#precision cnc machined parts supplier

Text

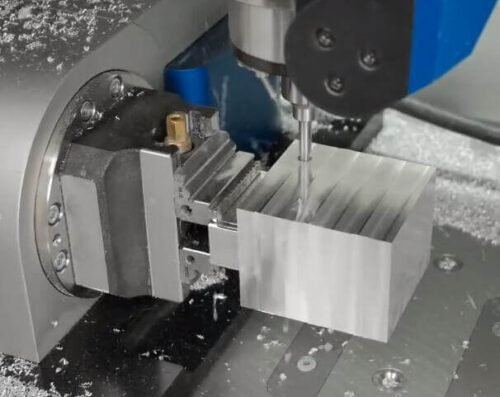

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

MxmParts, a trusted CNC machining parts supplier from China, specializes in offering a comprehensive Swiss Type CNC Machining service for precision machine parts. With advanced CNC lathes such as combination Mill Turn CNC and Swiss type CNC lathe, MxmParts provides a wide range of precision machining capabilities, ensuring the production of small and large machined parts with the highest level of accuracy.

MxmParts offers the machining of various materials, including but not limited to steel and brass, through their precision CNC turning service. Their commitment to crafting parts that meet the highest standards ensures that customers receive quality machined parts that align with their specifications.

The Swiss Type CNC Machining service by MxmParts caters to industries requiring precision machine parts, including but not limited to automotive, aerospace, medical, and electronics. Through their expertise in precision CNC turning, MxmParts serves as a reliable supplier for companies seeking high-quality machined parts for diverse applications.

For further details and inquiries about the Swiss Type CNC Machining service for precision machine parts, provided by MxmParts from China, you can visit their official website at [mxmparts.com](https://www.mxmparts.com/) or get in touch with them directly through their contact information.

For more information, MxmParts can be reached at [[email protected]](mailto:[email protected]).

Using ChatG : Unlimited AI Chatbot

Entire Chat Link: www.brutusai.com/c/ycAzPJnaPSYTCODnfnvTy004sZu1/064a4be4-3010-4718-b874-4204f94d9709

#Swiss Type CNC machining China#china supplier#cnc turning#CNC parts China#precision CNC Turning parts#precision machine parts#precision turned parts#precision CNC machining#precision CNC Turning#mxmparts#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#steel Parts machining#ball Studs

0 notes

Text

Discover the essential factors for choosing the right CNC machining supplier in the USA. Dive into considerations like product quality, precision, costing, industry experience, on-time delivery, and customer support. Learn valuable tips to make an informed decision and explore a leading CNC machining manufacturer, Brogan & Patrick, with a proven track record in delivering high-quality CNC machined parts across diverse industries.

#CNC Machining#Machined Parts#CNC Supplier#Precision Manufacturing#Industry Experience#Customer Support#Manufacturing Technology#Supplier Selection

1 note

·

View note

Text

3 Points Should Consider for Finalizing a CNC Precision Machining Parts Supplier

As a manufacturer, you may have a lot of confusion before starting production of precision machined components. It may be in the form of the type of material choice—titanium or plastic, for example. And which process is applicable for fulfilling your demands?

These questions will end up leading you to the right CNC precision machining parts supplier, right? This supplier recommends a relevant strategy, material choice, operational work, and deadlines to finish this manufacturing procedure.

Then, what is the challenge you will face ahead? It is finding an appropriate supplier who offers every service for the production of precision machined components. How do you identify a suitable supplier for your needs? This blog post will give a closer look at how to get this work done. Read it to the end.

Communication

Keep all problems to yourself. Settle down by discussing the main questions with your CNC precision machining parts supplier. For instance, what will be the deadline for your projects? Get from them recommendations on material choice and go through their experience, skills, and expertise.

These factors are significant to ask about before dealing with any supplier because each CNC machine shop serves its purposes. Manufacturing dealers may be capable of resolving these issues, or you may not want to consider them. And notice how good a communication channel is, whether it is through video or photo updates or any other.

