#Styrenic Polymers Market overview

Text

#Styrenic Polymers Market Overview#Size#Share#Trends#Scope#and Growth Predictions for 2022-2028 | 200 Pages Report#intellectualmarketinsights

0 notes

Text

#global styrenic polymer packaging market#styrenic polymer packaging research report#styrenic polymer packaging business research report#styrenic polymer packaging research insights#styrenic polymer packaging market overview#styrenic polymer packaging

0 notes

Text

Global Styrenic Block Copolymer Market to be Driven by Growing Demand for Green Construction Materials in the Forecast Period of 2022-2027

The new report by Expert Market Research titled, ‘Global Styrenic Block Copolymer Market Report and Forecast 2022-2027’, gives an in-depth analysis of the global styrenic block copolymer market, assessing the styrenic block copolymer market, based on its segments like products, applications, and major regions. The report tracks the latest trends in the industry and studies their impact on the overall market. It also assesses the market dynamics, covering the key demand and price indicators, along with analysing the market based on the SWOT and Porter’s Five Forces models.

Request a free sample copy in PDF or view the report summary@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market/requestsample

The key highlights of the report include:

Market Overview (2017-2027)

Historical Market Size (2020): About USD 8.1 billion

Forecast CAGR (2022-2027): 4.60%

Forecast Market Size (2026): Nearly USD 10.6 billion

The growth in the global market for styrenic block copolymer is being driven by the rising demand for styrene-butadiene-styrene (SBS). This can be associated with the rising demand for SBS from the polymer modification, footwear, construction, adhesives and sealant segments. The demand for SBS in the construction sector is being led by its applications in paving and roofing. This trend is further supported by rising construction and reconstruction activities around the world on account of rising urbanisation and industrialisation. Geographically, the Asia Pacific region is likely to account for a significant share of the market during the forecast period.

Industry Definition and Segmentation

Styrenic block copolymers refer to high-performance thermoplastic elastomers. These are specifically designed to increase product application and performance in end-use sectors. Styrenic block copolymers are thermally stable, crystal clear, and resistant, with little cytotoxic or mutagenic potential.

Explore the full report with the table of contents@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market

Based on product, the market can be segmented into:

Styrene-Butadiene-Styrene (SBS)

Styrene-Isoprene-Styrene (SIS)

Hydrogenated SBC (HSBC)

On the basis of application, the market divisions are:

Asphalt Modification

Wires and Cables

Polymer Modification

Adhesives and Sealants

Footwear

Others

The regional markets for styrenic block copolymer include:

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Latest News on Global Styrenic Block Copolymer Market@ https://www.expertmarketresearch.com/pressrelease/global-styrenic-block-copolymer-market

Market Trends

The growth in the global market for styrenic block copolymer is being positively influenced by applications in the medical equipment manufacturing sector. The increasing demand for medical equipment like tubing, bags, and IV drip chambers is driving the market forward. This can be attributed to the favourable properties of styrenic block copolymer which include high transparency, flexibility, good mechanical strength, kink resistance, and excellent UV and chemical resistance. Increasing medical spending and advancements in medical equipment technology are expected to further contribute to the growth of the market. Apart from this, the construction sector is projected to be a leading application segment owing to increasing investments in green building projects. This is likely to raise the demand for lightweight, environmentally friendly material like styrenic block copolymers, hence fuelling the growth of the market.

Key Market Players

The major players in the market are China Petrochemical Corporation, Asahi Kasei Corporation, JSR Corporation, Ineos Styrolution Group GmbH, Eastman Chemical Company, and Kumho Petrochemical, among others. The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

About Us:

Expert Market Research is a leading business intelligence firm, providing custom and syndicated market reports along with consultancy services for our clients. We serve a wide client base ranging from Fortune 1000 companies to small and medium enterprises. Our reports cover over 100 industries across established and emerging markets researched by our skilled analysts who track the latest economic, demographic, trade and market data globally.

At Expert Market Research, we tailor our approach according to our clients’ needs and preferences, providing them with valuable, actionable and up-to-date insights into the market, thus, helping them realize their optimum growth potential. We offer market intelligence across a range of industry verticals which include Pharmaceuticals, Food and Beverage, Technology, Retail, Chemical and Materials, Energy and Mining, Packaging and Agriculture.

Media Contact

Company Name: Claight Corporation

Contact Person: Steven Luke, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

City: Sheridan

State: Wyoming

Country: United States

Website: https://www.expertmarketresearch.com

Read More:

Health Insurance Market: https://www.digitaljournal.com/pr/global-health-insurance-market-is-expected-to-grow-steadily-at-cagr-of-6-in-the-forecast-period-of-2021-2026-2

Noninvasive Neuromodulation Market: https://www.digitaljournal.com/pr/global-noninvasive-neuromodulation-market-to-be-driven-by-technological-and-medical-advancements-in-the-forecast-period-of-2021-2026

Alumina Trihydrate Market: https://www.digitaljournal.com/pr/global-alumina-trihydrate-market-to-be-driven-by-the-versatility-and-application-flexibility-of-alumina-trihydrate-in-the-forecast-period-of-2021-2026

Food Dehydrators Market: https://www.digitaljournal.com/pr/global-food-dehydrators-market-to-be-driven-at-a-cagr-of-5-in-the-forecast-period-of-2021-2026

Glucuronolactone Market: https://www.digitaljournal.com/pr/global-glucuronolactone-market-to-be-driven-by-the-heightened-demand-for-the-product-in-the-pharmaceutical-sector-in-the-forecast-period-of-2022-2027

Also, Check Procurement Intelligence which provides you with Infallible research solutions.

*We at Expert Market Research always thrive to give you the latest information. The numbers in the article are only indicative and may be different from the actual report.

