#onsite mixed concrete

Text

Efficient Volumetric Concrete Delivery Services for Your Construction Projects

Find the convenience of volumetric concrete delivery for your construction needs. Our services provide precise and on-demand mixing of concrete at your job site, ensuring optimal quality and consistency. With volumetric concrete delivery, you have greater flexibility and control over your project timelines and budgets. Say goodbye to overordering or wastage and streamline your construction process with our efficient delivery solutions.

1 note

·

View note

Text

Onsite Mixed Concrete

Onsite mixed concrete, also known as "ready-mix concrete" or "site-mix concrete," is a type of concrete that is produced and prepared at the construction site rather than being transported from a central mixing plant. This method offers several advantages, including flexibility, cost savings, and the ability to tailor the mix to specific project requirements. Here are some key aspects of onsite mixed concrete:

Mixing at the Construction Site

Instead of being delivered in a ready-to-use state from a central plant, the individual components of concrete (cement, aggregates, water, and sometimes additives) are brought to the construction site separately.

Mixing takes place on-site using mobile concrete mixers or other portable mixing equipment.

Advantages

Freshness: Onsite mixing allows for the production of fresh concrete, which can be crucial for certain applications where the concrete needs to be used immediately.

Customization: The mix can be adjusted on-site to meet specific project requirements, taking into account factors like temperature, humidity, and other site-specific conditions.

Reduced Transport Costs: Since only the raw materials are transported to the site, there is a reduction in transportation costs compared to the delivery of ready-mix concrete.

Equipment Used

Mobile Concrete Mixers: These are trucks equipped with a rotating drum that can mix concrete as it travels to the construction site.

Batch Plants: Some larger construction sites may use on-site batch plants, which are portable plants that can produce concrete in large quantities.

Quality Control

Onsite mixed concrete requires careful monitoring of the mixing process to ensure the right proportions of materials are used and that the concrete meets the required specifications.

Quality control measures are essential to ensure the strength and durability of the final product.

Application

Onsite mixed concrete is commonly used in small to medium-sized construction projects, where the volume of concrete needed may not justify the use of a central mixing plant.

Challenges

Time Constraints: Onsite mixing may require more time than using ready-mix concrete, especially for larger projects.

Skill Requirements: Proper training and expertise are essential for on-site mixing to ensure the quality and consistency of the concrete.

It's important to note that the choice between onsite mixed concrete and ready-mix concrete depends on various factors, including the scale of the project, time constraints, and specific project requirements.

0 notes

Text

Revolutionizing London Construction with Onsite Mixed Concrete

In the bustling metropolis of London, construction projects are a common sight. From towering skyscrapers to residential developments, the city's landscape is ever-evolving. One critical element that underpins these projects is concrete, the lifeblood of construction. But not all concrete is created equal. For those in the know, the term "Onsite Mixed Concrete" is music to their ears. In this comprehensive guide, we will explore how onsite mixed concrete is changing the game in London's construction industry.

The Heart of Construction: Concrete

Before delving into the intricacies of onsite mixed concrete, let's take a step back and appreciate the role of concrete in construction. Concrete is the backbone of the industry, a versatile building material that can take on various forms and structures. From foundations to walls, bridges to pavements, the world as we know it would not exist without this formidable substance.

Concrete's composition, primarily made up of cement, water, and aggregates, gives it unparalleled strength and durability. It's no wonder that it's the go-to choice for construction professionals. However, the key to a successful construction project lies in using the right type of concrete for the job.

The Challenge of Concrete Delivery

Historically, obtaining the right concrete mix and delivering it to the construction site was a challenge. Traditional methods involved pre-mixed concrete being transported to the site in ready-mix trucks. While this approach works for many projects, it's not without its drawbacks.

Firstly, pre-mixed concrete has a limited lifespan, meaning it can't be stored for extended periods. This often results in overordering or underordering, both of which have financial implications. Secondly, the quality of pre-mixed concrete can degrade during transport, affecting the final result. Lastly, the scheduling and logistics of concrete delivery can be complex, causing delays and disruptions to the construction process.

Enter Onsite Mixed Concrete

Onsite mixed concrete is a game-changer in the world of construction, and London is at the forefront of this innovation. This approach involves mixing the concrete directly at the construction site, eliminating the challenges associated with pre-mixed concrete. Let's dive into the numerous advantages of onsite mixed concrete:

1. Precision and Freshness

Onsite mixed concrete is prepared right when you need it. This ensures that the concrete is at its freshest and most potent state. It can be tailored precisely to meet the project's requirements, whether it's a high-strength mix for a skyscraper's foundation or a smoother blend for decorative elements.

2. Cost-Efficiency

With onsite mixed concrete, there's no need to overorder to account for possible delays in delivery. This translates to cost savings, as you only pay for what you use. It also minimizes waste, which is a significant environmental benefit.

3. Versatility

Onsite mixed concrete provides unparalleled flexibility. If there are any sudden changes or adjustments required during the project, it's easy to modify the mix to suit the new needs. This adaptability is invaluable in the ever-evolving world of construction.