Quality

Quality control completely relies on the skills and training of operational staff. An appropriate facility must contain a team of skilled machinists to serve design purposes and ensure customer satisfaction. They should know about serviced machines, tool utilization, and many other functionalities from precision machined components.

Social Proof

Branded and well-known suppliers have their digital images to justify their works or portfolios. You should evaluate the social media profiles and websites of these dealers to shortlist one of them.

0 notes

Text

MAIJIN

Maijin is specialized in all various custom-made CNC machining parts and CNC milling parts as well as non standard fasteners.

Our Business Address: 10F, 9 Building Block B, Bao Neng Science and Technology Park, NO.1 Qing Xiang Rd, Long Hua District, Shen Zhen City, China.

Contact: +86-755-28079075/ +86-755-28079546

Visit Us: https://www.chinamaijin.com/

Keyword: precision turned parts, cnc machining parts supplier, machining parts manufacturer, machining parts supplier, cnc turned parts manufacturer

Category: hardware

Follow Us on:

https://twitter.com/DanielXian7

#precision turned parts#cnc machining parts supplier#machining parts manufacturer#machining parts supplier#cnc turned parts manufacturer

1 note

·

View note

Text

CNC Machined/Turned Parts & Swiss Turn Parts Manufacturer, Exporters & Suppliers in India

Vijay Industries is a leading cnc machined parts, cnc turned parts, swiss turn parts, sub assembly, swiss turned components, pressure & gravity die cast parts, precision machined parts, sand casting parts and investment casting parts Manufacturer, Exporters & Suppliers in India, USA, Germany, UK, France, Italy, Switzerland. Call: +91- 9376186396 or mail us [email protected]

2 notes

·

View notes

Text

What are the Specifications of Customized CNC Machined Hastelloy?

Hastelloy is a group of nickel-based alloys known for their exceptional corrosion resistance and high strength, making them ideal for demanding applications. Customized CNC machining of Hastelloy involves creating components with precise specifications to meet specific requirements. Here are five key points about the specifications of customized CNC machined Hastelloy:

1. Material Grade Selection

Hastelloy comes in various grades, each with unique properties suitable for different environments and applications. The most commonly used grades include Hastelloy C-276, Hastelloy X, and Hastelloy B-2. Choosing the right grade is crucial as it determines the alloy's resistance to corrosion, oxidation, and high temperatures. The selection process takes into account factors like chemical exposure, operating temperatures, and mechanical stresses.

2. Dimensional Precision

Customized CNC machining ensures that Hastelloy components are produced with high precision, adhering to strict dimensional tolerances. This precision is vital for parts that need to fit seamlessly into complex assemblies or perform reliably under extreme conditions. CNC machines can achieve tolerances as tight as ±0.001 inches, ensuring that each component meets the exact specifications required for its application.

3. Surface Finish

The surface finish of machined Hastelloy components is another critical specification. A smooth surface finish is often required to enhance the corrosion resistance of the alloy and improve its performance in harsh environments. CNC machining can achieve various surface finishes, from rough to highly polished, depending on the specific needs of the application. Common finishing techniques include grinding, polishing, and bead blasting.

4. Complex Geometries

One of the significant advantages of CNC machining is its ability to produce complex geometries with high accuracy. Hastelloy components often feature intricate designs that are essential for their functionality in specialized applications. CNC machines can create detailed features such as internal channels, threads, and undercuts that would be challenging or impossible to achieve with traditional machining methods.

5. Customization and Prototyping

CNC machining allows for extensive customization of Hastelloy components. This flexibility is beneficial for prototyping new designs or producing small batches of parts tailored to specific requirements. Engineers can quickly iterate on designs, making adjustments based on testing and performance feedback. This capability speeds up the development process and ensures that the final product meets all performance criteria.

