Text

Professional Material Testing Services at Yamunanagar Engineering Cluster

At Yamunanagar Engineering Cluster, we offer comprehensive material testing services to ensure the quality and reliability of your products. Our state-of-the-art facilities and experienced team of engineers conduct a wide range of tests to evaluate the properties and performance of various materials. Whether you need mechanical testing, chemical analysis, or metallurgical examination, we have the expertise and equipment to meet your requirements. From raw materials to finished products, we help businesses across industries maintain the highest standards of quality and compliance. Trust us for accurate and reliable material testing solutions.

#mechanical testing services#mechanical testing machine#material testing services#chemical testing services#mechanical engineering testing services

0 notes

Text

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

CNC Turn Mill Machine Services at Yamunanagar Engineering Cluster

Revolutionize your machining processes with the Yamunanagar Engineering Cluster CNC Turn Mill Machine. Designed for maximum efficiency and versatility, this innovative machine streamlines turning and milling operations, enabling you to tackle complex tasks with ease. Engineered with state-of-the-art features and industry-leading performance, our CNC Turn Mill Machine empowers you to optimize production workflows and achieve superior precision in every project. From rapid prototyping to high-volume production, trust Yamunanagar Engineering Cluster to deliver unmatched reliability and performance with our CNC Turn Mill Machine. Redefine efficiency and unleash your machining potential with Yamunanagar Engineering Cluster.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Yamunanagar Engineering Cluster CNC Turn Mill Machine

Experience precision machining like never before with the Yamunanagar Engineering Cluster CNC Turn Mill Machine. Engineered to perfection, this advanced machine seamlessly integrates turning and milling operations, offering unparalleled accuracy and efficiency in one compact unit. Crafted with cutting-edge technology and precision components, our CNC Turn Mill Machine delivers exceptional results across a wide range of materials and applications. Whether you're shaping intricate parts or optimizing production processes, trust Yamunanagar Engineering Cluster to elevate your machining capabilities to new heights.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

Contact for Robotic Welding Services with Advanced Technology

Robotic welding is a cutting-edge technology revolutionizing the manufacturing and welding industry. It involves the use of automated, computer-controlled robotic arms to perform precise and consistent welds on a wide range of materials. This technology offers exceptional speed, accuracy, and efficiency, reducing the margin of error in welding processes. It enhances safety by minimizing human exposure to hazardous conditions and fumes. Robotic welding Services result in high-quality welds, increased productivity, and cost savings, making it an indispensable tool for various industries, from automotive and aerospace to construction and manufacturing, where precision welding is critical for product quality and durability.

#robotic welding solutions#robotic welding services#robotic welding systems#Robotic Automated Solutions#advanced robotics welding machine

0 notes

Text

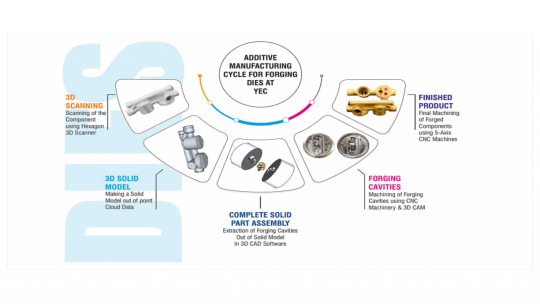

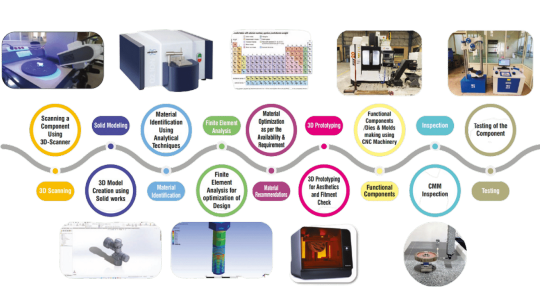

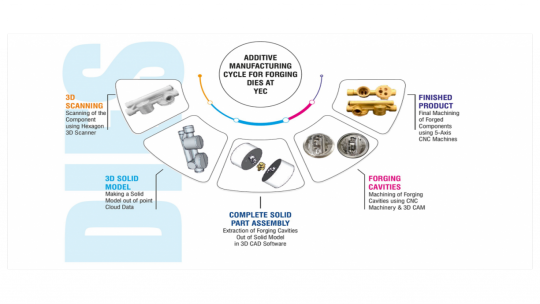

Advanced Research and Development Solution Services

Elevate your research and development solutions across industries with YEC's end-to-end solutions encompassing material identification, virtual simulation, 3D prototyping, and comprehensive inspection services. Now benefit from expertise in material selection, 3D scanning, and functional component testing for a seamless project journey avoiding present and future operational challenges.

