#turbo hydramatic 400 transmission

Text

Torque Converter Turbo TH350 TH400 Dual Pattern Ultimate StreetFighter - 3800+ Stall

The Ultimate StreetFighter torque converter th400 was created with street/strip racers in mind, making them ready for the street and strip. This converter is ideal for situations requiring more mid-to-high RPM engines since it benefits from greater RPM horsepower.

You can Also buy from this link -

Launches at higher RPM, faster reactions - Ultimate StreetFighter Converters are ideal for vehicles with a racing mindset. Ideal for use with aftermarket carburetors, greater compression, and performance cams

Stall RPM is increased by 2,000 RPM using Ultimate StreetFighter Converters compared to factory converters. For Strip-oriented builds, The Ultimate StreetFighter is the greatest option.

The highest caliber All TCI Converters are equipped with HDT Coating, the most innovative heat-dissipating technology in the market. Computer testing and pressure checks are performed on torque converters.

Direct Approach:

1800351351

Official Website:

Facebook:

Address:

Melbourne at 1/10 BRAND DRIVE, THOMASTOWN, 3074, VIC

#autoparts#auto#carparts#automotive#car#cars#autorepair#turbo 400#turbo#transmission#turbo 400 transmission#th400#turbo 400 rebuild#th400 transmission#turbo 400 transmission on a 2jz#2jz with turbo 400 transmission#turbo 400 transmission rebuild#turbo 400 transmission shifting#turbo 400 transmission filter change#turbo hydramatic 400 transmission#turbo 400 transmission governor adjustments#turbo camaro#400 turbo manual valve body from stock#turbo 400 trans brake#th400 transmission in camaro

0 notes

Text

THIS JAGUAR XJ-S IS NOT MY CAR

The XJ-S was introduced on 10 September 1975. The design and development had begun in the late 1960s by the code name of project XJ27, with an initial shape penned by Malcolm Sayer ..

BUT I LIKE IT

The XJ-S was introduced on 10 September 1975. The design and development had begun in the late 1960s by the code name of project XJ27, with an initial shape penned by Malcolm Sayer, but after his death in 1970 it was completed by the in-house Jaguar design team, headed by Doug Thorpe. Power came from the Jaguar V12 engine with a choice of a manual or an automatic transmission, but…

View On WordPress

#Doug Thorpe#Fotonique#FX30#Infomatique#Jaguar#Jaguar V12#Not My Car#project XJ27#Sony#The XJ-S#Turbo-Hydramatic 400 transmission#William Murphy

0 notes

Text

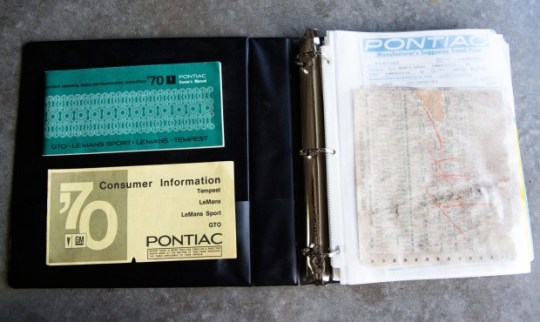

This 1970 Pontiac GTO convertible was first delivered to the A.C. Morris Garage of Summersville, West Virginia, and during prior ownership it underwent a body-off rotisserie refurbishment that was completed in 2006. The car is claimed to be one of just 241 examples that were ordered with 455ci V8 and an optional automatic transmission for the model year, and it is finished in Burgundy over red vinyl upholstery. Other equipment includes a four-barrel carburetor, a Ram Air hood, a power-operated convertible top, power steering, front disc brakes, and a 12-bolt rear end housing a Safe-T-Track limited-slip differential. Acquired by the selling dealer in 2013 out of Arizona, this GTO convertible is offered in Missouri with refurbishment photos, manufacturer’s literature, build sheets, a reproduction window sticker, documentation from Pontiac Historical Services, correspondence with the GM Heritage center, and a clean Missouri title.

The car was finished from the factory in Burgundy, and the body was stripped, mounted to a rotisserie jig, and repainted during the refurbishment, at which time a replacement convertible top was installed. Features include a color-matched Endura front bumper, a chrome rear bumper, a Ram Air hood, and quad exhaust outlets with polished finishers.

Rally II 14″ wheels are mounted with 215/70 Firestone Wide-Oval tires. Braking is provided by power-assisted front discs and rear drums, and the car was optioned with power steering when new.

