#pellet feed making machine

Text

Herm’s Exhibition in China Commodities Expo-Nigeria 2023 was a Complete Success

As a relatively well-known animal feed-making machine manufacturer in China, Henan Herm Machinery Co., Ltd participated in China Commodities Expo-Nigeria 2023. This exhibition has brought us rich rewards.

Enhanced Visibility: Showcasing our products and services at the exhibition provided an excellent opportunity to increase our visibility. We meticulously arranged our booth, showcasing our latest and most attractive products, as well as the various services we offer. Our feed pellet production line videos, 3D models, image displays, and various types of feed products were comprehensively presented to customers.

During the exhibition, our team members actively engaged with visitors, introducing the features, advantages, and applications of our products. We also provided demonstrations and samples for visitors to experience our products firsthand. Meanwhile, our staff patiently answered visitors' questions, addressing any concerns or queries they may have had.

Market Insights: By interacting with other exhibitors and observing the activities of competitors and other exhibitors, we gained valuable insights into market trends, customer preferences, and emerging technologies. This information is crucial for shaping our strategies and maintaining market competitiveness.

Expanded Customer Base: Through interactions with attendees, we collected a large number of potential customer contact information, laying a solid foundation for expanding our business.

youtube

In-depth Product Understanding: During the exhibition, we noticed that many attendees showed a keen interest in our products and sought detailed information about them. Firstly, we showcased our products at the booth and provided detailed demonstrations and explanations to customers. Our displays included information on product features, characteristics, application scenarios, and comparative advantages over competing products.

This allowed customers to gain a comprehensive understanding of our products and deepen their appreciation of their performance and suitability. Secondly, our team members accompanied customers throughout the exhibition, patiently answering their questions and concerns. Customers had the opportunity to engage in in-depth discussions with us, asking about technical details, usage methods, and after-sales service.

Our team members provided professional answers and comprehensive support and guidance to customers. In addition to face-to-face interactions at the booth, we also provided customers with readily available materials such as product manuals, technical specifications, and user case studies. These materials allowed customers to continue their product exploration after the exhibition, enabling them to make more informed decisions.

Overall, we provided customers with ample opportunities and resources to deepen their understanding of our products. Customers' keen interest in and detailed understanding of the products demonstrate the attractiveness of our products and their ability to meet customer needs, laying a solid foundation for establishing strong business relationships with these customers in the future.

New Customers Placing Direct Orders: During the exhibition, some new customers showed a strong interest in our products and placed direct orders to purchase them. This direct ordering behavior indicates their trust and satisfaction with our products and reflects the attractiveness and competitiveness of our products. These new customers may have gained a comprehensive understanding of our products after interacting with our team members and developed confidence in their performance, quality, and suitability. Their positive attitude towards our products is gratifying and makes us more optimistic about the market prospects for our products.

For our team, new customers placing direct orders are an important achievement and recognition of our efforts and performance at the exhibition. It also demonstrates the effectiveness of our sales strategies and product demonstrations. The orders from these new customers not only bring tangible business revenue but also establish new customer relationships, laying the foundation for future business development.

Meeting with Existing Customers: During the exhibition, we were delighted to find that some existing customers specifically came to meet with us. This indicates their trust and loyalty to our brand and services, as well as their continued interest in maintaining business relationships with us. Firstly, meeting with existing customers is a meaningful interaction. This face-to-face communication not only strengthens our relationship with customers but also allows us to gain deeper insights into their needs and feedback.

We can listen to their opinions and suggestions, understand their views on our products and services, and further enhance the quality of our products and services. Secondly, the arrival of existing customers also brought valuable feedback and suggestions. They may share their usage experiences, encountered problems, and views on our future development direction. This feedback is significant for improving products, optimizing services, and formulating future development strategies. We will listen carefully and adopt their suggestions to ensure that we can continue to meet customer needs and provide better services.

Lastly, the arrival of existing customers also serves as an affirmation and support for our brand. Their willingness to come to the exhibition specifically to meet with us indicates their recognition and trust in our brand. This support inspires us to continue working hard to provide customers with better products and services and maintain long-term cooperation with them.

Overall, meeting with existing customers is a valuable experience that demonstrates their trust and loyalty to us. This interaction not only deepens our relationship with customers but also brings valuable feedback and suggestions, providing important references and support for our future development.

Media Coverage and Promotion: During the exhibition, we also attracted considerable attention from international media and received detailed interviews and coverage.

In summary, this exhibition has brought us rich rewards, and we are deeply grateful and pleased. Customer trust and support are key factors in our success. It is because of your support and encouragement that we can continue to grow and progress. We will continue to work hard to provide you with better products and services and grow and develop. Thank you once again for your trust and support!