#Styrenic Block Copolymer Market#Styrenic Block Copolymer Market Size#Styrenic Block Copolymer Market Analysis#Styrenic Block Copolymer Market Report

2 notes

·

View notes

Text

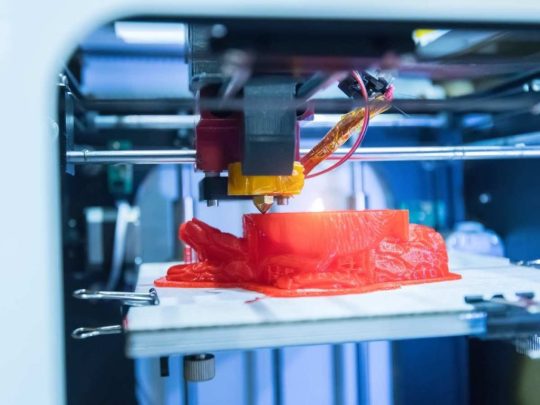

Market Resilience: Adapting to Global Changes in 3D Printing Extrusion Materials

The 3D printing extrusion materials market is estimated to be valued at US$ 12.77 Bn in 2023 and is expected to exhibit a CAGR of 19.% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

3D printing extrusion materials are polymers that are used as filaments or pellets to produce parts and prototypes through extrusion-based 3D printing processes. Some common extrusion materials used are acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high impact polystyrene (HIPS), polyethylene terephthalate glycol-modified (PETG), and many others. These materials find applications in various industries including aerospace, automotive, consumer products and industrial goods for producing functional prototypes and end-use parts.

Market Dynamics:

The 3D printing extrusion materials market is driven by rising demand from automobiles industry for prototyping components. Several automakers are adopting 3D printing technology for manufacturing vehicle parts owing to its ability to produce complex designs that are lightweight and durable. ABS and PLA are widely used 3D printing materials for automotive applications.

Another driver is the growing applications of 3D printing in healthcare industry. Materials such as PLA, polyvinyl alcohol (PVA) and polyethylene glycol (PEG) are used to produce medical implants, surgical guides and prototypes of human organs through 3D printing. This is positively impacting the demand for specialty healthcare extrusion materials. However, high capital investment requirement for 3D printing equipment and technology is a major challenge for widespread adoption.

SWOT Analysis

Strength: The 3D Printing Extrusion Materials Market provides enhanced product customization which helps in producing lightweight and complex design parts. It reduces manufacturing expenses by eliminating tooling costs and lowering waste. It offers greater design flexibility to produce prototypes and finished goods with fewer design limitations.

Weakness: High initial investment required for printers and material development limit the adoption of 3D printing technology. Lack of standardized processes and performance issues related to mechanical properties restrict the use of 3D printing.

Opportunity: Growing demand from healthcare and aerospace industries for producing customized medical implants and aircraft components offer significant opportunities. Increasing research on developing sustainable biodegradable materials will expand the application scope.

Threats: Availability of substitute technologies like CNC milling and injection molding poses threat to 3D printing adoption. Stringent regulations over material formulations and recyclability cause compliance challenges.

Key Takeaways:

The global 3D Printing Extrusion Materials Market is expected to witness high growth, exhibiting CAGR of 19.% over the forecast period, due to increasing demand from end-use industries like automotive, aerospace, and healthcare. Advances in material science for developing high-performance plastics and composites tailored for specific 3D printing processes fuel the market growth.

Regional analysis North America dominates the global market, owing to presence of major manufacturers, availability of advanced 3D printing technologies and government funding for additive manufacturing based R&D activities in the region. Asia Pacific exhibits the fastest growth in the coming years on account of rising industrial automation, low production cost and increasing foreign investments in the region.

Key players operating in the 3D Printing Extrusion Materials Market are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. The players focus on new product launches, expansions, partnerships and mergers & acquisitions to gain competitive edge in the market.

#3D Printing Extrusion Materials Market Share#3D Printing Extrusion Materials Market Growth#3D Printing Extrusion Materials Market Demand#3D Printing Extrusion Materials Market Trend

0 notes

Text

United States Styrene Butadiene Rubber (SBR) Market Industry Trends, Share, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the United States styrene butadiene rubber (SBR) market size at USD 1.41 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects United States styrene butadiene rubber (SBR) market size to grow at a significant CAGR of 6.45% reaching a value of USD 2.06 billion by 2029. Major growth drivers for the United States styrene butadiene rubber (SBR) market include an increasing interlinking of polymer chains brought on by oxidation. Unlike natural rubber, which tends to harden with time, SBR retains its softness due to this cross-linking, rendering it a favorable material for manufacturing tires. This distinctive property underscores SBR's prominence as a preferred option within the market. The demand for SBR is particularly significant in the tire industry due to these attributes. Also, as the population grows, leading to higher vehicle demand and subsequently increased tire production, the demand for SBR is expected to rise in the USA. Also, its non-slip attributes make SBR suitable for producing footwear soles and heels, contributing notably to market expansion. It is projected that the USA's styrene butadiene rubber (SBR) market will likely reach a volume of 1500 thousand tons throughout the forecast period. However, fluctuations in prices of raw materials and limited supplies of natural rubber are anticipated to restrain the overall market growth during the forecast period.

United States Styrene butadiene rubber (SBR) Market – Overview

Styrene butadiene rubber (SBR) is a synthetic rubber derived from the copolymerization of styrene and butadiene. The predominant method for its production is emulsion polymerization. SBR boasts exceptional mechanical attributes, including high heat resistance, strong tensile strength, resistance to cracking and tearing, and notable resilience. Consequently, it finds widespread application, notably in tire manufacturing. Often combined with natural rubber for enhanced resilience, SBR is employed in various industries, such as tire production, conveyor belts, foam articles, adhesives, sealants, domestic mats, footwear soles, chewy candy, food container adhesives, car mats, brake pads, tubing, V-belts, floor coverings, military tank pads, and rubberized battery box cases.