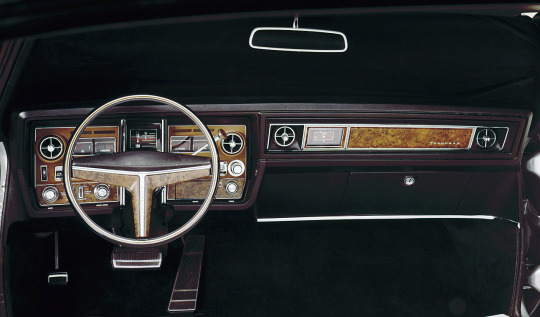

The cabin has been retrimmed with red vinyl upholstery (2254) as well as color-coordinated carpets and interior trim. Equipment includes front bucket seats and a rear bench, a woodgrain steering wheel, an AM/FM radio, and an 8-track player. A pre-delivery-style instruction tag is attached to the steering column, and Pontiac-branded rubber floor mats line the front and rear footwells.

The turned metal and woodtone trim-accented cluster houses Rally instrumentation consisting of a 140-mph speedometer, a tachometer, and a combination gauge. The five-digit odometer shows under 96k miles, approximately 50 of which have been driven by the seller. True mileage is unknown.

The optional 455ci V8 features a four-barrel carburetor and a Ram Air hood, and it produced a factory-rated 360 horsepower and 500 lb-ft of torque when new. The engine stamping shown within the gallery ends in 0P121234, which matches the final eight digits of the car’s serial number. Additional identification numbers are presented in the gallery.

Power is sent to the rear wheels through an optional Turbo Hydramatic 400 three-speed automatic transmission and a 12-bolt rear end housing a Safe-T-Track limited-slip differential. Additional photos are provided in the gallery to illustrate the underside, drivetrain, and suspension components.

Photos showing various stages of the refurbishment are depicted above.

Additional items accompanying the car include manufacturer’s literature, build sheets, a reproduction window sticker, documentation from Pontiac Historical Services, and 2012 correspondence with the GM Heritage center confirming the car’s specifications and equipment, photos of which are provided in the gallery.

24 notes

·

View notes

Photo

1976 Cadillac Mirage Pickup.

Far more than a simple hack-job, the Mirage was created by hot rodding legend Gene Winfield, who worked at Traditional Coach Works between 1974 and 1977Several coachbuilders tried their hand at converting the El Dorado and Coupe de Ville to a luxury pickup truck, but Traditional Coach Works maintained the stringent standards imposed by Cadillac.

This company is the only professional coachbuilder to make alterations to a Cadillac car to create a luxury truck model. It’s the one that created the examples that were made available through select Caddy dealerships. The agreement became the equivalent of a seal of approval by Cadillac dealerships, but not from the company of manufacture. The designer who created the Mirage was Gene Winfield who joined Traditional Coach Works in 1974 and remained with the company until 1977. These were the only three years that the Mirage was produced by Traditional Coach Works. Winfield achieved numerous accolades for his coachbuilding skills. He was named Car Craft Magazine’s 2008 builder of the year. His cars are original, considered works of art, and quite rare. Winfield was hired by James Kribbs, manager of Wilshire Cadillac in the 1970s. James Patrick was an associate in the business who first approached Kribbs with his ideas for creating a luxury truck. Patrick presented three drawings to Kribbs to show the possibilities associated with converting a Cadillac to a truck. Kribbs liked the idea and he founded the Traditional Coachworks company to bring the concept to reality. The first example of the Mirage completed in 1976 was snapped up by the legendary Evel Knievel who purchased the converted Caddy and ordered a second one to feature in a film. What makes the Mirage such a valuable classic these days? According to Alt-Driver, the Mirage is an extremely rare classic vehicle. You can’t classify it as a car, or as a truck because it’s both. The site elevates the Mirage to the status of a unicorn in its rarity. They’re sticking with the widely accepted production number of just 204 examples ever built in the US. They reveal that GM did enter a phase of experimentation with the 1976 Coupe de Villes to add a pickup truck bed to a cut and widened car. This disputes the theory that GM didn’t endorse the Mirage built by Traditional Coach Works, but they did manage to keep it on the down-low. The Mirage was offered exclusively from Cadillac Dealers and the conversion was the work of a third-party coachbuilder. It was never a factory production model.

The design of the Mirage was unique and although some cars were similar in aesthetics. Only 60 of the vehicles were made each year according to Winfield, which brings the production numbers to just 120 over two years. He offered no guess about how many were made the final production year at Traditional Coach Works, or if the other 100 or so models were built by other conversion specialists. The power plant was an 8.2-liter 500 cubic inch engine that generated 200 horsepower with 400 lb-ft of torque. The flying buttresses behind the cab gave it an additional feature that distinguished the Traditional Coach Works editions from the others. The camshaft was custom ground and the compression was elevated to 0.05:1 with Diamond Racing projects forged pistons. The Turbo Hydramatic transmission that was fortified with heavy-duty components. The tranny was modified by Jack Merkel Performance Engines of New York. The braking system was a Hydratech hydro-boost conversion. When’s the last time you saw a Gene Winfield design that didn’t bear an outlandish price tag? With just 200 or so made, it’s very unlikely that you’ll park next to another one at the next classic car show.