4. Quality Control

Having full control over the mixing process guarantees a higher level of quality. You can be confident that the concrete is made to the exact specifications and standards required for your project.

5. Sustainability

Reducing waste and emissions associated with concrete transportation is an essential step towards a more sustainable construction industry. Onsite mixed concrete significantly reduces the carbon footprint of a project.

The Onsite Mixing Process

Now that we've established the importance of onsite mixed concrete, let's walk you through the process. This is a step-by-step guide on how this innovative method is transforming the way construction happens in London.

1. Assessment

The journey begins with a thorough assessment of your project's concrete requirements. We take into account the type of structure, expected load, and any special characteristics needed for your concrete mix.

2. Customized Mix Design

Once we understand your project's needs, we formulate a custom mix design. This ensures that your concrete will meet the specific requirements, guaranteeing its strength and durability.

3. Onsite Mixing

The magic happens at the construction site. Our expert team arrives with the necessary raw materials: cement, aggregates, and water. Using state-of-the-art equipment, we mix the concrete on-site, allowing for real-time adjustments if necessary.

4. Quality Assurance

Every batch of concrete is subjected to rigorous quality control checks. This ensures that your concrete mix adheres to the highest industry standards. You can trust that your project's foundations are rock solid.

5. Delivery to the Point of Use

The freshly mixed concrete is then transported directly to the point of use. There's no need to worry about delays or compromised quality during transit.

6. Pouring and Curing

With the concrete delivered to the site, it's ready to be poured and molded into the desired forms. Our experts ensure that the curing process is carried out correctly to maximize the concrete's strength and durability.

7. Clean-Up and Efficiency

Once the job is done, we clean up the site, leaving it in pristine condition. The efficiency of the onsite mixed concrete process means that there's minimal disruption to your project's timeline.

Success Stories of Onsite Mixed Concrete in London

The proof of the pudding is in the eating, they say, and the success stories of onsite mixed concrete in London are testament to its effectiveness. Let's explore a few notable examples:

1. Towering Achievements

London's iconic skyscrapers, such as The Shard and The Gherkin, owe their towering success to onsite mixed concrete. The precision and strength of the concrete used in these projects are unrivaled, making them architectural marvels.

2. Residential Marvels

From luxury apartments to affordable housing, London's residential projects benefit greatly from onsite mixed concrete. The customization and cost-efficiency have made high-quality housing accessible to a broader range of people.

3. Infrastructure Advancement

Infrastructure projects, like the construction of the Crossrail tunnels, demand a concrete solution that can withstand tremendous pressure and maintain structural integrity. Onsite mixed concrete has been the unsung hero behind many of London's infrastructure advancements.

The Future of London Construction

As London continues to evolve and grow, the role of onsite mixed concrete in shaping the city's landscape cannot be overstated. The construction industry is becoming more sustainable, efficient, and cost-effective, thanks to this innovative approach.

Conclusion: London's Concrete Revolution

In the dynamic world of construction, staying ahead of the curve is paramount. Onsite mixed concrete is the future of London construction, offering a fresh, efficient, and eco-friendly alternative to traditional concrete delivery. Its precision, cost-efficiency, and adaptability make it the go-to choice for projects of all sizes.

Join the revolution and elevate your construction project with the power of onsite mixed concrete. Your success is our success, and together, we can build a better, more sustainable London.

0 notes

Photo

West London Concrete Offers Superior-Quality On Site Mixed Concrete at Affordable Pricing. West London Concrete is a preferred service provider of on site mixed concrete covering London and its surrounding areas. We have been serving our customers for many years and have always ensured to meet their requirements with the highest degree of material specifications. So, if you have a new construction project coming up, you can contact us right away, and we will give you the most sustainable solution.

#ready mixed concrete#mix concrete#onsite mixed concrete#onsitemixedconcrete#concrete supplier#construction#construction materials#Watford#uk

0 notes

Link

Save Time Concrete supplies best quality of Onsite concrete mix in West Drayton, London. Starting from 1 cubic meter, we supply as much as you require.

0 notes

Text

Unshakable Faith (2023)

Episode 34 Breakdown

Ji Danyang gets his team to check their equipment but the vibrations havent caused any errors, and Officer Tongbin goes to check on the cooper mine.

Inside the sealed cabin Nurse Bai opens a secret compartment left by Assistant Welder Rui and pull out a tool and a small bottle of phosphorus powder and uses it to start a fire in a side chamber. The cabin team have to use water to douse it but the air quality is compromised. He Xiwan convinces Ji Danyang to not abort the experiment and they increase the air filtration and wait.

Fake Li Qiuchen spies on Expert Chief Chu's hospital room but it's guarded and the windows are covered. Expert Chief Chu is recuperating elsewhere and Factory Chief Han visits to advise him of the cabin fire.

Officer Hongmei and Police Captain Chen look into possible causes for the fire and Ji Danyang gives the cabin team the good news that the air filtration system has worked and the air levels are back to normal.

Fake Li Qiuchen spies on Expert Cheif Chu's room again and notices the IV bottles the nurse is carrying hasn't changed. He figures he's been moved and discharges himself from the hospital.