Conclusion

Customized CNC machined Hastelloy components are essential in applications that demand high precision, complex geometries, and superior material properties. By selecting the appropriate grade, ensuring dimensional precision, achieving the desired surface finish, and leveraging CNC machining's capability for intricate designs, engineers can produce components that perform reliably in the most challenging environments. For those seeking a reliable supplier for hastelloy machining, Marine Techq offers expertise and quality service in delivering customized CNC machined Hastelloy parts tailored to meet your specific needs.

0 notes

Text

The Impact of OEM Services on Supply Chain Management

Outsourcing has become an integral part of modern business practices, with companies relying on external partners to provide goods or services that they require. One area that has seen a significant rise in outsourcing is Original Equipment Manufacturer (OEM) services. These services involve the production of components and products for other companies to use in their final product. In this article, we will explore the impact of OEM services on supply chain management and how it has revolutionized the way products are made.

Understanding OEM Services

OEM services are a type of outsourcing that allows companies to focus on their core competencies while leaving the production of parts and components to external partners. This is especially common in industries such as automotive, aerospace, and electronics, where the final product consists of various parts from different suppliers. These suppliers are known as original equipment manufacturers or OEMs.

The Benefits of OEM Services

The rise of OEM services has brought numerous benefits to both manufacturers and customers. For manufacturers, outsourcing the production of parts and components means that they can focus on their core competencies, leading to increased efficiency and cost savings. It also allows them to expand their product offerings without investing in new equipment or facilities. Customers, on the other hand, benefit from lower costs and increased flexibility as they can choose from a wider range of suppliers for their required parts.

Impact on Supply Chain Management

Traditionally, supply chain management involved managing the flow of materials and products from raw materials to finished goods. With the introduction of OEM services, this model has evolved to include managing relationships with external partners. This has led to a more integrated supply chain, with manufacturers working closely with their OEM partners to ensure smooth production and delivery of products.

Metal Machining and OEM Services

One key aspect of OEM services is metal machining, which involves shaping metal parts through various processes such as cutting, drilling, milling, and turning. This process is essential in the production of many products, from car engine parts to computer components. With the increasing demand for precision and efficiency, metal machining has become a vital component of OEM services.

Advancements in Technology

The growing popularity of OEM services has also led to advancements in technology within the metal machining industry. Computer Numerical Control (CNC) machines, for example, have revolutionized the manufacturing process by allowing for more precise and efficient production. This has not only improved the quality of products but also reduced production costs for both manufacturers and customers.

Specialized Expertise

OEM services also offer specialized expertise in metal machining processes, ensuring that products are manufactured to meet specific requirements and standards. This is especially important in industries such as aerospace or medical, where precision and quality are paramount. By partnering with OEM service providers, manufacturers have access to a team of experts who can provide valuable insights and techniques for metal machining.

Streamlined Supply Chain

Outsourcing metal machining services through OEM partners also helps streamline the supply chain. Instead of managing multiple suppliers for different parts and components, manufacturers can rely on one OEM service provider to handle all their metal machining needs. This not only saves time and resources but also ensures consistency in product quality.

Cost-Effective Solutions

OEM services also offer cost-effective solutions for metal machining. By leveraging their expertise and economies of scale, OEM partners can provide competitive pricing for high-quality products. This is especially beneficial for smaller manufacturers who may not have the resources to invest in expensive machinery or a dedicated team for metal machining.

Innovative Technology

OEM service providers often have access to the latest and most advanced technology for metal machining. This allows them to offer innovative solutions that can improve product quality, reduce production time, and increase efficiency. By partnering with OEMs, manufacturers can stay competitive in their industry without having to invest in expensive equipment or constantly upgrade their technology.

Collaboration and Customization

OEM service providers work closely with manufacturers to understand their specific needs and requirements. This collaboration allows for customized solutions that meet the exact specifications of each product. Whether it's a unique component or a specialized material, OEM partners can provide tailored metal machining services to ensure the final product meets all necessary standards.

