#global Welding Equipment Market

Text

Acetylene Prices, Price Trend, News, Analysis & Forecast

Acetylene Prices: During the first quarter of 2024

Acetylene prices fluctuate in response to various market factors and industry dynamics, impacting a wide range of sectors that rely on this versatile gas for welding, cutting, and other industrial applications. The cost of acetylene is influenced by the supply and demand dynamics of raw materials, primarily calcium carbide, from which acetylene is produced through a chemical reaction. Additionally, factors such as energy prices, transportation costs, and regulatory changes can also contribute to price volatility in the acetylene market.

One of the primary drivers of acetylene prices is the availability and cost of calcium carbide, which is derived from calcium carbonate and coke in an electric arc furnace. Any disruptions in the production or supply chain of calcium carbide, such as fluctuations in the prices of raw materials or operational issues at manufacturing facilities, can impact the overall supply of acetylene, leading to price fluctuations. Furthermore, changes in the demand for calcium carbide from other industries, such as steel production or chemical manufacturing, can also affect its availability and, consequently, acetylene prices.

Energy prices play a significant role in determining the cost of producing acetylene. The production process involves heating calcium carbonate and coke to high temperatures in an electric arc furnace, which requires a considerable amount of energy. Fluctuations in electricity or natural gas prices can directly influence the production costs of acetylene, thereby affecting its market price. Additionally, the cost of transportation, including shipping and logistics, can impact the final price of acetylene products, especially for regions that rely on imports or long-distance transport.

Get Real Time Prices of Acetylene: https://www.chemanalyst.com/Pricing-data/acetylene-21

Regulatory factors also contribute to price volatility in the acetylene market. Environmental regulations, safety standards, and compliance requirements imposed by governmental agencies can lead to increased production costs for acetylene manufacturers. Investments in pollution control equipment, safety measures, and regulatory compliance efforts can add to the overall cost of production, which may be passed on to consumers in the form of higher prices. Moreover, changes in regulations governing the transportation, storage, or handling of acetylene can also affect operational costs for distributors and retailers, influencing market prices accordingly.

Global economic trends and geopolitical events can have indirect effects on acetylene prices by impacting factors such as currency exchange rates, trade policies, and market sentiment. Economic downturns or geopolitical tensions can disrupt supply chains, affect investor confidence, and lead to currency fluctuations, all of which can contribute to price volatility in the acetylene market. Conversely, periods of economic growth, increased infrastructure spending, or stability in global markets may lead to higher demand for acetylene and subsequent price increases.

In addition to these external factors, internal industry dynamics also influence acetylene prices. Competition among acetylene manufacturers and distributors, technological advancements in production processes, and shifts in consumer preferences can all affect pricing strategies within the industry. Companies may adjust their pricing strategies in response to changes in market conditions, seeking to maintain competitiveness while maximizing profitability. This dynamic interplay between supply, demand, and market forces ultimately determines the prevailing prices of acetylene products.

In conclusion, acetylene prices are influenced by a complex interplay of factors, including the availability and cost of raw materials, energy prices, regulatory requirements, global economic trends, and industry dynamics. Understanding these factors and their impact on the acetylene market is essential for businesses and consumers alike to make informed decisions regarding purchasing, investment, and strategic planning. As the market continues to evolve, stakeholders must remain vigilant and adaptable to navigate the challenges and opportunities presented by fluctuations in acetylene prices.

Get Real Time Prices of Acetylene: https://www.chemanalyst.com/Pricing-data/acetylene-21

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

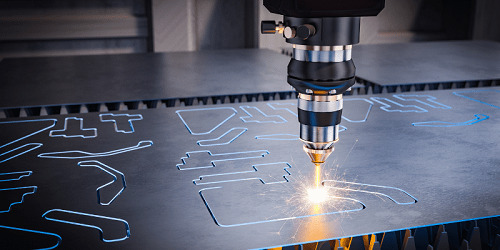

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes

Text

Side Body Trailer Manufacturers In India

Side Body Trailer Manufacturers In India

VST coreB Trailers, was founded in 2018 by Mr. Sitaram Yadav, Founder Chairman of the VST United Group. VST coreB Trailers is one of the biggest brands of trailers and truck bodies in India. The manufacturing of several Articulated and Rigid categories Trailers, Tipping Trailers, Bulkers, Containers, Tankers etc. began operation in 2019.

Our headquarters in Kotput, Rajasthan, has a monthly production capacity of 600 trailers. Currently we are producing 450–500 units per month and delivering across India. Providing best quality, our devoted RD team conducts the greatest research possible on product development.

We have a production area of more than 4 lac square feet, 720 onsite engineers, and 905 people overall in India. More than 6150 satisfied customers use VST coreB’s B28 and B2C products And services in the Indian market. Read more Side Body Trailer Manufacturers In India

VST CoreB Trailers in one of the biggest brands of trailers and truck bodies in India. With a present Production capacity of 600 trailers per month and more than 6150 happy clients, the company is fairly optimistic about its future growth potential in India and globally. Click now Side Body Trailer Builders In India

To continually follow the highest quality standards. Become India’s first choice company in Trailers Manufacturing. Supply best in-class and quality products to global partners. Provide customized Products to clients that accelerate their enterprise and be their most trust-worthy go-to partner.

We are Equipped with epic infrastructure (CNC, Robotic welding and automated machineries with emerging technologies) to design and develop customized vehicles, which can be fabricated for industrial and commercial transport solution.

By 2023, we expect to sell and produce across PAN India with additional production facilities in four new states. Click now Cargo Trailer Manufactures in India

VST coreB is ISO 9001:2015 certified company and our designs are approved by international centre for automotive technology (ICAT) authorities. VST coreB is best known for quality and eco friendly brand. Read more Semi lowbed Trailer Builders in India

VST CoreB Trailers in one of the biggest brands of trailers and truck bodies in India. With a present Production capacity of 600 trailers per month and more than 6150 happy clients, the company is fairly optimistic about its future growth potential in India and globally. Click for more knowing Tipping Trailers Manufacturer in India

To continually follow the highest quality standards. Become India’s first choice company in Trailers Manufacturing. Supply best in-class and quality products to global partners. Provide customized Products to clients that accelerate their enterprise and be their most trust-worthy go-to partner. Click now Flatbed Trailer manufacturers

By 2025, we hope to establish a global business with operations in Asia, the Middle East, and Africa, With a monthly production capacity of 1300–1400 trailers. Quality is a major concern for Indian as Well international transporters, because they are currently implementing a new ecosystem and Prefer to cut operational costs over onetime charges. Read more truck body manufacturers in india

VST coreB to produce high-quality, cutting Edge trailers with all necessary safety features for the Indian, Bangladesh, Nepal, African, and South American markets.

VST CoreB Trailers is one of the biggest brands of trailers and truck bodies in India. With a present production capacity of 600 trailers per month and more than 6150 happy clients.