Source: moneyinc.com

4 notes

·

View notes

Text

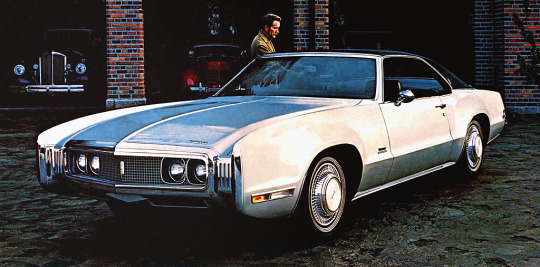

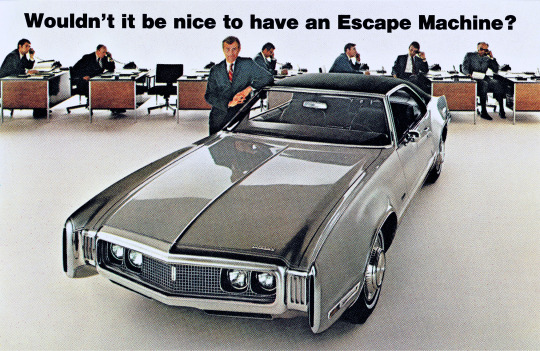

Oldsmobile Toronado, 1970. This was the final version of the first generation Toronado. The Toronado had pioneered the Unitised Power Package (UPP), combining a Rocket V8 with Turbo-Hydramatic 400 transmission and a transaxle driving the front wheels. It was the first US made front-wheel drive automobile since the demise of the Cord in 1937.

#Oldsmobile#Oldsmobile Toronado#first generation#Unitised Power Package#front wheel drive#Rocket V8#1970#personal luxury car#General Motors#dead brands

274 notes

·

View notes

Photo

1949 Chevrolet

3100 Pickup Truck

Magazine Featured Custom Rat Rod Truck 454 V8 Automatic Air Ride

HIGHLIGHTS

* Outstanding, one-of-a-kind Chevy Rat Rod that's been featured by Dennis Gage

* Featured in Rat Rod Magazine

* 454 cubic inch Chevrolet V8 with an electric Oberhausen blower

* Turbo-Hydramatic 400 3-speed automatic transmission

* GM 10-bolt rear axle

* Power drum brakes

* Custom chassis with a heavily modified suspension and adjustable air bags

* Custom leather interior

* Heavily modified steel body

* 19-inch front wheels with custom, 15-inch rear wheels

* Internally restricted Zoomies

* Engine build receipt

* Rat Rod magazine feature

* All RK Motors vehicles receive a comprehensive, multi-point inspection.

Perpetually cool and visually stunning, this awesome Chevy is a refreshing take on the classic truck concept. Combining top-notch innovation with proven mechanicals, it presents the rare opportunity to land a truly unique classic that easily doubles as a well-oiled cruiser. Don't miss your chance to own this killer custom!

RK Motors

#1949 chevrolet#3100 pickup truck#Rusty Car#rusty truck#chevy rat rod#rat rod#v8 engine#old age#old car#classic beauty#old classic car#old classic#Vintage Trucks#vintage car#automotive#automobile#modified cars#car rusting#old trucks#truck#transportation#Ford Cars#ford trucks#american car#german car#italian car

171 notes

·

View notes

Photo

1963 Pontiac

LeMans$59,900

Frame Up Built Lemans Convertible Restomod Fuel Injected 400 V8 Auto

SUMMARY

* The beneficiary of a detailed, ground-up restoration

* 400 cubic inch Pontiac V8

* Turbo-Hydramatic 350 3-speed automatic transmission

* House Of Kolor Tangerine Kandy paint / Hot Rod Black paint / Charcoal outlining stripes