Conclusion

In Ontario, OEM services and metal machining have become essential pillars for manufacturers striving to streamline operations, cut costs, and maintain a competitive edge. These OEM services in Ontario provide a one-stop solution, offering advanced technology, customization capabilities, and cost-effective solutions that are integral to the success of any manufacturing operation. It's evident that the benefits of partnering with an OEM service provider for metal machining in Ontario are manifold – from ensuring consistency in product quality to enabling manufacturers to adapt to the ever-evolving technological landscape without hefty investments. In this highly competitive industrial scenario, such partnerships can indeed be the key to unlocking increased efficiency and growth.

Choose the best in OEM services Ontario has to offer. Streamline your metal machining Ontario needs with our exceptional quality, efficiency, and dedication to your success. Act now!

0 notes

Text

Linear Sliding Tables: Enhancing Precision

Linear Sliding Tables: Enhancing Precision and Efficiency

Linear sliding tables play a crucial role in various industrial and manufacturing applications. These versatile devices facilitate precise linear motion, making them essential components in machine tools, assembly lines, robotic systems, and more. In this article, we’ll explore the key features, benefits, and applications of linear sliding tables.Get more news about Get more news about linear sliding table suppliers,you can vist our website!,you can vist our website!

1. What Are Linear Sliding Tables?

Linear sliding tables consist of a rigid base and a movable carriage that slides along a linear guide. The guide can be a ball screw, a linear rail, or other precision mechanisms. The carriage typically holds the load (workpiece, tool, or other components) and moves smoothly along the guide. These tables provide controlled linear motion in one or more axes.

2. Features and Benefits:

Precision: Linear sliding tables offer high positional accuracy, making them ideal for tasks that require precise positioning.

Smooth Motion: The ball bearings or other sliding mechanisms ensure smooth and low-friction movement.

Load Capacity: Tables come in various load capacities, allowing customization based on application requirements.

Compact Design: Linear tables are compact and space-efficient, fitting seamlessly into tight spaces.

Versatility: They can be used in X-Y stages, Z-axis lifts, and other configurations.

Maintenance: Proper lubrication ensures long-lasting performance with minimal maintenance.

3. Applications:

Machine Tools: Linear tables enable precise movement in CNC machines, lathes, and milling machines.

Assembly Lines: They facilitate automated assembly processes by positioning components accurately.

Robotics: Linear sliding tables are integral to robotic arms, allowing them to reach specific points with precision.

Laboratory Equipment: Scientific instruments, such as spectrometers and microscopes, use linear tables for sample positioning.

Consumer Products: Printers, 3D printers, and other devices incorporate linear motion for smooth paper feed or part alignment.

Conclusion:

Linear sliding tables enhance efficiency, accuracy, and productivity across various industries. Whether you’re designing a new system or upgrading existing equipment, consider the benefits of incorporating these versatile components.

0 notes

Text

Unleashing Creativity: Exploring CNC Machining and Laser Cutting in Toronto and Beyond

Plastics Source, a leading supplier of plastic materials across the UK, ventures across the pond to explore the exciting world of CNC machining and laser cutting in Toronto, Canada. This comprehensive guide delves into the capabilities of these technologies, explores the vibrant acrylic sheet market in Calgary, and sheds light on the creative potential of colored plexiglass.