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Phone/Whatsapp: 0086-18037508651

0 notes

Text

#✅GROW YOUR BUSINESS WITH Sanjivani Agro Machinery#👉👉 Sanjivani Agro Machinery#WE ARE THE MANUFACTURE & EXPORTER OF ANIMAL FEED MAKING MACHINE !#Sanjivanii Agro Machinery & Vidarbha Sales#One of the leading manufacturers and exporters of the Cattle Feed Machine#Poultry Feed Machine#Biomass Pellet Machine#Floating Fish Food#Organic Fertilizer Machine etc.#- Customer Care Support#- Safe & Trusted Transport#- 100% Original Product -#All India Delivery Available#More Details: www.sanjivanii.com#Youtube Link: https://bit.ly/2AKrcz0#Call: +91 72190 30002#smallbusinessidea2022#manufacturingbusinessidea#animalfeedmachine#animalfeed#animalfeedpelletmachine#animalfeedmachinepriceindia#agromachine#fishfeedmachine#cattlefeedpelletemakingmachine#pelletmachine#agromachinenagpur#agromachinemanufactures#cyclonegrinder#poultryfeed

2 notes

·

View notes

Text

youtube

Feed pellet making machine,chattle animal feeding machine,animal feed pellet making machine.

#Youtube#youtube shorts#youtube video#laxmi enterprises is the leading manufacturer#laxmienterprises#Feed pellet making machine#chattle animal feeding machine#animal feed pellet making machine.

0 notes

Text

Fish Feed Pellet Making Machine Market Outlook, Current and Future Landscape Analysis 2023 to 2033

The global fish feed pellet making machines market is expected to reach US$ 2,167.9 million in 2033, growing at a 5.6% CAGR between 2023 and 2033. The market is expected to reach $1,257.2 million by 2023.

According to FMI, increased exports of fish and other seafood products from various countries around the world are expected to drive market sales. International companies are expected to enter emerging economies in order to capture the overall industry.

Furthermore, rising awareness of the importance of sustainability as well as animal welfare is expected to boost sales of organic farming. As a result, fish farmers use organic farming methods to provide chemical-free and genetically modified products.

The growing consumer preference for organic foods is expected to compel key manufacturers to increase their organic feed production capacity. Other factors that would accelerate market sales include changing eating habits and lifestyles of consumers in both developed and developing countries.

Request a Sample to Obtain Authentic Analysis @

https://www.futuremarketinsights.com/reports/sample/rep-gb-16533

Key Takeaways from the Fish Feed Pellet Making Machine Market Study:

Top 3 countries in the global fish feed pellet making machine market are projected to generate a share of 8% in the next ten years.

The global fish feed pellet making machine market is estimated to be valued at US$ 1,190.5 million by the end of 2022 from a valuation of US$ 1,006.0 million in 2018.

The USA fish feed pellet making machine market is anticipated to generate the lion’s share of nearly 8% by 2033.

Germany fish feed pellet making machine market is predicted to account for a considerable share of about 3% in Europe during the estimated time frame.

In Asia Pacific, India is likely to witness moderate growth and exhibit a CAGR of 3% from 2023 to 2033.

“Key companies in the fish feed pellet making machine market are anticipated to invest huge sums in the manufacturing of dry pelleted fish feed. This type of feed is projected to be extensively used for improving digestibility and balance of nutrients for matching specific needs of various fish species,” says a lead analyst at Future Market Insights.

Competition Landscape: Fish Feed Pellet Making Machine Market

Leading players in the fish feed pellet making machine market are CPM Asia, Andritz Group, Buhler AG, Salmco Ltd., and Zhengchang Group among others. These companies are aiming to strengthen their positions in the global market by launching state-of-the-art equipment. A few other players are striving to generate more shares by joining hands with local companies across the globe.

Get Valuable Insights into Fish Feed Pellet Making Machine Market

FMI, in its new offering, provides an unbiased analysis of the fish feed pellet making machine market presenting historical demand data (2018 to 2022) and forecast statistics for the period from (2023 to 2033). The study divulges compelling insights on the demand for fish feed pellet making machine market based on type (ring die pellet mill, flat die pellet mill), by application (small-scale aquaculture, large-scale aquaculture, others), by sales channel (online, offline), and by region (North America, Europe, Asia Pacific, Latin America, the Middle East and Africa).

For More Information on this Report @

https://www.futuremarketinsights.com/reports/fish-feed-pellet-making-machine-market

Fish Feed Pellet Making Machine Market Outlook by Category

By Type:

Ring Die Pellet Mill

Flat Die Pellet Mill

By Application:

Small-Scale Aquaculture

Large-Scale Aquaculture

Others

By Sales Channel:

Online

Offline

By Region:

North America

Europe

Asia Pacific

Latin America

MEA

RoW

0 notes

Text

hot sale poultry animal feed mill in Philippines

Hammer mill & Cyclone

Multifunctional straw crusher produces 200kg-2000kg/h, which can meet the daily production needs. The core part -- the hammer is scientifically designed with two impact parts, so when one part wears out, you can roll over and use the other part.Rough grinding and fine grinding can be achieved by adjusting the gap between the hammer and the screen.

