#B111 C12200

Text

We Jaydeep Tubes Pvt. Ltd. one of the Largest Manufacturers, Stockist & Suppliers of Cupro Nickel 90/10, Cupro Nickel 70/30, Copper, Aluminium Brass, Admiralty Brass Tubes & Finned Tubes. We enjoy a strong presence in the Marketing, Exporting, Importing and supplying of high quality Hot Extruded & Cold Drawn Copper Tubes, Finned Tubes, PVC Coated Copper Tubes, Inner Grooved Coils, Level Wound Coil, Copper Plumbing Tubes & Fittings, which is in compliance with BS, IS, DIN, JIS, ASTM & ASME Standards.

0 notes

Text

C70600 COPPER ALLOY STEEL TUBE

C70600 pipe/tube using UNS C70600 copper-nickel alloy is primarily used in seawater service as forged and machined valve and pump components, fittings, and hardware. The alloy UNS C70600 pipe is also used in applications where high corrosion resistance is required, and where chloride stress corrosion cracking prevention measures prevent the use of stainless steel. Just like UNS C71500, copper alloy UNS C70600 tubes are seamless Copper Nickel Alloy Tubes of standard specifications for Water Desalting Plants.

UNS C70600 COPPER NICKEL PIPE/TUBE SPECIFICATION

Model NO.

C70600 C71500

Standard

ASTM

Od

6.35-406mm

Wt

0.5-80mm

Length

1-6m or as the Customer requires

Transport Package

Standard Export Packing

Specification

Pure Cu99.9%

Trademark

Tongmao

origin

China

HS Code

7411101900

SB111 C70600 TUBE PROPERTIES

Copper or Alloy

Copper

Tin

Aluminum

Nickel incl Cobalt

Lead

lron

Zinc

Manganese

Arsonic

Antimony

Phosphonus

Chromium

Elements

C10100

99.99 min@0

002 max

0.0010 max

0005 max

0.0010 max

0.0001 max

0.00005 max

0.0005 max

0.0004 max

0.0003 max

0.0001 max

C10200

99.95 min_

C10300

99.95 minE

0.001-0.005

C10800

99.95 minF

0.005-0.012

C12000

99.90 min

0.004-0.012

C12200

99.9 min

0.015-0.040

C14200

99.40 min

0.15-0.50

0.015-0.040

C19200

98.5 min

0.8-1.2

0.20 max

0.01-0.04

C23000

B4.0- 86.0

0.05

0.05 max

remainder

C28000

59.0- 63.0

0.09

0.07 max

remainder

C44300

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02-0.06

C44400

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02 -0.10

C44500

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02 -0.10

C60800

remainder

5.0-6.5

0.1

0.10 max

0.02-0.35

C61300

remainder

0.20 -0.50

6.0-7.5

0.15 max

0.01

2.0-3.0

0.10max

0.20 max

0.015 max

C61400

remainder

6.0-8.0

0.01

1.5-3.5

0.20 max

1.0 max

0.015 max

C68700

76.0-79.0

1.8-2.5

0.07

0.06 max

remainder

0.02-0.06

C70400

remainder

4.8-6.2

0.05

1.3-1.7

1.0max

0.30-0.8

C70600

remainder

9.0-11.0

0.05

1.0-1.8

1.0 max

1.0 max

C70620

86.5 min

9.0-11.0

0.02

1.0-1.8

0.50 max

1.0 max

0.02 max

C.05 max

C71000

remainder

19.0-23.0

0.05/

0.50-1.0

1.0 max"

1.0 max

C71500

remainder

29.0-33.0

0.05/

0.40-1.0

1.0 max

1.0 max

C71520

65.0 min

29.0-33.0

0.02

0.40-1.0

0.50 max

1.0 max

0.02 max

C .05 max

C71640

remainder

29.0-32.0

0.05*

1.7-2.3

1.0 max"

1.5-2.5

C.06 max

C72200

remainder

15.0-18.0

0.054

0.50-1.0

1.0 max"

1.0 max

0.30-

UNS ALLOY C70600 PIPE HIGHLIGHTS

The properties of copper-nickel tube alloy C70600 are usually supplied as redrawn tubes in the annealed condition. The combination of strength and good ductility provides excellent formability for ASTM B111 tubes.

0 notes

Text

ASTM B111/ ASME SB111 COPPER ALLOY STEEL TUBE

ASME SB111 C70600 Tube Copper-nickel alloy that resists seawater corrosion and has high antifouling properties against marine microorganisms. You can find ASTM B111 tubes using ASME SB111 alloy are widely used in shipbuilding repair, petrochemical, natural gas, and other marine engineering and related industries. ASME SB111 materials, like SB111 C7060, have good corrosion resistance, especially in seawater.

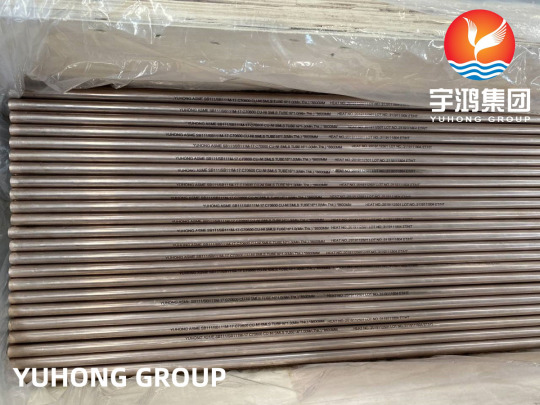

ASTM B111/ ASME SB111 TUBES PROVIDED BY YUHONG

ASTM B111/ ASME SB111 Copper Alloy Steel Tube

YUHONG GROUP provides the best ASTM B111/ ASME SB111 tubes including straight tube, U tube for heat exchanger, boiler, and superheater.