Toronto’s Thriving Hub for CNC Machining and Laser Cutting

Toronto boasts a thriving community of fabrication companies adept at CNC Toronto and laser cutting. These technologies offer unparalleled precision and versatility, making them ideal for crafting unique products and components from various materials, including:

Acrylic

Wood

Metals

Plastics

CNC Machining: Precise Control for Complex Designs

CNC laser cutting utilizes computer numerical control to meticulously guide cutting tools, enabling the creation of intricate shapes and features on a workpiece. This technology is particularly suited for:

Prototyping

Manufacturing custom parts

Engraving

Milling

Drilling

Laser Cutting: Focused Light for Clean and Accurate Cuts

Laser cutting employs a concentrated beam of light to melt or vaporize material along the desired cutting path. This method results in:

Clean, precise cuts

Minimal heat-affected zones

Ability to handle intricate designs

Suitability for a wide range of materials

Calgary’s Allure: A Look at the Acrylic Sheet Market

Calgary offers a vibrant market for acrylic sheets, commonly known by brand names like Plexiglass Calgary. Acrylic’s unique properties, including:

Exceptional clarity

Impact resistance

Lightweight nature

Ease of fabrication

Make it a popular choice for diverse applications such as:

Signage

Point-of-purchase displays

Furniture components

Shelving

Machine guards

The Allure of Colored Plexiglass: Red Hot Designs

Red plexiglass sheets inject a burst of vibrancy into any project. This fiery hue is perfect for:

Eye-catching signage

Retail displays

Art installations

Traffic control signs

Decorative elements

The Tranquility of Blue Plexiglass Sheets: A Soothing Choice

Blue plexiglass sheets exude a sense of calmness and serenity. This cool tone finds applications in:

Signage for healthcare facilities

Aquarium components

Decorative lighting fixtures

Furniture accents

Pool and spa enclosures

Beyond the Rainbow: A Spectrum of Creative Possibilities

FAQs: Unleashing Your Creativity with Plastics Source

What are the advantages of CNC machining over laser cutting?

CNC machining offers greater versatility in terms of material handling and can create three-dimensional features, while laser cutting excels at achieving clean, precise cuts on flat materials.

Can I get custom-sized acrylic sheets?

Yes, many suppliers offer custom cutting services for acrylic sheets to meet your specific project requirements.

Is colored plexiglass less durable than clear plexiglass?

No, the color has no bearing on the durability of the material. Blue plexiglass offers the same exceptional strength and impact resistance as clear plexiglass.

How can I clean plexiglass sheets?

Use a soft microfiber cloth with a mild soap solution or a dedicated acrylic cleaner to avoid scratching the surface.

Where can I find inspiration for using colored plexiglass?

Many online resources and design communities showcase creative applications of colored plexiglass sheets.

Plastics Source, though located in the UK, is a valuable resource for understanding the potential of CNC machining, laser cutting, and colored acrylic sheets. With their expertise in plastic materials, they can assist you in finding the perfect solution for your project, regardless of your location.

0 notes

Text

Cylindrical Grinder for Sale: Precision Grinding for Industrial Applications

A cylindrical grinder for sale is a precision machine tool used in various industrial applications to shape the outer surface of a workpiece. These machines are essential in manufacturing processes where high accuracy and surface finish are critical, such as in aerospace, automotive, and tool manufacturing industries.

Importance of Cylindrical Grinders

Cylindrical grinders are designed to perform external cylindrical grinding, which involves rotating a workpiece against a grinding wheel to remove material and achieve the desired shape and size. They can grind both external and internal cylindrical surfaces with high precision, making them versatile tools for producing components with tight tolerances.

Key Features and Benefits

Precision Grinding: Cylindrical grinders are capable of achieving very fine tolerances and surface finishes, ensuring the accuracy and quality of machined components.

Versatility: These machines can grind a variety of materials, including metals, ceramics, and composites, allowing for a wide range of applications across different industries.

Flexibility: Cylindrical grinders come in different configurations, such as manual, semi-automatic, and CNC-controlled, offering flexibility to match the specific needs and production volumes of the user.

Efficiency: Modern cylindrical grinders are equipped with advanced features like automatic wheel dressing, in-process gauging, and integrated coolant systems, enhancing productivity and reducing setup times.

Cost-effectiveness: Investing in a cylindrical grinder can lead to long-term cost savings by improving process efficiency, reducing scrap rates, and minimizing the need for secondary operations.