0 notes

Text

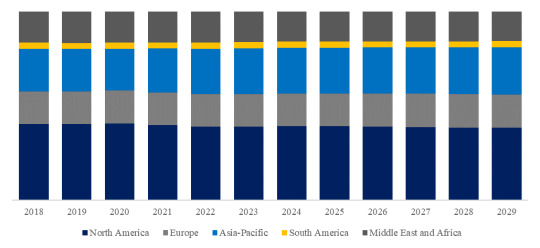

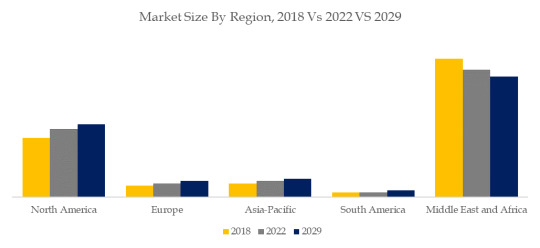

Insights from Welding Equipment, Accessories, and Consumables Market Forecast 20233 And Promising Future Projections

Overview and Scope

Welding equipment, accessories, and consumables refer to the set of products that are used during the process of welding, which is the process of fabrication of metals in which two pieces of metal are joined together by applying heat by using instruments such as welding goggles, welding helmets, welding glass, welding spray, and welding positioners.

Sizing and Forecast

The welding equipment, accessories, and consumables market size has grown strongly in recent years. It will grow from $24.84 billion in 2023 to $26.73 billion in 2024 at a compound annual growth rate (CAGR) of 7.6%.

The welding equipment, accessories, and consumables market size is expected to see strong growth in the next few years. It will grow to $34.83 billion in 2028 at a compound annual growth rate (CAGR) of 6.8%.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/welding-equipment-accessories-and-consumables-global-market-report

Segmentation & Regional Insights

The welding equipment, accessories, and consumables market covered in this report is segmented –

1) By Technology: Arc Welding, Oxy-fuel Welding, Other Technologies

2) By Equipment Type: Welding Electrode, Filler Metal, Oxy-fuel Gas

3) By Application: Automotive, Building and construction, Heavy Engineering, Railway & Shipbuiding, Oil & Gas, Other Applications

Asia-Pacific was the largest region in the welding equipment accessories and consumables market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the welding equipment, accessories, and consumables market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8388&type=smp

Major Driver Impacting Market Growth

The growing demand for the steel industry is expected to propel the growth of the welding equipment accessories and consumables market. The increased demand for welded metals in the fabrication industry and the use of welding equipment is used for applications such as stick welding, tungsten inert gas (TIG) welding, and metal inert gas (MIG) welding.

Key Industry Players

Major companies operating in the welding equipment, accessories, and consumables market report are Air Liquide S. A., British Oxygen Company, Bug-O Systems Inc., Carl Cloos Schweisstechnik GmbH, Cavagna Group UK Ltd., Colfax Corporation, Daihen Corporation, GCE Holding AB, Gentec Corporation, Illinois Tool Works Inc., Kobe Steel Ltd., Koike Aronson Inc., Lincoln Electric Holdings Inc.

The welding equipment, accessories, and consumables market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Ferrosilicon Market is Likely to Reach Value of US$ 15.1 Bn by 2031

The value of global ferrosilicon market stood at US$ 11.3 Bn. The global market is projected to develop at 2.5% CAGR during the forecast period, from 2022 to 2031. It is estimated that by 2031 the global ferrosilicon market is likely to touch value of US$ 15.1 Bn. Industries are exploring options in metallic addition agents that are utilized in the production of steel and iron to add an alloying element to refined steel or molten metal. In the manufacturing of iron and steel ferrosilicon is utilized as a master alloy.

In order to reduce release of harmful particles into the environment, businesses are expected to take additional precautions, such as storing ferroalloys in watertight containers and isolating equipment and machinery utilized for handling raw materials. Due to the fact that steel is a crucial raw material for the majority of end-use sectors, leading players in ferrosilicon market have been creating steady income streams in the steel sector since COVID-19 outbreak.

Request Sample Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=73340

The main application of ferrosilicon in steel mills is the production of steel. Ferrosilicon has advantages such as high strength, high temperature resistance, high magnetism & hardness, and high specific gravity. It is also resistant to corrosion and abrasion. As a result, a number of businesses are investing in the manufacture of ferrosilicon, which is estimated to as one of the key recent developments in ferrosilicon market.

Market Segmentation

By Service Type: Production, Distribution, Export/Import

By Sourcing Type: Primary Production, Recycling

By Application: Steelmaking, Foundry, Welding Electrodes, Ferroalloys Production, Others

By Industry Vertical: Steel Industry, Automotive, Construction, Machinery & Equipment, Others

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Regional Analysis

North America: Mature industrial infrastructure and technological advancements drive steady market growth.

Europe: Stringent environmental regulations and emphasis on sustainable manufacturing practices impact market dynamics.

Asia-Pacific: Rapid industrialization, urbanization, and infrastructural development fuel significant market demand.

Latin America, Middle East & Africa: Emerging economies witness growing industrial activities, driving regional market expansion.

Market Drivers and Challenges Drivers:

Steel Industry Growth: Increasing steel production for automotive, construction, and machinery sectors boosts ferrosilicon demand.

Infrastructure Development: Rising investments in infrastructure projects drive demand for ferrosilicon in construction and related industries.

Technological Advancements: Innovations in ferrosilicon production processes enhance efficiency and product quality, driving market growth.

Challenges:

Raw Material Price Volatility: Fluctuations in raw material prices, such as silicon and iron, impact production costs and market stability.

Environmental Regulations: Compliance with environmental standards and emissions regulations poses challenges for ferrosilicon producers.

Competitive Landscape: Intense competition among key players necessitates continuous innovation and cost-effective production methods.

Market Trends

Focus on Energy Efficiency: Adoption of energy-efficient production technologies and sustainable practices to reduce environmental impact.

Product Diversification: Expansion into niche applications such as welding electrodes and specialty ferroalloys to cater to diverse market needs.

Market Consolidation: Mergers, acquisitions, and strategic partnerships among key players for market expansion and global presence.

Future Outlook The ferrosilicon market is poised for steady growth, driven by sustained demand from key industries, technological advancements, and strategic market initiatives. Focus on sustainability, product innovation, and market expansion strategies will shape the industry's future landscape.

Key Market Study Points

Market Size and Growth Projections

Segmentation Analysis by Service Type, Sourcing Type, Application, Industry Vertical, and Region

Impact of Regulatory Environment and Technological Advancements

Market Drivers, Challenges, and Opportunities

Competitive Landscape and Key Players' Strategies

Recent Developments and Industry Trends

Competitive Landscape Major players in the ferrosilicon market include ABC Ferro Alloys, XYZ Group, DEF Metals, among others. Competitive strategies such as product innovation, expansion into emerging markets, and strategic alliances are crucial for maintaining market leadership and meeting evolving customer demands.

Recent Developments

Launch of high-purity ferrosilicon grades for specialized applications in electronics and aerospace industries.

Investments in research and development for advanced production processes and environmental sustainability.

Strategic partnerships with end-user industries to develop customized ferrosilicon solutions and enhance market presence.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=73340<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Storage Tank Market Share

Storage Tank Market Share:

Understanding the market share of key players in the storage tank industry provides valuable insights into the competitive landscape and market dynamics. This analysis aims to examine the Storage Tank Market Share of leading companies operating in the storage tank market, highlighting their strengths, strategies, and contributions to the industry.

