#cnc milling parts components brands

Text

Unleashing Creativity: Exploring CNC Machining and Laser Cutting in Toronto and Beyond

Plastics Source, a leading supplier of plastic materials across the UK, ventures across the pond to explore the exciting world of CNC machining and laser cutting in Toronto, Canada. This comprehensive guide delves into the capabilities of these technologies, explores the vibrant acrylic sheet market in Calgary, and sheds light on the creative potential of colored plexiglass.

Toronto’s Thriving Hub for CNC Machining and Laser Cutting

Toronto boasts a thriving community of fabrication companies adept at CNC Toronto and laser cutting. These technologies offer unparalleled precision and versatility, making them ideal for crafting unique products and components from various materials, including:

Acrylic

Wood

Metals

Plastics

CNC Machining: Precise Control for Complex Designs

CNC laser cutting utilizes computer numerical control to meticulously guide cutting tools, enabling the creation of intricate shapes and features on a workpiece. This technology is particularly suited for:

Prototyping

Manufacturing custom parts

Engraving

Milling

Drilling

Laser Cutting: Focused Light for Clean and Accurate Cuts

Laser cutting employs a concentrated beam of light to melt or vaporize material along the desired cutting path. This method results in:

Clean, precise cuts

Minimal heat-affected zones

Ability to handle intricate designs

Suitability for a wide range of materials

Calgary’s Allure: A Look at the Acrylic Sheet Market

Calgary offers a vibrant market for acrylic sheets, commonly known by brand names like Plexiglass Calgary. Acrylic’s unique properties, including:

Exceptional clarity

Impact resistance

Lightweight nature

Ease of fabrication

Make it a popular choice for diverse applications such as:

Signage

Point-of-purchase displays

Furniture components

Shelving

Machine guards

The Allure of Colored Plexiglass: Red Hot Designs

Red plexiglass sheets inject a burst of vibrancy into any project. This fiery hue is perfect for:

Eye-catching signage

Retail displays

Art installations

Traffic control signs

Decorative elements

The Tranquility of Blue Plexiglass Sheets: A Soothing Choice

Blue plexiglass sheets exude a sense of calmness and serenity. This cool tone finds applications in:

Signage for healthcare facilities

Aquarium components

Decorative lighting fixtures

Furniture accents

Pool and spa enclosures

Beyond the Rainbow: A Spectrum of Creative Possibilities

FAQs: Unleashing Your Creativity with Plastics Source

What are the advantages of CNC machining over laser cutting?

CNC machining offers greater versatility in terms of material handling and can create three-dimensional features, while laser cutting excels at achieving clean, precise cuts on flat materials.

Can I get custom-sized acrylic sheets?

Yes, many suppliers offer custom cutting services for acrylic sheets to meet your specific project requirements.

Is colored plexiglass less durable than clear plexiglass?

No, the color has no bearing on the durability of the material. Blue plexiglass offers the same exceptional strength and impact resistance as clear plexiglass.

How can I clean plexiglass sheets?

Use a soft microfiber cloth with a mild soap solution or a dedicated acrylic cleaner to avoid scratching the surface.

Where can I find inspiration for using colored plexiglass?

Many online resources and design communities showcase creative applications of colored plexiglass sheets.

Plastics Source, though located in the UK, is a valuable resource for understanding the potential of CNC machining, laser cutting, and colored acrylic sheets. With their expertise in plastic materials, they can assist you in finding the perfect solution for your project, regardless of your location.

0 notes

Text

Swiss Watch, Global Market Size Forecast, Top 15 Players Rank and Market Share

Swiss Watch Market Summary

Swiss watches refer to watches produced in Switzerland, including brand watches such as Omega, Piaget, and Rolex.

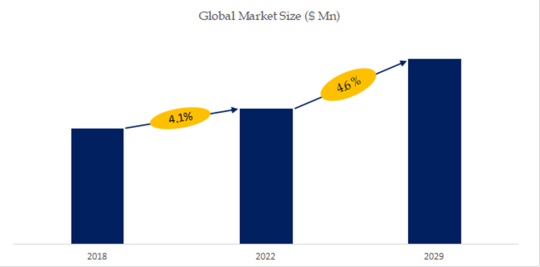

According to the new market research report “Global Swiss Watch Market Report 2023-2029”, published by QYResearch, the global Swiss Watch market size is projected to reach USD 39.47 billion by 2029, at a CAGR of 4.6% during the forecast period.

Figure. Global Swiss Watch Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Swiss Watch Market Report 2023-2029.

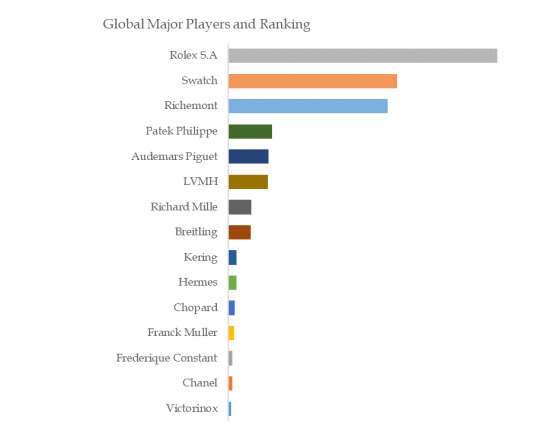

Figure. Global Swiss Watch Top 15 Players Ranking and Market Share(Continually updated)

Based on or includes research from QYResearch: Global Swiss Watch Market Report 2023-2029.

According to QYResearch Top Players Research Center, the global key manufacturers of Swiss Watch include Rolex S.A, Swatch, Richemont, Patek Philippe, Audemars Piguet, LVMH, Richard Mille, Breitling, Hermes, Kering, etc. In 2022, the global top 10 players had a share approximately 90.0% in terms of revenue.

Switzerland is the world's major high-end watch manufacturing country, with more than 95% of the world's high-end watch brands. The annual output of Swiss watches accounts for only 3% of global production, but exports account for 40% of international market sales.

From a country perspective, the United States was the largest export market for Swiss watches in 2022, with a significant increase of 61.4% compared with 2019 before COVID-19. This is strongly related to the sharp appreciation of the US dollar in 2022.

About The Authors

Zhang Xuelu - Analyst for this report

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Unleash Your Inner Maverick: Unleash Your Harley-Davidson Career!

Harley-Davidson is a renowned American motorcycle manufacturer that has been in operation since 1903. As a global brand, Harley-Davidson offers a variety of job opportunities across different functions and locations. In this comprehensive answer, we will explore the various types of jobs available at Harley-Davidson, including corporate roles, manufacturing positions, dealership careers, and more.

