#instrument valve

Text

Understanding the Functionality of Valves in Instrumentation Systems |Arcellor controls

The tricky global of instrumentation structures is predicated on a silent orchestra of additives working collectively to exactly control and monitor business strategies. Among these key players are device valves, regularly small but robust in their features. Let's discover the crucial role instrument valves play in making sure the easy operation of diverse commercial packages.

Instrument Valves: Masters of Control

Instrument valves, also called instrumentation valves or gauge valves, are specialized valves designed for specific regulation of float charges, pressures, and course of fluids (liquids, gasses, or slurries) inside instrumentation structures. Unlike their larger cousins in commercial piping, instrument valves usually address smaller glide charges and require an excessive diploma of manipulation.

Key Features of Instrument Valves:

Smaller Size: Ranging from 1/eight inch to one inch in length, device valves are nicely-applicable for tricky managed loops inside instrumentation structures.

High Precision: Their design prioritizes precise management over on/off float or throttling (gradually adjusting) to go with the flow prices and pressures.

Leak-Tight Performance: Tight close-off abilities are essential to save you leakage and keep gadget integrity.

Applications of Instrument Valves:

Instrument valves find software in a huge variety of industries relying on precise process manage:

Chemical Processing: Regulating the float of chemicals in reactors, pipelines, and analytical systems.

Oil and Gas Production: Controlling glide rates and pressures at some point of drilling, refining, and transportation.

Power Generation: Maintaining the most reliable glide and stress of fluids in boilers, generators, and cooling structures.

Pharmaceutical Manufacturing: Ensuring sterile and precise go with the flow of fluids in production approaches.

Water Treatment Plants: Regulating glide prices of water and treatment chemicals.

Types of valves instruments:

A diverse variety of tool valves exist, each catering to unique manipulate wishes:

Needle Valves: Offer exceptional-tuned control over float quotes, perfect for low-flow applications.

Ball Valves: Provide short on/off waft management with a rotating ball detail.

Globe Valves: Offer correct throttling capabilities with a forestall-disc design.

Globe Valves: These valves are known for his or her tight close-off abilities and throttling ability.

Check Valves: Allow glide in one direction handiest, preventing backflow.

Butterfly Valves: Offer a fee-powerful alternative for on/off drift management in large traces.

Arcellor Controls: Your Partner in Industrial Control

Arcellor Controls, a globally recognized leader in business automation solutions, knows the crucial position of device valves in manner control. They provide a comprehensive range of amazing tool valves, catering to various industrial programs. Their valves are acknowledged for their:

Durability: Manufactured from high-grade substances to withstand harsh industrial environments.

Reliability: Built to perform consistently and dependably beneath disturbing situations.

Compliance: Adhere to industry requirements and specs for protection and performance.

Conclusion

By understanding the capability of tool valves, we benefit from a deeper appreciation for the problematic workings of instrumentation systems. These silent maestros make sure to manipulate over numerous commercial tactics, keeping them operating effectively and effectively. For dependable and awesome tool valves, Arcellor Controls may depend on associates in reaching the most desirable process manipulation.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments#valves in instrumentation

0 notes

Text

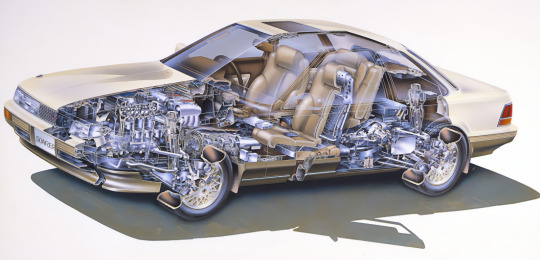

Toyota Soarer 3.0 GT-Limited, 1986. The second generation Z20 Soarer shared its platform with the A70 series Supra. It introduced the Electro Multi Vision digital vehicle information display. The 3.0 GT was powered by a DOHC 24 valve turbocharged straight 6

#Toyota#Toyota Soarer#Toyota Soarer Z20#1986#sports coupé#straight 6#24 valve#DOHC#digital instrumentation

305 notes

·

View notes

Text

Still Alive (Radio Mix)

// Portal (2007)

#portal#portal (game)#still alive#playstation 3#xbox 360#PC#valve#game#instrumental#2007#oktaviaslabyrinth

27 notes

·

View notes

Text

They need to add more stupid attachment thingies to instruments. Instruments need to get scrunklier.

#-Loki#instruments#trombone#F trigger trombone#trumpet#euphonium#compensating valve euphonium#french horn#double french horn#triple french horn#Music

6 notes

·

View notes

Text

Wait fuck I’m learning a wind instrument. The band kids fucking won.