Change the size of the screen and the variable speed inverter control so that the same crusher can process various raw materials.Equipped with a blower, the mesh material can be collected directly and transported to the next step for further processing.

Mixing machine

Unique design system ensures full airflow balance of feed, suitable for premix, poultry feed, aquatic feed, additives, chemical and pharmaceutical industries.Different types of raw materials are added to the mixer in batches according to different animal formula requirements. Come to see the feed mixer machine.

Widely used for mixing animal feed and fertilizer powder, granule etc.,various liquid can be added. Mixing time per batch is just 3-6minutes, Now it is widely used in animal feed industry, fertilizer industry, aquatic product breeding, chemical industry, aquatic product breeding, medicine and so on.

Pellet machine

Pellet machine is the key equipment of production the feed pellet, Widely used in feed factory, farm and other. Come to see the fish pellet making machine.

1. Flat Die Pellet Mill Mainly suitable for medium-and small-scale farming professional households and other processing of various livestock and poultry and aquatic pellet feed can reduce the cost of aquaculture.

2.Feed machine can be used for raising rabbits, chickens, ducks, geese, fish, pigs, cattle, sheep, aquatic products and so on.

Cooling & screening machine

The pellets from the granulator at a temperature of 70 ° C to 90 ° C to a temperature slightly above room temperature of 3 ° C to 5 ° C, and can be reduced to safe moisture (≤ 12.5%), which is convenient for pellets. Transportation, storage and storage.

The screening machine can screened out complete granules, and unqualified granular products will be separated for secondary granulation, effectively reducing waste.

Have a good day!

#lima feed machine#animal feed machine#lima machinery#fish feed machine#fish pellet making machine#feed mixer machine#lima feed machines#feed cooler machine

1 note

·

View note

Video

#animal feed pellet machine for sale#feed pellet making machine#richi pellet machine#richi machinery

0 notes

Text

Tips On Feeding Betta Fish

Lastly, check the regulations in individual reasons area across the keeping of chickens as there is nothing worse than generating a backyard brood and discovering you aren't allowed keep them, or have since or your coop is with the wrong placed. There can be restrictions which you'll want to get before you'll consider several of the above so when you are positioned your chickens will be nothing but a full satisfaction.

If the pellet stove does not have a back-up power supply, the loss of electric power means no heat a few potential smoke in a ton of snakes. A battery back-up can thought of good idea.

When developing a hamster to buy pet you will have adequate housing. Hamsters love tunnels and exercise wheels and will definitely spend hours on small gym. A holder is quite aware the time a hamster spends awake until the exercise wheel can a great annoying squeak. When you have listened to two hours or even more straight owing to an exercise wheel you should exactly a few things i am referring to.

It will often be difficult trying to obtain a suitable food offering one almost all the desired nutrients to feed two fish of different varieties when there always be several of every in water-feature. To make wood chipper price , finding one easy food to match both fish is like finding a packet of gold.

Every responsible bird owner should know that there are certain foods and particular ingredients that has got to never be fed to a dog bird. This is the list of six (6) food items that should not be fed a new bird or caution must be taken from the preparation of the food.

You might set up a variety of targets within a large circular pattern, each target becoming progressively smaller as you progress around the circle. Assign points each and every target, the cost of each rising as the targets grow smaller. Appoint a scorekeeper to follow each competitor and record points they accumulate. Figure out how many shots may be permitted per target, and determine the penalty for feed pellet mill for sale doesn't quite get.

pellet making machine for sale in south africa and Bettas should certainly have their bowl clean or they'll get hurt. Remember that they live, breathe and eat typically the same environment in them to poop. Nice and clean of pleasant opinion. cmg granulators should clean your fishbowl about once 7 days.

A pellet stove usually needs regarding refueled every day. It has a fuel storage made in that supports the pellets until they will be required for reduction. Normally these storages fit between 35 to 130 pounds of pellets, dependant upon the model.

#pellet mill#pellet machine#feed pellet making machine#pellet making machine#wood pellet machine#wood pellet maker#fish feed machine#pellet press#poultry feed machine#straw pelletizer#pellet extruder#feed pellet machine#wood pellet mill

1 note

·

View note

Text

Be Warmer This Winter With A Pellet Stove

The fuel for pellet stoves is certainly not less than pure recycled power. Is actually also made from 100% recycled sawdust without additives. Pellet is can be a heating source made from manufacturing by-products that would certainly end up at the landfill. Pellets can additionally be made from wood chips, bark, agricultural crop waste, waste paper, and other organic provides. It is truly quite remarkable how stuff that seems like waste can be turned into great warmth for you home.

Grit (small rocks): Chickens hold grit in their gizzards. A gizzard is an organ that ginds up feed this easier to digest. Use more grit in the winter months when rocks are harder to seek out. If you realize that shells are thin and soft add oyster shells for lime scale.