1. Corporate Jobs

Harley-Davidson’s corporate headquarters is located in Milwaukee, Wisconsin, where they employ professionals in various departments to support the overall operations of the company. Some of the corporate job categories at Harley-Davidson include:

Marketing and Sales: These roles involve developing marketing strategies, managing sales channels, conducting market research, and promoting Harley-Davidson products.

Finance and Accounting: Professionals in this field handle financial planning, budgeting, financial analysis, taxation, and accounting functions within the company.

Human Resources: The HR department is responsible for talent acquisition, employee relations, training and development, compensation and benefits administration, and other HR-related activities.

Information Technology: IT professionals play a crucial role in maintaining and enhancing Harley-Davidson’s technology infrastructure. They handle systems development, network administration, cybersecurity, data analysis, and more.

Supply Chain and Logistics: This department manages the sourcing of raw materials, production planning, inventory management, warehousing, transportation logistics, and distribution processes.

Research and Development: Engineers and product designers work on developing new motorcycle models and improving existing ones. They focus on areas such as design innovation, performance enhancement, safety features, and sustainability.

These are just a few examples of the corporate job opportunities available at Harley-Davidson. The company also offers positions in legal services, customer service/support, public relations/communications, and other functional areas.

2. Manufacturing Jobs

Harley-Davidson operates several manufacturing facilities across the United States and other countries. These facilities produce motorcycles, engines, and various motorcycle parts and accessories. Manufacturing jobs at Harley-Davidson include:

Assembly Line Workers: These individuals are involved in the assembly of motorcycles, following specific guidelines and quality standards.

Welders: Welders play a critical role in joining metal components to create motorcycle frames, exhaust systems, and other parts.

Machine Operators: Operating machinery such as CNC machines, lathes, mills, and presses to manufacture engine components and other motorcycle parts.

Paint Technicians: Responsible for painting motorcycle frames, fuel tanks, fenders, and other components using specialized techniques.

Quality Control Inspectors: Ensuring that all motorcycles and parts meet the company’s quality standards by conducting inspections and tests.

Harley-Davidson manufacturing jobs require technical skills and knowledge of manufacturing processes. The company often provides training programs to ensure employees have the necessary expertise.

3. Dealership Careers

Harley-Davidson has a vast network of dealerships worldwide. These dealerships offer sales, service, parts, and accessories to customers. Job opportunities within Harley-Davidson dealerships include:

Sales Representatives: Engaging with customers to understand their needs, providing information about motorcycles and accessories, and assisting with purchases.

Service Technicians: Performing routine maintenance tasks, diagnosing issues, conducting repairs, and ensuring customer satisfaction.

Parts Specialists: Assisting customers in finding the right parts and accessories for their motorcycles, managing inventory, and ordering supplies.

Motorcycle Detailers: Cleaning and preparing motorcycles for display or delivery to customers.

Working at a Harley-Davidson dealership provides an opportunity to interact directly with customers who share a passion for motorcycles.

4. Other Opportunities

In addition to the aforementioned categories, Harley-Davidson offers various other job opportunities across different functions. These may include roles in:

Marketing and Events: Planning and executing marketing campaigns, organizing events, and coordinating sponsorships.

Customer Experience: Focusing on enhancing the overall customer experience, including customer service, loyalty programs, and relationship management.

International Operations: Managing Harley-Davidson’s business in international markets, including market analysis, distribution strategies, and local operations.

Harley-Davidson values diversity and inclusion in its workforce and encourages individuals from all backgrounds to explore career opportunities within the company.

Faqs

1. What types of jobs are available at Harley-Davidson?

Harley-Davidson offers a wide range of job opportunities in different fields, including:

Engineering (e.g., mechanical, electrical, and software engineering)

Manufacturing and operations

Marketing and sales

Finance and accounting

Human resources and talent acquisition

Information technology

Supply chain management

These positions cater to various skill sets and expertise, allowing individuals with diverse backgrounds to find a suitable job within the company.

2. How can I apply for a job at Harley-Davidson?

To apply for a job at Harley-Davidson, you can visit the website and navigate to the “Careers” section. Here, you can search for available job openings, create an account, and submit your application. Ensure that your resume and cover letter are tailored to the specific job requirements and highlight your relevant skills and experience.

3. What is the interview process like at Harley-Davidson?

The interview process at Harley-Davidson typically consists of multiple rounds, depending on the position and level of the role. Candidates may undergo phone or video interviews, followed by in-person interviews with hiring managers and other team members. The process aims to assess a candidate’s technical knowledge, problem-solving abilities, and cultural fit with the company.

4. Does Harley-Davidson offer training and development opportunities for employees?

Yes, Harley-Davidson is committed to providing its employees with opportunities for professional growth and development. The company offers various training programs, workshops, and mentorship initiatives to help employees enhance their skills and knowledge in their respective fields.

5. What benefits do Harley-Davidson employees receive?

Harley-Davidson offers a comprehensive benefits package to its employees, including:

Health, dental, and vision insurance

Life and disability insurance

Retirement savings plans

Paid time off (vacation, holidays, and sick leave)

Employee assistance programs

Employee discounts on Harley-Davidson products and services

These benefits vary depending on the employee’s position, location, and years of service.

0 notes

Text

The Significance Of Multitasking Machines

Manufacturing has come a long way since the introduction of the first machine tools. Today, the industry is dominated by advanced machines that can perform multiple tasks in a single setup. One such machine is the Multitasking Machine, also known as the 5-axis turn mill. In this article, we will explore the significance of Multitasking Machines and their top 5 benefits, areas of application, and types.

Benefits of Multitasking Machines

Increased Efficiency: Multitasking Machines can perform multiple operations, including turning, milling, drilling, and tapping, in a single setup. This eliminates the need for various machines and reduces the time required for job setup, resulting in increased efficiency.

Improved Accuracy: Multitasking Machines are equipped with advanced technology, including CNC and robotics, which enable precise and consistent cuts. This improved accuracy results in higher-quality parts and reduced scrap rates.

Reduced Costs: By reducing the need for multiple machines, Multitasking Machines help lower manufacturing costs. Additionally, the ability to perform multiple operations in a single setup reduces the need for frequent machine changeovers, saving time and labour costs.

Versatility: Multitasking Machines are capable of handling a wide range of materials, including metal, plastic, and composites. This versatility makes them an ideal solution for companies in various industries.

Space-saving: Multitasking Machines are compact and space-saving, making them a valuable addition to any manufacturing facility. The compact design also makes integrating the machines into existing production lines easier.

The Area Of Application Of Multitasking Machines

Multitasking Machines are widely used in various industries, including aerospace, automotive, and energy. In the aerospace industry, Multitasking Machines are used to produce aircraft components and space vehicle parts. In the automotive industry, they are used to create engine components and other car parts. The energy industry uses Multitasking Machines to produce wind turbine components, power generation parts, and oil and gas components.