Sample Request @ https://www.blueweaveconsulting.com/report/united-states-styrene-butadiene-rubber-market/report-sample

Impact of COVID-19 on United States Styrene butadiene rubber (SBR) Market

COVID-19 pandemic adversely affected the United States styrene butadiene rubber (SBR) market. It led to disruptions in supply chains, reduced manufacturing capacities, and shifts in consumer demand. Lockdown measures and reduced economic activity during the pandemic's peak resulted in decreased demand for automotive and industrial products, influencing SBR utilization. While the gradual recovery in economic activities led to a rebound in demand, challenges remained due to supply chain bottlenecks and labor shortages. The pandemic emphasized the need for resilient supply chains and adaptive production strategies to navigate uncertainties and ensure the United States SBR market's sustained growth amidst such unprecedented challenges.

United States Styrene butadiene rubber (SBR) Market – By Application

Based on application, the United States styrene butadiene rubber (SBR) market is divided into Tires, Industrial, Footwear, Polymer Modification, and Adhesives segments. The tires segment held the highest share in the United States styrene butadiene rubber (SBR) market by application. SBR's unique blend of mechanical properties, such as durability, abrasion resistance, and high tensile strength, make it a preferred material for tire production. As the automotive sector continues to grow, the demand for high-quality, long-lasting tires has surged. SBR's ability to enhance tire performance and safety while meeting stringent industry standards has propelled its widespread adoption. This strong alignment between SBR's properties and tire manufacturing requirements underscores its dominant position in the United States SBR market within the tires application segment.

Competitive Landscape

Major players operating in the United States styrene butadiene rubber (SBR) market include Goodyear Tire and Rubber, LANXESS AG, Lion Elastomers, Bridgestone Corporation, Trinseo, Zeon Chemical, Dow Chemical, INEOS Styrolution, Chevron Phillips Chemical Company, and Sinopec. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

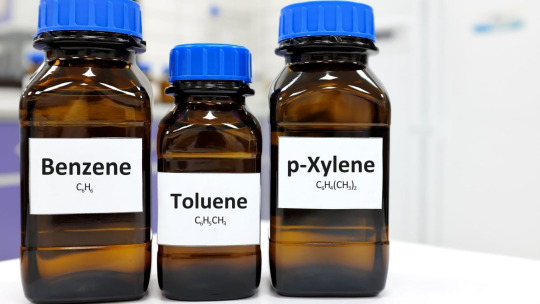

Navigating the Global Benzene Toluene Xylene Market: Key Players and Growth Factors

Definition: Benzene, toluene, and xylene are organic compounds characterized by a six-carbon ring structure with alternating single and double bonds. They are classified as aromatic hydrocarbons due to their unique ring arrangement and exhibit distinct chemical properties. These compounds serve as fundamental building blocks in the chemical industry, finding applications in the production of various products, including plastics, resins, synthetic fibers, and solvents.

Market Overview: The BTX market is a vital segment of the global petrochemical industry. These aromatic compounds are primarily derived from crude oil or natural gas through processes such as catalytic reforming and steam cracking. The market is characterized by its significance in supplying raw materials to numerous downstream industries, making it a critical component of the global supply chain.

Market Growth: The Benzene toluene xylene market has witnessed steady growth over the years, driven by factors such as increasing demand for plastics, polymers, and synthetic fibers in various industries, including automotive, packaging, and textiles. Additionally, the rising focus on the development of eco-friendly and sustainable products has spurred innovations in the BTX market, further fueling its growth.

Market Industry: The BTX market serves as a cornerstone for several industries, including petrochemicals, chemicals, and manufacturing. Benzene, toluene, and xylene are essential raw materials for the production of a wide range of products. For instance, benzene is a key ingredient in the manufacturing of styrene, used in the production of plastics, while toluene is a vital component in the production of adhesives and paints. Xylene is crucial in the production of plastics and synthetic fibers.

Trends: Several Benzene toluene xylene market trends have shaped market in recent years. Environmental concerns have prompted the development of bio-based alternatives to traditional BTX products, reflecting a growing emphasis on sustainability. Additionally, there is a rising interest in the Asia-Pacific region, particularly in countries like China and India, as emerging markets for BTX consumption, driven by their expanding manufacturing sectors and consumer markets.

In conclusion, the BTX market plays a pivotal role in various industries, supplying essential raw materials for the production of a diverse array of products. Its continued growth is influenced by global demand patterns, environmental considerations, and evolving industry trends, making it a dynamic and integral component of the modern industrial landscape.

#Benzene Toluene Xylene Market#Benzene Toluene Xylene Market Size#Benzene Toluene Xylene Market Growth

0 notes

Text

Africa Bitumen Market Is Estimated To Witness High Growth Owing To Increasing Infrastructure Development

The Africa Bitumen Market is estimated to be valued at US$418.71 Mn in 2020 and is expected to exhibit a CAGR of 5.3% over the forecast period 2021-2028, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Bitumen is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It is primarily used as a binder in road construction and waterproofing applications. The Africa Bitumen Market is witnessing high growth due to increasing infrastructure development in the region. The need for advanced road networks, airport runways, and waterproofing solutions has boosted the demand for bitumen in Africa. Bitumen provides excellent adhesive properties, durability, and resistance to weathering, making it an ideal choice for road construction.

Market Key Trends:

One key trend in the Africa Bitumen Market is the adoption of modified bitumen for road construction. Modified bitumen is a blend of bitumen and additives that enhance its performance and improve its quality. These additives can include polymers, such as styrene-butadiene-styrene (SBS) or ethylene-vinyl acetate (EVA), which improve the elasticity, flexibility, and resistance of bitumen. Modified bitumen offers better resistance to cracking, rutting, and aging, leading to longer-lasting road surfaces. For example, in South Africa, the South African National Roads Agency Limited (SANRAL) has incorporated modified bitumen in road construction projects to enhance the durability and performance of roads.

PEST Analysis:

- Political: The political stability of a country is essential for infrastructure development projects, including road construction. Political instability can lead to delays and disruptions in project execution.

- Economic: Economic growth and investment in infrastructure drive the demand for bitumen in Africa. Growing economies and urbanization create a need for improved transportation networks and infrastructure facilities.

- Social: The growing population and increasing urbanization in Africa are driving the demand for improved road networks and infrastructure facilities. Better road connectivity improves accessibility, reduces travel time, and enhances socio-economic development.

- Technological: Technological advancements in the production and application of bitumen are driving market growth. The development of modified bitumen and innovative techniques for road construction enhance the durability and performance of roads.

Key Takeaways:

- The Africa Bitumen Market Growth is expected to witness high growth, exhibiting a CAGR of 5.3% over the forecast period, due to increasing infrastructure development in the region.

- In terms of regional analysis, North Africa is expected to be the fastest-growing and dominating region in the Africa Bitumen Market. The region is witnessing significant investments in road infrastructure, including the construction of new highways and expressways.

- Key players operating in the Africa Bitumen Market include Exxon Mobil Corporation, Royal Dutch Shell Plc., RAHA Bitumen, Inc., Tekfalt Binders (Pty) Ltd., SprayPave, Indian Oil Corporation Ltd., GOIL Company Limited, Wabeco Petroleum Ltd., Tiger Bitumen, and Richmond Group. These players focus on strategic partnerships, product innovations, and expansion strategies to gain a competitive edge in the market.

In conclusion, the Africa Bitumen Market is expected to grow significantly due to increasing infrastructure development in the region. The adoption of modified bitumen for road construction and advancements in technology are key trends driving market growth. With the fastest-growing and dominating region being North Africa, key players in the market continue to strategize and innovate to stay competitive in this growing market.

0 notes

Text

0 notes

Text

Supreme PMB(Elastomeric) Market Overview, Size, Share, Trend, Growth and Outlook

Polymer Modified Bitumen (PMB) is a type of bitumen that has been enhanced with the addition of polymers to improve its properties and performance. Bitumen is a black, sticky, and highly viscous material obtained from crude oil during the refining process. It is commonly used in the construction industry for road surfacing, waterproofing, and various other applications.

The addition of polymers to bitumen enhances its characteristics, making it more suitable for specific purposes. The polymers used in PMB can be either thermoplastic or elastomeric. Some common types of polymers used for modification include styrene-butadiene-styrene (SBS), styrene-butadiene rubber (SBR), ethylene-vinyl acetate (EVA), and polyethylene.

The key advantages of Polymer Modified Bitumen include:

Improved elasticity and flexibility: PMB has higher elongation and recovery properties, making it more resilient to temperature-induced stress and deformation, particularly in regions with extreme weather conditions.

Enhanced strength and durability: The addition of polymers improves the fatigue resistance and overall mechanical properties of bitumen, resulting in longer-lasting pavements and structures.

Better resistance to cracking and rutting: PMB reduces the risk of cracking and rutting, which are common issues in traditional bitumen pavements.

Increased resistance to water damage: PMB exhibits improved water resistance, reducing the potential for damage caused by water infiltration and increasing the lifespan of pavements.

Better adhesion: PMB has superior bonding properties, allowing it to adhere well to different aggregates and surfaces, which is crucial for road construction.

Higher temperature susceptibility: The use of PMB can expand the temperature range in which bitumen remains workable, making it easier to handle during construction.

Read more@ https://supremebituchem.com/

PMB is commonly used in road construction for asphalt mixtures, such as hot mix asphalt (HMA) and warm mix asphalt (WMA). It is also used in various other applications, including waterproofing membranes, bridge deck coatings, and airport runways.

0 notes

Text

3D Printing Materials Market Size, Share, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated global 3D printing materials market size at USD 2.1 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global 3D printing materials market size to grow at a robust CAGR of 17.6% reaching a value of USD 6.51 billion by 2029. Major growth drivers for global 3D printing materials market include an increasing need for polymers in 3D printing, a rising demand for mass customization, and government initiatives to encourage and facilitate the adoption of 3D printing. The global 3D printing market is expected to further expand due to the rising demand for 3D printing, as well as the increased demand for better quality materials in various industries such as automotive and aerospace. Also, the use of 3D printing reduces the risk of errors and is highly advantageous for production, leading to an increase in market growth during the forecast period. However, high cost of 3D printing materials, equipment, and maintenance and limited availability of high-quality and specialized 3D printing materials are anticipated to restrain the market growth during the period in analysis.

Global 3D Printing Materials Market - Overview

3D printing, also known as additive manufacturing, is a process that produces an object in three dimensions using 3D printing materials. Initially, simple thermoplastics and wax were used for 3D printing, but now, diverse materials in powder, liquid, and filament form are widely used. The automotive industry can drive market growth in the future by using technologies such as Fused Filament Fabrication (FFF) to create prototypes and end-use components. 3D printing materials and equipment allow speedy prototyping and find their end-users in creating molds, grips, and fixtures. The increasing demand for 3D printing from the aerospace and defense industries will drive 3D printing materials and equipment market share. It offers flexibility in product design and helps in producing highly detailed and sleek models.

Sample Request @ https://www.blueweaveconsulting.com/report/3d-printing-materials-market/report-sample

Impact of COVID-19 on Global 3D Printing Materials Market

COVID-19 adversely affected the global economy and caused uncertainty in all industries, including the 3D printing materials market. However, the healthcare sector experienced a surge in demand for medical equipment and devices required for COVID-19 treatment. This increased demand for medical equipment and personal protective equipment created opportunities for 3D printing companies globally. PLA and PETG materials were predominantly used to produce face shields due to their high resistance to temperature and weather conditions, contributing to the growing demand for 3D printing materials worldwide. In 2021, the global 3D printing materials market recovered due to the rising demand from the healthcare and industrial sectors worldwide. Hospitals and healthcare organizations are increasingly seeking environmentally friendly printing materials and 3D printers to produce critical equipment.