#chit chat#DAMN it#all throughout high school the marching band kids wanted me to become one of them#and i said I’d never take up mouth instruments because they were gross#and now...#sigh#i do admit that i do find the harmonica a little gross and i do have to try and wipe it down after every exercise#but i don’t have to deal with spit valves or reeds or whatever the flutes do#so there is that#harmonica adventures

6 notes

·

View notes

Text

Band of 107th U.S. Colored Infantry at Fort Corcoran, Arlington, Va. holding saxhorn brass valve instruments. These saxhorns were the type of instruments played at the funeral of African Civil War hero and Captain Andre Cailloux. Many of the instruments were played over the shoulder to play to the army following the band. Instruments today face forward and bands can be in the middle or back of a procession.

Library of Congress

Smith, William Morris, photographer

Created / Published

1865

#african#afrakan#kemetic dreams#africans#brownskin#brown skin#afrakans#library of congress#william morris#1865#fort corocran#arlington#va#saxhorn brass#valve instruments#civil war heros#photographers#photographer

16 notes

·

View notes

Text

Whoever pioneered making a valve this shape should be shot

#euphonium#baritone#tuba#low brass#brass#brass instrument#valves#brass valves#valve instrument#2nd valve

3 notes

·

View notes

Text

I started renting a valve trombone from my school a few days ago and I can say, with full confidence, that it is now one of my favorite instruments. It’s like a trumpet, but bigger and lower and 1000 times cooler. The only thing cooler than it is the tuba, because nothing can compare to the tuba.

3 notes

·

View notes

Text

From my experience with the more cursed instruments I gotta say they all would make really great spell focuses for bards and even better magic wands adjacent things. The three most cursed instruments might have to be the Bassoon, Sarrusophone, and valved Trombone, each something that feels magical all differently...

#Sarrusophone#bassoon#wizard#wizard posting#band#valved Trombone#bard#musical instruments#having tried playing them all the Bassoon is the only one that i ended up buying

4 notes

·

View notes

Text

Why you shouldn't use something small and pointy to try removing a stuck piston.

After a bit of work with a dent ball on a stick to smooth down the raised areas.

Small solder patch to seal the hole. Still some small ridges because the sharp edges of the hole just did not want to completely flatten out — leverage is difficult when you can't really brace against anything due to needing to avoid warping the sides of the ports — but at least now it doesn't leak anymore.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#euphonium#piston valve#there I fixed it#sometimes things SHOULD be left to the professionals actually#this is one of those times

2 notes

·

View notes

Text

The Ultimate Guide to Different Types of Valves for Instruments |Arcellor controls

Presenting the final compendium on instrument valves, courtesy of Arcellor Controls India – your esteemed companion in precision engineering answers. As the most reliable producer, dealer, and exporter of instrumentation valves, we concentrate on offering a wide variety of valves instruments tailored to suit the needs of numerous industries and programs. Whether you're on the lookout for instrument valves, instrumentation valves, valves instruments, valve instruments, or valves and instruments, look no similarly than our comprehensive services.

Understanding Instrumentation Valves:

Instrumentation valves play a vital position in controlling the waft of beverages and gases inside commercial processes. They are designed to face up to excessive strain, extreme temperatures, and corrosive environments, making them indispensable additives across a huge range of industries consisting of oil and fuel, petrochemical, prescription drugs, and more.

Types of Instrumentation Valves we offer:

Needle Valves:

Needle valves are precision-engineered valves with a slender, tapered needle-like stem that permits for particular manage of flow costs.

Ideal for packages requiring quality modifications and throttling, needle valves are normally used in instrumentation systems and manner manage packages.

Ball Valves:

Ball valves characteristic a spherical disc (the "ball") with a hole thru the center that may be circled to control the glide of fluid.

Known for his or her reliability, sturdiness, and brief quarter-flip operation, ball valves are appropriate for both on/off and throttling programs.

Gate Valves:

Gate valves utilize a sliding gate or wedge mechanism to alter flow. When completely open, the gate creates a instantly-thru passage for maximum waft.

These valves are properly-desirable for packages requiring minimal restriction and low strain drop, along with in pipelines and isolation offerings.

Globe Valves:

Globe valves feature a disc that moves perpendicular to the drift to modify fluid control. The design offers precise throttling capabilities and first rate close-off characteristics.

Commonly used in applications requiring precise manage and mild pressure drops, inclusive of in steam structures and water remedy flora.

Manifold Valves:

Manifold valves combine multiple valves into a unmarried compact unit, making an allowance for the simultaneous manipulate of multiple procedure lines.

These valves streamline installation, lessen potential leak factors, and enhance gadget performance, making them perfect for device isolation and calibration packages.

Check Valves:

Check valves, also known as non-return valves, permit fluid to waft in a single path whilst preventing reverse glide.

Essential for preventing backflow and protecting gadget, take a look at valves find packages in pumps, compressors, and piping structures.

Monoflange Valves:

Monoflange valves integrate isolation and venting capabilities into a unmarried compact unit, disposing of the need for separate valves and fittings.

These valves reduce capability leak factors, keep space, and simplify set up and maintenance, making them best for instrument mounting and gauge isolation.