The testing of Expert Chief Chu's medicine reveals a rare virus mixed in, and when asked Nurse Leader Ge advises the police that Nurse Shanshan was in charge of his medicine.

Another vibration rocks the cave, and Ji Danyang and Officer Hongmei check the cavern behind the sealed cabin, finding a miasma of dust that's coming through the cave walls. The digger team has reached the concrete wall of the air raid shelter and set up their next explosives. The police team does a fully manned search of the back hill and Liu Simao watches as they find a trail in the grass leading to the cave. The police enter and arrest the digging team, extinguishing the lit fuse just in time to stop the next explosion.

The digging team confess to being recruited by Electrician Liu Simao and they search his house and find evidence that links him to Lai Guangrun and the molotov cocktail attempt on Officer Hongmei.

With 4 days left in the experiment, Nurse Bai loosens the bolts around a mercury pipe and then hides the tool in Nurse Shanshan's pocket. The mercury leak is detected in the cabin and the team is evacuated into the transition chamber, but He Xiwan stays behind to try and clean up the spill, refusing to withdraw even when Ji Danyang orders her to. Officer Hongmei enters the cabin to drag her out and replaces her while the emergency clean up crew is preparing. Once the clean up crew gives the all clear, Officer Hongmei is send to the hospital and He Xiwan insists on finishing the experiment. An investigation finds the loosened bolts and the police call for Nurse Shanshan to exit the chamber for questioning and they find the tool in her pocket but she protests that she doesn't know where it came from.

Dr Bai attends to Officer Hongmei in the hospital, and Police Captain Chen deliberately lets it slip that it was sabotage. As he leaves, Dr Bai runs into Nurse Leader Ge and learns that Nurse Bai is now in the sealed cabin.

With only a few days left and everyone exhausted, Ji Danyang gives a speech of encouragement to the cabin and laboratory teams.

Officer Ding searches for the tailor shop that Liu Simao used and sees Dr Bai enter Seamstress Miao's shop. Dr Bai closes the doors and confronts the seamstress about their sabotage endangering Nurse Bai.

.....................................................

Good for the hospital and nurses to keep up with the guise of Cheif Chu still being onsite, but why was no one noticing that fake Li was skuking around the same corrider all the time?? Surely they could have had a covert guard on him while he was there.

They've identified Electrician Liu Simao as a spy, now they've just got to find him.

Blaming Shanshan for Chief Chu's medicine! And hiding the tool in her pocket!?!? The only reason Shanshan is in the cabin is to be a scapegoat?? You bitch! Shanshan is in tears and Tongbin isn't looking much better.

Thats it. I'm not giving Nurse Bai any more grace, she's irredeemable now. Enjoy prison.

I find it curious that when the police team has to interrogate a friend, the officer closest to them is involved in the investigation. When they questioned Nurse Bai at various times Officer Hongmei was always present, same for when they questioned Dr Bai. When Ji Danyang was facing the fallout of the miscalculation he was questioned by both Hongmei and Captain Chen. And when Shanshan is questioned here, Tongbin is one of her interrogators. It would seem rational to have them interrogated by someone else as to not have a conflict of interest (like Hongmei was accused of when she led the tampered medicine investigation), but at the same time the officer who knows them the best would be able to see more flaws in their story? Would a suspect be more truthful in front of a friend, or more likely to hide their shame in front of a friend? I'd love to know the in-universe reason. Maybe it also demands the police team to be transparent with their own feelings and biases.

Dr Bai looks to be out for blood, but with Officer Ding right on his heels I can't imagine he'll walk off without being questioned. And how's he going to feel when he learns that Nurse Bai is a willing participant in the sabotage and not being coerced like the seamstress told him? That's going to break his heart especially if he learns about the Nanshen Training class.

4 eps to go!

3 notes

·

View notes

Text

What You Need to Know About Concrete Delivery Services in Derby and Nottingham

When it comes to construction projects in Derby and Nottingham, having a reliable concrete delivery service is crucial. Whether you're working on a small residential project or a large commercial development, the right concrete supplier can make all the difference. In this article, we'll explore everything you need to know about concrete delivery services in Derby and Nottingham, including the benefits they offer and how to choose the right supplier for your needs.

What is Concrete Delivery?

Concrete delivery involves the transportation of freshly mixed concrete from the supplier's plant to the construction site. This ensures that the concrete is delivered promptly and is ready to be used immediately. With concrete delivery services in Derby and Nottingham, you can save time and labor by having the concrete delivered directly to your project site, eliminating the need for onsite mixing.

Benefits of Concrete Delivery Services

Convenience: With concrete delivery services, you can eliminate the hassle of transporting and mixing concrete onsite. This saves time and labor, allowing your construction project to proceed more efficiently.

Quality Assurance: Professional concrete suppliers ensure that the concrete is mixed to the correct specifications, resulting in a high-quality end product. This reduces the risk of errors and ensures that your project meets the required standards.

Cost-Effectiveness: By outsourcing your concrete delivery needs, you can avoid the expense of purchasing and maintaining your own mixing equipment. This can result in significant cost savings over the course of your project.

On-Time Delivery: Reliable concrete delivery services ensure that your concrete arrives on time, allowing your project to stay on schedule. This is essential for meeting deadlines and avoiding costly delays.

What to Look for in a Concrete Delivery Service

Experience: Choose a concrete supplier with extensive experience in the industry. This ensures that they have the knowledge and expertise to meet your project's specific requirements.

Reputation: Research the reputation of the concrete delivery service by reading customer reviews and testimonials. A reputable supplier will have a track record of delivering quality products and excellent customer service.

Reliability: Look for a concrete supplier that offers reliable delivery services, with a fleet of well-maintained vehicles and experienced drivers. This ensures that your concrete arrives on time and in good condition.

Flexibility: Choose a supplier that can accommodate your project's schedule and requirements. Whether you need a small quantity of concrete for a residential project or a large volume for a commercial development, a flexible supplier can meet your needs.

Concrete Delivery in Derby

In Derby, construction projects ranging from residential renovations to large-scale infrastructure developments rely on dependable concrete delivery services. Whether you're building a new driveway, patio, or foundation, having access to quality concrete is essential for ensuring the success of your project.

Concrete Delivery in Nottingham

In Nottingham, construction projects are thriving, with new developments springing up across the city. From residential housing to commercial buildings, concrete is a fundamental building material for construction projects of all sizes. With reliable concrete delivery services in Nottingham, contractors can access the materials they need to complete their projects efficiently and effectively.

Choosing the Right Supplier

When choosing a concrete delivery service in Derby or Nottingham, it's essential to consider factors such as experience, reputation, reliability, and flexibility. By selecting a reputable supplier that meets your project's specific requirements, you can ensure that your construction project proceeds smoothly and successfully.

Conclusion

In conclusion, concrete delivery services play a vital role in construction projects in Derby and Nottingham. By outsourcing your concrete needs to a reliable supplier, you can enjoy the benefits of convenience, quality assurance, cost-effectiveness, and on-time delivery. When choosing a supplier, be sure to consider factors such as experience, reputation, reliability, and flexibility to ensure the success of your project. With the right concrete delivery service by your side, you can build with confidence and achieve outstanding results.

0 notes

Text

Steel vs. Other Building Materials_ Why Tata Structura Stands Out

In the 21st century, customs, traditions, and practices have undergone a significant evolution in various spheres of life. From the way we communicate to the medical treatments we receive. Evolution is evident in every walk of life. Even the construction world isn’t lagging behind in the race. Amongst the many changes that have taken place in the construction world, the utilization and application of steel is the most significant one. It has shaken up the realty sector with it’s valuable characteristics like strength-to-weight ratio, durability, malleability, and very high sustainability quotient. Let's explore how the other building materials have fared in this race and why Tata Structura pipe are leading the way in this revolution.

Concrete

Concrete is a mixture of cement, water, sand, and gravel which hardens to create a solid, strong substance. Concrete is the most widely used construction material in the world after water. However, Steel has many advantages over concrete.

Accelerated Pace

Structures that are made of steel hollow sections, are fabricated in a controlled facility and hence reduce the time consumed on the construction site. It also reduces on-site labor requirements thereby increasing the pace of construction.

Less waste and Pollution

The steel tubes used in the construction can be recycled 100% and hence be reused, unlike concrete.

steel has a very low carbon footprint(1.16 tons of CO2 per ton of fabricated hot-rolled steel). This results in an overall reduction of the pollution caused in the construction activity.

Longevity

Structural steel has the strength and integrity required to withstand small-scale seismic events. With applied coatings, steel is protected from the environmental factors and hence this adds to its longevity, even in corrosion-causing conditions.

Quality Control

Off-site fabrication allows for controlled conditions, ensuring a higher quality product configured to precise tolerances. Thanks to quality control measures, the engineers can exactly predict the building’s response against natural disasters like hurricanes, earthquakes,etc. Concrete is a mix of cement, water, sand, and gravel. It is prepared onsite and cannot always be monitored for quality.

Valuation

Steel's resale value is consistent over its lifetime, with the benefit of superior durability in all environments, unlike concrete.

Wood

Wood is commonly used in the construction of walls, ceilings, and floors, while softwoods are often used to make doors, furniture, and window frames.

Accelerated schedule

Prefabricated steel structures made of hollow section steel pipes reduce the significant amount of time that goes into construction. The wooden structures require sawing or trimming even on the site to fit in the intended use. Moreover, wooden structures can be fitted only during dry weather conditions as they expand during rainy seasons.

Reduced waste and pollution

As discussed steel can be recycled and the wastage percentage is also very less or none. However, when the wood is used, almost 56% of the lumber harvest is lost in the production and converted to chips, sawdust, burned or sent to the landfill. Also if wood gets damaged, it needs to be discarded and an entirely new log is required to advance the construction.

Longevity

Steel offers unparalleled longevity and hence hollow section steel pipes and tubes are rampantly used in the construction world. Whereas, wooden structures can fall prey to insect or vermin infestation, moisture-related mold, rot or decay, or gradual creep under load. Unlike steel, wood is combustible and hence a fire hazard.