Market Share Overview:

The storage tank market is characterized by the presence of several prominent players, each competing for market share across various regions and industry segments. Key players in the market include manufacturers, suppliers, and service providers involved in the design, construction, installation, and maintenance of storage tanks for different applications.

Analysis of Key Players:

1. CST Industries, Inc.: CST Industries is a leading provider of storage tanks, covers, and aluminum domes, serving various industries including water, wastewater, oil and gas, agriculture, and mining. With a global presence and a diverse product portfolio, CST Industries holds a significant market share in the storage tank industry.

2. Tanco Engineering, Inc.: Tanco Engineering specializes in the design, fabrication, and installation of welded storage tanks, pressure vessels, and process equipment. Known for its expertise in engineering solutions and customer-centric approach, Tanco Engineering commands a notable market share in the storage tank segment.

3. DN Tanks: DN Tanks is a recognized leader in the design and construction of prestressed concrete storage tanks, serving municipal water, wastewater, and industrial markets. With a focus on innovation and quality craftsmanship, DN Tanks has established a strong market presence and secured a considerable market share in the industry.

4. Columbian TecTank: Columbian TecTank is a leading manufacturer of epoxy-coated bolted steel tanks, serving industries such as water, wastewater, fire protection, and industrial liquids storage. With a reputation for reliability and performance, Columbian TecTank holds a significant market share in the bolted steel tank segment.

5. PermianLide: PermianLide is a prominent provider of storage tank solutions, offering a wide range of products including API-12F tanks, ASME vessels, and custom-engineered tanks. With a focus on quality, safety, and customer satisfaction, PermianLide has captured a notable market share in the oil and gas storage tank sector.

6. Tank Connection: Tank Connection specializes in the design, fabrication, and installation of bolted RTP (rolled, tapered panel) storage tanks for various applications including water, wastewater, and dry bulk storage. With a reputation for innovation and efficiency, Tank Connection commands a significant market share in the bolted tank segment.

7. Superior Tank Co., Inc.: Superior Tank Co. is a leading manufacturer of bolted steel tanks, welded steel tanks, and fiberglass tanks for water storage, wastewater treatment, and fire protection applications. Known for its quality products and reliable service, Superior Tank Co. holds a considerable market share in the storage tank industry.

Conclusion:

The storage tank market is highly competitive, with several key players vying for market share across different segments and regions. By offering innovative products, superior quality, and exceptional customer service, these companies have established strong market positions and contributed significantly to the growth and development of the storage tank industry. Understanding the market share of these key players is essential for stakeholders to make informed decisions and navigate the competitive landscape effectively.

Top trending reports:

Bagging Machine Market

Residential Water Softening Systems Market

Portable Filtration System Market

Boiler System Market

Handheld Blower Market

0 notes

Text

Understanding SS Square Pipe Price Per KG

Stainless steel (SS) square pipes are versatile and durable materials used in various industries and applications, from construction to automotive, furniture, and beyond. When dealing with stainless steel square pipes, one crucial aspect is the price per kilogram (kg). Understanding the factors influencing this pricing can provide valuable insights for businesses and consumers.

Quality and Grade:

The grade and quality of stainless steel significantly impact its price. Stainless steel is available in different grades, the most common being 304 and 316. These grades vary in composition, corrosion resistance, and mechanical properties—generally, higher grades command higher prices due to their superior characteristics and performance. When comparing prices, it's essential to consider the grade and quality of the stainless steel square pipe being offered.

Market Demand and Supply:

The basic economic principle of supply and demand is crucial in determining stainless steel prices. Fluctuations in demand from various industries, coupled with changes in the supply of raw materials, can lead to price volatility. Global economic conditions, geopolitical events, and industry trends influence market dynamics, impacting stainless steel prices.

Raw Material Costs:

The cost of raw materials, primarily nickel and chromium, directly affects the price of stainless steel. Nickel is a key component in stainless steel production, and its price fluctuations can significantly impact overall costs. The energy, transportation, and labour costs also contribute to the final price of stainless steel square pipes.

Manufacturing Processes:

The manufacturing processes of producing stainless steel square pipes also influence their price. Advanced manufacturing techniques, such as seamless pipe production or precision welding, may produce higher costs but yield superior quality products. Factors such as labour costs, equipment maintenance, and technological advancements can affect the overall manufacturing expenses, thereby reflecting the product's final price.

Market Competition:

Competition among stainless steel manufacturers and suppliers can drive prices down as companies strive to attract customers. However, this competition can also lead to price wars and compromises on quality. Consumers must balance price considerations with product quality and reliability when purchasing.

Trends and Forecasts:

Keeping track of market trends and forecasts can help businesses and consumers anticipate future price movements. Technological advancements, regulation changes, and emerging market trends can impact the demand for stainless steel square pipes and their prices. Staying informed about industry developments enables stakeholders to make informed decisions and adapt to market dynamics effectively.

Conclusion

Various factors, including the grade and quality of the material, market demand and supply dynamics, raw material costs, manufacturing processes, and market competition, influence the price per kilogram of stainless steel square pipes. Understanding these factors is essential for businesses and consumers to make informed purchasing, budgeting, and planning decisions. By staying informed about market trends and forecasts, stakeholders can effectively navigate the stainless steel market and optimize their operations.

0 notes

Text

PPR Pipes Supplier in Mumbai

Parthiv Polymers is a Manufacturer, Exporter, and PPR Pipes Supplier in Mumbai, Maharashtra.

Parthiv Polymers an ISO 9001:2015 Certified Company, Ahmedabad, Gujarat, India.

Our company Manufactures, Supplies, Exports, and retails a flawless range of PPR Pipes.

The entire range is crafted using superior-grade materials sourced directly from certified and reputable market vendors.

Our dedicated researchers consistently conduct rigorous research to understand customer demands and set market trends.

Thanks to their efforts, we can adapt our range to meet prevailing industry trends and demands.

Our skilled workers utilize modern machines, cutting-edge tools, and advanced equipment to produce an exclusive range of PPR Pipes.

Offered in various sizes, dimensions, and thicknesses, our range meets the requirements of our esteemed global customers.

A distinguishing feature of our PPR Pipes is their ability to withstand pressures exceeding 20 kg/cm2.

Our pipes can efficiently transport hot, cold, hard, or seawater with ease and durability.

Features:

Easy to Weld

Easy to fit

Chemical resistant

Parthiv Polymers is a Manufacturer Exporter and PPR Pipes Supplier in Mumbai, Maharashtra and various locations like Thane, Mumbai, Nagpur,

Pune, Ahmednagar, Aurangabad, Daulatabad, Dhule, Jalgaon, Kalyan, Nanded, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Wardha, Yavatmal.

For more information, please feel free to contact us.

Read the full article

0 notes

Text

Navigating Regulatory Challenges in the Ilmenite Industry

Ilmenite: An Important Mineral For Titanium Dioxide Production

It is a weakly magnetic mineral that contains iron, titanium, and oxygen. Its chemical formula is FeTiO3 and it crystallizes in the trigonal system. Its usually contains around 50-65% titanium dioxide and ranges between 35-49% iron(II) oxide. Trace amounts of other elements like magnesium, manganese, chromium are also sometimes present in the mineral. Ilmenite has a black to steel-gray color and its hardness on the Mohs scale ranges between 5-6.5. It has a submetallic to dull luster and leaves a brown streak.