Types of Cylindrical Grinders

Plain Cylindrical Grinders: These machines have a straightforward design and are used for external grinding of cylindrical surfaces.

Universal Cylindrical Grinders: Universal grinders have a swiveling wheel head that allows them to grind both external and internal surfaces.

Centerless Cylindrical Grinders: Centerless grinders do not use a chuck or centers, allowing for high production rates of cylindrical components.

Buying Considerations

When purchasing a cylindrical grinder, consider the following factors:

Machine Size and Capacity: Choose a machine that can accommodate the size and weight of your workpieces.

Grinding Wheel Size: The size and type of grinding wheel affect the machine's capability and performance.

Control System: Decide between manual, semi-automatic, or CNC-controlled machines based on your production requirements and operator skill level.

Accuracy and Repeatability: Look for machines that offer high precision and repeatability to ensure consistent part quality.

Service and Support: Ensure the supplier provides adequate support, including training, maintenance, and spare parts availability.

Leading Manufacturers

Studer: Known for precision cylindrical grinding machines suitable for various applications.

Toyoda: Offers a range of cylindrical grinders with advanced features for high-precision grinding.

Jones & Shipman: Provides versatile cylindrical grinders known for their reliability and performance.

Okuma: Offers CNC cylindrical grinders with integrated automation options for enhanced productivity.

Conclusion

A cylindrical grinder is a valuable tool for achieving high precision and quality in cylindrical grinding operations. Whether you're looking to upgrade your current machinery or expand your capabilities, investing in a quality cylindrical grinder can significantly improve your manufacturing processes. Consider your specific requirements, such as size, capacity, and automation level, when selecting a machine to ensure it meets your production needs and enhances your overall efficiency and profitability.

For More Information

Visit us- https://moderntools.com.au/product-category/machine-workshop-tools/grinders-linishers/

Contact-397612929Email- [email protected]

0 notes

Text

Supplier of Laser Marking Machine in Tamil Nadu

Company Overview:

Miracle Machineries, headquartered in Ahmedabad, is a renowned Manufacturer and Supplier of Laser Marking Machine in Tamil Nadu, India.

Established in 2019, Miracle Machineries specializes in manufacturing Laser Marking Machines and other industrial equipment.

Miracle Machineries offers a diverse range of equipment, including Laser Cutting Machines, Laser Welding Machines, CNC Routers, Laser Cleaning Machines, Robotic Solutions, and more.

Committed to exceptional manufacturing standards, Miracle Machineries ensures that its Laser Marking Machines are crafted with top-grade components and cutting-edge technology under the supervision of skilled professionals.

Features of Laser Marking Machine:

Precision and Speed

Precision and Speed

Versatility

Permanent Marking

Types of Laser Marking Machine:

Handy Fiber Laser Marking Machine

CO2 Laser Marking Machine

Mopa Color Laser Marking Machine

UV Laser Marking Machine

3D Laser Marking & Engraving Machine

Applications:

Product Identification and Traceability

Personalization and Branding

Medical Devices and Instruments

Automotive Parts

Aerospace and Defense

Service Area:

Miracle Machineries serves as a Supplier of Laser Marking Machine in Tamil Nadu, covering regions including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam

For further inquiries or customization options, interested parties are encouraged to contact Miracle Machineries.

Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#Kallakurichi#kanchipuram#Kanniyakumari#Karur#Krishnagiri#LaserMarkingMachine#Madurai#Manufacturer#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#Pudukkottai#Rajapalayam#Ramanathapuram#Ranipet#Salem

0 notes

Text

8 Star Metal Engineering - Delivering Quality and Precision in Metal Fabrication

At 8 Star Metal Engineering, we are a team of passionate and qualified metal fabrication experts dedicated to providing exceptional service and high-quality craftsmanship to clients across Haryana and beyond.