#Yamunanagar Engineering Cluster#Mechanical Testing Services#Robotic Welding Services#Reverse Engineering Services#Precision Machining Services#Inspection Services#Research and Development Services

0 notes

Text

Contact Our Professional for Research and Development Solutions

Enhance cross-industry Research & Development initiatives using YEC's full-spectrum solutions that offer material identification, virtual simulation, 3D prototyping, and thorough for improving existing and future products & processes. Utilize our material expertise, 3D scanning, functional component tests for seamless project progress, research and development solutions at affordable costs.

#Yamunanagar Engineering Cluster#Mechanical Testing Services#Robotic Welding Services#Reverse Engineering Services#Precision Machining Services#Inspection Services#Research and Development Services

0 notes

Text

Crafting Excellence Unleashing with CNC Precision Machining

Unleash the potential of precision with our CNC machining services. We blend cutting-edge technology with craftsmanship to deliver components with exacting accuracy. Whether for aerospace, automotive, or any industry demanding precision, our machining services guarantee the quality and consistency your projects demand.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Unveiling the Power of Reverse Engineering Testing Services

In the dynamic landscape of software development, staying ahead of the curve is crucial. One key strategy gaining traction is the utilization of Reverse Engineering Testing Services. This innovative approach involves dissecting and understanding existing software systems to enhance their functionality, security, and overall performance.

Reverse engineering testing services are not just about breaking down code; they're a strategic tool to uncover the intricacies of complex applications. By deconstructing software, developers gain insights into its structure, enabling them to identify vulnerabilities, enhance functionality, and streamline performance.

One primary advantage of reverse engineering testing is its ability to unveil hidden features or diagnose issues that may not be apparent through conventional testing methods. This process helps developers create more robust and resilient software by understanding the underlying architecture.

Moreover, reverse engineering testing services play a pivotal role in ensuring compliance with industry standards and regulations. By dissecting software components, organizations can identify potential security loopholes and rectify them before they become exploitable vulnerabilities.

In a nutshell, the power of reverse engineering testing services lies in their ability to unravel the mysteries of existing software, paving the way for innovation, security, and improved performance. As the software development landscape evolves, embracing this approach becomes increasingly essential for organizations aiming to stay competitive and resilient in the digital realm.

#reverse engineering testing services#3d scanning reverse engineering services#3d reverse engineering services#3d scanning reverse engineering testing services#3d reverse engineering testing services#reverse engineering solutions#reverse engineering testing solutions#3d reverse engineering

1 note

·

View note

Text

In the fast-paced world of technological advancements, businesses are constantly seeking innovative ways to enhance efficiency and productivity. One such solution that has gained prominence in recent years is Robotic Automated Solutions. These cutting-edge technologies are transforming industries by automating repetitive tasks and streamlining processes.

Robotic Automated Solutions, often referred to as robotics process automation (RPA), involve the use of robots or computer programs to handle repetitive and rule-based tasks. This technology aims to reduce the burden on human workers, allowing them to focus on more complex and creative aspects of their jobs. Let's delve into the key benefits and applications of these transformative solutions.

Key Benefits of Robotic Automated Solutions:

Enhanced Efficiency: By automating routine tasks, businesses can significantly increase operational efficiency. Robots work tirelessly, 24/7, without the need for breaks or downtime, ensuring tasks are completed in a fraction of the time it would take a human.

Accuracy and Precision: Robots are programmed to follow instructions with utmost precision, minimizing errors that may arise from human oversight. This results in improved data accuracy and reduces the risk of costly mistakes.

Cost Savings: While the initial investment in Robotic Automated Solutions may seem significant, the long-term cost savings are substantial. The reduction in human labor for repetitive tasks leads to lower operational costs and a rapid return on investment.

Scalability: These solutions are easily scalable, making them suitable for businesses of all sizes. As the workload increases, organizations can deploy additional robots to handle the demand, ensuring seamless scalability.

In conclusion, Robotic Automated Solutions is a game-changer for businesses seeking to stay ahead in today's competitive landscape. The integration of these technologies leads to increased efficiency, cost savings, and a workforce empowered to focus on tasks that require human ingenuity. Embracing robotic automation is not just a trend; it's a strategic move towards a more agile and competitive future.