If you aren't sure about the insulation inside your home, by yourself want to see whether there are grants or incentives strengthen the padding. Free insulation is on the market for some people, and as a consequence it can dramatically lessen amount of cash you commit to heating your home.

AEG's (automatic electric guns): These would definitely be the chosen the more seasoned, serious hobbyist. Normally consisting associated with full metal body and metal gearbox, these guns use a battery-operated motor providing an entirely automatic machine gun, if desired. Again, you would use .2 g or heavier 6mm BBs.

You don't need a big stove in order to big. A lot of the used corn and wood pellet stoves I've seen produce 35,000-45,000 btus - enough to heat a common 1,200 sq . ft . ranch as well as main living areas that are of a two story home.

Say the cord of firewood costs $150 green, delivered to your residence. websites equals $750 for one year, which usually considerably as compared to pellet press machine gas or oil. Probably less than half might. If you buy seasoned firewood, you will pay up to double that amount.

So something else ? conclude which are generally unhappy and they generally to be able to stay method? That doesn't make any sense either. Walk up to your random person on the highway and inquire list heli-copter flight things that are connecting badly in life right now and are usually almost restricted by rattle off a quick list of five or ten things.

#pellet mill#pellet machine#feed pellet making machine#pellet making machine#wood pellet machine#wood pellet maker#fish feed machine#pellet press#poultry feed machine#straw pelletizer#pellet extruder#feed pellet machine#wood pellet mill

1 note

·

View note

Text

I love Warframe, so much.

The super fluid, only touch the ground to start another parkour sequence, the floor is lava, bouncing off walls and flying across rooms and down hallways style of movement.

The >utterly overwhelming< number of weapons available. Primaries range from bows (Paris, Dread) to rocket launchers (ogris) grenade launchers (penta, tonkor), a handheld laser cannon (opticor), spicy bows (Lenz and Bramma are both rocket launchers cosplaying as bows), an 18th century naval cannon (zarr), machine guns with a 200 round magazine (soma prime) and machine guns that get more accurate the longer you fire (Tenora my beloved), innately suppressed smg (baza). You want a chaining lightning gun that will kill the guy you’re aiming at, and the next two rooms of people via daisy chains? Amprex. if you need a tactical weapon for grouping enemies the Mutalist cernos shoots an arrow full of grabby tentacles that brings enemies together for group hugs. Do you need a rifle to hunt cthulu T-Rexes (eidolons)? Rubico (Prime) or, my favorite, Kuva Chakkhurr - a black powder musket that shoots moderately slow projectiles, high skill high reward, you land a shot, it’s gonna feel it. Here’s a goody - Tigris (Prime) - it’s a double barreled shotgun, with a duplex trigger - you squeeze the trigger, it fires one round, you release the trigger, it fires the second! really interesting to play with, though with the changes to shotgun status a few years ago it’s no longer the powerhouse it was, though quite potent. Phenmor is also one of my favorites, a precision semi auto rifle, land a couple headshots to charge it, and it evolves into an archgun (gun for mecha or exosuits, bigger, and badder) that’s basically a minigun. Corinth (prime) is cool, primary fire is crit based shotgun, alt fire shoots an air burst grenade you can manually detonate over enemies heads (prime version, regular corinth is locked at 20m detonation). Kohm is an auto shotgun that spoils up like a minigun, the higher the spool the more pellets it shoots, very ammo hungry, but man if it isn’t satisfying to point down a hallway and watch it fill with red mist. Astilla is a shotgun that shoots glass slugs that explode on impact. Arcs Plasmor shoots solid walls of energy. like straight up, point down hallway, and you shoot a bright blue (ur energy color) brick wall of plasma. you can’t miss. Simulor is a gun that shoots miniature black holes. Trumna charges it’s alt fire with the literal souls of the enemies you kill. Shedu and Bubonico are the weapon arm cannons of sentient (enemy robot faction) that we ripped off and stole.

secondaries are have a bit less variety, but we’ve still got oodles of goodies

Pandero, a pocket sniper rifle, this lil handcannon is hella accurate for reaching out to touch someone, and alt fire dumps the entire magazine in an automatic burst. Laetum is the cooler pandero, land a few headshots and it evolves into an automatic assault rifle. Lex (Prime) was my starchart clearing gun, back in the day. space deagle. Nukor (and it’s cooler older sister Kuva Nukor (Kukor)) are similar to the amprex in that they chain to enemies, however they also have the quirk of having the highest critical damage in the game, with the lowest critical chance. (there’s shenanigans you can do to force them to crit, making them devestating). Pyrana (Prime) is an auto shotgun, it’s got high spread and high rate of fire, but get in their face and drop mag and see the magic. Zakti (Prime) shoots small needles that explode in clouds of aoe gas after a moment, really good for priming status effects and swapping to melee or primary to take advantage of. Euphona Prime - look, i love it, it’s not great, you gotta build it exclusively for the slug firemode or for the shotgun fire mode. it’s really cool, you should try it if you can, but it’s solidly just okay. Sepulcrum feeds on the souls of its victims to power its alt fire, and it’s just a massive beefy fuckin pistol straight out of 40K. Tenet Spirex force procs impact, and with the hemorrhage mod you can guarantee you turn some of those impact procs into bleed procs for DOT damage. Athodai is straight up like retro sci-fi laser pistol, it shoots beams, and alt fire has a big burst of energy aoe in front of you. Twin Kohmak are like the kohm, but smaller, and akimbo, for pocket dakka. Twin Grakata MOAR DAKKA. A beloved meme gun in the warframe community. just two fuckin bullet hoses that will eat your ammo faster than you can find it. truly one of the guns of all time, and a joy to fire.