We possess a wealth of experience in the industry, allowing us to tackle projects of all sizes and complexities, ensuring they meet all your specifications and exceed expectations.

Why Choose 8 Star Metal Engineering?

When you choose 8 Star Metal Engineering, you partner with a team dedicated to providing exceptional metal fabrication solutions. We offer:

Unmatched Expertise: Our team possesses a wealth of experience and expertise in all aspects of metal fabrication.

Comprehensive Services: We offer a wide range of services to cater to your diverse metalwork needs.

Quality Commitment: We are committed to delivering the highest quality metalwork, utilizing advanced technology and skilled craftsmanship.

Our Commitment to Quality and Precision

We understand the importance of precision and quality in metal fabrication. Our commitment to excellence is reflected in every aspect of our work, from the initial consultation to the final product delivery. We utilize cutting-edge technology and equipment alongside proven techniques to ensure our projects are completed to the highest standards.

State-of-the-Art Equipment: Our workshop is equipped with advanced machinery, including CNC cutting machines, robotic welders, press brakes, and more. This advanced technology allows us to achieve exceptional accuracy, efficiency, and repeatability in our projects.

Skilled Craftsmanship: Our team comprises highly skilled and experienced metal fabricators who take pride in their work. Their expertise and dedication to detail ensure every project receives the utmost care and attention.

Quality Materials: We understand that the quality of the final product hinges on the materials used. That's why we source our materials from reputable suppliers, ensuring they meet the highest standards and are suitable for your specific project requirements.

Rigorous Quality Control: We implement a stringent quality control process throughout every project stage. This ensures we identify and address any potential issues promptly, maintaining the integrity and quality of the final product.

Our Diverse Metal Fabrication Services

8 Star Metal Engineering offers a comprehensive range of metal fabrication services to cater to your specific needs. We are proficient in working with various metals, including steel, stainless steel, aluminium, and more. Our core services include:

Cutting: We utilize CNC cutting machines for precise and efficient cutting of various sheet metals. This ensures clean cuts and minimal material waste.

Welding: Our team comprises certified welders skilled in various welding techniques, including MIG, TIG, and arc welding. We can create strong and durable welds for any metal fabrication project.

Bending and Forming: Our press brakes allow us to precisely bend and form sheet metal into your desired shapes and specifications.

Machining: We offer a range of machining services, including drilling, tapping, threading, and milling, to create intricate components and features in your metalwork.

Fabrication Assembly: Our team has the expertise to assemble various metal components into finished products. We ensure all parts fit together seamlessly and function as intended.

We Specialize In:

Structural Steel Fabrication: We design, fabricate, and install structural steel components for various projects, including buildings, bridges, and industrial structures.

Metal Cladding: We offer metal cladding solutions for walls, roofs, and other building elements, ensuring durability, weather resistance, and a sleek aesthetic appeal.

Metal Stairs & Railings: Our team designs, fabricates, and installs staircases and railings that are not only functional but also aesthetically pleasing and compliant with safety regulations.

Custom Metal Fabrication: We excel at custom metal fabrication projects. Bring us your design concepts, and we'll transform them into high-quality metal products that meet your specific requirements and applications.

The 8 Star Metal Engineering Difference

We differentiate ourselves from other metal fabrication companies through our unwavering commitment to:

Client Satisfaction: We prioritize client satisfaction in everything we do. We work closely with our clients throughout the project lifecycle, ensuring clear communication, timely updates, and a product that surpasses expectations.

Competitive Pricing: We offer competitive pricing for our services without compromising on quality. We work with you to find cost-effective solutions that meet your budgetary needs.

On-Time Delivery: We understand the importance of adhering to project timelines. We employ efficient processes and maintain clear communication to ensure your project is delivered on time, every time.

Safety: Safety is paramount at 8 Star Metal Engineering. We prioritize a safe working environment for our team and adhere to all relevant safety regulations.

1 note

·

View note

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes