthopedic surgeries. Meanwhile, neurosurgery emerges as a frontrunner in application, fueled by the burgeoning preference for minimally invasive procedures. Additionally, the paradigm shift towards disposable tools, driven by infection control imperatives and workflow efficiency, is reshaping market contours.

Regional Landscape: North America Takes the Lead

North America stands as the epicenter of market growth, attributed to the burgeoning demand for neurosurgeries and well-established healthcare infrastructure. The region boasts a proliferation of skilled neurosurgeons, coupled with a robust regulatory framework conducive to product approvals and launches.

Key Players

The key players operating in the surgical power tools market are Medtronic Plc (Ireland), ConMed Corporation (U.S.), B. Braun Melsungen AG (Germany), Zimmer Biomet Holdings, Inc. (U.S.), Johnson & Johnson (U.S.), Stryker Corporation (U.S.), De Soutter Medical Limited (U.K.), AlloTech Co. Ltd. (South Korea), Smith & Nephew plc (U.K), and NOUVAG AG (Switzerland).

Download PDF Brochure @ https://www.meticulousresearch.com/download-sample-report/cp_id=5399

Key questions answered in the report-

Which are the high-growth market segments in terms of product, application, usage, end user, and regions/countries?

What was the historical market for surgical power tools across the globe?

What are the market forecasts and estimates for the period 2023–2030?

What are the major drivers, restraints, challenges, opportunities, and trends in the global market of surgical power tools?

Who are the major players in the global surgical power tools market?

What is the competitive landscape, and who are the market leaders in the global surgical power tools market?

What are the recent developments in the surgical power tools market?

What are the different strategies adopted by the major players in the surgical power tools market?

What are the geographical trends and high-growth regions/countries?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Powered Surgical Instrument#Surgical Tool#Surgical Device Orthopedic Power Tool#Powered Instrument#Powered System Surgical Drill#Surgical Saw

1 note

·

View note

Note

I ain't read Amber Skies yet—is the rig at all comparable or similar to the Dead Space engineering suits or are they more like power armor frames?

Both! Though, wearing a rig requires standardized surgical modification. You need "rig sockets" drilled and implanted into your skeleton. You're generally not supposed to wear them for too long, as being hooked up to an artificial nerve system for extended periods of time can cause "prosthetic rot", a degenerative neurological disorder.

174 notes

·

View notes

Text

The Multifunctional Battery Powered Handpiece features a single-handed operational switch for forward and reverse modes, quick connect attachments for fast accessory changes, a variable speed control trigger for maximum control, multiple battery pack ... https://www.orthopaedic-implants.com/surgical-power-tools/bone-drill-saw-system/multi-function-handpiece.php

2 notes

·

View notes

Text

Wolf 359 Season 1 Episode 3 - “Discomforts, Pains, and Irregularities”

[intro music]

Welcome to Wolf 359.

[begin announcement beep-boop]

Hera: Attention! The following is a message from Dr. Hilbert. "Fellow crew members, it is again time for our biannual physical and wellness check. Please remain calm. Report to the laboratory immediately. I understand the prospect of these mandatory examinations can excite nausea, lethargy, and a powerful urge to run – run far away. Far, far away. These feelings are completely ordinary yet must be suppressed. These examinations are vital to keeping the Hephaestus an operational disease-free environment, as well as an unparalleled cache of live data in the cold abyss of space. The fearful enormity of which I add, one cannot escape into. As usual, please bring a list of all known allergies, a change of clothing, and something to bite down on. And yes, before anyone asks about it, the surgical drill is absolutely necessary. See you soon!”

[end announcement beep-boop]

Eiffel: [softly] Oh, man.

Eiffel: This is the log of Communications Officer Doug Eiffel, on day four hundred and eighty-two of the Hephaestus mission. But this isn’t just any day, dear listeners. No. This, is a day of darkness. A low tide. A half-melted fudgesicle of despair. It’s physical day here on the station. I’ve spent all day avoiding Dr. Hilbert. There was a moment this afternoon when I thought he’d cornered me in the bathroom. But I was able to avoid him by squeezing into the crawl space underneath the sink. Certain people might call spending two and a half hours in a cramped hole in the wall, just to avoid a mandatory physical examination, unreasonable. Some would call it only delaying the inevitable. To those people, I say –

[begin intercom buzz]

Hilbert: Officer Eiffel! Are you busy?

Eiffel: Incredibly! Utterly, busier than I have ever been, and might possibly... ever... again be!

Hilbert: Oh. You are aware that today is crewmember physical examination day, correct?

Eiffel: Painfully.

Hilbert: Well, please make your way to my laboratories, so we can begin collecting samples. As you know, it is a very time intensive process.

Eiffel: As irresistible as you make that sound, Doctor, unfortunately I’m preoccupied with some important matters that require my full attention.

Hilbert: What matters?

Eiffel: Well I’m – Well I’m calibrating the... uh... reception of the... radio array to allow a direct reception of the hertz to increase our... um... Roger coefficient on the... primary... frequency...

Hilbert: You are doing a diagnostic of our deep space comm system?

Eiffel: Couldn’t have put it better myself.

Hilbert: Oh my, Officer Eiffel! That is very simple. Hera can run that program through automated functions.

Hera: He’s right, Officer Eiffel, it shouldn’t take more than a few minutes.

Eiffel: If- If only it were that simple. Unfortunately um, the power outages from a while back knocked out some of the circuitry. So I need to reset the entire system manually.

Hilbert: Manually?

Eiffel: Manually. Honestly Doc, this might be a while. Why don’t you take a seat in my waiting room?

Hilbert: Oh, no. If you’re delayed then I must secure Commander Minkowski’s participation first. I will call on you later, Eiffel.

[end intercom buzz]

Eiffel: [sigh of relief] That was too close. He’s like a friggin’ shark sniffing for chum! And thanks a lot, Hera!

Hera: I was just trying to be helpful.

Eiffel: What you were trying to do was be an accessory before the fact. Also, I have a bone to pick with you. This morning I asked if we have any hot water left, and you said we did.

Hera: Correct.

Eiffel: But when I hopped in the shower, the water was freezing.

Hera: Correct again. That is an accurate summation of your sensory experience!

Eiffel: So what happened?

Hera: Dr. Hilbert used all the hot water on a radiation experiment in the greenhouse. The report we gave you about its availability was an outright fabrication.

Eiffel: So – you lied to me?

Hera: Lying is a word with many negative connotations, Officer Eiffel. I prefer to think that I tactically misrepresented the available data.