Global 3D Printing Materials Market – By Type

By type, the global 3D printing materials market is divided into Plastics, Metals, and Ceramics segments. The plastic type segment held the highest share in the global 3D printing materials market due to several factors. Plastic is a widely available and affordable material, making it a popular choice for 3D printing. Additionally, plastics offer a wide range of properties that make them suitable for various applications. For example, ABS (Acrylonitrile Butadiene Styrene) is commonly used for prototyping and functional parts due to its durability and resistance to impact. PLA (Polylactic Acid) is another popular plastic used in 3D printing due to its biodegradability and sustainability. Furthermore, advancements in 3D printing technology have made it possible to produce high quality plastic parts with complex geometries and intricate details, making it a preferred choice for a wide range of industries.

Competitive Landscape

Major players operating in the global 3D printing materials market include Stratasys, 3D Systems, Arkema, Royal DSM, EOS GmbH, Materialise NV, Evonik Industries AG, SABIC, BASF SE, CRP Technology Srl, EnvisionTEC, Solvay SA, HP Inc., Carbon Inc., and Dow Chemical Company. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Spain Acrylonitrile Butadiene Styrene Market: A Comprehensive Analysis

Introduction

In recent years, the Spain Acrylonitrile Butadiene Styrene (ABS) market has witnessed significant growth due to the increasing demand for lightweight and durable materials in various industries. ABS, a thermoplastic polymer, is widely used in sectors such as automotive, electronics, and construction. This article provides an overview of the Spain ABS market, its applications, factors driving its growth, challenges and opportunities, future trends, and concludes with frequently asked questions.

What is Acrylonitrile Butadiene Styrene (ABS)?

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic polymer known for its excellent mechanical properties and versatility. It is a copolymer composed of three monomers: acrylonitrile, butadiene, and styrene. ABS exhibits a combination of strength, toughness, and impact resistance, making it suitable for various applications.

Spain Acrylonitrile Butadiene Styrene Market Overview

The ABS market in Spain has experienced substantial growth in recent years. The market size has expanded significantly, driven by the increasing adoption of ABS in key industries. The demand for ABS is primarily fueled by its lightweight characteristics, chemical resistance, and excellent mechanical properties.

Applications of ABS in Spain

The versatility of ABS has led to its widespread use in several industries in Spain.

4.1. Automotive Industry

In the automotive sector, ABS is extensively used for manufacturing various components such as bumpers, interior trims, dashboard panels, and exterior body parts. ABS provides excellent impact resistance, dimensional stability, and surface finish, making it an ideal material for automotive applications.

4.2. Electronics Industry

ABS is widely employed in the electronics industry for manufacturing computer and television housings, keyboard keys, printer components, and other consumer electronic devices. The electrical insulating properties of ABS, along with its resistance to heat and chemicals, make it a preferred choice for these applications.

4.3. Construction Industry

ABS finds applications in the construction industry

0 notes

Text

A Complete Overview Of Different Markets Driving the Increasing Demand for ABS Plastic Injection Molding

Acrylonitrile Butadiene Styrene, commonly known as ABS, is a widely used thermoplastic polymer that has gained immense popularity in the injection molding industry. ABS offers a range of beneficial properties such as high impact resistance, good thermal stability, and excellent electrical insulation. These unique properties make ABS an ideal material for the production of various consumer goods, automotive parts, and electronic components. In this blog, we will explore the markets driving the demand for ABS plastic injection molding solutions.

Automotive Industry

The automotive industry is one of the largest markets driving the demand for ABS plastic injection molding. ABS is widely used in the production of automotive parts such as interior and exterior trims, instrument panels, and door handles. The high impact resistance and good thermal stability of ABS make it an ideal material for these applications. Additionally, ABS can be easily molded into complex shapes, which allows automotive designers to create aesthetically pleasing and functional parts. As the demand for lightweight, fuel-efficient vehicles increases, the demand for ABS plastic injection frisbee is expected to grow in the automotive industry.

Consumer Goods Industry

ABS plastic injection molding is also extensively used in the production of consumer goods. ABS is widely used to produce various household appliances such as vacuum cleaners, washing machines, and refrigerators. The excellent electrical insulation properties of ABS make it an ideal material for these applications. Additionally, ABS can be easily molded into various shapes and sizes, which allows designers to create visually appealing and functional products. The growing demand for high-quality consumer goods is expected to drive the demand for ABS plastic injection molding in the coming years.

Electronics Industry

The electronics industry is another major market driving the demand for ABS plastic injection molding. ABS is widely used to produce various electronic components such as computer keyboards, mouse devices, and printer housings. The excellent thermal stability and good electrical insulation properties of ABS make it an ideal material for these applications. Additionally, ABS can be easily molded into various shapes and sizes, which allows designers to create aesthetically pleasing and functional products. With the growing demand for electronic devices, the demand for ABS plastic injection molding is expected to increase in the electronics industry.

Medical Industry

ABS plastic injection molding is also used in the production of various medical devices such as surgical instruments, diagnostic equipment, and drug delivery systems. ABS is an FDA-approved material that offers good biocompatibility, making it suitable for medical applications. Additionally, ABS can be easily sterilized, which makes it ideal for use in the medical industry. With the growing demand for advanced medical devices, the demand for ABS plastic injection molding is expected to grow in the medical industry.