Occurrence and Deposits

It is one of the most abundant titaniferous minerals found on Earth. It occurs in igneous and metamorphic rocks as well as in some sedimentary deposits formed by erosional processes. Some of the major occurrences of ilmenite deposits include Australia, South Africa, Canada, Norway, India, Ukraine, Russia and the United States. Australia has some of the largest deposits in the world located in Western Australia. Its deposits often form placers and heavy mineral sands near ancient or contemporary coastlines. Alluvial deposits concentrated by ocean currents and wave actions have also produced many ilmenite accumulations over geologic time.

Uses and Application

It is primarily used for the production of titanium dioxide which possesses valuable properties like brightness, high refractive index and stability under light exposure. Around 95% of the mined element is processed to obtain titanium dioxide, which is used extensively as a white pigment in paints, paper, plastics, textiles, ceramics, floor coverings etc. Titanium dioxide has superior opacity and hiding power compared to other white pigments like zinc oxide and lead carbonate. It is also used as a reinforcing agent in laminates, abrasives and welding rods. Ilmenite can be transformed into titanium tetrachloride or titanium sponge - important intermediates needed for the manufacturing of titanium metal. Due to its magnetite content, it also finds applications as an important source of iron.

Mining and Processing

Ilmenite deposits are mined through conventional open-pit mining methods. Overburden and waste rock are first removed to expose the ore bodies. Heavy mining equipment like excavators and haul trucks are used to extract and transport the run-of-mine ore rocks. The mined element is crushed and ground to liberate individual mineral grains before being concentrated through gravity or magnetic separation techniques. This results in an upgraded ilmenite concentrate ranging between 55-65% TiO2. The concentrate is then subjected to various pyrometallurgical processes to convert it into usable materials. The sulfate process and chloride processes are commonly used for transforming the concentrate into synthetic rutile, titanium slag or titanium tetrachloride respectively. These intermediates serve as feedstock for various titanium products worldwide.

Market Dynamics and Industry Trends

The global market was valued at around USD 2.5 billion in 2020 and has been growing steadily. China, India and Japan are the leading consumers of ilmenite due to large-scale paint, plastic and paper manufacturing industries prevalent in these countries. China alone accounts for more than 40% of the total global demand. Rising population and economic growth in Asia Pacific are projected to elevate its consumption in the coming decade. Tightening environmental regulations regarding the use of lead and other toxic pigments will also boost demand for titanium dioxide pigments produced from it. New mining projects coupled with advancement of mining and processing methods are helping to augment global ilmenite supplies.

0 notes

Text

From Gujarat to Global: Exploring India's Leading ABS Sheet Manufacturers

In the world of industrial materials, 4x8 Abs Sheet Manufacturers in Gujarat stand out as versatile and essential components. Singhal Industries Private Limited, a renowned manufacturer based in Gujarat, emerges as a leading player in the production and export of ABS sheets, catering to diverse industries and clients in Ahmedabad and across India. In this comprehensive guide, we will delve into the significance of ABS sheets, the role of Singhal Industries, and address frequently asked questions to provide a deeper understanding of this essential industrial material.

Understanding ABS Sheets: The Versatile Solution

ABS sheets are thermoplastic materials known for their exceptional mechanical properties, versatility, and durability. Composed of acrylonitrile, butadiene, and styrene, ABS sheets exhibit high impact resistance, good heat resistance, and excellent dimensional stability. These properties make ABS sheets suitable for a wide range of applications, including automotive parts, electronics, appliances, construction, and signage.

Singhal Industries Private Limited: Your Trusted ABS Sheet Manufacturer

Singhal Industries offering high-quality products and innovative solutions to meet the diverse needs of its customers. With state-of-the-art manufacturing facilities, advanced technology, and a commitment to quality and customer satisfaction, Singhal Industries has earned a reputation for excellence in the industry. As a leading exporter in Ahmedabad, Singhal Industries extends its reach to international markets, delivering reliable ABS sheet solutions to clients worldwide.

Key Features of Singhal Industries' ABS Sheets:

4x8 Sheet of Abs Plastic Exporters in Ahmedabad are versatile thermoplastic materials known for their exceptional mechanical properties, durability, and versatility. Here are the key features that make ABS sheets stand out:

High Impact Resistance: One of the most notable features of ABS sheets is their excellent impact resistance. ABS sheets can withstand significant external forces without breaking or cracking, making them ideal for applications where durability and toughness are required. This property makes ABS sheets suitable for use in automotive parts, electronic enclosures, protective covers, and consumer products that are subject to impact and rough handling.

Good Heat Resistance: ABS sheets exhibit good heat resistance, allowing them to maintain their mechanical properties over a wide temperature range. They remain stable and retain their shape and structural integrity even at elevated temperatures, making them suitable for applications where heat resistance is essential. ABS sheets are commonly used in components exposed to heat sources, such as automotive interiors, electronic housings, and appliances.

Excellent Dimensional Stability: ABS sheets demonstrate excellent dimensional stability, meaning they maintain their shape and size with minimal shrinkage or distortion during processing and use. This property ensures precise and accurate fabrication, making ABS sheets easy to machine, cut, drill, and thermoform into complex shapes and designs. The dimensional stability of ABS sheets contributes to their versatility and suitability for various manufacturing processes.

Chemical Resistance: ABS sheets offer good resistance to many chemicals, oils, and solvents, making them suitable for applications where exposure to harsh chemicals is a concern. ABS sheets are commonly used in chemical processing equipment, laboratory enclosures, and storage containers where resistance to chemical corrosion is essential for long-term performance.

Ease of Processing: ABS sheets are easy to process and fabricate using conventional methods such as cutting, routing, drilling, thermoforming, and welding. They can be machined into precise shapes and designs with minimal effort, allowing for customization and intricate detailing. The ease of processing of ABS sheets makes them popular among manufacturers and designers seeking cost-effective and efficient solutions for their projects.

In summary, ABS sheets offer a combination of high impact resistance, good heat resistance, excellent dimensional stability, chemical resistance, ease of processing, and aesthetic appeal, making them versatile materials for a wide range of applications across various industries. Whether it's automotive components, electronic enclosures, consumer products, or industrial equipment, ABS sheets provide reliable performance and durability to meet the demands of diverse applications.

Key Uses ABS Sheets:

Automotive Parts: ABS sheets are widely used in the automotive industry for manufacturing interior and exterior components such as dashboard panels, trim pieces, door handles, and bumper covers. Their high impact resistance and dimensional stability make them ideal for withstanding the rigors of automotive applications.

Electronic Enclosures: ABS sheets are commonly employed in the production of electronic enclosures and housings for devices such as computer towers, printers, routers, and control panels. Their heat resistance, durability, and ease of customization make them well-suited for protecting electronic components and providing aesthetic appeal.

Consumer Products: ABS sheets find extensive use in the production of various consumer goods, including appliances, toys, luggage, and consumer electronics. They are used to manufacture components such as appliance housings, toy parts, handles, and casings due to their strength, impact resistance, and aesthetic versatility.