Masonry

Masonry consists of building structures made from single units that are bound together with mortar. Brick, stone and, concrete blocks are the most common materials used in masonry construction.

Future modification and adaptability

The structures made of tata steel tubes are designed in such a way that they can be modified or even altered even during construction. This flexibility is not available in masonry.

Wastage

In masonry if the blocks get cracks then it is more likely to be wasted as it has no alternate use.

Lack of ease to operate

The stone blocks used in masonry are difficult to carry around and require more labor power. They also need to be handled carefully to avoid accidents.

High Maintenace

The stone blocks used in masonry are literally sculpted stones and hence susceptible to the growth of moss, small plants, and other flora and fauna if not maintained properly. They require regular upkeep, unlike steel.

In conclusion, while each building material has its own unique characteristics and advantages, steel emerges as a superior choice in terms of strength, durability, recyclability, and ease of construction. Tata Structura's steel pipes, in particular, exemplify these qualities, making them an ideal solution for modern construction projects that demand efficiency, sustainability, and long-lasting performance.

For more details, visit our website: https://www.tatastructura.com

0 notes

Text

Ready Mix Plants Near Me

Exploring Ready Mix Plants Near Me: Convenience, Quality, and Sustainability

Introduction:

In the bustling world of construction, time is often of the essence. Whether you're a contractor working on a large-scale project or a homeowner tackling a DIY endeavor, having access to high-quality concrete is essential. Ready mix plants, often conveniently located near construction sites, offer a solution to this demand. In this article, we delve into the significance of ready mix plants, their benefits, and their contribution to the construction industry's efficiency and sustainability.

The Convenience of Ready Mix Plants:

Ready mix plants, also known as concrete batching plants, are facilities where concrete ingredients are mixed in precise proportions to meet specific project requirements. One of the primary advantages of these plants is their proximity to construction sites. By locating these plants strategically, construction teams can minimize transportation time and costs, thereby increasing overall efficiency.

Imagine a scenario where a construction project requires a steady supply of concrete throughout the day. Without a nearby ready mix plant, contractors would have to transport raw materials to the site and mix them onsite, consuming valuable time and resources. However, with a ready mix plant nearby, concrete can be delivered promptly, allowing construction activities to proceed smoothly.

Moreover, ready mix plants offer the flexibility to adjust concrete mixes according to project needs. Whether it's a high-strength mix for structural elements or a flowable mix for intricate designs, these plants can accommodate various specifications with precision and consistency.

Quality Assurance:

Consistency in quality is paramount in construction projects, and ready mix plants excel in this aspect. These plants employ state-of-the-art equipment and rigorous quality control measures to ensure that each batch of concrete meets industry standards.

Unlike onsite mixing, where factors like weather conditions and human error can affect the quality of the concrete, ready mix plants operate in controlled environments, minimizing variability. Additionally, skilled technicians monitor the mixing process closely, conducting tests to verify the strength, durability, and workability of the concrete.

By adhering to strict quality standards, ready mix plants contribute to the longevity and safety of constructed structures. Contractors can rely on the consistency of ready mix concrete to meet project specifications and exceed client expectations.

Sustainability in Construction:

In an era where sustainability is a growing concern, ready mix plants play a significant role in reducing environmental impact. By optimizing transportation routes and minimizing material wastage, these plants contribute to lower carbon emissions and resource conservation.

Centralized batching at ready mix plants enables efficient use of raw materials, reducing the amount of cement, water, and aggregates required for concrete production. Moreover, advancements in concrete technology have led to the development of eco-friendly mixes that incorporate recycled materials, further reducing environmental footprint.

Furthermore, by promoting just-in-time delivery, ready mix plants help minimize excess inventory and construction waste on-site. This lean approach not only improves efficiency but also reduces the overall environmental footprint of construction projects.

Conclusion:

Ready mix plants near me represent more than just convenient suppliers of concrete; they are pillars of efficiency, quality, and sustainability in the construction industry. By streamlining the concrete production process, these plants enable faster project completion, ensure consistent quality, and minimize environmental impact.

As construction practices evolve to meet the demands of a rapidly changing world, ready mix plants will continue to play a crucial role in shaping the built environment. Whether it's supporting infrastructure development, housing projects, or commercial ventures, these facilities stand as testament to the industry's commitment to innovation and progress. Next time you embark on a construction endeavor, consider the benefits of partnering with a nearby ready mix plant. Not only will you save time and resources, but you'll also contribute to a more sustainable future for generations to come.