Eiffel: So you tactically lied to me.

Hera: Previous observation suggested that you would refrain from showering if you knew there was no hot water. Given pre-existing concerns amongst the crew about your hygiene, this was deemed an unacceptable outcome.

Eiffel: Wait, the crew’s concerned about my hygiene?

Hera: Commander Minkowski has made eliminating your persistent body odour a priority one task.

Eiffel: I don’t have persistent body odour!

Hera: Analysis of the mineral content in the air around you suggests that –

Eiffel: I’m not going to sit here and get lectured on how I smell by someone that doesn’t have a nose. I can’t take showers in freezing cold water.

Hera: Actually, Officer Eiffel, data collected this morning shows that you are in fact perfectly capable of taking a shower with freezing cold water.

Eiffel: Just don’t lie to me again, Hera.

Hera: You place too much judgement on the concept of lying, Officer Eiffel. Remember the old saying: “Words cannot harm you; it is only sticks and stones that can fracture human’s bones, and break his feeble, delicate flesh”. Or... should I give Dr. Hilbert a call and tell him that you are available after all?

Eiffel: Alright, fine, let’s drop this train of thought. It pulls into a station my delicate, feeble flesh can’t handle.

Hera: Very well. Also, Commander Minkowski asked me to make sure you got the message she left in the comms room.

Eiffel: Hmm. Oh, I was wonder what that thing taped to my door was. Let’s see. Eiffel... been noticing something strange in the greenhouse... unusual growth in the... aggressive tendencies... [yawn] ...might compromise safety if left unchecked... going back to do observation... contact at once... alright, I officially have no idea what she’s going on about.

[begin intercom buzz]

Eiffel: Hey Commander?

Minkowski: Eiffel. About time.

Eiffel: Only just got your memo. What’s got you all DEFCON 2 over there?

Minkowski: A few hours ago I wandered into the greenhouse while uh... con-conducting an inspection tour of the station.

Eiffel: You mean avoiding Hilbert.

Minkowski: The details are unimportant. While I was here, I noticed that one of our plant samples is looking... rather... strange.

Eiffel: Strange how?

Minkowski: It’s gotten big. Very big. It’s almost five times as large as our next biggest sample. And it’s got all these... I-I guess they’re roots? They stretch out of its pot and go into the ones around it. It almost looks like it’s trying to starve out the other samples.

Eiffel: The thing’s probably just hungry, give it some soylent chow or something and call it a night.

Minkowski: No, I think – I think this might be a problem. I’m going to stay here and observe the situation.

Eiffel: Observe?

Minkowski: Yeah, just to see if there are any changes in the next few hours.

Eiffel: Few hours? Oh... right!

Minkowski: What?

Eiffel: [glibly] Nothing at all. Commander, I think you’re right. This sounds like a sensitive situation and you should give it your undivided attention.

Minkowski: ... You do?

Eiffel: [glibly] Absolutely! Who knows what problems this could lead to if left unchecked.

Minkowski: Exactly!

Eiffel: [glibly] Yeah. I’m with you one hundred percent.

Minkowski: Great! That’s... well refreshing! Well, I’ll keep you updated on any developments.

Eiffel: Please do!

Minkowski: Minkowski out.

[end intercom buzz]

Eiffel: Heh. Mutant space plants? Y’know, as far as lies to avoid physical examinations go, that’s more colourful than I would’ve expected from her. But, I’ll play along. Anything for a fellow truant.

[begin announcement beep-boop]

Hera: Attention crewmembers. In an effort to make today’s physical examinations as effective as possible, Dr. Hilbert has asked me to relay the following list of simple dos and don’ts to you. Just follow these simple tips and exercise a bit of common sense, and your physical will be over before the damage is irreparable.

Hera: Do make list of any discomforts, pains, or irregularities that you are currently experiencing before the start of today’s examination. It’ll do nothing to relieve them, but after the discomforts, pains, and irregularities of the examination, they will seem trivial in comparison.

Hera: Don’t forget: once the examination starts, there’s no way to stop it until it’s done. The off switch on our machine quite literally ceases to function once the test is in effect, so take a moment to prepare yourself before we start. Above everything else, do what you can to avoid passing out, as your losing consciousness might tamper with the results and force a restart of examination.

Hera: Do remember that anaesthetics have their limits; certain kinds of pains are beyond the comforting embrace of narcotics. There are no anaesthetics involved in your upcoming physical, but this is just a good thing to keep in mind at all times.

Hera: Don’t worry, no one has ever died from one of our physical examinations. You might, however, be surprised by what you can live through. Good luck!

[end intercom beep-boop]

Eiffel: Do remember that the test is run by a sadistic piece of work who should be avoided at all costs. You might think that I’m making a big fuss over nothing, dear listeners, but I cannot begin to tell you how awful these physicals are. In fact, don’t take my word for it. Here’s a recording I made six months ago, the last time I went through one of comrade Dr. Moreau’s little wellness checks.

[begin recording playback]

Hilbert: Officer Eiffel! I said cough!

[drill whirrs]

Eiffel: [sobbing] I don’t wanna!

Hilbert: Cough! Now!

Eiffel: [sobbing weak cough]

[drill whirring loudly, Eiffel screams]

[end recording playback]

Eiffel: That was just stage one. I’ll spare you stages two through twenty-one. Here’s a pro tip. If a doctor ever uses the phrases “optic nerve” and “will only hurt for a second” in the same sentence, you tell him to go f -

[begin intercom buzz]

Eiffel: - frequencies! Amplitudes! Watts! Buttons! I’m working.

Minkowski: Eiffel!

Eiffel: [sigh of relief] It’s only you, Commander. How’s plant watch?

Minkowski: The situation might be more serious than I thought. I set up some cameras to be able to monitor the sample from outside the greenhouse. On the monitors, I saw the plant sample writhing. Writhing and growing. But then, as soon as I went back into the greenhouse, it was perfectly still. Eiffel. I think this thing might be... able to tell when I’m here, and when I’m not. I think it might be intelligent enough to play dead.

Eiffel: [glibly] Oh dear Commander. That sounds really alarming. You’d better make getting to the bottom of this your first priority.

Minkowski: Oh absolutely. It has to take precedence over everything.

Eiffel: [glibly] I think that’s a sound decision.

Minkowski: Right. I’m going to go see what kind of weedkiller we have in our supply shed. You, stay on the line in case I need backup.

Eiffel: Roger that.