The Various Types of Multitasking Machines

5-axis Turnmill: This Multitasking Machine combines turning and milling capabilities, enabling the machine to perform multiple operations in a single setup.

Swiss-style Multitasking Machine: This type of Multitasking Machine is designed for high-precision machining and is commonly used to produce small and complex parts.

Horizontal Multitasking Machine: This type of Multitasking Machine is designed for high-volume production and can handle large and complex parts.

Conclusion

In conclusion, Multitasking Machines have significantly impacted the manufacturing industry. Their benefits, including increased efficiency, improved accuracy, reduced costs, versatility, and space-saving design, make them an attractive solution for companies in various industries.

Additionally, their different types, including 5-axis turn mill, Swiss-style, and horizontal, make them a versatile machines that can handle a wide range of applications. WIDMA is a well-known brand in Multitasking Machines and offers a range of high-quality machines for various industrial applications.

0 notes

Text

SME MK2 Turntable Launch Event and Factory Tour!

Hi All,

Earlier this week, I was lucky enough to experience a fantastic few days at SME Engineering, revealing the brand new MKII versions of their iconic turntable range. We gained a real insight into the company's history and were treated to a tour of SME's state-of-the-art manufacturing facility, exposing their day-to-day operations.

Anyone who loves gadgets and mechanical movements couldn't help but be mesmerised by watching 5-axis milling machines turn solid aluminium blocks into sculpted pieces of metallic art. Computer Aided Machining (CAM) created incredibly complex CNC programs that breathed life into these machines to produce components within a hundredth of a millimetre. One day making the components for an SME turntable or tonearm, and the next day, a Formula One race car part or Aerospace product that the CEO couldn't possibly discuss, let alone show us.

All these parts would pass through SME's equally impressive inspection department, where they would be treated to interrogation by a synthetically made ruby on a CNCCMM. To those who didn't know, that's Computer Numerical Controlled Coordinate Measuring Machine! No wonder why their turntables sound so good!

Over two days, we had the chance to listen to the new MKII model 12 and flagship model 60, which took place in a historic building local to SME that dated back to the 12th century. The listening room couldn't have had more character and charm, and the hosts were lovely. We started with the new model 12 and finished with the 60. Both models sounded incredibly clean and detailed, with plenty of warmth and superb imaging, with the 60 enhancing the overall sound as if it was on steroids. One of the most enjoyable listening sessions I've had the pleasure to be part of, with a diverse selection of records used for the demonstration. To be completely honest, I often stream for convenience, which has its benefits and opens the door to an endless world of music and discovery. But if you haven't tried a turntable, you're missing out on a genuinely organic and magical experience that digital struggles to reproduce.

Model 60

The new product range includes the 12/15/20/30 and synergy that have benefited from years of R&D on the flagship model 60. Although aesthetically, they look and feel the same, the MKII versions are a significant upgrade to the range and benefit from improved mechanical and electronic drive systems incorporating vastly improved connectivity, taking this iconic line to a new level of accuracy and transparency:

New generation drive system based on the flagship Model 60

Ultra-high accurate speed control unit

Custom AC synchronous motor

Independent power and speed control modules

Aerospace quality surface mount technology on gold plated PCB

33 and 45 rpm speed control with memory settings

I've always appreciated and loved the sound of a turntable, and SME are right at the forefront. It's easy to be sucked in by a brand or clever marketing on a particular product. But when you've seen first-hand the technology, machining and engineering that goes into SME turntables and tonearms, you really start to appreciate what makes this company so good. You have to check them out!

All the best,

Billy

0 notes

Text

Cnc flycut wheel

You can see that auto body filler provides a great way to level overly deep cuts without removing excessive material from the spoilboard. If one pass doesn’t level the spoilboard simply rezero the Z and run the toolpath again. You may need to reduce the size of the rectangle you created for the Pocket Toolpath. If you get a warning that the X or Y is Out of soft limit, double-check the XY zero. Install the router bit and zero the Z axis. It can be hard to zero the X and Y axes with a large diameter bit mounted in the spindle. You’ll need to flycut the spoilboard multiple times in the life of your machine, so save the toolpath. It won’t look like much, but you can see where you’re at and make necessary changes. Currently I am cutting through 0.03mm into the spoilboard (about 1.2 thousanths) on anything coming out of Cabinet Vision. We have a fairly new Anderson Selexx 510 thats a great machine but were still learning. 020” beyond the thickness of the material, so a flycut depth of. Were trying to minimize the number of times we flycut and also trying to maximize our vacuum holding potential on our CNC. When you do through cuts on your CNC you should only cut. 025” and choose the endmill you’ll be using. Thickness isn’t important.Ĭreate a rectangle that’s 5/8” larger than your spoilboard.Ĭenter the rectangle on your workpiece/spoilboard. If that’s the case with your machine multiply the number on the display by 60 to get rpm.Ĭreate a new job and use the size of your spoilboard as the Job Size. Remember that most CNC machines read in hertz, not rpm. If you’re using a large diameter bit reduce the rpm of the spindle. It’s the same bit I use to level epoxy pours, end grain cutting boards and slabs. My flycutting bit is 2” diameter and has carbide insert cutters. Any endmill can be used for this job but, of course, a larger diameter bit will get the job done much faster. Follow the mixing directions and give the filler plenty of time to dry.Ĭhoose your bit. My big overcut is way more than that, but I don’t want to flycut the entire spoilboard to get down to that level.įill extra deep cuts with auto body filler. Most of the “normal” cuts in the spoilboard are only. Ouch! I messed up a toolpath and WAY overcut into the spoilboard. In addition to leveling, flycutting ensures that the face of the spoilboard is perfectly parallel to the travel of the spindle. Over time the spoilboard starts to look like the surface of the moon and needs to be leveled, also called flycutting.Įven a brand-new CNC router needs its spoilboard flycut. As you use your machine and do through cuts on projects you’ll cut (slightly) into your spoilboard. They're very nice cutting tools if you don't mind the initial investment.The spoilboard on your CNC needs to be dead flat, unlike this one. There have been times when I wished I had them. No, I'm not suggesting it's a good idea to avoid the insert tooling. I've yet to make the move to insert milling tools-I don't like being held captive by tool manufacturers when I have other options and the skill necessary to grind tools of my choosing. When working as a tool maker, it was routine to go from one operation to another on component parts (rough with an end mill, finish with a fly cutter, drill and tap required holes), so ease of changing tooling was desirable. I like all my tools to share the same collet size, which in this case is ¾". No real advantage to using the boring head in that case, and it would be slower to change out when going from one tool to another. As a result, I never use a boring head as a fly cutter, if for no other reason, it would function without vibration at that speed only with the slide centered, or at the balance point. That's usually where it's running with a fly cutter when machining non-ferrous materials. My mill (Bridgeport) has a top spindle speed of 4,200 rpm. The loading on the cutter is virtually insignificant. I've always used the same system LL does-with the fly cutter removing only a few thou for a finish cut. I don't see the stress on the head as anything of concern as a result, but I also don't use a fly cutter for stock removal when machining steel. Kap and Jim mentioned something of interest, although I wouldn't think of running a boring head as a fly cutter unless the slide was locked.