Construction Materials: ABS sheets are utilized in construction applications for producing architectural features, signage, decorative panels, and trim pieces. Their ability to be machined into intricate shapes and their resistance to weathering make them suitable for both interior and exterior architectural elements.

Point-of-Purchase Displays: ABS sheets are commonly used in point-of-purchase (POP) displays and retail fixtures due to their versatility and aesthetic appeal. They can be easily fabricated into custom shapes and sizes to create eye-catching displays for showcasing products in retail environments.

Medical Equipment: ABS sheets are employed in the manufacture of medical equipment and devices such as instrument panels, equipment housings, and storage containers. Their resistance to chemicals and sterilization methods, as well as their ease of cleaning, make them suitable for use in medical settings.

Model Making and Prototyping: ABS sheets are popular materials for model making, prototyping, and DIY projects due to their ease of fabrication and affordability. They can be cut, shaped, and assembled to create prototypes, architectural models, cosplay costumes, and other hobbyist projects.

Educational Materials: ABS sheets are used in educational settings for creating visual aids, teaching tools, and classroom materials. They are often utilized in school projects, science fair exhibits, and educational displays due to their versatility, durability, and ease of customization.

Furniture Components: ABS sheets are employed in the production of furniture components such as drawer fronts, cabinet doors, and decorative trims. Their ability to be thermoformed and laminated with other materials makes them suitable for adding decorative elements to furniture pieces.

Conclusion:

In conclusion, Abs Sheet Manufacturers in India offer a versatile and durable solution for a wide range of industrial applications, and Singhal Industries Private Limited stands as a trusted manufacturer and exporter of ABS sheets in Gujarat, India. With a commitment to quality, innovation, and customer satisfaction, Singhal Industries continues to lead the way in providing reliable ABS sheet solutions to clients across industries and markets. Choose Singhal Industries as your partner for ABS sheets, and unlock the endless possibilities of this versatile material for your next project.

Frequently Asked Questions (FAQs):

Q1: What are the typical applications of ABS sheets?

A1: ABS sheets find applications in various industries, including automotive, electronics, appliances, construction, and signage. They are commonly used for manufacturing components such as dashboards, trim panels, housings, enclosures, and display signage.

Q2: How are ABS sheets manufactured?

A2: ABS sheets are typically manufactured through a process called extrusion, where molten ABS resin is forced through a die to form a continuous sheet. The sheet is then cooled and cut to the desired size and thickness.

Q3: Are ABS sheets recyclable?

A3: Yes, ABS sheets are recyclable and can be processed into new products through mechanical recycling methods. Recycling ABS helps conserve resources and reduce waste sent to landfills.

Q4: How can Singhal Industries assist in selecting the right ABS sheets for specific applications?

A4: Singhal Industries provides technical support and expertise to help customers select the appropriate ABS sheets based on their requirements. With a team of experienced professionals and a focus on customer satisfaction, Singhal Industries offers guidance on material properties, fabrication techniques, and product specifications.

0 notes

Text

High-Frequency Welder Market Sees High Growth Backed by Dominant Trend | GQ Research

The High-Frequency Welder market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global High-Frequency Welder market showcased a significant presence, boasting a valuation of US$ 14.26 Billion. This underscores the substantial demand for High-Frequency Welder technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-high-frequency-welder-market/

Projected Growth: Projections suggest that the High-Frequency Welder market will continue its upward trajectory, with a projected value of US$ 20.34 Billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.30 %, reflecting a steady and robust growth rate for the High-Frequency Welder market over the coming years.

Technology Adoption: In the High-Frequency Welder Market, cutting-edge technologies are transforming traditional welding processes. Advanced high-frequency welding equipment and automation solutions are increasingly adopted, enhancing precision, speed, and efficiency in various welding applications.

Application Diversity: The High-Frequency Welder Market exhibits remarkable application diversity, spanning industries such as automotive, construction, aerospace, and manufacturing. From tube welding to sealing and embossing, high-frequency welders cater to a wide range of applications, offering versatility and adaptability to different production needs.

Consumer Preferences: Consumer preferences in the High-Frequency Welder Market are shifting towards welders that offer superior quality, reliability, and efficiency. There is a growing demand for welders equipped with advanced features such as real-time monitoring, automatic adjustment, and easy operation, aligning with the need for enhanced productivity and cost-effectiveness.

Technological Advancements: Continuous technological advancements drive innovation in the High-Frequency Welder Market. From the development of new welding techniques to the integration of digital controls and IoT connectivity, these advancements enhance weld quality, process control, and overall performance, leading to increased efficiency and competitiveness.

Market Competition: Intense competition among high-frequency welder manufacturers fuels innovation and drives product development. Companies strive to differentiate themselves through superior technology, reliability, and customer service, leading to a dynamic market environment characterized by rapid innovation and continuous improvement.

Environmental Considerations: Environmental sustainability is gaining importance in the High-Frequency Welder Market. Manufacturers are increasingly focusing on energy-efficient designs, eco-friendly materials, and waste reduction strategies to minimize their environmental impact. Additionally, the use of recyclable materials and compliance with environmental regulations are becoming key considerations in purchasing decisions.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Thermatool Corp.

Rollform India

Taicang Global Machinery

Sifang Sanyi

Chenguan Technology

NIRMAL OVERSEAS PRIVATE LTD.

Zemat Technology Group

INDUCTOTHERM GROUP

Surya Electric

HEBEI SANSO MACHINERY

Liaoning Unify High-Frequency Equipment

The research report provides a comprehensive analysis of the High-Frequency Welder market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-high-frequency-welder-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

#highfrequencywelders hashtag#electricalmanufacturing hashtag#machinerymanufacturing hashtag#industrialmanufacturing hashtag#marketgrowth

0 notes

Text

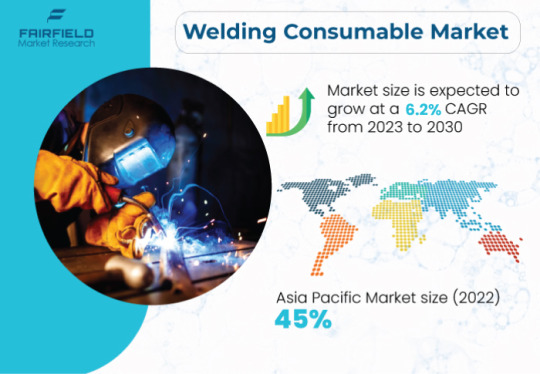

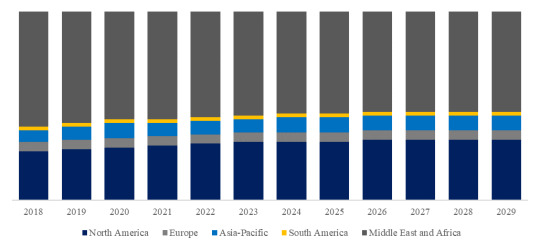

Welding Consumables Market Size, Status, Top Emerging Trends, Growth and Business Opportunities 2030

Global welding consumables market is set to witness substantial growth in the coming years, with projections indicating a rise from US$12.6 billion in 2022 to a staggering US$19.2 billion by the year 2030. This forecasted growth represents a robust Compound Annual Growth Rate (CAGR) of 6.2% between 2023 and 2030, driven by various key trends and determinants.