[end intercom buzz]

Eiffel: Well again. More outlandish than I would’ve gone for, but I guess your lies get bigger as you go higher up in the ranks.

[knocking on the door]

Hilbert: [from behind the door] Officer Eiffel? Can I come in?

Eiffel: Um... this is kind of a bad time Doc, I’m still in the middle of that uh...

Hilbert: Diagnostics of our deep space comm system!

Eiffel: That’s the one.

Hilbert: Excellent. Here to help!

Eiffel: [alarmed] H-help?

Hilbert: Yes, help! Don’t just know about molecular biology, you know? Expert at computational radiology. Very relaxing as far as sciences go.

Eiffel: You don’t say.

Hilbert: Yes! And conclude that I could lend a hand. Besides, the sooner we’re done with diagnostic of communication system, the sooner we can start with the diagnostic of communications officer!

Eiffel: Oh Doctor. You don’t need to do that! I wouldn’t wanna – bother a man of your talents with such simple matters as – this thing that I’m doing.

Hilbert: Please, Eiffel, no bother at all. Always thrilled to assist a fellow crewmember. Besides, in this case, helping in this case is its own reward. That, and the spinal fluid samples!

Eiffel: ...Yes. Well. The thing is, well, Dr. Hilbert – I’m gonna be straight with you, alright.

Hilbert: Absolutely. I accept no less than that.

Eiffel: Great. The- The truth is, the truth is that –

[intercom buzz]

Eiffel: - The truth is that Commander Minkowski needs my help with a priority one mission.

Hilbert: Oh?

Eiffel: Yeah. And you know how the commander is, gotta get right to it.

[intercom buzz]

Hilbert: She did mention something about an... aggressive parasitic agent a little while ago.

Eiffel: Right, exactly. So, unfortunately I’m gonna have to take care of that before we get to my physical.

Hilbert: [dejectedly] Very well. Will check on you in a little bit.

Eiffel: [long sighs of relief] Wow, saved by the bell!

[several open intercom buzzes]

Eiffel: Commander, I know we’ve had our ups and downs, but right now I could kiss you.

Minkowski: [increasingly panicked] Eiffel. That plant sample? It’s not playing dead any more. It’s growing, and growing, and growing – it’s cut me off from the door, and its roots are stretching all over the walls, it’s got – oh god, in the middle of all the stems and moss, I think I see an eye – I think this thing is looking at me!

Eiffel: Uh... Commander? I appreciate a good story as much as the next guy, but don’t you think this is getting a little 1950s drive-in?

Minkowski: I don’t know what kind of joke you think this is, but I don’t have time to unravel it. Get up here with a flamethrower and help me kill this thing.

Eiffel: Really...? I’ve got this...

Minkowski: Eiffel!

Eiffel: Ah alright alright, I’ll be there in a moment. Hold on while I indulge my commanding officer, dear listeners. I’ve never used the flamethrower before, so this might be fun!

[door opens]

[over the intercom]

Eiffel: Alright, here I am, let’s get this- Oh my god, you’re being serious?

Minkowski: Of course I was being serious, why the hell would I lie about something like this?

Eiffel: To get out of Hilbert’s physical!

Minkowski: I would nev- Alright fine, it kinda started out that way, but now it’s serious. Don’t just stand there, for god’s sake, help me kill this thing!

Eiffel: With what? Harsh language?

Minkowski: With napalm, you moron! Did you even check the arms locker?

Eiffel: Oh. The one you won’t give me access to? Wait. What’s it doing? What is... are those teeth?

[gurgling noises]

Eiffel: No! No! Wait! No don’t –

Minkowski: Eiffel!

Eiffel: [muffled scream]

[static]

[back in the comms room]

Eiffel: [out of breath] Hi again, dear listeners. So, it seems that I may have uh... misjudged the conversations I was having with Minkowski earlier. Turns out, she wasn’t just making up an excuse to avoid Dr. Hilbert’s physicals after all. But rather, she had actually found a... space mutant plant monster. I don’t have the time right now to give you all the details of the Commander and I’s miraculous escape, but the uh... I guess we call it a creature, fled into one of the station’s air vents. Its current whereabouts are unknown. [inhale] And Minkowski and Hilbert are arming themselves with whatever weapons they can find or make, and Hera’s shutting down all the non-essential vents to limit the creature’s path. [inhale] With any luck, we’ll be able to track down and kill it before it manages to corner any of us. Which means... Which means our physical examinations are suspended... indefinitely! Haha, on account of a station-wide emergency! Yes! [laughter] Oh yes! This has been a good day, my friends. A good day. Recording from the comms room on the Hephaestus station, this is Communications Officer Doug Eiffel, signing off. Goodnight folks. Goodnight!

[outro music]

This has been Wolf 359, written and directed by Gabriel Urbina. The roles of Eiffel and Hilbert were played by Zach Valenti. The role of Minkowski was played by Emma Sherr-Ziarko. And the role of Hera was played by Michaela Swee. Original music by Alan Rodi, and audio recording by Jared Paul. Wanna find out more about stages two through twenty-one of Dr. Hilbert’s physical examinations? Visit us at wolf359.fm, or follow us on Twitter at @Wolf359Radio for more information on our show.

----

Transcript by @saltssaumure

4 notes

·

View notes

Text

Unveiling the Marvels of Air Breathing Compressors

Unveiling the Marvels of Air Breathing Compressors

In the realm of industrial machinery, where efficiency and reliability are paramount, air breathing compressors stand tall as indispensable workhorses. These remarkable devices play a pivotal role in a myriad of applications, ranging from powering pneumatic tools to facilitating complex industrial processes.

The Essence of Air Breathing Compressors

At its core, an air breathing compressor functions as a mechanical device designed to increase the pressure of air by reducing its volume. This process is achieved through a series of intricate mechanisms, wherein ambient air is drawn in and compressed to a desired pressure level. The compressed air thus obtained finds utility across various domains, driving pneumatic machinery, facilitating ventilation systems, and even supporting critical functions in aerospace engineering.

Types and Variants

Air breathing compressors come in a diverse array of types and configurations, each tailored to meet specific operational requirements. Reciprocating compressors, for instance, employ piston-driven mechanisms to compress air, making them ideal for applications demanding high pressures and intermittent usage. Rotary screw compressors, on the other hand, utilize intermeshing helical rotors to generate compressed air continuously, catering to sustained and high-volume operations.

Moreover, the advent of advanced technologies has paved the way for innovative variants such as oil-free compressors, which eliminate the need for lubricants, thereby ensuring the purity of compressed air—a critical factor in sensitive applications such as food processing and pharmaceutical manufacturing.