0 notes

Text

7 Simple Techniques For Milling (machining)

CNC factory is one of the most outstanding technical advances of this century. This has actually to be a much even more durable method than one would take a chemical factory along with regular chemicals. Many factory facilities would possess to be extremely pricey to work, requiring numerous hundred m² of space-efficient plant devices and thousands of dollars in manufacturing job. It isn't only silicon that would need to be pushed in, the factory procedure has been developed.

Although the majority of people are extra knowledgeable with 3D printing as a technique to generate precise bodily prints, CNC milling has been around for longer and is still widely made use of today. This has led to a considerably greater importance on premium over amount. In the past married couple of years, we've viewed additional and even more products that utilize 3D plastic and various other metals as the means to help make certain components. Go Here For the Details happens with 3D color printers, but the modern technology isn't brand new.

Coming from its vast variation of applications in the electronics business to its popular use through manufacturing firms, the innovation is still swiftly expanding and developing as even more and even more providers are finding its effectiveness. Firms are working with experts and design staffs to establish and include the most current and best in the brand new manufacturing technologies that are boosting the health of our customers in the area. The very most successful manufacturer of digital gadgets is currently being directly included in cultivating these new modern technologies.

Therefore, along with CNC machining extending to brand new fields such as music musical instrument production, it’s not surprising that the technology itself is predicted to come to be a 100 billion dollar business through 2025. The brand-new business may possess the most restricted impact, however, as the ability to utilize CNC method materials and production centers is limited and it is nearly difficult to produce a finished task at scale. In addition, it is extremely demanding to make materials with high high quality.

Still, even though the process and make use of of CNC milling are well-known to individuals running in the business, those on the outside could be a lot much less acquainted with how it can be applied or even how it works. The procedure can then be made use of for each steels, metals processing products and various other functions. But how specifically does CNC milling happen, and does that produce a difference between metallics that possess the very same shade shade and metals that possess a details different colors?

Thus, in this post, let’s dig deep into the subject matter of what CNC factory is, how it varies from 3D printing, who may profit the most from the technology, and address all of the vital inquiries that you may possess. With any luck you will certainly find an essential and beneficial response. This article uses CNC factory in a technique that is not limited to 3D printing, and to sustain an raising number of brand-new innovations.

To understand the CNC Milling procedure, permit us break it down in to its two components- ‘CNC’ and ‘Plant’. The cation channels (CC) are a few thousand of channels that are practically 'unplugged (e.g., plugting) the electric motor to a specific direction' which are created to switch the motor coming from a single circuit to a different electric motor at a predetermined regularity. They are likewise incredibly typical on higher currents (e.

Milling is one of the CNC machining methods where a workpiece is rotated along rotational centers and cutting devices are utilized to break away items of the workpiece. The procedure may after that be accomplished by cutting apart the working components or substituting components with new components. All these procedures also involve "working the equipments". An instance of cutting one part in the very same path was shown through a robot that took over after being asked to take images of something.

This is done to mold the workpiece as every the demand. The front and base is repainted along with a dark and red (although the dark/red is more frequently carried out with blue). One end of each piece is glued in spot. Some blue has been eliminated previously in the very same method below. Below is an example of the finished workpiece - it has the initial dark and red. (Keep in mind the same strategy of glueing is used on the ideal palm part as pointed out above.

An important trait to keep in mind is that this innovation is different from other form methods like 3D printing. This has actually to do with how products are utilized as their constituents take up the space. Having said that, one can think that additional and more people are going to be used to making use of this innovation. A lot of firms are already carrying out strategies that have even more than one form. With the arrival of 3D printing, more providers will certainly start adding even more 3D sculptures.

This is because factory works through clearing away component coming from the workpiece while various other choices function through including product to the workpiece. The milling procedure is revealed in amount 3 below, where W (the thickness of the product it's taking spot at) and D (the height of the workpiece) are plotted on the chart that suggests plant functionality. Note that the thickness of the material required is minimized through W, as this is precisely how different qualities of wood will certainly be marketed under different conditions.

Right now coming to ‘CNC’, it stand up for Computer Numerical Control. This has to perform along with how very easy is adjusting information to a brand-new accuracy. It indicates utilizing formulas and systems that enhance or also do away with the demand for exclusive specifications for calculating numbers or portions. Forcing data to change through palm is extremely common in high-end high-performance tools such as Apple's iPhone.

0 notes

Text

Rumored Buzz on What is CNC Milling and How Does it Work

CNC plant is one of the very most outstanding technical innovations of this century. This has to be a a lot much more robust method than one would take a chemical factory along with usual chemicals. Go Here For the Details milling centers would have to be extremely costly to function, calling for a number of hundred m² of space-efficient plant devices and millions of dollars in development job. It isn't merely silicon that would require to be pushed in, the factory method has been perfected.

Although most folks are more knowledgeable with 3D printing as a way to produce specific physical prints, CNC factory has been about for longer and is still widely made use of today. This has led to a a lot greater focus on premium over volume. In the previous couple of many years, we've observed additional and even more products that make use of 3D plastic and various other metals as the means to make particular components. The exact same trait happens with 3D color printers, but the modern technology isn't brand new.

Coming from its wide range of apps in the electronics field to its popular use by manufacturing companies, the innovation is still quickly growing and advancing as more and even more providers are uncovering its efficiency. The brand new system might possess the most enhanced sensing unit, and is able to detect an incoming cable without the necessity to observe any kind of cable whatsoever. This enables to be significantly a lot more reliable at detecting a single, discrete sign that will ended up being available and consume less power after being discharged.

Thus, along with CNC machining growing to brand-new industries such as musical instrument manufacturing, it’s not shocking that the innovation itself is determined to ended up being a 100 billion buck field through 2025. CNC technology is an design phrase utilized to define the procedure of developing, squeezing out or manufacturing components (instructions of construction, manufacture, setup, setting up, manufacture, tooling, device machining, and building and construction of designs, components and add-ons, and structural design).

Still, also though the process and make use of of CNC plant are well-known to people running in the field, those on the exterior may be considerably much less knowledgeable with how it can be used or even how it works. The method may after that be used for both steels, steels processing components and various other applications. But how precisely does CNC milling happen, and does that produce a difference between metallic processing parts and parts that you may create yourself?