Key Trends Fueling Market Growth

Growing Demand from Construction and Automotive Industries: The welding consumables market is experiencing a surge in demand, particularly from the construction and automotive sectors. Technological advancements in welding processes are enhancing efficiency and quality, making welding consumables indispensable in these industries.

Rapid infrastructure projects in developing economies and the expansion of the aerospace industry are creating lucrative opportunities for welding consumables.

Technological Advancements Driving Innovation: Continuous innovation in welding technologies, including automation, robotics, and the development of advanced materials, is revolutionizing the industry. These advancements are improving the efficiency, precision, and safety of welding processes, driving market expansion.

Integration of automation, robotics, and Artificial Intelligence (AI) in welding systems is streamlining operations and increasing productivity.

Shift Towards Environmentally Friendly Practices: With a growing emphasis on sustainability, manufacturers are developing eco-friendly welding consumables to comply with environmental regulations. This trend is reshaping the market landscape and driving further innovation in the sector.

Smart welding consumables equipped with sensors and IoT capabilities enable real-time monitoring of weld quality, ensuring compliance with industry standards.

Major Growth Determinants

Pacing Infrastructural Development: The global focus on infrastructural development and rapid urbanization is a significant driver propelling the welding consumables market. Increased investments in construction projects and the automotive sector are driving demand for welding consumables.

Growing Emphasis on Sustainable Practices: Environmental regulations and concerns about the ecological impact of welding processes are driving the development of eco-friendly welding consumables. Manufacturers are investing in research and development to create consumables with reduced emissions and energy consumption.

Key Growth Barriers

High Raw Material Costs and Price Volatility: Fluctuations in the prices of metals, fluxes, and gases, essential components of welding consumables, pose a significant challenge to market players. Economic uncertainties and geopolitical factors contribute to price volatility, impacting profit margins.

Stringent Regulatory Compliance: Meeting stringent environmental regulations and industry standards requires significant investments in research and development. Varying standards across regions and industries add complexity and costs to manufacturers, potentially affecting competitiveness.

Opportunities to Look at

Rapid Adoption of Automation and Robotics: Industries are increasingly integrating robotic welding systems for higher precision and efficiency. Brands are likely to capitalize on this trend by offering compatible consumables and specialized training.

Focus on Environmentally Friendly Consumables: The shift towards eco-friendly welding consumables is on the rise, driven by stringent environmental regulations worldwide. Brands will focus on sustainable products, catering to environmentally conscious consumers and complying with regulations.

Digitalization and IoT Integration: Smart welding consumables embedded with sensors and IoT capabilities enable real-time monitoring and data analysis. Brands are likely to invest in advanced IoT integration, offering predictive maintenance services and enhancing customer experiences.

Regional Outlook

Asia Pacific: With robust industrial growth and extensive infrastructural developments, Asia Pacific remains the largest revenue-contributing region in the global welding consumables market. The region's large-scale construction projects drive significant demand for welding consumables.

North America: Significant growth is expected in North America, driven by technological advancements, innovation in welding processes, and a focus on automation and eco-friendly consumables. The region's highly developed industrial sector fuels demand for high-quality welding consumables.

Competitive Landscape

In the competitive landscape, differentiation through product innovation and quality remains pivotal. Manufacturers are investing heavily in research and development to create cutting-edge welding consumables, with a focus on sustainability and digitalization.

Leaders in Global Welding Consumables Space

Bavaria Schweisstechnik Gmbh

Carboweld Schweissmaterialien Gmbh

Colfax Corporation

Corodur Verschleiss-Schutz Gmbh

Daiko Welding Consumables

And more...

For more information: https://www.fairfieldmarketresearch.com/report/welding-consumables-market

1 note

·

View note

Text

Semi lowbed Trailer Builders in India

Semi lowbed Trailer Builders in India

VST coreB Trailers, was founded in 2018 by Mr. Sitaram Yadav, Founder Chairman of the VST United Group. VST coreB Trailers is one of the biggest brands of trailers and truck bodies in India. The manufacturing of several Articulated and Rigid categories Trailers, Tipping Trailers, Bulkers, Containers, Tankers etc. began operation in 2019. Click for more knowing truck trailer manufacturers in india

Our headquarters in Kotput, Rajasthan, has a monthly production capacity of 600 trailers. Currently we are producing 450–500 units per month and delivering across India. Providing best quality, our devoted RD team conducts the greatest research possible on product development. Click now truck body manufacturers

We have a production area of more than 4 lac square feet, 720 onsite engineers, and 905 people overall in India. More than 6150 satisfied customers use VST coreB’s B28 and B2C products And services in the Indian market. Read more truck trailer body building

VST CoreB Trailers in one of the biggest brands of trailers and truck bodies in India. With a present Production capacity of 600 trailers per month and more than 6150 happy clients, the company is fairly optimistic about its future growth potential in India and globally. Click now truck trailer company

To continually follow the highest quality standards. Become India’s first choice company in Trailers Manufacturing. Supply best in-class and quality products to global partners. Provide customized Products to clients that accelerate their enterprise and be their most trust-worthy go-to partner. Click for more knowing Manufacturer of Rock Body Tipper Trailers

We are Equipped with epic infrastructure (CNC, Robotic welding and automated machineries with emerging technologies) to design and develop customized vehicles, which can be fabricated for industrial and commercial transport solution. Click now truck body manufacturers near me

By 2023, we expect to sell and produce across PAN India with additional production facilities in four new states. Click now list of trailer manufacturers in india

VST coreB is ISO 9001:2015 certified company and our designs are approved by international centre for automotive technology (ICAT) authorities. VST coreB is best known for quality and eco friendly brand. Read more Semi lowbed Trailer Builders in India

VST CoreB Trailers in one of the biggest brands of trailers and truck bodies in India. With a present Production capacity of 600 trailers per month and more than 6150 happy clients, the company is fairly optimistic about its future growth potential in India and globally. Click for more knowing Tipping Trailers Manufacturer in India

To continually follow the highest quality standards. Become India’s first choice company in Trailers Manufacturing. Supply best in-class and quality products to global partners. Provide customized Products to clients that accelerate their enterprise and be their most trust-worthy go-to partner. Click now Tipper Trucks manufacturers in india

By 2025, we hope to establish a global business with operations in Asia, the Middle East, and Africa, With a monthly production capacity of 1300–1400 trailers. Quality is a major concern for Indian as Well international transporters, because they are currently implementing a new ecosystem and Prefer to cut operational costs over onetime charges. Read more Box Body Tipper Trailer Fabrication Manufactures

VST coreB to produce high-quality, cutting Edge trailers with all necessary safety features for the Indian, Bangladesh, Nepal, African, and South American markets.

VST CoreB Trailers is one of the biggest brands of trailers and truck bodies in India. With a present production capacity of 600 trailers per month and more than 6150 happy clients.

0 notes

Text

Helium Purification Technology, Global Market Size Forecast, Top 12 Players Rank and Market Share

Helium Purification Technology

Helium purification technology involves processes and methods used to obtain high-purity helium gas by removing impurities and contaminants from helium sources. Helium is a valuable industrial gas with various applications, including cryogenics, welding, cooling for superconducting magnets, and analytical instrumentation. Purifying helium is crucial to meet specific purity requirements for these applications.