and don’t think for a moment i’m going to forget about melees lmao.

we got Nikanas (space katana - nikana (prime) , skiajati ), we got greatswords(Gram (prime), Galatine (prime)), we got throwing glaives(Glaive(prime) Xoris), we got gun blades (like think those bizarre renaissance era swords with guns built into the hilts? got it? yeah, those, but space-y. redeemer (prime), sarpa), we have claws (venka) , we have sword & board (silva & aegis) scythes (reaper prime), hammers (heliocor, jat kittag), dual blades up the wazoo, single daggers, dual daggers, fist weapons, fist and feet weapons, war fans (quassus, arum spinosa), staves (Bo, pupacyst), tonfa (kronen), a gigantic saw (ghoulsaw), rapiers (endura, ), blade & whips (atterax, lacera)

#warframe#long post#totally normal about this game#also i own almost every weapon#i’m missing the most recent 5

28 notes

·

View notes

Text

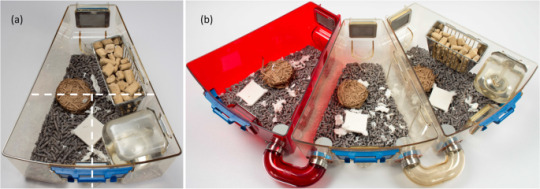

Upgrading Lab-mouse cages

This topic goes close to me bc I work in a lab and have hours every day to think about what I can do for these tiny creatures

Lab mice are kept in these cages by standard:

The minimum legal enrichment (at least in germany) is a nest, something to climb, something to chew, and a way to socialize. This cage has a hut for a nest, the top bars for climbing and the hardened pellets for chewing

In my opinion that's both unfitting and not enough. There's some very simple changes and a lot of bigger/harder changes:

Simple changes:

Using wooden or paper huts. It's commonly believed that mice can't see red, but in reality they will always choose darker colours and more natural materials as hides

lowering the light in one part of the cage, eg simple cage sleeves, lowering the general room light, shading the rack

raising the temperature. Mouse are generally kept at 21 - 24°C, but really prefer 26 - 30°C

scanning the room for ultra sounds

scattering some grains for foraging (this is also perfect for training the mice to make health checks easier)

Other still very simple changes:

adding nesting materials. Mouse prefer paper scraps, paper towels, etc, but there's also cotton squares and wood wool commercially available

adding wood for chewing. Again there's many options ranging from wooden bricks over wooden huts to whole branches

adding a running plate or wheel (I know running plates are said to cause spinal deformity, but in my experience that is a very low chance as opposed to the negative effects no movement has)

adding more bedding so digging is easier

adding tubes, boxes, swings and climbing structures

Changes that get closer to pet keeping:

add diggable bedding for builing nests and tunnels

add more huts. More! Mooore! (seriously mouse love a cluttered space and feel most comfortable walking along walls)

add a second layer (most easy part is just wedging a wooden board in there) and raising the top bars (there's raised cage tops for more height)

adding a maze/labyrinth to allow the mice to compartimentalise their cage/hide from light, sounds, movement, etc

stopping to feed ad libitum. In comercial setting, this can be done with feeding machines, privately this can be done by feeding like any other pet (adding a bowl of fresh food twice a day and removing after an hour or two)

scatter feeding instead of having the food in a rack

adding a digging box

Changes for pet keeping:

Going at least one, better two sizes up with the cages

adding toys

adding more mice to the group (in research most mice are kept in groups of 2 to 5. Mice prefer bigger groups though (plus "two" is a pair, not a group))

adding a big, big layer of bedding (see previous category)

adding toys, including food toys, smell toys, etc

giving food treats like yogurt, comercial treats, varied food, dead or life insects (mice are good hunters!)

feeding grains and similar (if you're unsure about a balanced diet, feeding grains additionally to pellets is totally fine)

adding a bigger wheel or running plate (a wheel is better, if you can provide a good one with appropriate size)

offer a free run time. This could for example be in a bath tub. Lay it out with linen or carpets, fill the tub with toys, treats and cardboard boxes, and offer the mice to go there (eg by builing a stairwell, or by training them "taxi" with a travel box)

spend regular time with them to aclimate them to humans

Changes for a near perfect enclosure:

Upgrate to an aquarium with a grid top

add more climbing options. Like way more!