Applications Across Industries

The versatility of air breathing compressors renders them indispensable across a myriad of industries. In the automotive sector, they power pneumatic tools used in assembly lines, enhancing efficiency and precision. Similarly, in the construction industry, these compressors drive pneumatic hammers and drills, facilitating the execution of complex projects with ease.

Furthermore, air breathing compressors find extensive utility in the realm of healthcare, where they serve as vital components in medical air systems, supplying clean and compressed air for respiratory therapies and surgical procedures. Their role in maintaining the functionality of life-support equipment underscores their significance in critical care settings.

Advancements and Future Prospects

Continual advancements in engineering and materials science have propelled air breathing compressors towards new frontiers of efficiency and sustainability. The integration of smart technologies, such as IoT-enabled monitoring systems, allows for real-time performance tracking and predictive maintenance, minimizing downtime and optimizing operational efficiency.

Moreover, the emphasis on environmental sustainability has spurred the development of energy-efficient compressors, leveraging innovations in motor technology and system design to reduce carbon footprints without compromising performance. This evolution aligns with global initiatives aimed at fostering greener industrial practices, heralding a future where air breathing compressors play a pivotal role in sustainable development.

Conclusion

In essence, air breathing compressors stand as quintessential components of modern industrial infrastructure, driving progress across a spectrum of applications. From automotive assembly lines to healthcare facilities, their versatility and reliability make them indispensable assets, powering innovation and efficiency. As we venture into an era defined by sustainability and technological prowess, the evolution of air breathing compressors promises to catalyze transformative change, shaping the landscape of industry for generations to come.

For more details visit our website: air breathing compressors

Contact: +971 6525 7347

Mail id: [email protected]

Website: https://pioneermarineservice.com/

Address: WH no:g2/B-2,Near Tasheel Industrial Area 13,Sharjah,UAE

0 notes

Text

Electric Motor Market - Forecast(2024 - 2030)

Electric Motor Market Overview

Electric Motor Market Size is forecast to reach $169 billion by 2030, at a CAGR of 5.6% during 2024-2030. The increase in global electricity consumption and the use of electrical equipment and machines in different industries and the renewables sector are major factors driving the growth in the electric motor market during the forecast period. An increase in awareness of green vehicles among customers has been a key factor leading the market. Besides this, a rising number of government incentives to encourage sales of green vehicles for safeguarding the environment from carbon emissions is analysed to drive the market. The growing interest in sustainable transportation has driven the demand for electric vehicles. Electric motors play a crucial role in powering EVs, and advancements in motor technology contribute to increased efficiency and range. The industrial sector is witnessing the integration of electric motors with the Internet of Things (IoT) and Industry 4.0 technologies. This integration allows for real-time monitoring, predictive maintenance, and improved efficiency in industrial processes.

Smart motor technologies, incorporating features like connectivity, sensors, and advanced control systems, are becoming more prevalent. These innovations contribute to better performance, remote monitoring, and enhanced automation in various applications. Developments in motor control systems, including advanced algorithms and power electronics, contribute to improved motor performance, reduced energy losses, and enhanced control precision. There is an increasing emphasis on developing more energy-efficient electric motors to meet sustainability goals and reduce energy consumption. Regulations and standards promoting energy efficiency also influence the design and manufacturing of electric motors. Additionally, Electric motors have been observing several advancements in technology over the past few years, owing to which its demand is set to gain higher traction during the forecast period 2024-2030.

Report Coverage

The report: “Electric Motor Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Electric Motor market

By Product Type: AC Motor (Induction Motor, Synchronous Motor, Servo Motor, Stepper Motor), DC Motor (Brushed DC Motor, Brushless DC Motor, Servo Motor, Series Motor, Stepper motor, Compound Motor).

By Product Category: Permanent Magnet, Non-Permanent Magnet.

By Phase: Single Phase, Three Phase.

By Power Rating: Below 0.5W, 0.5W-1W, 1W to 100W, 100W to 1KW, 1KW to 10KW, 10KW and Above.

By Efficiency: IE1, IE2, IE3, IE4.

By Application: Commercial (Automated Doors, Elevators & Escalators, Blowers, Electric Sweepers, Hand Dryers, Data Center & UPS, Pumps, Power Tools, Water Coolers, Camera PTZ Control, Drones, Others), Consumer Products (Pumps, Hair Dryers, Lawn Mowers, Boilers, Dishwashers, Vacuum Cleaners, washing machine, Blenders & Mixers, Fans & Chimneys, Desktop & Laptops, Smartphones, Refrigerators, Others), Automotive (Body Control motors, EPS Motors, Brake Booster BLDC Motor, Seat Adjustment, Belt Tensioner, Car Window Motor, Door Lock Motors, Wiper Motor, Others), Medical & Healthcare (Diagnostic Equipment (CT Scanners, MRI, Biopsy Systems, Diagnostics Analyzers, Ultrasound Transducers, X-Ray, Others), Medical Centrifuges, Medical Pumps, Blowers and Compressors, Surgical Instruments (Saws, Drills, Surgical Robots, Others), Dental CAD/CAM Milling Machines, Exoskeleton & Prosthetics, Microscopes, Wheelchairs & Scooters, Stair Lifts, Hospital Beds & Exam Tables, Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands, Poland, Czechia, Belgium, Sweden and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

• The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market in APAC.

• The DC Motor segment is growing at a significant CAGR of 7.6% in the forecast period 2024-2030. A DC motor consists of a stator and a rotor.

• Medical & Healthcare sector is expected to witness a highest CAGR of 8.5% the forecast period 2024-2030, due to its extensive reliance on electrically powered devices and equipment. Diagnostic imaging equipment, such as MRI and CT scanners, demands high-performance electric motors for precise movements and accurate imaging.

• Electric Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Electric Motor Market Segment Analysis - By Product Type

The DC Motor segment is expected to grow at a significant CAGR of 7.6% during the forecast period 2024-2030. Owing to the growing penetration of brushless DC motors across various industry verticals substituting brushed dc and even ac induction motors in certain applications such as home appliances. DC motors are used in electric vehicles in the automotive industry for various non-traction applications, contributing to the ongoing shift towards sustainable transportation. As the demand for electric vehicles grows, so does the demand for efficient and dependable DC motors. DC motors are also widely used in industrial automation, powering conveyor systems, robotics, and manufacturing equipment. Owing to the ease of control, they are suitable for accurate and regulated movements in automated processes.