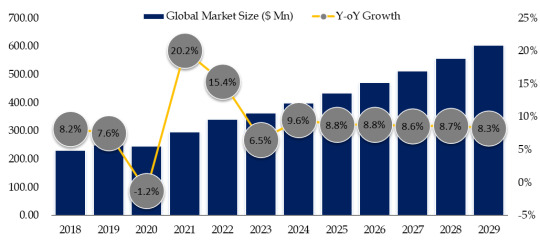

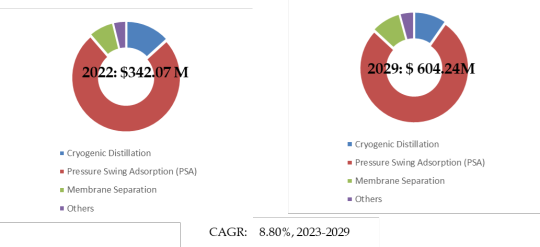

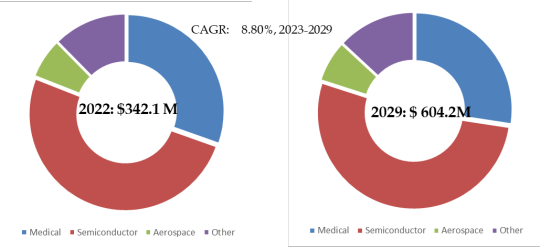

Helium Purification Technology Market Summary

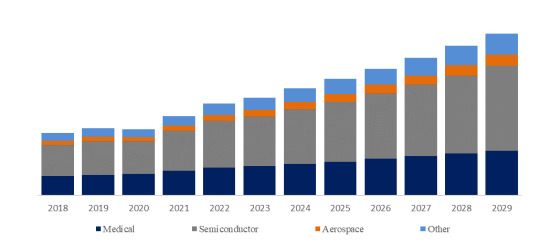

According to the new market research report "Global Helium Purification Technology Market Report 2023-2029", published by QYResearch, the global Helium Purification Technology market size is projected to grow from USD 364.36 million in 2023 to USD 604.24 million by 2029, at a CAGR of 8.80% during the forecast period.

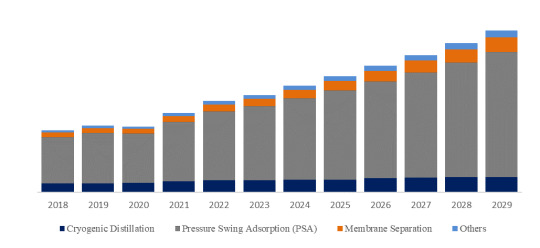

Figure. Global Helium Purification Technology Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

Market Drivers:

Growing Demand for High-Purity Helium:

Industries such as aerospace, semiconductor manufacturing, healthcare (MRI machines), and scientific research require high-purity helium for various applications. The increasing demand for high-purity helium is driving the need for efficient helium purification technologies.

Rising Applications in Healthcare Sector:

The healthcare sector, particularly in magnetic resonance imaging (MRI) machines, relies heavily on helium for cooling. As the healthcare sector continues to grow, the demand for high-quality and pure helium in healthcare applications is expected to rise, driving the need for advanced helium purification technologies.

Expanding Use in Semiconductor Manufacturing:

Helium is a critical component in the semiconductor manufacturing process, where high-purity helium is essential for various applications like cooling during the manufacturing of semiconductors. As the semiconductor industry continues to grow, so does the demand for purified helium.

Restraint:

Energy Intensive Processes:

Helium purification often involves energy-intensive processes, especially when dealing with cryogenic temperatures. The need for cooling and maintaining low temperatures during purification contributes to higher energy consumption, which can be a significant drawback.

Complexity and Cost of Equipment:

Helium purification setups can be complex and require specialized equipment. The complexity and cost of such equipment can pose a restraint, especially for smaller facilities or organizations with limited budgets.

Cost of Helium Extraction and Production:

The cost associated with extracting and producing helium, which forms the basis for purification, can be relatively high. Fluctuating helium prices and the cost of extraction from natural gas fields can impact the overall economics of helium purification.

Opportunity:

Increasing Demand for High-Purity Helium:

The demand for high-purity helium continues to rise, particularly in critical applications such as aerospace, healthcare (MRI machines), semiconductor manufacturing, and scientific research. Helium purification technology provides a valuable opportunity to meet this growing demand.

Advancements in Purification Techniques:

Ongoing advancements in purification techniques, including membrane separation, adsorption, and cryogenic distillation, create opportunities to enhance the efficiency and cost-effectiveness of helium purification processes. Improving these techniques can lead to higher purity levels and increased demand.

Cryogenic and Gas Processing Industry Growth:

The growth of the cryogenic and gas processing industry, which relies heavily on helium, offers a significant opportunity for helium purification technology. Helium is crucial in cryogenics for applications like superconducting magnets and liquefied natural gas (LNG) production.

Figure. Helium Purification Technology, Global Market Size, The Top Five Players Hold 64.45% of Overall Market

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

This report profiles key players of Helium Purification Technology such as Linde, Sumitomo Chemicals, Air Products, Air Liquide, Entegris. In 2022, the global top five Helium Purification Technology players account for 64.45% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Helium Purification Technology.

Figure. Helium Purification Technology, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

In terms of product type, Pressure Swing Adsorption (PSA) is the largest segment, hold a share of 75.43%.

Figure. Helium Purification Technology, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

In terms of product application, Semiconductor is the largest application, hold a share of 55.55%.

Figure. Helium Purification Technology, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

Figure. Helium Purification Technology, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Helium Purification Technology Market Report 2023-2029.

About The Authors

Zixin Lin - Lead Author

Email: [email protected]

Ms. Lin, she joined QYResearch in 2021 and has 3 years of industry research experience. She mainly studies semiconductors and electronics, energy and power, and automation and process control markets. She utilizes her technical knowledge to provide insight into the electronics industry.

QYResearch简介

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch has been a reliable source for end-to-end market research needs of businesses. The report coverage at QYResearch is massive and unlocks an access to hundreds of key industry verticals and thousands of micro markets. When it comes to ready-to-purchase research, our clients can select from a huge repository. Custom research and pre-booked reports have also been the popular offerings of QYResearch.

0 notes

Text

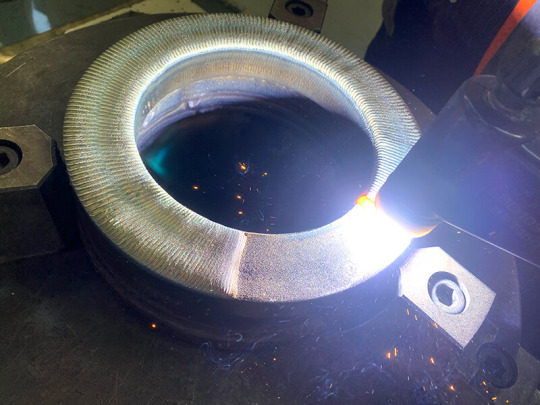

Deewi Automation-Pioneering the Future of Manufacturing with Cutting-Edge Solutions

Since its establishment in 2009, Deewi Automation has quickly become a beacon of innovation in the field of integrated automation equipment. As a pioneer in our field, we are committed to pushing global manufacturing to new heights of efficiency and intelligence. Our product lines, including cutting-edge weld overlay machines, plasma cladding, laser cladding machines, automated weld overlays, micro-plasma welding, thermal spray systems, and custom CNC machines, are engineered to meet our customers' evolving needs. Whether you are looking for a stand-alone unit or a complete integrated system, Deewi has everything you need.