1 note

·

View note

Text

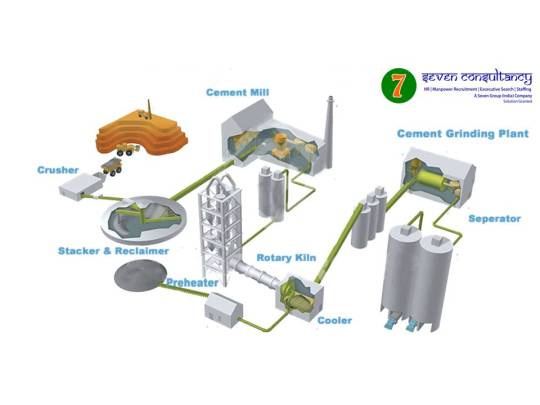

Being the top Cement plant recruiting nation, India provides the best workforce from different regions

Cement is a material that's used to build very strong, hard surfaces and structures. Cement is an ingredient in both mortar, which holds bricks together, and concrete, with which dams and roads and buildings are constructed. The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semi-dry process. Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protection. The significant component in making cement is limestone which is first crushed then sent for pre-blending via belt conveyor. After this activity, the material is stored with other materials. These components are then extracted in precise proportions taking assistance of electronic weigh feeder. At the end the material is sent to raw mill for further fine grinding. The excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. Generally, limestone is 80% and remaining 20% is the clay. In the cement plant, the raw mix is dried, heavy wheel type rollers and rotating tables blend the raw mix and then the roller crushes it to a fine powder to be stored in silos and fed to the kiln.

As a leader in the cement and mining industries, they have taken on the responsibility of developing sustainable solutions. They have an ambition to engineer the zero emissions cement plant and the zero emissions mining process by 2030. And your know-how and innovative mindset will take them from idea to action. As Manager Standardization you will be heading a team of people who supports on the design automation across Mining products in the areas of Proposal, Pricing documents along with product optimization. Your responsibilities are estimate the time line and efforts required to complete the tasks or activities and communicate them to the counterpart, track the projects/tasks on its status and challenges with the onsite team, head the product Standardization team and execute various Standardization projects, organize gate meeting with stake holders and review the project progress, define the design automation required for the project/product and communicate with the team member, maintain the productivity and efficiency of the team, monitor the status of the projects/tasks and provide periodic update to the onsite team. Cement Plant Recruitment Agency in India provides services recruitment.

Recruitment is the process of actively seeking out, finding candidates for a specific position or job. The recruitment definition includes the entire hiring process, from inception to the individual recruit’s integration into the company. Searching out the sources from where required persons will be available for recruitment. If young managers are to be recruited then institutions imparting instructions in business administration will be the best source. Developing is the techniques to attract the suitable candidates. Best Cement Plant Recruitment Agency in India also provides consultancy service. They seek professionals through internal references from their employees, job postings on popular job search portals and recruitment consultants. You are invited to submit your resume on their website for current or future openings. They will maintain it in their database and will contact you in case your profile is suitable for a particular position. Outsourcing is an indirect source of talent. It is a major feature in the oil and gas and building sectors, with many key functions often subcontracted. Taken to the limit, the result is a virtual company directly employing little more than its directors. Finally, the cement industry needs people who can shape its future and create value. Looking to that future, leaders need to be aware that younger workers that they currently employ seek fulfillment, appreciation and being part of a greater goal, rather than just job security.

The last decade or so has seen a lot of growth in the outstanding capacity of cement production and consumption in India. Top Cement Plant Recruitment Agency in India also provides in consultancy sectors. They were already known to be one of the largest producers of cement in the world, and the future is only going to make that position stronger. With digitalization, a mystery can be revealed. Raw meal can be finely controlled to ensure the optimal mix to meet quality targets, while avoiding overspend on additives and higher-quality materials. This optimization brings benefits in terms of lower energy consumption and less wear on mechanical parts. All of which is great for the long-term sustainability of the industry. At higher levels of fuel substitution, such as those implied by BCG, that instability can only be controlled with the aid of digital control solutions.

#CementPlantRecruitmentAgencyinIndia#BestCementPlantRecruitmentAgencyinIndia#TopCementPlantRecruitmentAgencyinIndia

0 notes

Text

7 Ways To Control The Amount Of Cement Pumping

In the bustling world of construction and infrastructure development, managing resources efficiently is the cornerstone of success. Among these resources, cement stands out as a pivotal material, fundamental in laying the foundation and structure of numerous projects such as concrete driveways Hunter Valley. The process of cement pumping, a method employed to transport mixed cement to various parts of a construction site, is critical in ensuring the timely and efficient completion of projects. However, controlling the amount of cement pumped is essential to avoid wastage, ensure structural integrity, and maintain budgetary constraints.

Understanding the intricacies of cement pumping is crucial for any project aiming for success. The process, though seemingly straightforward, involves a complex interplay of machinery, manpower, and material properties. As such, optimising this process can lead to significant improvements in efficiency, cost reduction, and environmental sustainability. With the right approaches, it's possible to achieve a balance that benefits all stakeholders involved, from the contractors and workers to the eventual occupants of the structures being erected.

This article delves into the strategies and methodologies that can be employed to effectively manage and control the amount of cement pumping, a challenge faced by industry professionals worldwide.

Pre-Planning and Calculations

Before initiating the cement pumping process, thorough pre-planning and accurate calculations are essential. This involves a detailed analysis of the project blueprints to determine the exact quantity of cement required for each phase. Utilising advanced software for simulation and modelling can help in predicting the flow of cement and identifying potential bottlenecks or wastage points. By doing so, you ensure that the amount of cement pumped is precisely aligned with the needs of the project, thus minimising excess.