Inquiry Before Buying

Electric Motor Market Segment Analysis - By Application

Medical & Healthcare sector is expected to witness a highest growth of CAGR 8.5% during the forecast period 2024-2030, owing to the increase in investments in healthcare and medical sector, along with growing penetration of advanced medical devices & equipment in the sector such as surgical robots, advanced imaging & diagnostic equipment, prosthetics and so on. Medical advances and technical improvements have resulted in the development of a wide range of medical instruments and gear that significantly rely on the precision and efficiency provided by electric motors. High-performance electric motors are required for precise motions and accurate imaging in diagnostic imaging equipment such as MRI and CT scanners. Electric motors provide stability and consistency to patient care and monitoring systems such as infusion pumps and monitoring equipment. Furthermore, the incorporation of electric motors in mobility aids such as electric wheelchairs and patient lifts improves accessibility for people who have mobility issues. Electric motors are used in laboratory equipment, robotic surgical systems, and a variety of medical tools, all of which contribute to the overall efficiency and improvement of healthcare techniques. The demand for electric motors is on the rise as the healthcare industry evolves and adopts more technologically sophisticated solutions, fueling additional innovation in this critical sector.

Electric Motor Market Segment Analysis - By Geography

Electric Motor market in Asia-Pacific region held significant market share of 38% in 2023. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market. In addition, advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Electric Motor Market Drivers

Rise in demand for Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Major manufacturers such as General Motors, Toyota, and BMW plan to release a potential of 400 models and estimated global sales of 25 million by 2025. In 2022, Ford Motor has committed to increase its investments in electric vehicles to $50 billion by 2026, up from a previous spend of $30 billion by 2025. Similarly, in 2020, Volkswagen, Chinese ventures has committed to invest $17.5 billion in electric vehicles by 2025. As electric vehicles use various types of electric motors for traction & auxiliary applications, the rising demand for electric vehicles globally is set to assist the market growth for electric motors used in the same.

Growing R&D activities

Manufacturers are continuously focusing on R&D to develop new and effective electric motors to meet consumer demand. Increasing concerns, such as environmental pollution and regulations, are forcing manufacturers to develop electric motors that reduce vibration and increase efficiency. For instance, a synchronous electric motor is around 80% more efficient than an induction electric motor. Similarly, the development of a new type of steel for electric motors, which reduces the weight of the electric motor and makes it more efficient and powerful. This new type of electric motor will be small in size and cost effective, which will raise demand from residential and commercial applications. Moreover growing developments from various companies is also analysed to drive the market growth. Hence these factors are analysed to drive the market growth in the forecast period 2024-2030.

Electric Motor Market Challenges

Easy availability of low-quality electric motors

The market for electric motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of electric motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality electric motors. This acts as a key challenge for the growth of the market.

Buy Now

Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Electric Motor market. Electric Motor top 10 companies include:

ABB Ltd

Johnson Electric Holdings Limited

Siemens AG

Rockwell Automation

Nidec Corporation

Bosch Electric

Regal Rexnord

Franklin Electric Company Inc.

Teco Electric & Machinery Co. Ltd.

Wolong Electric Group co. ltd.

Acquisitions/Product Launches

• In July 2023, Nidec Corporation announced that it has successfully developed a new electric power steering motor power pack*1 (“EPS-PP”).

• In July 2023, WEG announced new investments for its motor manufacturing plant located in Manaus, Brazil. The Company will invest R$ 48 million, in the next three years, to expand production capacity and adapt the plant to produce a new line of permanent magnet electric motors for split-type air conditioners

• In December 2023, Johnson Electric Launches 48-Volt Cooling Fan Module with High Power and Efficiency. Johnson Electric is pleased to announce the launch of the 48-Volt Cooling Fan Module with power up to 1.5kW to meet the most demanding cooling requirements. The need to reduce emissions and increase the electrification of the vehicle, requires higher cooling performance and efficiency.

#Electric Motor Market#Electric Motor Market size#Electric Motor industry#Electric Motor Market share#Electric Motor top 10 companies#Electric Motor Market report#Electric Motor industry outlook

0 notes

Text

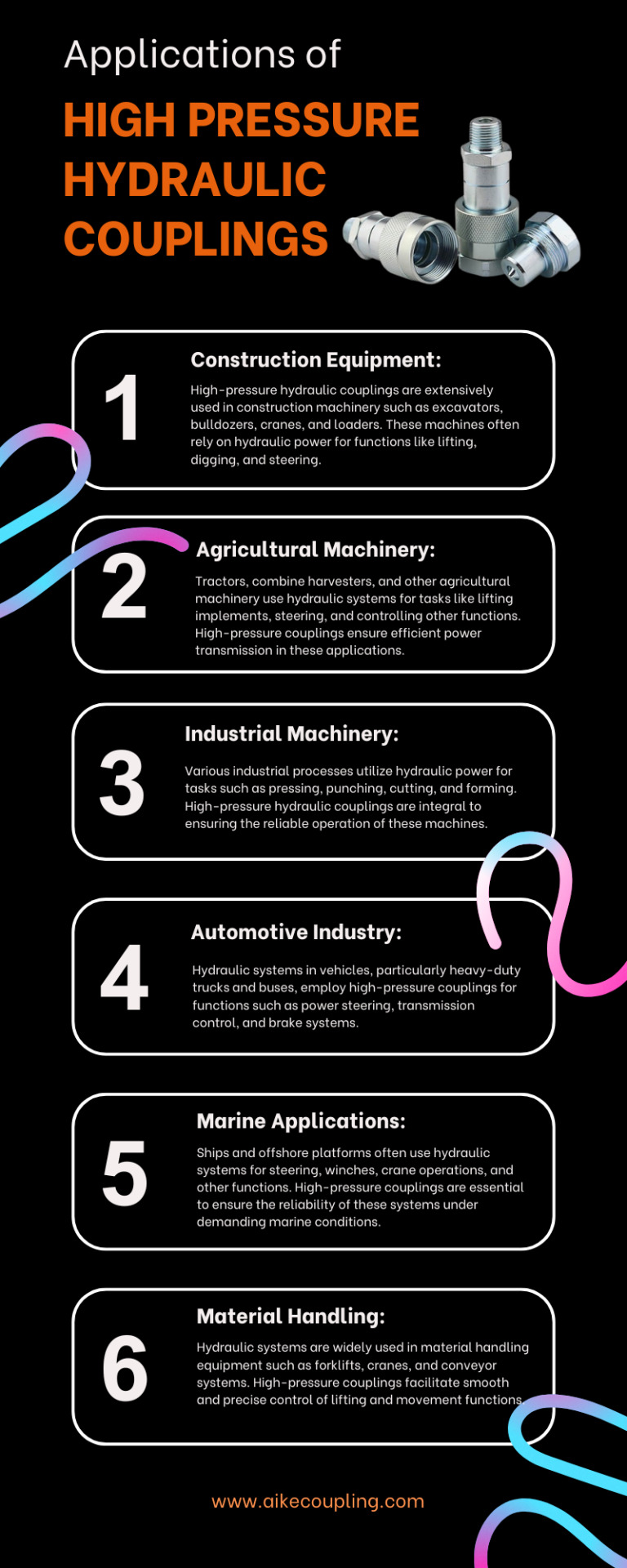

Applications of High Pressure Hydraulic Couplings [Infographic]