Put heavier huts on stilts

Add even more tunnels

provide fresh food

change up their enrichment (eg digging box, swimming pool, fresh plants, offer tea additionally to water)

All these images have good and bad items, and imo all enclosures can be adapted to the housed animals needs. I'll try to add credit, but please message me if you have questions about specific images

I was about to add sources but found some great in a single site: here

I also always recommend bin cages as they are cheap and very very customisable. The best example I found is this one

#long post#mouse care#mice#rodents#pet enclosure#my post#lab mice#enrichment#idk I have no based opinions about beddings#this post is not quite yet what I want it to but we're getting there#feel free to message me about any of this#I love talking about mice#I'll try to add some sources#lowkey proud of my first post#pls support me by reblogging and commenting

18 notes

·

View notes

Video

youtube

Biomass Pellet Machine Manufacturer, Biomass Pellet Production Line, JNSHARE, China, Fuel Plants

We are a pellet machine manufacturer, and we provide pellet machines to fuel plants to make fuel pellets. Not only fuel plants, but also feed mills, wood processing plants, fertilizer plants, chemical plants, etc., our biomass pellet machines with small investment, quick results and high profits.

Our company is JINAN SHARE PRECISION MACHINERY CO.,LTD. We are producing pellet machine and complete lines already for 18 years, and our key machines are biomass pellet machine, wood pellet mill, wood chipper, wood crusher, wood hammer mill, rotary dryer, pellet cooler and the complete lines. The output is from several kgs to several tons per hour. If any interest, feel free to connect us.

#pelletmachine #pelletmachinemanufacturer #biomasswoodpelletmachine #biomassenergy #biomassfuel #biomasspellets #pelletmachinesuppliers #msw

TEL/Wechat/ Whatsapp: +86 15053177578

Email: [email protected]

[email protected]

web: www.jnshare.com

www.pelletmill.cn

0 notes

Text

Factors Influencing the Production Benefits of Feed Pellet Machines

Due to challenges in process design and operational technology, the feed factory faced issues with the quality and output of its finished products. The particles exhibited uneven surfaces, high powder content, brittleness, and inconsistency. A comprehensive practical analysis revealed several critical factors influencing granulation efficiency:

Raw Materials:

Starch Content: High starch content facilitates gelatinization, which, when combined with proper conditioning, creates a conducive, viscous state for effective molding.

Crude Fiber: Elevated crude fiber increases friction in the ring die. The addition of a specific amount of grease aids material passage through the die hole and enhances the surface finish of the final product.

Crushing Diameter: Optimal crushing diameters vary based on raw materials. For instance, using a 2.5-3mm sieve plate is recommended for crushed corn in livestock and poultry feed.

Feed Control:

Comprehensive Monitoring: During periods of reduced production efficiency, addressing pelleting issues alone is insufficient. Comprehensive monitoring of incoming material control is crucial.

Production Operation:

Precise Adjustments: Fine-tuning each part of the poultry feed pellet machine, including the die and pressure roller (controlled at 0.05~0.30 mm), prevents issues such as excessive noise and ensures optimal material granulation.

Gap Control: Maintaining a controlled gap of 2-3 mm between the upper edge curve of the scraper and the die and die cover is critical for smooth pellet feed machine operation.

Start-Up Observations: Careful observation during start-up helps identify irregularities in particle discharge. Preventing the introduction of contaminants into the die contributes to a more efficient granulation process.

Ring Die:

Factors Influencing Material Ejection: Factors like the friction coefficient between the material and the die wall, moisture content, particle size, temperature, plasticity, and compressibility influence the smooth ejection of material.

Conditioning Factors:

Blade Wear Impact: Worn conditioner blades negatively impact material conditioning, affecting particle output and steam absorption.

Material Softening: Proper softening of conditioner material is crucial for achieving the desired pulverization rate and output.

Temperature Control: Specific temperature recommendations, like 70~88°C for livestock and poultry feed, optimize conditioning effects.

Steam Factor:

Steam Conveyance Challenges: Saturated steam entry during conveying results in energy loss and condensed water formation, negatively affecting conditioning.

Condensed Water Management: Discharging condensed water before conditioning and converting it into low-pressure dry hot steam through a pressure-reducing valve enhances conditioning effects.

Pressure and Temperature Control: Maintaining steam pressure above 0.2 MPa and a temperature not lower than 120 ℃ post-decompression ensures an optimized conditioning process.