C70600 Copper Alloy Steel Tube

C71500 Copper Alloy Steel Tube

C44300 Copper Alloy Steel Tube

C12200 Copper SMLS Tube

68700 Copper Alloy Steel Tube

ASTM B111 TUBES FEATURES

The characteristics of ASTM B111/ ASME SB111 copper alloys are mainly good electrical and thermal conductivity and have a certain strength (higher than aluminum alloys and magnesium alloys). You can find ASTM B111/ ASME SB111 tubes widely used in electronic power and other fields with high electrical conductivity requirements, such as various electrodes, electrical contacts, and high-strength wires;

The ASTM B111/ ASME SB111 tubes are also used in fields with high heat dissipation requirements such as heat dissipation components or devices, such as molds, thermonuclear reactor radiators, air conditioning condenser pipes, etc.

ASTM B111/ ASME SB111 TUBES SPECIFICATIONS

ASTM B111 Specification

ASTM B111/ASME SB111

ASTM B111 Copper&Copper Alloy Tube Type

Condensers, Evaporators, Heat Exchangers

ASTM B111 Tube Size in Outside Diameter

Up to 3 1⁄8 in. [80 mm] inclusive

ASTM B111 Tubing Length

Up to 6 mater,custom cut lengths

ASTM B111 Heat Exchanger Tube Thickness

Up to 0.120 inch[3 mm] inclusive

ASTM B111/ ASME SB111 TUBES CHEMICAL COMPOSITION

UNS No.

ASTM B111 Copper&Copper Alloy Tube (%)

Cu

Ni Incl Co

Ti

Al

Lead Max

Fe

Zn

Mn

As

Other Named Elements

C44300

70.0-73.0

...

0.9-1.2

...

0.07

0.06 max

reminder

...

0.02-0.06

...

C68700

76.0-79.0

4.8-6.2

...

1.8-2.5

0.07

0.06 max

reminder

...

0.02-0.06

...

C70600

reminder

9.0-11.0

...

...

0.05

1.0-1.8

1.0 max

1.0 max

...

...

C71500

reminder

29.0-33.0

...

...

0.05

0.4-1.0

1.0 max

1.0 max

...

..,

C71640

reminder

29.0-33.0

...

...

0.05

1.7-2.3

1.0 max

1.5-2.5

...

C.06 max S.03

ASTM B111/ ASME SB111 TUBES TENSILE REQUIREMENT

UNS No.

Temper Designation

Tensile Strength

Yield Strengh

Elongation

Code

Name

min MPa

min MPa

in 50mm min%

C44300

O61

annealed

45

15

...

C68700

O61

annealed

50

18

...

C70600

O61

annealed

40

15

...

C70600

H55

light-drawn

45

35

...

C71500

O61

annealed

46

16

...

C71640

O61

annealed

72

50

15

C71640

HR50

light-drawn

63

25

...

ASTM B111 EQUIVALENT STANDARD

Product Description

ASTM B111

JIS H3300

DIN

Admiralty Brass Tube/Pipe

C44300

C4430T

DIN17660 CuZn28SnI

2.0470

Al-Brass Tube/Pipe

C67800

C6870T

DIN 17660 CuZn20Al2

2.0460

Copper Nickel 90/10 Tube/Pipe

C70600

C7060T

DIN 17664 CuNi10FeMn

2.0872

Copper Nickel 70/30 Tube/Pipe

C71500

C7150T

DIN17664 CuNi30MnFe

2.0882

ASTM B111 ASME SB 111 TUBES TYPICAL APPLICATIONS

ASTM B111 and ASME SB 111 are specifications that define the requirements for seamless copper and copper alloy tubes used in various applications. These ASTM b111 tubes are typically utilized in industries such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and heat exchangers. Here are some typical applications of ASTM B111/ASME SB 111 tubes:

Plumbing Systems: Copper tubes specified under ASTM B111/ASME SB 111 are commonly used in plumbing systems for transporting water and other fluids. They are resistant to corrosion, have excellent heat transfer properties, and are relatively easy to install.

HVAC and Refrigeration: Copper asme sb111 tubes are widely employed in heating, ventilation, air conditioning, and refrigeration systems due to their excellent thermal conductivity. These tubes efficiently carry refrigerants, allowing for effective heat exchange and temperature regulation.

Heat Exchangers: ASTM B111/ASME SB 111 tubes find extensive use in heat exchangers where the transfer of heat between two fluids is required. Their high thermal conductivity ensures efficient heat transfer, making heat exchanger pipes suitable for applications in power plants, chemical processing plants, and industrial machinery.

Oil and Gas Industry: oil field tubing specified under these standards is used in the oil and gas industry for applications such as oil coolers and hydraulic lines. Their corrosion resistance and ability to withstand high pressures and temperatures make them suitable for these demanding environments.

Shipbuilding and Marine Applications: Copper asme sb111 tubes are employed in shipbuilding and marine applications due to their resistance to corrosion in seawater. They are used for various purposes, including piping systems, heat exchangers, and condensers.

Electrical Applications: Copper tubes specified under ASTM B111/ASME SB 111 are also used in electrical applications where their excellent electrical conductivity is required. They are used in busbars, conductors, and other components of electrical systems.

It is important to note that the specific application of ASTM B111/ASME SB 111 tubes may vary depending on the alloy composition and specific requirements of the industry or application. Copper alloy tube manufacturers and engineers typically select the appropriate copper alloy and tube dimensions based on the intended use and the operating conditions of the system.

0 notes