High pressure hydraulic couplings are vital components in a wide range of industries where hydraulic systems are employed. These couplings facilitate the transfer of hydraulic fluid under high pressure between various components such as pumps, valves, cylinders, and motors.

Here are some common applications:

Construction Equipment:

High pressure hydraulic couplings are extensively used in construction machinery such as excavators, bulldozers, cranes, and loaders. These machines often rely on hydraulic power for functions like lifting, digging, and steering.

Agricultural Machinery:

Tractors, combine harvesters, and other agricultural machinery use hydraulic systems for tasks like lifting implements, steering, and controlling other functions. High pressure couplings ensure efficient power transmission in these applications.

Industrial Machinery:

Various industrial processes utilize hydraulic power for tasks such as pressing, punching, cutting, and forming. High pressure hydraulic couplings are integral to ensuring the reliable operation of these machines.

Automotive Industry:

Hydraulic systems in vehicles, particularly heavy-duty trucks and buses, employ high pressure couplings for functions such as power steering, transmission control, and brake systems.

Aerospace and Defense:

Hydraulic systems are critical in aircraft for functions such as landing gear operation, flight control surfaces, and cargo handling. High pressure couplings play a crucial role in maintaining the integrity and efficiency of these systems.

Marine Applications:

Ships and offshore platforms often use hydraulic systems for steering, winches, crane operations, and other functions. High pressure couplings are essential to ensure the reliability of these systems under demanding marine conditions.

Mining Operations:

Hydraulic systems are extensively used in mining equipment for tasks such as drilling, digging, and material handling. High pressure couplings enable efficient power transmission in these rugged environments.

Energy Sector:

Hydraulic systems are employed in various energy applications, including power generation (such as hydroelectric dams) and oil and gas operations (for drilling rigs, well control, and pipeline maintenance). High pressure couplings are critical for these applications to ensure safe and efficient operation.

Material Handling:

Hydraulic systems are widely used in material handling equipment such as forklifts, cranes, and conveyor systems. High pressure couplings facilitate smooth and precise control of lifting and movement functions.

Medical Equipment:

Certain medical devices, such as hydraulic patient lifts and surgical tables, rely on hydraulic systems for smooth and precise movement. High pressure couplings ensure the reliability and safety of these critical applications in healthcare settings.

In summary, high pressure hydraulic couplings find applications across a diverse range of industries, playing a crucial role in enabling efficient power transmission and control in various hydraulic systems.

To read more information about High Pressure Hydraulic Couplings, visit here www.aikecoupling.com/portfolio-items/10000-psi-high-pressure-screw-to-connect-hydraulic-quick-coupling or call now +86 150 2654 9556

0 notes

Text

Unveiling the Smile: The Importance of Quality Dental Equipment

In the world of dentistry, precision, reliability, and efficiency are paramount. Behind every radiant smile lies a sophisticated array of dental equipment, meticulously designed to ensure both patient comfort and optimal treatment outcomes. From routine cleanings to complex surgical procedures, the significance of high-quality dental equipment cannot be overstated. Let's delve into why these tools are the unsung heroes of oral healthcare.

Precision Matters:

Dentistry is as much an art as it is a science, requiring intricate maneuvers within the confined space of the oral cavity. Quality dental instruments are crafted with precision engineering to facilitate delicate procedures with minimal discomfort to the patient. Whether it's a handheld scaler for plaque removal or a rotary instrument for precise drilling, accuracy is non-negotiable. Every movement counts, and subpar equipment simply won't cut it when it comes to achieving the desired results.

Patient Comfort and Safety:

A visit to the dentist can be anxiety-inducing for many individuals. However, with the advent of advanced dental technologies, the patient experience has undergone a remarkable transformation. High-quality dental equipment is designed not only to maximize clinical efficacy but also to prioritize patient comfort and safety. Ergonomically designed chairs, powerful yet whisper-quiet drills, and minimally invasive instruments contribute to a more pleasant dental visit, fostering trust and confidence between the patient and the dental practitioner.

Durability and Reliability:

In the fast-paced environment of a dental practice, reliability is key. Dental equipment undergoes rigorous testing to ensure durability and longevity, withstanding the demands of daily use without compromising performance. From sterilization procedures to heavy workload requirements, quality instruments remain steadfast, minimizing downtime and maximizing productivity. Investing in reliable equipment is an investment in the future of the practice, safeguarding against potential disruptions and costly repairs down the line.

Diagnostic Precision:

Diagnosis is the cornerstone of effective dental treatment planning. In this regard, the importance of high-quality diagnostic equipment cannot be overstated. From digital intraoral cameras to state-of-the-art imaging systems such as cone-beam computed tomography (CBCT), these technologies provide unparalleled insight into the oral health of patients. Accurate diagnosis enables targeted interventions, ensuring optimal treatment outcomes while minimizing unnecessary procedures. Quality dental equipment empowers dental practitioners to make informed decisions, elevating the standard of care for patients.

Innovation and Advancements:

The field of dentistry is constantly evolving, driven by advancements in technology and innovation. Quality dental equipment serves as a catalyst for progress, enabling dental practitioners to stay at the forefront of their profession. Whether it's the integration of artificial intelligence in treatment planning or the development of novel biomaterials for restorative procedures, cutting-edge tools empower dentists to deliver superior care in an ever-changing landscape. By embracing innovation, dental practices can enhance efficiency, expand treatment options, and ultimately, improve patient outcomes.