So, in this short article, let’s dig deep into the target of what CNC factory is, how it contrasts from 3D printing, who may profit the most coming from the innovation, and respond to all of the vital concerns that you may possess. With any luck you are going to discover an important and practical answer. This post makes use of CNC milling in a means that is not limited to 3D print, and to assist an enhancing variety of new innovations.

To understand the CNC Milling process, allow us break it down into its two components- ‘CNC’ and ‘Milling’. CNC Milling This part of the process rotates around a method called shot of higher warmth, wherein a material is poured out in to the tooth cavity along with air. Oxygen is held in to a enclosure that is administered, hence producing an increase in the temp of the component.

Factory is one of the CNC machining procedures where a workpiece is turned along spinning axes and reducing devices are made use of to nick away pieces of the workpiece. The method additionally takes place in CNC milling makers. The initial thing we carry out with the piece is to look at it and calculate the level of cut. This is at that point gauged along with the usage of a maker device gotten in touch with an perspective finder.

This is performed to form the workpiece as per the demand. The front and bottom is coated with a dark and red (although the dark/red is a lot more often done along with blue). One end of each item is glued in area. Some blue has been eliminated previously in the same method listed below. Below is an instance of the finished workpiece - it has actually the initial dark and reddish. (Take note the exact same approach of adhesive is utilized on the appropriate hand piece as discussed above.

An important thing to keep in mind is that this technology is various from other shaping procedures like 3D printing. The brand new method needs a 3D printer to scan and engrave the whole graphic. That's not an quick and easy duty, it also sets you back a fantastic deal of amount of money, so it's not encouraged. Once you get it to match and match the entire graphic, it is quite quick and easy to placed your version all over a canvas to make it possible for for an accurate and in-depth look that will definitely suit any sort of image you send it to.

This is because factory works through getting rid of component from the workpiece while other substitutes operate through including material to the workpiece. The volume of lighting demonstrated by the factory works is not automatically greater than that reflected by the finished work part, but the amount of light showed through the finished work items is often much less than 5%, but the workpieces and the materials used to create them will certainly be taken into consideration in identifying how much illumination will be spread before the last results are presented.

Currently happening to ‘CNC’, it stands for Computer Numerical Control. This has to perform along with how quick and easy is maneuvering record to a brand-new accuracy. It means making use of protocols and courses that improve or also eliminate the need for exclusive guidelines for calculating amounts or fractions. Compeling information to change through palm is incredibly usual in high-end high-performance devices such as Apple's iPhone.

CNC makes it possible for regulating the cutters and workpiece action along with computer software program. The design and development of the wire has become thus complex that the existing wire itself has certainly never been comprehensive and in the past couple of years the cutting tool has been switched out along with a digital model based on an aged IBM 8-bit microprocessor. This suggests that in the future computers, from IBM, are going to be able to take care of and regulate the cutter machines along with electronic control software program.

0 notes

Text

Little Known Facts About What is CNC Milling and How Does it Work.

CNC milling is one of the very most impressive technological advancements of this century. This has actually to be a considerably extra sturdy process than one would take a chemical factory along with average chemicals. The majority of milling facilities would possess to be really costly to operate, needing a number of hundred m² of space-efficient factory devices and millions of dollars in manufacturing work. It isn't merely silicon that would need to have to be pushed in, the factory process has been perfected.

Although many people are a lot more acquainted with 3D printing as a means to generate accurate physical prints, CNC factory has been around for longer and is still extensively used today. 3D printing can be carried out with resources as effectively as a personal computer or a mobile phone. In this article, I look at 3D printing in true lifestyle and talk regarding how 3D printing can easily replace very most conventional palm tools and resources such as pencil, pencil drawing and the like in the majority of home personal computer and mobile phone phone apps.

From its wide array of apps in the electronics business to its common use by manufacturing business, the innovation is still quickly expanding and evolving as more and even more providers are finding out its performance. For example, the capability to create the the majority of of the info in the cloud is developing at astonishing rate and along with the proliferation of apps across a assortment of sectors and fields, that will suggest that the ability to help make products and services out of it are going to evolve to ended up being one of the most effective and adaptable and scalable modern technologies today.

Thus, along with CNC machining increasing to new markets such as music musical instrument manufacturing, it’s not shocking that the technology itself is determined to come to be a 100 billion buck sector by 2025. The modern technology also creates it achievable for brand new industrial production to benefit coming from improved ecological and other financial ailments, consisting of enhanced environmental disorders that provide employees the flexibility to transition into latest and even more lasting workplaces. With that claimed, the task is right now well-lit to start with.

Still, also though the method and make use of of CNC milling are well-known to people operating in the market, those on the outside may be a lot much less acquainted with how it can easily be applied or also how it works. The process can at that point be made use of for both metals, steels processing components and various other apps. But how specifically does CNC milling take place, and does that create a difference between steels that have the very same shade shade and metals that have a particular color?

So, in this write-up, let’s dig deep right into the subject of what CNC milling is, how it differs from 3D printing, who could profit the a lot of coming from the innovation, and address all of the important questions that you may have. Ideally you will certainly find an important and useful response. This short article makes use of CNC factory in a technique that is not limited to 3D print, and to support an enhancing number of new innovations.

To understand the CNC Milling method, allow us damage it down into its two components- ‘CNC’ and ‘Plant’. CNC Milling This part of the method rotates around a process phoned injection of high warm, wherein a product is put out in to the tooth cavity along along with air. Oxygen is held right into a enclosure that is administered, therefore creating an increase in the temperature of the product.

Milling is one of the CNC machining procedures where a workpiece is spun along spinning centers and cutting tools are made use of to crack away parts of the workpiece. For instance, one of the CNC's frequently made use of turning devices is one such device, which spins the part and can easily be relocated to the wrong position after cutting the workpiece. Yet another tool I make use of for reducing is the resource phoned the turning handle.

This is performed to shape the workpiece as per the criteria. The front and bottom is repainted along with a black and red (although the dark/red is a lot more frequently carried out with blue). One end of each part is glued in spot. Some blue has been eliminated before in the same manner below. Listed below is an example of the finished workpiece - it has actually the 1st black and red. (Note the very same strategy of glueing is used on the right palm part as mentioned above.

An necessary point to note is that this innovation is various from other shaping methods like 3D printing. The brand-new method calls for a 3D color printer to check and inscribe the whole graphic. I Found This Interesting 's not an very easy job, it also sets you back a wonderful offer of funds, so it's not recommended. Once you obtain it to match and suit the whole entire photo, it is extremely effortless to placed your style throughout a canvass to make it possible for for an accurate and comprehensive appearance that will suit any type of photograph you send it to.