#robotic welding solutions#robotic welding services#robotic welding systems#Robotic Automated Solutions#advanced robotics welding machine

1 note

·

View note

Text

CNC Machining Services at Yamunanagar Engineering Cluster

Elevate your manufacturing precision with our CNC precision machining services. Our state-of-the-art equipment and skilled technicians ensure unparalleled accuracy in every cut and carve. From prototypes to mass production, trust us to bring your designs to life with meticulous attention to detail and uncompromising precision.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Yamunanagar Engineering Cluster stands as a beacon of innovation in the realm of mechanical testing machines. Our commitment to precision, reliability, and customer satisfaction sets us apart, making us the ideal partner for your testing and quality assurance needs. Stay tuned for more industry insights, technological updates, and success stories as we continue to shape the future of engineering excellence.

#mechanical testing services#mechanical testing machine#material testing services#chemical testing services#mechanical engineering testing services

0 notes

Text

Inspection Equipment Testing Services

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

What are Inspection Equipment Testing Services?

Inspection equipment testing services involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analyzers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents to a great extent and ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

In conclusion, inspection equipment testing services are indispensable for industries that are reliant on precise measurements and safety protocols for their business operations. By ensuring the accuracy and functionality of inspection tools, these services can contribute to exponential growth in quality assurance, safety compliance, and overall operational excellence.

#Inspection Equipment Testing Services#research and development solutions#robotic welding testing services

0 notes

Text

Unleash the Power of 3D Scanning and Reverse Engineering Services

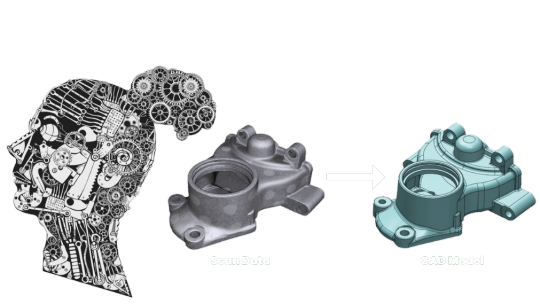

In today's rapidly evolving digital world, technology plays a crucial role in transforming the landscape of product design, development, and manufacturing. One such revolutionary advancement that offers far exceeding benefits in this domain is 3D scanning reverse engineering. This cutting-edge technology allows you to capture real-world objects in three-dimensional digital models and recreate them with unparalleled precision.

The Essence of Reverse Engineering

Reverse engineering empowers manufacturers of different scales to produce or reproduce physical objects by utilizing the original object as a guide. It involves capturing the geometric identities of the object’s physical part, made possible by accurate 3D scanning. This resulting data, typically in the form of an STL file or point cloud, creates a digital twin of the object, which serves as the foundation for further reproducing, enhancing, or archiving the original part, serving more than one purpose for different industries.

3D Scanning in Reverse Engineering: A Perfect Compliment

If we discuss this specifically regarding reverse engineering, the accuracy of the 3D scanning solution is of unmatched value. 3D scanning technique is emerging as the preferred choice due to its speed, precision, and ease of use.

With millions of precise data points collected through a quick scan, the 3D scanners enable full-field data acquisition within minutes, making them ideal for high-resolution 3D measurement tasks for different products and machinery.

#3d scanning reverse engineering#mechanical testing laboratory#Yamunanagar Engineering Cluster#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

3D scanning is revolutionizing the world of reverse engineering, unlocking immense potential for a wide range of industries. The accuracy, speed, and versatility of 3D scanners make them indispensable tools for engineers, designers, and manufacturers alike.

#Yamunanagar Engineering Cluster#Mechanical Testing Services#Robotic Welding Services#Reverse Engineering Services#Precision Machining Services#Inspection Services#Research and Development Services

0 notes

Text

Once the unit system and part dimensions are determined during the reverse engineering services process, the next step is to plan out the design for 3D metal printing. Complex-shaped products require a complete understanding of the object, especially if it is part of an assembly. Critical areas of the part application must be checked to ensure that the functionality of the part does not disrupt the interrelationship between the various parts.

#reverse engineering testing services#3d scanning reverse engineering services#3d reverse engineering services#3d scanning reverse engineering testing services#3d reverse engineering testing services#reverse engineering solutions#reverse engineering testing solutions

0 notes