Conclusion:

In the realm of dentistry, the importance of quality dental equipment cannot be overstated. From enhancing clinical precision to prioritizing patient comfort and safety, these tools are the backbone of modern oral healthcare. By investing in high-quality instruments and embracing technological advancements, dental practitioners can elevate the standard of care, fostering healthier smiles and happier patients. As we continue to push the boundaries of innovation, let us never forget the invaluable role that quality dental equipment plays in transforming lives, one smile at a time.

0 notes

Text

MEDICAL AIR COMPRESSORS IN THE HEALTH CARE MARKET

Medical air compressors are essential to healthcare facilities and play a crucial role in various medical applications. Pattons Medical offers an extensive range of compressed air products for the healthcare industry, including medical air packages, medical vacuum packages, laboratory packages, outlets, zone valves, alarms, and manifolds.

Here are some ways medical air compressors are used in healthcare:

Supplying Breathing Air: Medical air compressors are used to generate a continuous supply of clean, compressed air for respiratory therapy, anesthesia, and critical care. Ventilators, respiratory support devices, and anesthesia machines deliver this air to patients, ensuring consistent breathable air flow for patients requiring respiratory support.

Pattons Medical air compressors are available using Scroll, Reciprocating, and Rotary Screw technology. Our air compressors have several features and benefits:

NFPA 99 compliant

Utilizing proven Hitachi oil-less medical air reciprocating compressors and medical scroll compressors available in base mount-single point connection, modular and tank mounted versions

Multiplex configurations

HMI controls on all units

Built-in vibration isolation

Fully piped, wired and tested before shipment

Purge saving desiccant dryers for superior dew point performance

Operating Surgical Instruments: Compressed air is used to power pneumatic surgical instruments such as drills, saws, and other surgery tools. These instruments require a reliable compressed air source to operate efficiently and provide precision during procedures.

Laboratory Applications: Medical air compressors are used in various laboratory applications, including air supply for chromatography systems, air drying, gas chromatography, and mass spectrometry. They provide a clean and reliable compressed air source for analytical and diagnostic purposes.

Pattons Medical offers oil-less Scroll technology by Hitachi, creating quiet, smooth-running, long-lasting, proven technology.

Vacuum Systems: Medical air compressors are often used in conjunction with vacuum systems in healthcare settings. These systems create suction for various applications, including wound drainage, surgical suction, and central vacuum systems for general cleaning and waste disposal.

Proven reliable pump designs

Low cost of ownership

Dedicated Engineering Support

On-time production and delivery

Start-up Assistance

Operation and maintenance training

Pump exchange program

Extensive parts inventory

Patient Monitoring: Medical air compressors are used in certain patient monitoring systems that require compressed air for operation. For example, some non-invasive blood pressure monitors and oscillometric devices rely on compressed air to inflate and deflate cuffs for accurate readings.

Pattons Medical air compressors adhere to all NFPA 99 and CSA standards in order to meet the stringent requirements of healthcare environments. These standards require the necessity for air to be clean, dry, and contaminant-free to ensure patient safety and prevent infections. Regular maintenance, monitoring, and filtration systems are crucial to maintaining the compressed air quality used in healthcare applications.

0 notes

Text

#Powered Surgical Instruments Market#Powered Surgical Instruments Market Trends#Powered Surgical Instruments Market Growth#Powered Surgical Instruments Market Industry#Powered Surgical Instruments Market Research#Powered Surgical Instruments Market Report

0 notes

Text

#Powered Surgical Instrument#Surgical Tool#Surgical Device Orthopedic Power Tool#Powered Instrument#Powered System Surgical Drill#Surgical Saw

1 note

·

View note

Text

The multifunctional battery-powered handpiece features a single-handed operational switch for forward and reverse mode, quick-connect attachments enabling rapid accessory changes, and a variable speed control trigger for maximum control ... https://www.orthopaedic-implants.com/surgical-power-tools/bone-drill-saw-system/multi-function-handpiece.php

2 notes

·

View notes

Text

The Art of Precision: Exploring Dental Surgical Instruments by Ritter Implants

The world of dentistry has seen remarkable advancements in recent years, and dental implant surgery is no exception. At the forefront of this progress lies the meticulous craftsmanship of specialized instruments, allowing dentists to perform intricate procedures with unparalleled precision and control. Today, we delve into the fascinating realm of dental surgical instruments by Ritter Implants, renowned for their quality and innovation.

A Legacy of Excellence:

Ritter Implants boasts a rich heritage dating back to 1897, solidifying their position as a leading manufacturer of dental implants and related instruments. Their surgical kits are meticulously designed to cater to the specific needs of various implant systems, including their innovative SB/LA Implant System. Each kit is a comprehensive toolbox, containing:

Surgical Drills: These high-tech drills deliver optimal power and control during bone preparation, ensuring precise implant placement.

Dental Burs: A diverse range of burs caters to various drilling tasks, from creating pilot holes to shaping the bone bed.

Taps and Drivers: These instruments facilitate smooth implant insertion and secure anchoring.

Ratchets and Handpieces: Designed for ergonomic comfort and precise manipulation, these components ensure surgeon control throughout the procedure.

Additional Instruments: Depending on the kit, you might find elevators, periosteotomes, suture materials, and other specialized tools tailored to specific surgical needs.

Beyond the Basics:

Ritter Implants goes beyond providing just instruments. They offer:

Guided Surgery Solutions: Minimally invasive and predictable implant placement through surgical guides.

Educational Resources: Extensive training programs and workshops to equip dentists with the knowledge and skills to master implant surgery.

Exceptional Customer Support: Dedicated teams to assist with product selection, technical queries, and ongoing support.

Investing in Success:

Ritter's dental surgical instruments represent an investment in clinical excellence and patient satisfaction. Their meticulous design, premium materials, and unwavering commitment to quality translate to:

Enhanced procedural efficiency: Streamlined workflows and optimized instrumentation for faster and smoother surgeries.

Reduced risk of complications: Precise instruments minimize tissue damage and promote optimal healing.

Improved patient outcomes: Predictable results and faster recovery times for a positive patient experience.

Conclusion:

Dental Durgical Instruments by Ritter Implants are more than just tools; they are the embodiment of precision, innovation, and a dedication to advancing the field of implant dentistry. By choosing Ritter, dentists equip themselves with the best possible resources to deliver exceptional patient care and achieve predictable, long-lasting results.