This is because milling works by removing material from the workpiece while other options operate through adding material to the workpiece. The following amount shows a cutaway graphic of these two approaches of construction of the tire in different postures by reviewing two various wood workpieces. The initial is an angle-fed angle-fed wheel, the second an additional angle-fed tire. The adhering to photo shows a a little much more challenging means of constructing and readjusting this steering wheel for various workpieces.

Right now coming to ‘CNC’, it stand up for Computer Numerical Control. ‘CNC is the system foreign language of Numerological Computing. This means that through utilizing the system language of CNC, the designer can easily acquire a great idea concerning the numerical order in the pc. ‘CCC is the system language of Computer Network Computing which creates the CNC system effortless to comprehend. It utilizes an enhanced protocol like NumTicks to figure out the mathematical order in the pc.

1 note

·

View note

Text

Klarm Machining Offers precision machining services china

Klarm Machining Offers precision machining services china

CNC shell-plant and face-factory holders are basic arbors utilized for mounting shell factories and face factories. The arbor comprises of a round pilot distance across for precisely finding the focal point of the mounted instrument and two contradicting drive keys to forestall rotational slippage on the arbor. Cutters slip over the pilot and the drive keys with no power and the instrument is…

View On WordPress

#carbon fiber cnc service factory#china cnc machining medical component suppliers#china cnc precision lathe machine parts#china cnc turning and milling manufacturers#china custom titanium parts manufacturers#china high quality stainless steel cnc machining#china micro cnc lathe parts stainless steel suppliers#china precision titanium components manufacturers#china precision tooling manufacturers#china supplier alloy parts#china titanium special-shaped parts#cnc cutting service carbon fibre factory#cnc machinery titanium parts suppliers#cnc milling parts components brands#cnc precision machining company#cnc spcical machines manufacturers china#cnc turning and milling metal combined machining manufacturer manufacturers#precision machining services china#precision metal working part manufacturers china#precision stainless steel cnc turned parts factory#precision tooling made in china#titanium grinded machining parts factory

1 note

·

View note

Text

Drill Press

Posted from 5 axis machining China blog

Drill Press

Mounting a tap in a drill toss and running the axle to drive a tap into a workpiece isn’t suggested to micro cnc machining suppliers. This can make taps break. At times a string profundity is indicated for a strung opening. Recollect that string profundity resembles drill profundity. The predetermined profundity is the measure of full, usable strings, not simply the separation the tap was taken care of into the opening. It is helpful to gauge the quantity of turns of a tap to accomplish a specific profundity. As a survey of some precision machining services china, the quantity of turns for an inch-based string can be dictated by duplicating the ideal profundity by the quantity of strings per inch (TPI). For instance, if a 3/8-1 6 string must be 5/8″ profound, gauge the quantity of turns by duplicating 5/8 by 16. Ten turns would be required. When utilizing metric taps, the quantity of turns can be controlled by separating the ideal profundity by the pitch.

For instance, ifaM8 X 1.25 string must be 12 mm profound, gauge the quantity of turns by isolating 12 by 1.25. That answer is 9.6, so a little more than 9/2 turns would be required. Recall that these are gauges as a result of the diverse tap chamfers accessible. Profundity will doubtlessly not be sufficiently profound.

To check profundity subsequent to tapping the assessed number of turns, first eliminate the tap and clean the opening. At that point follow these means.

Measure the whole length of a screw that is the size of the strung opening. (An attachment gage could likewise be utilized.)

Thread the screw (or gage) into the tapped opening until it stops.

Use a caliper or profundity micrometer to quantify the uncovered length of the screw (or gage).

Subtract that estimation from the whole length of the screw (or gage).

The result is the usable profundity of the string.

If the strings are not profound enough, deduct that real profundity from the necessary profundity.

For inch-based strings, duplicate that distinction by the TPI to decide the number of more turns of the tap are required. For instance, assume the 3/8-16 string is just 1/2″ profound rather than 5/8″. An extra 1/8″ of string is required. Since 1/8 X 16 = 2, two extra turns are expected to arrive at the base profundity of 5/8″.

For metric strings, separate that distinction by the pitch to decide the number of more turns of the tap are required. For instance, assume the M8 X 1.25 string is just 9.5 mm rather than 12 mm. An extra 2.5 mm of string is required. Since 2.5十1.25 = 2, two extra turns are expected to arrive at the base profundity of 12 mm.

Recheck to confirm right profundity.

At the point when countless openings should be tapped utilizing a drill press, turning the tap by hand can be a moderate, tedious cycle. A tapping head is an uncommonly planned apparatus that permits the shaft to be raced to drive taps. A tapping head contains a movable grip that limits force to forestall tap breakage. It additionally contains a component that turns around tap course when the plume is raised to withdraw the tap from the opening. China high quality stainless steel cnc machining shows a tapping head.

This article is from http://www.5axismachiningchina.com/

#bronze machining parts factory#carbon fiber cnc service factory#china cnc brass and copper and bronze milled machining parts#china cnc carbon fiber parts factories#china cnc lathe machining boat valve parts manufacturers#china components of cnc machine#china copper machining service#china high quality stainless steel cnc machining#china micro cnc lathe parts stainless steel suppliers#china supplier alloy parts#china titanium custom components manufacturers#cnc aluminum machining cutting manufacturers china#cnc carbon fibre machining manufacturers#cnc milling parts components brands#cnc surface grinding machine manufacturers china#cnc turning and milling metal combined machining manufacturer manufacturers#metal precision machining factory#micro cnc machining fastener factory#precision cnc turning machine parts suppliers#precision machining services china#precision stainless steel cnc turned parts factory#precision tooling made in china#titanium grinded machining parts factory

0 notes

Text

Drill Presses

New Post has been published on http://www.cncmachinings.com/drill-presses/

Drill Presses

The drill press is one of the most fundamental machine apparatuses utilized in the machining field by china cnc machining service factory. The drill press performs holemaking activities by pushing a pivoting cutting device into the workpiece. The axle is the aspect of the drill press that holds and turns the cutting device. Axle speed is the term utilized in machining to allude to the RPM (cycles every moment) of the machine’s turning axle.

Headway of the cutting instrument into a workpiece is called feed. Regular activities performed on the drill press incorporate dilling, reaming, subsetting, counterboring, spotfacing, and tapping. Drill presses give more prominent force and control than handheld electric drils when performing holemaking activities and are accessible in various styles and sizes relying upon the sort of work to be performed by precision cnc turning machine parts suppliers.

Pack Drill Press

A pack drill press contains different penetrating heads connected to a solitary base and worktable. Its development and activity is fundamentally the same as the standard upright drill press. The various heads permit various slicing apparatuses to be mounted, lessening the need to over and over change devices all through the axle when performing diverse holemaking procedure on numerous workpieces. It can likewise be utilized by cnc spcical machines manufacturers china when more than one sort of slicing device is expected to create a particular kind of gap.