Packaging Industry

ABS plastic injection molding is widely used in the production of various packaging applications such as food containers, bottles, caps, and closures. Its high impact resistance makes it ideal for food containers that need to withstand significant physical stress without breaking or cracking. Additionally, ABS plastic injection molding is an ideal process for creating custom packaging solutions, as it allows for precise design specifications and can produce large quantities of identical products. ABS plastic injection molding can contribute to this trend by using recycled materials in the manufacturing process. This not only aids in the preservation of natural resources but also minimizes waste. Additionally, ABS plastic injection molding can be used to create lightweight packaging, which can reduce the overall carbon footprint of products during transportation.

Conclusion

ABS plastic injection molding is a versatile manufacturing process that is widely used by top plastic moulding manufacturers in various industries such as automotive, consumer goods, electronics, and medical. The unique properties of ABS such as high impact resistance, good thermal stability, and excellent electrical insulation make it an ideal material for these applications. As the demand for lightweight, fuel-efficient vehicles, high-quality consumer goods, advanced electronic devices, and medical devices continues to increase, the demand for ABS cheap injection molding is expected to grow in the coming years.

#injection frisbee#plastic moulding manufacturers#cheap injection molding#plastic injection molding manufacturer

0 notes

Text

3D Printing Plastic Market Share by 2029: Upcoming Trends and Analysis

3D Printing Plastic Market is grow at a CAGR 27.70% in the forecast 2022 to 2029.

3D Printing Plastic Market scope and Size

3D printing plastic market is segmented of the basis of type, form, application and end-user. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

· On the basis of type, the 3D printing plastic market is segmented into polycarbonates, photopolymers, acrylonitrile butadiene styrene (ABS), polyamide/nylon, polylactic acid, polyethylene terephthalate (PET), glycolized polyester (PETG), high performance polymers, and others

· Based on form, the 3D printing plastic market is segmented into filament, liquid/ink and powder.

· The application segment of the 3D printing plastic market is segmented into prototyping and manufacturing.

· The end-user segment of the 3D printing plastic market is divided into healthcare, aerospace and defense, automotive, electrical and electronics and other.

Get the sample copy of Report here https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-3d-printing-plastics-market

Global 3D Printing Plastic Market Country Level Analysis

3D printing plastic market is segmented of the basis of type, form, application and end-user.

The countries covered in the global 3D printing plastic market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Competitive Landscape and 3D Printing Plastic Market Share Analysis

The global 3D printing plastic market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to 3D printing plastic market. MAJOR TOC OF THE REPORT

Chapter One: 3D Printing Plastic Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three : 3D Printing Plastic Market Competition, by Players

Chapter Four: Global 3D Printing Plastic Market Size by Regions

Chapter Five: North 3D Printing Plastic Market by Countries

Chapter Six: Europe 3D Printing Plastic Market Revenue by Countries

Chapter Seven: Asia- 3D Printing Plastic Market Revenue by Countries

Chapter Eight: South America 3D Printing Plastic Market Revenue by Countries

Chapter Nine: Middle East and 3D Printing Plastic Market Revenue Equipment by Countries

Chapter Ten: Global 3D Printing Plastic Market Segment by Type

Chapter Eleven: Global 3D Printing Plastic Market Segment by Application

Get TOC Details: https://www.databridgemarketresearch.com/toc/?dbmr=global-3d-printing-plastics-market

major players operating in the global 3D printing plastic market report are 3D Systems, Inc, Arkema, Stratasys Ltd, EOS GmbH, CRP TECHNOLOGY S.r.l., Oxford Performance Materials, Materialise, BASF SE, Evonik Industries AG, Clariant, HP Development Company, L.P., DuPont de Nemours, Inc., VEXMA TECHNOLOGIES PVT LTD, PolyOne Corporation, 3Dnatives, Protofab, Jariwala Robotics Private Limited Eaton, Oizom Instruments Pvt. Ltd., Air-Met Scientific Pty Ltd., Ecotech, and Breeze Technologies among other.

Access Full Report https://www.databridgemarketresearch.com/reports/global-3d-printing-plastics-market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Reports@

Global Agricultural fogging machines market

Global agriculture grade zinc chemicals market

Global Agriculture Seeder Market

Global Aluminium Nickel Catalyst Market

0 notes

Text

[Kraton Performance Polymers, TSRC, LCY Chemical Corp, Eastman Chemical Company] Hydrogenated Styrene Block Copolymer (HSBC) Market Competitive Outlook| 2023-2033

Hydrogenated Styrene Block Copolymer (HSBC) Market Overview

Market.Biz recently updated a research report titled “Global Hydrogenated Styrene Block Copolymer (HSBC) Market by Type (Industrial Grade, Consumer Goods Grade), by Application (Wire and Cable Shoes Adhesives, Asphalt Modifiers Artificial leather)- Industry segment, competition scenario and forecast for 2032" evaluating various factors that affect its trajectory. The global industry report offers a comprehensive, accurate, and high-quality research study to equip players with valuable information for making strategic business decisions. Research analysts have provided in-depth segmental analysis of the industry on the basis of type, application, and geography.

Light is also shed on the vendor landscape to inform readers about future changes in business competition. As part of the competitive analysis, the report includes detailed company profiles of top players of the global Hydrogenated Styrene Block Copolymer (HSBC) market. Players can also use the value chain analysis and Porter's Five Forces Analysis given in the report to strengthen their position in the global industry.

Leading players of the global Hydrogenated Styrene Block Copolymer (HSBC) Market are analyzed taking into account their market share, recent developments, new product launches, partnerships, mergers or acquisitions, and markets served. We also provide a comprehensive analysis of their product portfolios to explore the products and applications they focus on when operating in the global marketplace. Furthermore, the report offers two separate industry forecasts – one for the production side and one for the consumption side of the global industry. It also provides useful recommendations for new and established players of the global market.