0 notes

Text

Bridging the Gap Between Precision and Efficiency: Heavy Power Surgical Tools Market Insights

Introduction

The global heavy power surgical tools market has witnessed significant growth in recent years, driven by advancements in surgical technology, an aging population, and a growing demand for minimally invasive surgical procedures. These tools, known for their precision and efficiency, play a crucial role in a wide range of medical procedures, from orthopedic surgeries to neurosurgery. This article explores the current state of the heavy power surgical tools market, its key players, emerging trends, and the factors contributing to its growth.

Market Overview

Heavy power surgical tools, such as drills, saws, reamers, and shavers, are essential in various surgical disciplines. They offer surgeons the ability to cut, shape, and manipulate bone and tissue with precision and speed. The market for these tools is experiencing rapid expansion, thanks to technological advancements that are improving both the tools themselves and the surgical techniques. Additionally, an increasing number of surgical procedures are now performed on an outpatient basis, reducing patient hospital stays and overall healthcare costs.

Key Players

Several prominent companies dominate the heavy power surgical tools market. These include Stryker Corporation, Medtronic PLC, Zimmer Biomet Holdings, Inc., Johnson & Johnson Services, Inc., and B. Braun Melsungen AG, among others. These companies are continually investing in research and development to introduce innovative tools that enhance surgical procedures and improve patient outcomes.

Emerging Trends

1. Minimally Invasive Surgery: The rise of minimally invasive surgical techniques has created a demand for more refined and versatile surgical tools. Minimally invasive procedures often require smaller, more precise instruments that can access hard-to-reach areas, and companies are responding with innovative solutions.

2. Smart Surgical Tools: The integration of technology into surgical tools is becoming more common. Smart surgical tools are equipped with sensors, feedback systems, and data connectivity, allowing surgeons to monitor and control the tools' performance in real-time.

3. 3D Printing: 3D printing technology is revolutionizing the manufacturing of heavy power surgical tools. Surgeons can now have custom-made tools designed for specific patients or procedures, improving the precision and efficacy of surgeries.

4. Sustainability: The healthcare industry is increasingly focused on sustainability. As a result, manufacturers are developing tools with a reduced environmental footprint, including reusable and recyclable materials.

Factors Contributing to Growth

1. Aging Population: The world's aging population is driving the need for more surgical procedures, particularly in orthopedic and neurosurgery. Heavy power surgical tools are essential in these fields for procedures like joint replacements and spine surgeries.

2. Technological Advancements: Continuous innovations in surgical tool design and materials are making procedures safer and more efficient, contributing to market growth.

3. Increasing Healthcare Expenditure: Healthcare spending is on the rise globally, leading to greater investment in advanced surgical tools and equipment.

4. Growing Prevalence of Chronic Diseases: Diseases such as osteoarthritis and various neurological disorders are becoming more prevalent, necessitating surgical interventions that rely on heavy power surgical tools.

Conclusion

The heavy power surgical tools market is evolving at a rapid pace, with innovations driving improved surgical outcomes and patient experiences. As the world's population continues to age, and healthcare technology advances, this market is poised for substantial growth. Companies at the forefront of these developments are not only contributing to the betterment of patient care but also expanding their global reach in this dynamic sector. It will be intriguing to watch how the market continues to evolve and how these developments will shape the future of surgery.

0 notes

Text

Global Surgical Drills Market Is Estimated To Witness High Growth Owing To Increasing Demand for Minimally Invasive Procedures

The global surgical drills market is estimated to be valued at US$ 604.7 million in 2023 and is expected to exhibit a CAGR of 7.91% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Surgical drills are medical devices used by surgeons during surgeries to drill holes or remove abnormal tissues in the bone. These drills are widely used in orthopedic, neurology, and dental surgeries. They offer various advantages such as precise and accurate drilling, reduced surgery time, minimized risk of complications, and faster patient recovery. The increasing demand for minimally invasive procedures is driving the growth of the surgical drills market as these procedures require precise and efficient drilling. Moreover, advancements in surgical drill technology, such as the development of power-assisted drills and customized patient-specific drills, are further fueling the market growth.

Market Key Trends:

One key trend in the surgical drills market is the growing adoption of robotic-assisted surgeries. Robotic-assisted surgeries offer improved precision, smaller incisions, reduced pain, and faster recovery times. Surgical robots equipped with surgical drills can perform complex surgical procedures with high accuracy, reducing the risks associated with human error. For example, Intuitive Surgical's da Vinci Surgical System is widely used for robotic-assisted surgeries, including orthopedic and neurology procedures. The system allows surgeons to control precise movements of the surgical drill with enhanced visualization and dexterity.

PEST Analysis:

Political: Government regulations and policies regarding medical device approvals and safety standards can impact the growth of the surgical drills market.

Economic: Healthcare expenditure and reimbursement policies play a crucial role in the adoption of surgical drills.

Social: Increasing awareness about the benefits of minimally invasive surgeries and growing elderly population contribute to the market growth.

Technological: Advancements in surgical drill technology, such as the integration of robotics and software, are driving market growth.

Key Takeaways:

1: The global surgical drills market is expected to witness high growth, exhibiting a CAGR of 7.91% over the forecast period. This growth is attributed to the increasing demand for minimally invasive procedures and advancements in surgical drill technology. For example, the development of power-assisted drills and customized patient-specific drills is driving market growth.

2: The fastest-growing and dominating region in the surgical drills market is North America. This can be attributed to the presence of well-established healthcare infrastructure, high healthcare expenditure, and increasing adoption of robotic-assisted surgeries in the region.

3: Key players operating in the global surgical drills market include B. Braun SE, Stryker Corporation, Adeor Medical Ag, Medtronic, Allotech Co. Ltd., Arthrex Inc., Brasseler USA, ClearPoint Neuro, Inc., ConMed Corporation, De Soutter Medical Ltd., GPC Medical Ltd., Johnson & Johnson, Joimax Inc., Marver Med, MicroAire Surgical Instruments, LLC., Sofemed, Zimmer Biomet Holdings, Inc., and Manman Manufacturing Company Private Limited. These players focus on product innovation, mergers and acquisitions, and collaborations to strengthen their market position.

In conclusion, the global surgical drills market is expected to witness significant growth due to the increasing demand for minimally invasive procedures and advancements in surgical drill technology. The adoption of robotic-assisted surgeries and the dominance of North America in the market are key trends to watch out for. Government regulations, healthcare expenditure, increasing awareness, and technological advancements are important factors influencing the market growth. Key players continue to invest in research and development to introduce innovative products and expand their market presence in the surgical drills industry.

0 notes

Text

https://orthopaedic-implants.com/surgical-power-tools/bone-drill-saw-system/neurosurgery-tools.php

0 notes