Choosing the Right Valve inside the Instrument

Selecting the right instrumentation valve to your challenge requires cautious attention of numerous elements, along with:

Operating situations (stress, temperature, media)

Flow necessities

Material compatibility

Size and connection specs

Environmental and protection rules

At Arcellor Controls India, we provide a comprehensive range of instrumentation valves designed to meet the highest industry standards and specs. Our valves are to be had in numerous sizes, materials, and configurations to match diverse utility requirements. Whether you want precision control with needle valves, dependable close-off with ball valves, or flexible overall performance with manifold valves, we've got the solution for you.

Final Words!

Comprehending the diverse categories of instrumentation valves and their respective applications is paramount to ensuring top overall performance and dependability in commercial operations. With our tremendous collection of pinnacle-tier instrument valves and profound proficiency in precision engineering, Arcellor Controls India emerges as your pass-to ally for all your valve instruments necessities. Reach out to us nowadays to explore how our complete variety of valves and instruments can empower you to gain extraordinary overall performance and performance for your endeavors.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments

0 notes

Note

band camp moment,,,,, what do you play?

i play the baritone!

#if you havent heard of it#its a low brass instrument#it sounds the same as a trombone but it uses valves instead of a slide

4 notes

·

View notes

Text

Spectec Valves & Instruments Pvt. Ltd., based in India, is a prominent manufacturer of safety relief valves, offering a diverse range to ensure industrial safety standards. Their safety relief valves, integral to process safety, guarantee protection by releasing excess pressure. Spectec's product line encompasses various types of safety valves, tailored to different industrial needs. From conventional to pilot-operated valves, they provide reliable solutions. Considering quality and performance, Spectec's safety valves offer value for investment. For inquiries about safety valve prices and available types, Spectec Valves & Instruments Pvt. Ltd. serves as a trusted resource.

#Safety relief valve manufacturer in india#Safety relief valve#Safety valve price#Types of safety valve#Spectec Valves & Instruments Pvt. Ltd.

0 notes

Text

Top Stainless Steel 316 Valve Instrumentation Manufacturer, Supplier and Exporter in India - Mcneil Instruments

Mcneil Instruments is a leading manufacturer, supplier, and exporter of Stainless Steel 316 Instrumentation Valves in India. Known for our excellent corrosion resistance, these valves are ideal for marine engineering and low-pressure applications. The range includes SS316 Needle, Plug, Check, Swing Check, Butterfly, Ball, and Globe Valves, all designed for high-temperature and cryogenic environments. Available sizes range from 1/2" to 4" with various connection types and pressure classes. For pricing details, refer to Mcneil Instruments’ price list.

0 notes

Text

The Ultimate Guide to Choosing the Right Needle Valve for Your System

Choosing the right needle valve for your system can be straightforward if you know what to look for. Here's your ultimate guide to making an informed decision.

What is a Needle Valve?

A needle valve is a type of valve used to precisely control the flow of liquid or gas in a system. It's ideal for fine adjustments and is commonly used in applications requiring accurate flow regulation.

Why is Selecting the Right Needle Valve Important?

Choosing the correct needle valve ensures optimal performance, safety, and efficiency in your system. The wrong choice can lead to leaks, system damage, or inefficient operation.

Key Factors to Consider

1. Material Compatibility

Fluid Type: Ensure the valve material is compatible with the fluid type (e.g., water, oil, gas).

Corrosion Resistance: For corrosive environments, materials like stainless steel or brass are preferred.

2. Pressure and Temperature Ratings

Maximum Pressure: Check the valve’s maximum pressure rating and ensure it matches your system’s requirements.

Temperature Range: Confirm the valve can withstand the operating temperatures of your system.

3. Valve Size and Port Connections

Flow Rate: Select a valve size that matches the desired flow rate.

Connection Type: Ensure the port connections (e.g., threaded, flanged) are compatible with your system's piping.

4. Precision and Control

Adjustment Range: Look for a valve with a fine adjustment range if precise flow control is needed.

Turn Ratio: Higher turn ratios offer finer control but may be more complex to operate.

5. Maintenance and Durability

Ease of Maintenance: Choose valves that are easy to maintain and clean.

Durability: Consider the valve’s longevity and reliability, especially for critical applications.

Common Applications of Needle Valves

Laboratory Settings: Precise control of gases or liquids.

Industrial Processes: Regulating flow in pipelines and equipment.

Hydraulic Systems: Controlling fluid flow in machinery.

Top Tips for Installation and Use

Proper Installation: Follow the manufacturer’s instructions for installation to avoid leaks or damage.

Regular Inspections: Conduct regular checks for wear and tear to ensure the valve operates efficiently.

Training: Ensure that operators are trained on how to use and adjust the valve properly.

Where to Buy Quality Needle Valves

Look for reputable suppliers who offer a variety of needle valves suitable for different applications. Ensure they provide detailed product specifications and support.

0 notes