By addressing these factors systematically, the feed factory can optimize the performance of the feed pellet machine, improving product quality and increasing overall output.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Phone/Whatsapp: 0086-18037508651

0 notes

Text

Animal Feed Making Machine

We have the best deals for Animal Feed Making Machine at Indian Trade Bird. We are the leading manufacturer, supplier and exporter of Animal Feed Making Machine like Biomass Machine, Pelleting Machine 20HP, Bar Feeder Machine, Cattle Feed Plant, Poultry Feed Plant, Cattle Feed Mixer Machine, Hammer Mill Feed Grinder, Feed Mixer Machine and many more are available. A animal feed making machine is also called a animal feed maker, where they can be used to make animal feed from other animals. The feed machines are animal feed machines and animal feeders in large-scale, small-scale, and home animal feed making machines. Our Animal Feed Making Machine are highly demanded in the market due to their optimum efficiency, utility, and durability. The machines manufactured is assembled from the top quality component and advanced technology. These machines are highly beneficial as it provides complete automation, excellent performance, high production rates, and the best quality production.

0 notes

Text

The Essential Guide to Pipe Extruders by DRTS

Pipe Extruders are a crucial part of modern manufacturing, playing an essential role in creating various types of pipes used in countless industries. If you're looking to understand more about pipe extruders, you're in the right place. At DRTS, we specialize in providing top-of-the-line pipe extrusion equipment, and we're here to share our expertise with you.

What Are Pipe Extruders?

Pipe extruders are machines used to produce plastic pipes through a process called extrusion. This process involves melting raw plastic materials and shaping them into continuous pipes. These pipes can be used in various applications, including plumbing, irrigation, and industrial systems.

How Do Pipe Extruders Work?

The pipe extrusion process starts with feeding plastic pellets or granules into a hopper. These materials are then heated and melted in an extruder barrel. The molten plastic is pushed through a die, which shapes it into the desired pipe form. After exiting the die, the pipe is cooled and solidified, typically using a water cooling system. Finally, the pipe is cut to the required length and prepared for use.

Types of Pipe Extruders

Single-Screw Extruders: These are the most common type of extruders. They consist of a single rotating screw that moves the plastic material through the barrel. They are suitable for most general-purpose pipe extrusion tasks.

Twin-Screw Extruders: These extruders have two screws that rotate together, providing better mixing and more consistent output. They are ideal for producing pipes with complex materials or additives.

Co-Extruders: These are used for producing multi-layered pipes. Co-extrusion allows different materials to be combined in a single pipe, offering unique properties such as improved strength or chemical resistance.

Benefits of Using Pipe Extruders

Efficiency: Pipe extruders can produce pipes continuously, ensuring a steady supply for various applications.

Customization: The extrusion process allows for precise control over the pipe's dimensions, thickness, and material composition, enabling tailored solutions for specific needs.

Cost-Effectiveness: By producing pipes in large quantities, extruders help lower production costs, making it more economical for manufacturers and end-users.

Versatility: Pipe extruders can handle a wide range of plastic materials, including PVC, PE, PP, and more, making them suitable for diverse industries.

Applications of Pipe Extruders

Plumbing: Extruded pipes are commonly used in residential and commercial plumbing systems due to their durability and reliability.

Irrigation: Agriculture relies heavily on extruded pipes for efficient water distribution, ensuring crops receive an adequate water supply.

Industrial Systems: Many industries use extruded pipes for transporting fluids and gases, thanks to their strength and resistance to corrosion.

Telecommunication: Extruded pipes are also used to protect and manage cables in telecommunication systems.

Why Choose DRTS for Your Pipe Extrusion Needs?

At DRTS, we are committed to delivering high-quality pipe extrusion solutions. Here’s why you should consider us:

Expertise: With years of experience in the field, we understand the nuances of pipe extrusion technology and can provide tailored solutions to meet your specific requirements.

Innovation: We constantly innovate to bring the latest advancements in extrusion technology to our clients, ensuring you get the most efficient and effective equipment.

Support: Our team of experts is always ready to provide support and guidance, from selecting the right equipment to installation and maintenance.

Quality: We prioritize quality in every aspect of our service, from the materials we use to the finished products we deliver.

Conclusion

Pipe extruders are indispensable tools in the manufacturing of pipes for various applications. Understanding how they work and the benefits they offer can help you make informed decisions for your production needs. At DRTS, we are dedicated to providing top-notch pipe extrusion solutions to help you achieve your goals efficiently and effectively. Whether you're in plumbing, irrigation, or any other industry that relies on high-quality pipes, we have the expertise and equipment to support your success. Contact us today to learn more about our offerings and how we can assist you in your pipe extrusion needs.