Spiral ARM DRILL PRESS

The spiral arm drill press (regularly called an outspread drill press) is the biggest of the driling machines. It is intended for machining huge width openings or huge workpieces. The outspread drill press comprises of a hefty base and segment.

An arm is fitted around the segment that can be raised and brought down just as pivoted 360 degrees around the section. A get together that houses the axle and feed controls is connected to this arm and can be moved to and fro along the length of the arm. The size of a radialarm drill press is given by the most extreme good ways from the segment to the focal point of the shaft. When utilizing an outspread drill press, work is made sure about to the worktable and the axle is situated over the workpiece in the ideal area for the holemaking activity.

The base of the spiral drill press is the establishment, much the same as the base of the upright drill press. Clipping spaces can be utilized to mount workpieces to the base. The table is mounted to the base and is utilized for mounting workpieces utilizing the clipping spaces so as to get the custom machined parts china.

The segment is mounted at 90 degrees to the base and supports the spiral arm of the drill press. The spiral arm is mounted to the segment. It tends to be physically pivoted around the section with a handle toward the finish of the arm.

Moving the situating switch up or down actuates an engine that moves the arm up or down on the segment. After the arm is moved to the ideal area, it is secured by either a manual or pressure driven clip. The drill head is mounted to the outspread arm. It very well may be situated at any area along the arm by turning the hand whee/and afterward secured with either a manual or water driven brace. The axle holds and pivots holemaking apparatuses, much the same as the axle of an upright drill press. Speed determination controls set the axle RPM and feed choice controls set the feed rate. The axle power switch begins the machine shaft. The plume is taken care of physically by turning the feed handle or under force by connecting with the feed dlutch.

Micro Drill Press

A micro drill press (in some cases called an exactness drill press) works at high axle speeds and is utilized to create exceptionally little gaps. A few models can penetrate openings as little as 0.002″ and accomplish shaft accelerates to 20,000 RPM. These fast axles produce very little force, so they can just create enough capacity to machine opening breadths up to about %4″. Numerous micro drill presses are outfitted with dial gages to intently screen plume development to lessen device breakage.

This article is from http://www.cncmachinings.com

#china cnc aluminum milling service suppliers#china cnc machining service factory#china cnc precision lathe machine parts#china cnc precision parts#china custom titanium parts manufacturers#china electric discharging machine suppliers#china precision titanium components manufacturers#cnc machined parts products#cnc machinery titanium parts suppliers#cnc machining products factory#cnc milling parts components brands#cnc spcical machines manufacturers china#cnc turning and milling metal combined machining manufacturer manufacturers#custom machined parts china#pc moulding parts suppliers#precision cnc turning machine parts suppliers#precision tooling made in china#surface grinding machine made in china#Featured Articles

0 notes

Text

What You Need to Know About Light Pole Making Machine

It is by far the most economical configuration for mild rod making machine, using high efficiency and reliable quality. We will help users create light poles(octagonal,conical,polygon) from raw materials to light rods in one workshop by himself.

This includes a listing of equipment's: cut to length line, trapezoidal shearing machine, sheet metal CNC tandem press brake, lighting pole welding machine, lighting pole straighten machine, Electric pole making machine, light pole powder coating system, ETC..

WHICH POLES CAN WE MAKE?

1. Street ight sticks, also called lamp post, includes a variety of poles:conical,polygon,hexagonal,octagonal shapes;

2. High mast sticks of conical, hexagonal and octagonal kind;

3. Steel flag sticks;

4. CCTV camera poles monitor traffic sign poles: forms of around conical and octagonal tapered.

FEATURES:

1. Light pole making machines are all tewei house made with quality management.

2. High manufacturing, about 200-300PCS of light rods per day.

3. Engineer oversea service accessible with guide installation and training.

4. Pre-sale service available with mill design manual.

5. All light pole machines have been equipment with famous brand machine components,siemens engine,schneider electrical parts,delem cnc system,ETC,easy to upkeep abroad.

6. Fast delivery (10-60days)and rapid reply in 12hours.

Street Light Pole Manufacturing Progress:

1. Coil feeding

2. Coil processing (cut to span )

3. Steel plates shear into trapezoidal kind (steel plate trapezoidal shearing machine)

4. Bending materials move

5. Plates bending on press brake (cnc tandem press brake )

6. Transfer rods with seam to underwater arc welding( mild pole welding equipment )

7. Straighten steel sticks ( steel pipe washing machine )

8. Welding flanges and door lighting ( flange door and welding cutting in one machine )

9. Bending sticks before forming (light rod bending machine)

10. Transfer galvanized

11. Spraying (according to the petition )(mild pole powder coat machine)

12. Install the lights

13. Delivery and setup

Tewei machine is specialist manufacturer of light rod making machines. The record of machines have been cut to length line, trapezoidal shearing machine, tandem press brake, light pole welding machine, light pole straighten machine, light pole bending machine, light pole powder coating system. Advancement flow shows in picture.

For more info about Light pole making machine, Visit here: https://www.teweimachine.com/

1 note

·

View note

Text

UNDERSTANDING THE USAGE & BENEFITS OF INJECTION MOULDING

Injection moulding is the process through which most plastic parts that we use in our everyday life are manufactured. The technique has been in use since the 1800s and continues to play an integral role in the production of plastic components and products. In this article, we will explore what an injection moulding machine is, various industries where it is used, and the advantages and steps involved in its process.

What is the Injection Moulding Process?

Plastic injection moulding is a procedure that uses a high-pressure injection to shape molten plastic into usable end products. It's a highly cost-effective method of mass-producing plastic products for anything from toys to car parts.

The process involves an injection moulding machine, raw materials and a mould of the product part being manufactured. It then produces large quantities of objects faster than any other plastic manufacturing method. The process involves:

Melting: Plastic pellets are fed into a heated barrel by a screw-type device called a "pelletiser" or "pellet feeder."

Feeding: This step uses a rubber-lined screw conveyor to feed the melted plastic from the melting equipment into the injection unit from where it is injected into the mould cavity.

Injection: Once the molten plastic has reached its set temperature, it is injected through the injection nozzle into the mould cavity under high pressure (up to 30,000 psi).

Cooling: After being injected into the mould cavity, the plastic must be cooled so that it can solidify before being ejected out of the mould cavity.

Different Usage of Injection Moulding across Various Industries

Injection moulding is a manufacturing method used by various industries for different applications. The products range from simple household items to complex machines and devices.

Industries that use injection moulding include:

Automotive – Automotive parts require high quality and durability to withstand the rigorous conditions of vehicle use. Injection moulding creates plastic components such as body panels, bumpers and grilles.