Hydrogenated Styrene Block Copolymer (HSBC) Market Competitive Outlook, Product Types And Applications

GuysApplicationscompaniesIndustrial Grade

Consumer Goods GradeWire and Cable Shoes

Asphalt Modifying Adhesives Artificial LeatherKraton Performance Polymers

TSRC

LCY Chemical Corp

Eastman Chemical Company

Report Buy Now To Get The Best Discount: https://market.biz/checkout/?reportId=587419&type=Single%20User

All segments studied in the research study are analyzed on the basis of market share, revenue, and other important factors. Our research study shows how different segments are contributing to the growth of the global Hydrogenated Styrene Block Copolymer (HSBC) market. It also provides information on key trends related to the segments included in the report. This helps business players to focus on high-growth areas of the global market. The research study also offers a separate analysis of the segments based on absolute dollar opportunity.

The report authors have analyzed the developed and developing regions considered for research and analysis of the global Hydrogenated Styrene Block Copolymer (HSBC) market. The regional analysis section of the report provides extensive research study on different global regional and country markets to help players plan effective expansion strategies. In addition, it offers highly accurate estimates of CAGR, market share, and market size for key regions and countries. Players can use this study to explore untapped global Hydrogenated Styrene Block Copolymer (HSBC) markets to broaden their reach and create sales opportunities.

What to Expect From Our Report?

(1) An entire section of the global Hydrogenated Styrene Block Copolymer (HSBC) business report is dedicated to market dynamics, including influencers, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the global Hydrogenated Styrene Block Copolymer (HSBC) Industry, where significant regions and countries are evaluated for their growth potential, consumption, industry share and other vital factors that indicate the growth of your market.

(3) Players can use the competitive analysis provided in the report to create new strategies or adjust existing ones to overcome market challenges and increase their share in the global Hydrogenated Styrene Block Copolymer (HSBC) industry.

(4) The report also analyzes the competitive situations and trends, and sheds light on the expansions and mergers and acquisitions of companies taking place in the global Hydrogenated Styrene Block Copolymer (HSBC) market. Furthermore, it brings to light the industry concentration rate and the market shares of the top three and top five players.

(5) Readers are provided with the results and conclusion of the research study provided in the global Hydrogenated Styrene Block Copolymer (HSBC) Market report.

Inquire Here If You Have Any Inquiry@ https://market.biz/report/global-hydrogenated-styrenic-block-copolymer-hsbc-market-gm/#inquiry

0 notes

Text

Styrene-Butadiene-Styrene (SBS) Copolymer Block Market: Enhancing Electronics and Electrical Equipment

The Styrene-Butadiene-Styrene (SBS) copolymer block market has experienced significant growth and transformation over the years. This versatile material, known for its excellent properties such as elasticity, durability, and resistance to environmental factors, plays a crucial role in various industries. From adhesives and sealants to asphalt modification and footwear, SBS copolymers have established themselves as a cornerstone of modern manufacturing and construction. In this comprehensive analysis, we will explore the current state of the SBS copolymer market, recent innovations, emerging trends, and the future outlook for this remarkable material.

The SBS Copolymer Block: A Brief Overview

SBS copolymer blocks market are a type of thermoplastic elastomer, which means they exhibit both rubber-like elasticity and plastic-like processability. They are synthesized through the copolymerization of three monomers: styrene, butadiene, and styrene. The unique arrangement of these blocks within the polymer chain results in their distinct properties.

One of the key strengths of SBS copolymer blocks is their ability to undergo repeated deformation and return to their original shape. This property, known as "shape memory," makes SBS copolymers an ideal choice for products that require flexibility, resilience, and the ability to withstand mechanical stresses. It's no wonder they find applications in numerous industries.

Current Market Dynamics

The SBS copolymer market has witnessed steady growth over the past few years. This growth can be attributed to several factors, including the rising demand for lightweight, durable materials in automotive and construction industries, as well as the increasing popularity of sustainable and eco-friendly products.

Automotive Industry: SBS copolymers are widely used in the automotive sector for applications such as bumpers, door trims, and weatherstripping. As the automotive industry continues to focus on reducing vehicle weight and improving fuel efficiency, SBS copolymers have gained prominence due to their lightweight yet sturdy nature.

Construction Industry: In the construction sector, SBS copolymers are often used to modify asphalt and improve the performance of roads and roofing materials. They enhance durability and resistance to temperature fluctuations, thus prolonging the lifespan of the structures.

Footwear: SBS copolymers are an essential component in the manufacturing of sports shoes, sneakers, and other footwear. Their flexibility and cushioning properties make them ideal for comfortable and long-lasting shoe soles.

Adhesives and Sealants: SBS copolymers find application in the formulation of adhesives and sealants, where their ability to provide strong bonds and resistance to environmental factors is highly valued.

Recent Innovations in SBS Copolymer Applications

Innovations in SBS copolymer applications have expanded the market's reach and introduced new possibilities for various industries. Some of the notable innovations include:

Sustainable Alternatives: With the growing emphasis on sustainability, manufacturers have been exploring the development of bio-based SBS copolymers. These eco-friendly alternatives reduce the environmental impact of SBS production.

3D Printing: SBS copolymers are increasingly being used in 3D printing due to their excellent mechanical properties. This has opened up opportunities for rapid prototyping and customized product manufacturing.

Medical Devices: SBS copolymers are being employed in the production of medical devices and components, thanks to their biocompatibility and flexibility.

Emerging Trends in the SBS Copolymer Market

Several trends are shaping the SBS copolymer market trend and are likely to influence its trajectory in the coming years:

Smart Infrastructure: The integration of SBS-modified materials in infrastructure projects is expected to rise. These materials can enhance the durability and longevity of roads, bridges, and other structures.

Circular Economy: The adoption of circular economy principles is gaining momentum. SBS copolymers can be recycled and repurposed, aligning well with this sustainability trend.

Customized Formulations: Manufacturers are increasingly offering tailored SBS copolymer formulations to meet the specific needs of various industries, further expanding the market's scope.