At the heart of Deewi is a bold and transformative vision - to lead breakthroughs in automation technology and elevate manufacturing to unprecedented levels of efficiency and intelligence. Our commitment to continued technological innovation is more than a business strategy; it is our commitment to the future. By cultivating a culture of creativity and precision, we strive to be at the forefront of the automation revolution, delivering solutions that are not only innovative but also reliable and cost-effective.

In a highly competitive market, Deewi's distinction is not only our advanced technology products, but also our unwavering commitment to innovation, precision, reliability, and our core values of putting customers first. These guiding principles shape every aspect of our operations, ensuring that we always provide the highest quality products and services to our valued customers. It is this dedication to excellence that has made Deewi Automation a trusted name in the automation industry.

The cornerstone of Deewi's success is our outstanding team of engineers. With 7 industry-leading professionals, including senior experts with more than 20 years of experience, our team of engineers represents the pinnacle of expertise covering the fields of welding and CNC machining. Their deep knowledge and innovative approach enable us to deliver complex technical solutions to the specific challenges faced by our customers in multiple industries including valves, petroleum, medical, aerospace, and electronics.

We know that excellent products come from strict quality control. Therefore, Deewi has implemented a strict three-step quality inspection (QC) process, from the incoming inspection of raw materials, monitoring of each link in the production process, to the factory testing of the final product, every step is strictly controlled. This meticulous attention ensures that our equipment not only meets industry standards but also delivers unrivaled performance and durability.

Furthermore, we believe that excellent after-sales service is an integral part of our products. Therefore, we are committed to providing lifetime support for our products, and our customer service team is always ready to respond to provide fast, professional technical support and maintenance services. Whether you have installation issues, operational questions or need technical advice, Deewi will work with you to ensure your equipment runs smoothly and extends its service life.

Choosing Deewi Automation means choosing a partner with a top-notch engineering team, strict quality control system, and lifelong after-sales service commitment. We are here not only to manufacture industry-leading automation equipment but also to support and promote your business success.

1 note

·

View note

Text

Exploring Market Size and Share Trends Across Laser Welding Machine Industry Verticals

Laser welding machine market Overview:

In 2022, the laser welding machine market size was estimated to be USD 0.9 billion. The market for laser welding machines is expected to expand at a compound annual growth rate (CAGR) of 4.90% between 2023 and 2032, from an estimated USD 0.94 billion in 2023 to USD 1.38 billion by 2032.

Laser welding machines have emerged as indispensable tools in modern manufacturing, offering unparalleled precision, speed, and efficiency in joining metal components. The global laser welding machine market has experienced significant growth driven by advancements in laser technology, increasing demand for high-quality welds, and the adoption of automation in manufacturing processes. This article provides a comprehensive overview of the laser welding machine market, including segmentation analysis, key takeaways, and regional insights.

Get a free sample report of Laser welding machine market

By Segmentation:

1. Technology Type:

a. Fiber Laser Welding Machines: These machines utilize fiber-optic cables to deliver laser energy, offering high beam quality, flexibility, and reliability for precise welding in various applications.

b. CO2 Laser Welding Machines: CO2 lasers generate laser beams using carbon dioxide gas, providing versatility and power for welding thick materials and intricate designs in industries such as automotive, aerospace, and electronics.

c. Solid-State Laser Welding Machines: Solid-state lasers, including Nd:YAG (neodymium-doped yttrium aluminum garnet) and disk lasers, offer high energy density and beam quality, suitable for precision welding in medical devices, jewelry, and electronics.

2. Application:

a. Automotive: Laser welding machines play a crucial role in automotive manufacturing, facilitating the production of lightweight, durable components such as body panels, exhaust systems, and battery packs.

b. Aerospace: The aerospace industry utilizes laser welding for joining complex structures, engine components, and aircraft assemblies with high precision and reliability to meet stringent safety and performance standards.

c. Electronics: Laser welding is widely employed in electronics manufacturing for soldering, encapsulation, and assembly of microelectronics, PCBs (printed circuit boards), sensors, and consumer electronics.

d. Medical Devices: Medical device manufacturers rely on laser welding for producing implants, surgical instruments, and medical equipment with biocompatible materials and precise weld seams to ensure patient safety and efficacy.

3. Region:

The laser welding machine market is segmented into key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Each region exhibits unique market dynamics influenced by factors such as industrialization, technological adoption, regulatory environment, and end-user industries.

Key Takeaways:

1. Precision and Quality: Laser welding machines offer superior precision, minimal heat-affected zones, and high weld quality, enabling manufacturers to achieve tight tolerances, intricate designs, and defect-free welds in various materials.

2. Increased Efficiency and Productivity: The speed, automation capabilities, and repeatability of laser welding machines contribute to higher throughput, reduced cycle times, and cost savings in production processes compared to traditional welding methods.

3. Adoption of Additive Manufacturing: Laser welding machines are increasingly integrated into additive manufacturing (3D printing) systems for metal deposition, rapid prototyping, and production of complex geometries with high structural integrity and material purity.

4. Growing Demand for Fiber Lasers: Fiber laser welding machines are gaining popularity due to their compact size, energy efficiency, and suitability for high-speed, high-volume production in industries such as automotive, electronics, and metal fabrication.

Regional Insights:

1. North America: The United States leads the North American laser welding machine market, driven by robust demand from automotive, aerospace, and electronics sectors, coupled with investments in research and development for advanced manufacturing technologies.

2. Europe: Germany, Italy, and the UK are key markets in Europe, characterized by a strong manufacturing base, adoption of Industry 4.0 technologies, and emphasis on quality and innovation in automotive, aerospace, and medical device industries.

3. Asia Pacific: China, Japan, and South Korea dominate the Asia Pacific market, fueled by rapid industrialization, infrastructure development, and growing investments in automotive, electronics, and medical device manufacturing, driving demand for laser welding machines.

4. Latin America and the Middle East & Africa: These regions offer growth opportunities for laser welding machine manufacturers due to increasing investments in infrastructure projects, automotive production, and industrial development, particularly in emerging economies such as Brazil, Mexico, and South Africa.

The laser welding machine market continues to evolve with advancements in laser technology, increasing automation, and growing demand for high-quality welding solutions across industries. Manufacturers, suppliers, and end-users need to embrace innovation, adapt to changing market dynamics, and leverage regional opportunities to stay competitive and drive sustainable growth in the dynamic laser welding machine market. With a focus on precision, efficiency, and quality, laser welding technology is set to illuminate the future of manufacturing worldwide.

Top trending report:

Gaskets and Seals Market

Hydraulic Cylinder Market

Compressed Air Treatment Equipment Market

Commercial Refrigeration Equipment Market

Food Service Equipment Market

Industrial Dust Collector Market

0 notes