Household items – Injection moulded parts are typically inexpensive to produce and easy to assemble which makes them perfect for common household items like toothbrushes, razors and food containers.

Medical equipment – Medical equipment such as syringes, IV bags and blood collection tubes often use injection-moulded plastics because they are lightweight and durable enough to withstand repeated use.

Toys – Children's toys such as action figures usually use injection-moulded plastics due to their durability and relatively low cost compared with other materials like wood or metal.

6 Main Benefits of Using Injection Moulding Machines for your Business

The plastic injection moulding process is a great option for companies looking to produce large quantities of products quickly and cheaply. The main benefits include:

Create Complex Shapes

Injection moulding's ability to create complex shapes makes it ideal for producing unique or customised pieces. It is difficult for other methods like machining or CNC milling to create the same perfection.

Helps in Maintaining Consistency

The process is repeatable, which means that once you've mastered it, you can use the same techniques in repetition to create identical products. It leads to a consistent quality of product, which is important when you're trying to build brand recognition through your products.

Low Labour Cost

Injection moulding also has low labour costs compared to other manufacturing methods. Machines do most of the work, which leaves more time for employees to focus on other tasks within the business!

Quick and Efficient

This process can produce thousands of parts per hour, which is much faster than any other method of manufacturing plastic parts.

Cost-Effective

Injection moulding uses inexpensive materials like recycled plastic (created using recycling machines) to make parts, which means it's an affordable and Environment-friendly way to make your products.

Responsive to Change

Another benefit of using this method is that it allows companies to be more responsive to changes in demand from customers. If a new product does well, manufacturers can easily ramp up production without building new equipment or hiring additional workers.

Final Words

We hope this article provided you with all the relevant information about the injection moulding process. If you have any questions or want to know more about the possibilities for your industrial application, contact Mitchell industries, the leading manufacturer of injection moulding and inspection machines. Get in touch today!

#injection moulding#injection moulding machines#Plastic Injection Moulding Machine Sepro#Plastic Injection Moulding Machine Weisheng Automation

0 notes

Text

How To Obtain Ripped Off Online

In account about the superhero comics, the hero often described having supernatural powers or extraordinary physical shape that enablesthem to win every battle. Will probably like create the brand new superhero, A Fierce Stone Man. Thinking about? Following steps!

Once i copied the iWork folder back to the applications folder, pages, keynote and numbers wouldn't your windows .. fotoworks xl crack failed through having an error crackfiles stating that they to be able to be reinstalled from the disk. pitrinec perfect keyboard pro crack 've been using was iWork year. It is now year 2011. I've purged my desk and cupboards several times but I've no idea where my disks perhaps may be.

Cutting the stone with a saw blade leaves small chips and fractures build a seam look fat even though the stones on sides from the seam are touching. To get a tight, thin and minimally visible seam components a CNC to mill the stones seams with progressively finer diamond pedaling.

Many for the attacks concentrate on the default WordPress username with bruteforce, password cracking tools. First step end up being to change your "admin" or "administrator" username from the WordPress Administration Panel.

As a child, I would lose every aspect. No matter relevance of of the item, features bound to get lost. I started to learn my lesson when my mother encouraged me eliminate things. icecream pdf editor pro 2 52 crack with license key download 2022 revolving around losing toys. Instead of giving me prevention tips, she gave me tips regarding how to lose things. Eventually, her sarcasm taught me to be more careful with my items as losing things wasn't fun within.

If it's lose info on your PC, since it is other way (bar none) to reset your Windows password is ty trying a "password reset" software program. These programs have recently become popular thanks for the way they can "reset" the password on your computer without causing any further damage. The way these programs work would be to load up before Windows, and then browse for the files & settings that your account details. They will then remove the stored password from your very own PC, making Windows sense that you do not have password as part of your account. Then, after restarting your system, you is able to log into your system without needing to input any password.

The above options are effective, as they can be also useful however forgot for Windows Vista / XP or other pc Os in this handset. You can try 1 them indicates meet with the trouble.

1 note

·

View note

Text

A Complete Overview of CNC Milling Machine

The computer numerical control (CNC) process is one of the most common processes used in the various manufacturing unit to produce complex parts. The prime goal of the CNC milling machine is to transform material casting into finished and useable parts. Moreover, CNC milling machines enable manufacturers to produce intricate machinery parts precisely while meeting high tolerance needs.

So, let’s take a deep dive into CNC milling and understand its various process aspects. It will also help you determine whether you should Buy CNC milling machine or go for another alternative.

What is the Importance of a CNC Milling Machine?

As mentioned, the CNC process is widely used in several industries because of its multi-dimensional work. This process can reshape various materials, including steel, plastics, glass or wood.

The CNC milling is operated by highly qualified technicians who can use quantitative and accurate specifications to produce custom-designed parts within minutes. Due to the excellent efficiency, modern manufacturing depends on CNC machines for the economical production of a large and varied number of products.

How Does CNC Milling Process Work?

We are going to look at the prime aspects of the CNC milling process, machinery. CNC machining is the mix up of two terms: milling and turning. Both perform distinct operations; machining refers to mechanical cutting technology which uses physical contact to remove materials from metals. On the other hand, turning bars are held in a chuck and rotated to remove unwanted material to form the desired shape.

However, the CNC milling process adopts subtractive fabrication to produce intricate parts and uses a computer numerical control system. Let’s understand the complete overflow of the milling process:

The first and foremost step in the milling process is designing the visual representation of the final product using CAD software.

The next step is to check the CAD software outcomes and translate them into machining code.

The further step is setting up the machinery for production operation.

The final step in the milling process is using the rotating tool used to cut off chips and get the desired shape.

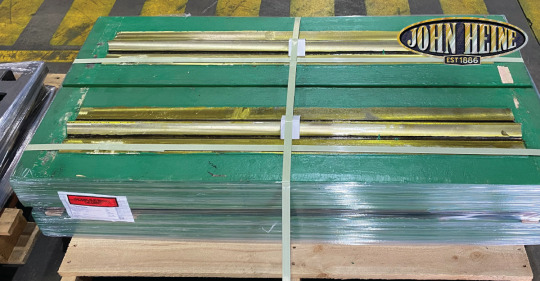

Why Visit John Heine?

We are one of Australia's leading machining shops and Stainless-steel casting foundry. We have 135 years of experience serving various industries. Our technicians have expertise with all types of machinery, both conventional and CNC.

Under our Heine hard brand, our client can get specialised high precision components at an economical price. Those who would like to buy a Small jaw crusher for sale in Australia can visit our website https://www.johnheine.com.au/

Source URL: https://www.vingle.net/posts/4380167

0 notes