Use of Automated Control Systems

Incorporating automated control systems into cement pumps can significantly enhance precision in the pumping process. These systems use sensors and feedback loops to adjust the flow of cement in real-time, based on the actual requirements of the site. This technology not only reduces the likelihood of over-pumping but also contributes to uniformity in cement distribution, crucial for structural integrity.

Regular Maintenance of Pumping Equipment

The condition of cement pumping equipment directly influences the efficiency and accuracy of the pumping process. Regular maintenance and calibration of pumps ensure that they operate at optimal levels, preventing malfunctions that could lead to uncontrolled cement flow. Scheduled checks should include inspection of hoses, valves, and other critical components to ensure they are in top condition and capable of precise operation.

Training for Operators

Skilled operators are fundamental in controlling the amount of cement pumped. Providing comprehensive training for operators on the nuances of cement pumping equipment and the specifics of each project can lead to more controlled and efficient pumping. This training should cover not only the technical aspects of operating the pumps but also the importance of precision in cement usage.

Real-Time Monitoring and Adjustment

Adopting a proactive approach to monitoring the cement pumping process allows for immediate adjustments if discrepancies arise. This could involve onsite personnel equipped with the knowledge and authority to modify pumping rates or volumes as needed. Real-time monitoring ensures that any deviation from the planned amount can be swiftly corrected, thereby maintaining control over the process.

Implementing Flow Metres

Flow metres installed on the cement pumps can provide accurate, real-time data on the volume of cement being pumped. This information allows for immediate adjustments and helps in maintaining a consistent flow rate, tailored to the requirements of the specific area being worked on. It's an effective way to ensure that the amount of cement pumped does not exceed the calculated need.

Optimising the Mix Design

The properties of the cement mix can significantly affect the ease and efficiency of the pumping process. By optimising the mix design, including adjusting water content and additives, the flow of cement can be more easily controlled. A well-designed mix reduces the risk of blockages and ensures a smoother pumping process, allowing for more precise control of volumes.

The control of cement pumping is a multifaceted challenge that requires a comprehensive approach, combining technology, skilled manpower, and strategic planning. As we have explored, numerous strategies can be employed to optimize this process, each contributing to the efficiency, sustainability, and cost-effectiveness of construction projects. By adopting these practices, industry professionals can ensure that the right amount of cement is delivered where and when it is needed, with minimal waste and maximum efficiency.

0 notes

Text

Simplifying Construction Projects With Onsite Ready Mix Concrete

Discover the convenience and efficiency of onsite ready mix concrete! With this solution, construction teams can have freshly mixed batches delivered directly to their location, eliminating the need for transportation from distant plants. Learn how onsite ready mix concrete streamlines construction projects, reduces waste, and promotes sustainability.

#Accelerating admixtures#ready mix concrete#on site concrete#construction#onsite mixed concrete#concretesupplier

1 note

·

View note

Text

How does Onsite Mixed Screed Works?

Onsite mixed screed refers to the process of preparing screed material at the construction site rather than purchasing pre-mixed screed from a manufacturer. Screed is a thin layer of concrete or a similar material that is applied over a base floor to create a smooth and level surface. Onsite mixed screed is often used in construction projects, and the process involves combining different materials at the site to create the screed mixture. Here are some key points regarding onsite mixed screed:

Components of Screed:Cement: The binding material that holds the screed together.

Aggregates: Typically, sand and sometimes other fine aggregates are used to give the screed its structure.

Water: Essential for the hydration process that causes the screed to harden.

Admixtures: These may be added to the mix to enhance certain properties of the screed, such as setting time or workability.

Mixing Process:The individual components are brought to the construction site, usually in separate bags or bulk form.

The screed mix is then created on-site using mixing equipment such as a concrete mixer or screed mixer.

Careful attention is given to the proportions of the components to ensure the desired properties of the screed.

Advantages:Customization: Onsite mixing allows for adjustments to the screed mix based on specific project requirements, such as strength, drying time, or other performance criteria.

Flexibility: The mix can be tailored to suit the conditions of the site, taking into account factors like temperature and humidity.

Reduced Waste: Onsite mixing can help minimize material waste since the screed is mixed in quantities based on immediate needs.

Quality Control:Quality control is crucial to ensure that the screed meets the required specifications.

Regular testing and monitoring of the mix during the mixing process help maintain the desired quality.

Application: Onsite mixed screed is commonly used in various construction projects, including residential, commercial, and industrial buildings.

It is often applied as a finishing layer over underfloor heating systems, as it provides a smooth and level surface.

Challenges:Skill and Experience: Proper training and experience are essential for onsite mixing to ensure the right proportions and consistency of the screed.

Time Constraints: Onsite mixing may require more time and effort compared to using pre-mixed screed.