Future Outlook

The future of the SBS copolymer block market appears promising, with continued growth on the horizon. As industries demand more versatile and eco-friendly materials, SBS copolymers are well-positioned to meet these requirements. The market is expected to witness innovation in terms of product formulations, applications, and manufacturing processes.

The automotive and construction sectors are likely to remain major consumers of SBS copolymers, driven by the need for lightweight and durable materials. Additionally, the emergence of advanced technologies, such as 3D printing, may further boost demand in other industries.

As sustainability and circular economy principles continue to gain traction, the market will also witness a shift toward more environmentally friendly practices and materials. Bio-based SBS copolymers and increased recycling efforts will contribute to this transformation.

In conclusion, the Styrene-Butadiene-Styrene (SBS) copolymer block market has shown remarkable resilience and adaptability, positioning itself as a cornerstone of various industries. With continuous innovation and the growing focus on sustainability, the future of this market is bright, offering new possibilities and applications in the ever-evolving world of materials science.

#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Share#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Growth#Styrene-Butadiene-Styrene (SBS) Copolymer Block Market Demand

0 notes

Text

Asia-Pacific Synthetic Rubber Market Share, Forecast 2023-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Asia-Pacific synthetic rubber market size at USD 9.2 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects Asia-Pacific synthetic rubber market size to grow at a CAGR of 3.9% reaching a value of USD 12 billion by 2029. Major factors for the expansion of Asia-Pacific synthetic rubber market include increasing use of synthetic rubber in a variety of applications, increasing penetration of EVs, surging demand from automotive industries, and growing production and demand for consumer and industrial goods. Likewise, the market's rise will be driven by an increase in sports activities such as motor racing competitions and detailed research into tire durability and demand. The growing middle class and rising industrialization have boosted the footwear industry, which will fuel the expansion of Asia-Pacific synthetic rubber market during the period in analysis. Asia-Pacific synthetic rubber market will expand rapidly due to increased production of various grades of non-automotive products and tires. Also, China, India, Thailand, Indonesia, Malaysia, and Vietnam are among the world's major producers of natural and synthetic rubber. Furthermore, the region serves a substantial application of synthetic rubber, such as tires. According to the International Organization of Motor Vehicle Manufacturers, more than 50 million automobiles were manufactured in Asia Pacific. India and China have the world's largest two-wheeler industries. The region is a hub for the manufacturing of consumer electronics which creates considerable demand for synthetic rubber in the region. However, environmental regulations and health hazards in manufacturing synthetic rubber are anticipated to restrain the growth of Asia-Pacific synthetic rubber market during the period in analysis.

Asia-Pacific Synthetic Rubber Market – Overview

Synthetic rubber, like other polymers, is manufactured from several petroleum-based monomers. The most common synthetic rubber is styrene-butadiene rubber (SBR), which is generated from the copolymerization of styrene and 1,3-butadiene. The automobile industry is the primary market driver, as it uses synthetic rubber in both tire and non-tire applications. The product's high score is due to its resilience, hardness, and elasticity, which make it a key component in the production of tires for the automobile industry. Bicycles, vehicles, and aircraft account for more than half of all rubber use.

Sample Request @ https://www.blueweaveconsulting.com/report/asia-pacific-synthetic-rubber-market/report-sample

Asia-Pacific Synthetic Rubber Market – Challenge

Volatile raw material prices

The fluctuation of raw material prices is one of the most serious issues confronting synthetic rubber companies. Because of the high competition in the synthetic rubber business, prices may fluctuate dramatically even when conditions stay consistent. The cost and availability of raw materials are critical factors in establishing the pricing structure of synthetic rubber manufacturers. Because crude oil is used to manufacture synthetic rubber, every increase in crude oil prices raises manufacturing costs and reduces profit margins for synthetic rubber makers.

Impact of COVID-19 on Asia-Pacific Synthetic Rubber Market

COVID-19 had a detrimental impact on synthetic rubber market in terms of both volume and value due to the imposition of severe movement restrictions and lockdowns. As a result, supply chains and production units were severely disrupted. Thus, decreased production in the automotive and other industries due to a lack of raw materials, mostly latex, as a result of delayed trade operations has had a detrimental influence on the synthetic rubber market. However, due to stringent standards being followed during the transfer of raw materials in the synthetic rubber industry, the reopening of country borders is assisting in the resolution of transport and logistic concerns. Manufacturers are increasing their reliance on domestic production in order to reduce their reliance on raw materials from other countries. Multinational corporations have begun to re-evaluate their supply chains and are in the process of reorganizing their supply chains to lessen concentration in a few nations. To keep the economy operating in the face of the ongoing epidemic, market participants are focused on major revenue-generating end uses such as tires, adhesives, and consumer goods.

Asia-Pacific Synthetic Rubber Market – By Application

Based on application, Asia-Pacific synthetic rubber market is segmented into Tire, Non-Tire Automotive, Industrial Goods, and Footwear. The tire automotive segment held the highest market share in 2022. One element that would promote market expansion is the growth of the automobile sector, together with advancements in tire technology. The non-tire automotive industry is the market's second-largest segment. Rubber usage can be found in automobile mats as well as wire and cables in this area. Conveyor belts, industrial mats, gloves, and wires and cables are examples of industrial rubber goods. Rising product demand in these applications will fuel market expansion.

Competitive Landscape

Major players operating in Asia-Pacific synthetic rubber market include Ube Industries, Ltd., Asahi Kasei Corp., Bridgestone Corp., Indian Synthetic Rubber Pvt. Ltd., JSR Corp., LG Chem, Ltd., Reliance Industries Ltd., SABIC, Sumitomo Chemical Co., Ltd., The Goodyear Tire & Rubber Co., Trinseo, and Pirelli & C. S.p.A. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Research Blog

Phone No: +1 866 658 6826

Email: [email protected]

0 notes