#Pipe Extruders#pipe extruder#extruding machine#Turnkey Extrusion Pipe Machinery#DRTS Pipe Extruders#plastic pipe extruders#pipe extrusion#pipe plastic extruder#pipe production line

1 note

·

View note

Text

Breeding technology of laying hens

1. Create a suitable living environment for laying hens

In order to make laying hens produce more eggs, it is necessary to create a suitable growth and egg-laying environment for the chickens as much as possible, and to take corresponding supporting feeding and management measures according to the changing laws of different seasons. In the high temperature and high humidity season in summer, attention should be paid to preventing heatstroke and cooling, strengthening ventilation in the house, maintaining a dry environment, providing sufficient and clean drinking water to the chickens, and appropriately increasing the feeding amount of green vegetables to improve the feeding ability of chickens . In winter, special attention should be paid to the cold protection and heat preservation of the chicken house and artificial supplementary lighting. The temperature in the house should be maintained above 13 ℃, the light should be 15-16 hours, and the drinking water should be properly warmed, and ice water should not be drunk.

So if you have a chicken farm, you can try the chicken feed pellet machine which can help you make the pellet.

2. Pay attention to saving feed

The biggest expense of raising chickens is feed, which accounts for more than 70% of the total cost of raising chickens. Improper feeding and management will inevitably lead to a large amount of waste of feed. The measures to reduce feed waste are: First, the installation height, depth and length of the feed trough should be exchanged according to the different weeks of age and cage density of laying hens, and the amount of feed added should not exceed 1/3 of the depth of the trough. It is necessary to feed less frequently, reduce the leftover food in the tank, and determine the daily feed amount based on the egg production rate. Generally, when the egg production rate is 50%-60%, the daily feeding amount of each chicken is about 95-100 grams, and the egg production rate is about 95-100 grams.

When the egg production rate is 60%-70%, the daily feeding amount is 105-110 grams, when the egg production rate is 70%, the daily feeding amount of the chicken is 115-120 grams, and when the egg production rate reaches more than 80%, the feed is not limited, let the chickens Eat ad libitum. The second is to cut the beak. Because chickens have the habit of slicing, therefore, chicks should be decapitated at 7-9 days of age. At around 15 weeks of age, beak trimming is required for those with poor beak trimming. Thirdly, promptly eliminate non-laying hens or chickens with poor egg-laying performance. At the end of breeding, when it is transferred to the laying house, a culling should be carried out. Those who are stunted, too small, too fat, sick, and lethargic should be eliminated. In the process of laying eggs, brooding chickens, sick chickens, disabled chickens, and discontinued chickens should be eliminated at any time. In the late stage of laying eggs, the chickens that are out of production are mainly eliminated, and hens with crests, pale faces, and shrinking crests should be eliminated immediately. Chickens that are found to be too fat or too thin should also be eliminated immediately.

3.The reasons for the decline in egg production

Environmental factors: changes in light program or light intensity: such as changing the color of light at any time, suddenly stopping light, shortening the light time, weakening the light intensity, irregular light time, long and short, early and late, suddenly light and suddenly stopped, evening Forgetting to turn off the lights etc. There is a serious lack of ventilation, and there is no ventilation for a long time. Attack of natural severe weather: A sudden attack by a heat wave, typhoon or cold snap without preparation or prevention in advance. Long-term water cutoff: The water supply system fails or forgot to turn on the switch, resulting in insufficient water supply or water cutoff for a long time.

Feed Factors: Significant changes in feed composition or quality issues in the diet can cause changes in egg production. For example, the types of raw materials in the diet suddenly change, the feed is not evenly stirred, the feed is moldy and deteriorated, the replacement of fish meal and yeast powder, the high salt content, the high amount of stone powder added, the replacement of cooked bean cakes with raw bean cakes, and forgetting to add salt in the feed, etc. Reduce the feed intake of chickens, causing indigestion. The egg production rate is normal, and the weight of the chicken does not decrease, indicating that the amount of feed and the nutritional standards provided meet the physiological needs of the chicken, and there is no need to change the feed formula.

Flock sickness: Acute and chronic infectious diseases can cause a sudden drop in egg production in a flock. If chickens are attacked by virulent Newcastle disease, egg production often decreases by more than 50%; infection with egg reduction syndrome can reduce egg production rate by 20% to 40%, such as mixed infection with other diseases, egg production rate decreases by 20% above. In addition, the infection of flocks with infectious bronchitis, infectious laryngotracheitis, cholera, coccidiosis, colibacillosis, avian influenza, etc. will greatly reduce the egg production rate.

4. Disease prevention work

Reducing dead chickens and preventing the occurrence of epidemics is the key to the success or failure of raising chickens. According to the scientific hygienic and epidemic prevention procedures for controlling the occurrence of chicken diseases, various vaccines should be injected according to the age of different chickens. At the same time, the chicken house and utensils should be regularly disinfected with drugs, and the feces in the house should be removed in time. mice, to prevent mice and sparrows from entering the house and bringing the epidemic. In order to reduce the chance of the spread of the epidemic, the entry and exit of people should be reduced as much as possible, strangers are not allowed to enter the chicken house, and visitors are refused to ensure the safe operation of the chicken farm.

Hope you can go to learn about the lima feed machine.

#lima feed machine#lima#animal feed machine#chicken feed pellet machine#feed making machine for chicken#chicken feed making machine#lima machinery

0 notes