In summary, onsite mixed screed offers flexibility and customization but requires careful attention to the mixing process and quality control to ensure a high-quality finished product. Contact readymix concrete supplier for construction work. The choice between onsite mixed screed and pre-mixed screed depends on project requirements, scale, and specific considerations of the construction site.

0 notes

Text

Achieving Excellence in Onsite Mixed Concrete Services in London

When it comes to construction projects, the importance of top-quality concrete cannot be overstated. Whether you're working on a small residential renovation or a large-scale commercial development, the foundation of your success lies in the quality of the concrete you use. In this article, we will delve deep into the world of onsite mixed concrete in London and how our services stand head and shoulders above the rest.

I. Introduction to Onsite Mixed Concrete

Concrete is the backbone of construction, and its quality is non-negotiable. The traditional method of preparing concrete at a central plant and then transporting it to the construction site has its limitations. Onsite mixed concrete, on the other hand, offers a superior alternative. It involves the mixing of concrete right at the construction site, ensuring the freshest and most tailored mix for the specific project.

II. The Advantages of Onsite Mixed Concrete

1. Precision and Customization: One of the key advantages of onsite mixed concrete is the ability to tailor the mix to the exact specifications of your project. We understand that every construction project is unique, and the concrete mix should be too. This precision results in a more robust and reliable foundation.

2. Freshness: Traditional concrete may face issues with setting times and quality due to long transit times from the plant to the construction site. Onsite mixed concrete eliminates this concern by ensuring the freshest mix, promoting better curing and overall strength.

3. Cost-Efficiency: While the initial setup for onsite mixing may seem like an added expense, it can actually save you money in the long run. You use only the amount of concrete you need, reducing waste and costs associated with overordering.

4. Environmentally Friendly: Onsite mixed concrete also contributes to a more sustainable construction process by minimizing the carbon footprint associated with transporting concrete from a central plant.

III. Our Commitment to Excellence

At Save Time Concrete, we take immense pride in our commitment to delivering top-notch onsite mixed concrete in London. Our years of experience in the industry have allowed us to fine-tune our services to ensure that our clients receive nothing but the best. Here's what sets us apart:

1. Premium Quality Materials: We source our raw materials from trusted suppliers, ensuring that the foundation of your project is built on the highest quality concrete components available.

2. Skilled and Experienced Team: Our team of professionals includes skilled technicians and concrete experts who understand the nuances of mixing concrete for different project requirements.

3. State-of-the-Art Equipment: We invest in cutting-edge, state-of-the-art mixing equipment that guarantees the precision and consistency that onsite mixed concrete demands.

4. On-Time Delivery: We understand that time is of the essence in construction. Our streamlined process ensures that your concrete mix is delivered promptly, without any delays.

5. Comprehensive Support: Our commitment doesn't end with the delivery of concrete. We offer guidance and support throughout your project, from initial consultation to post-construction evaluation.

IV. Types of Projects We Cater To

Our onsite mixed concrete services are versatile and can cater to a wide range of construction projects in London. Here are some examples:

1. Residential Construction: For new homes, extensions, or renovations, our concrete mix will provide the foundation your project needs.

2. Commercial Developments: From office buildings to industrial complexes, our concrete services are designed to meet the demanding needs of commercial construction.

3. Infrastructure Projects: Whether it's road construction, bridges, or other infrastructure developments, our concrete is built to withstand the test of time.

4. Landscaping and Hardscaping: Enhance your outdoor spaces with our concrete solutions for landscaping, patios, and more.

V. The Process of Onsite Mixed Concrete

Our process is straightforward, ensuring a hassle-free experience for our clients:

1. Consultation: We start with a comprehensive consultation to understand the specific needs of your project.

2. Customized Mix: Our experts will design a concrete mix that precisely matches your requirements, considering factors like strength, durability, and weather conditions.

3. Mixing and Delivery: The mixing process takes place right at your construction site, guaranteeing freshness and quality. Our efficient delivery ensures your project remains on schedule.

4. Expert Advice: Throughout the project, our team is available to provide guidance and address any concerns that may arise.

VI. Conclusion

In the world of construction, the quality of your concrete is the cornerstone of your success. With our onsite mixed concrete in London, you can be confident that your project is in the hands of experts who are committed to delivering excellence. Don't settle for less; choose the best in the industry.

At Save Time Concrete, we take pride in offering not just concrete but the foundation of your success. Contact us today for a consultation and experience the difference that our top-notch onsite mixed concrete services can make for your construction project.

0 notes

Photo

West London Concrete is a preferred service provider of on site mixed concrete covering London and its surrounding areas. We have been serving our customers for many years and have always ensured to meet their requirements with the highest degree of material specifications. West London Concrete Offers Superior-Quality On Site Mixed Concrete at Affordable Pricing. West London Concrete is known for its professional approach and high-quality materials, and customised services in everything related to construction.

#onsite mixed concrete#mix concrete#onsite mix concrete#Concrete Construction#concrete supplier#concrete#west london#Watford#concrete concreteservice WestLondon uk

0 notes

Photo

Our onsite concrete mix is the perfect solution for large-scale construction projects. Trust Save Time Concrete for all your concrete needs!

0 notes