* Black vinyl interior / Black canvas top

* 17-inch Hurst wheels

* 4-wheel power disc brakes

* Rack-and-pinion steering

* Upgraded suspension

* 10-bolt rear axle

.rkmotors

1K notes

·

View notes

Text

Building in Stages

Returning Sacrebleu to the best version of herself means ensuring that everything about her as as good as, or better than when she rolled off the assembly line. For example, she was built with a Turbo Hydramatic 400 transmission, which is a heavy duty 3 speed transmission with a final drive ratio of 1 to 1. She still has that transmission, BUT! Now she has an overdrive unit attached to it. Better than original. She was built with a Stage 1 engine. What’s a Stage 1 engine? Well, it’s essentially a performance version of the stock engine. Buick marketing decided to call it the Stage 1 in a nod to the Space Era, as the 1st stage of the rockets flying into space were the biggest and most powerful. I’m sure you can see the connection they were trying to make. I’m pretty sure the Stage 1 engine Sacrebleu was built with is gone, replaced with the big blue painted engine currently residing in the engine bay. *growls* What makes a Stage 1 engine is mainly two parts. The camshaft, and the cylinder heads. The Stage 1 camshaft came in two versions, one for the A-Body car, the Skylark/GS and the one for the big cars, including the Electra 225, LeSabre, Centurion and Riviera. The A-Body camshaft was designed for a bit more top end power, the other camshaft was engineered with more torque in mind, to help move the bigger, heavier cars from a stop. The actual specifications of the camshafts seem to be lost, there isn’t a definitive stock replacement for the GS/Stage camshafts. It’s left to be by guess and by golly. I relied on the best guess of one of the experts in the field, and had a camshaft core ground to the recommendation. With that done, it’s time to talk cylinder heads.

Stage 1 heads differ from standard heads in one respect. Valve size. Standard heads used a 2.000″ intake valve and a 1.600″ exhaust. Stage 1 heads used a 2.125″ intake valve and a 1.75″ exhaust valve. On the intake, that’s about 14% more surface area, and the exhaust sees a nearly 20% increase in surface area. This increase in surface area means more air flow, which in turn, means more power. Big block Buick cylinder heads were manufactured from 1967-1976, with the most desirable castings being the earlier years, specifically known as “Big Port” heads. These were found on 1967-1969 Buick 430 engines, typically without the larger Stage 1 valves. Later cylinder head castings are less desirable, with larger combustion chambers that lower compression and reduce power. These later heads were designed to meet new emissions standards, and one of the ways to do that was to reduce compression. It happens that I bought a set of the desired castings 12 years ago, and finally took them to a machine shop to have them built to Stage 1 specification, with a set of valves I had purchased over a decade ago. These things take time.

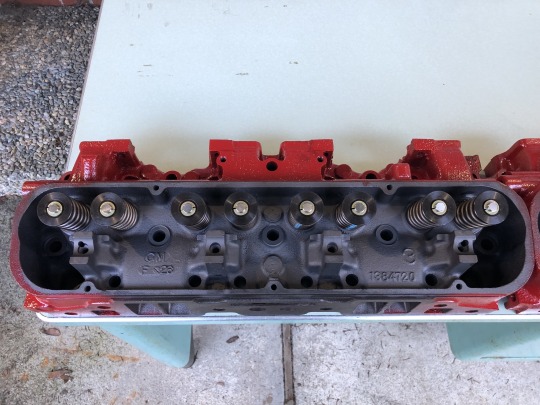

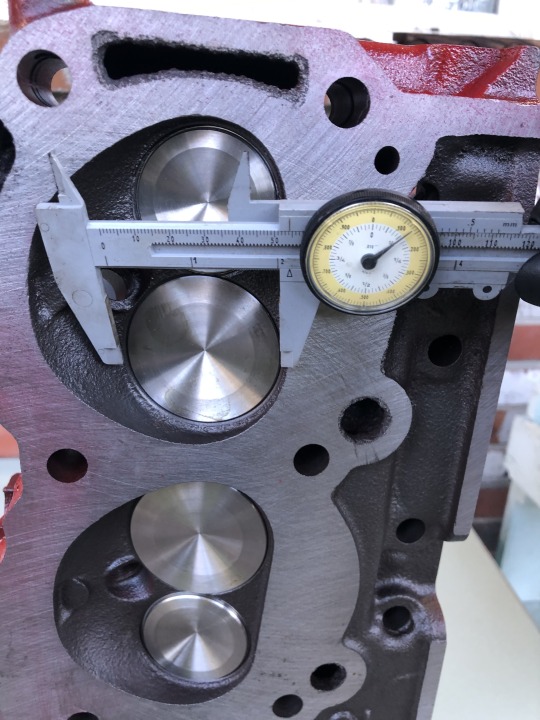

Here’s what the machinist returned to me:

Shiny!

Buick Red!

Look at those things, ain’t they just beauty? Here are a few more photos, including some with calipers showing the measurement of the new valves.

2.125″ Intake

1.750″ Exhaust

For reference, here is a comparison of a later cylinder head with the freshly rebuilt head:

It may be hard to see, but if you look at the unrebuilt head, there’s a very easily seen gap between the two valves in the cylinder, as well as the general volume of the combustion chamber. Compare that to the rebuilt cylinder head, where there’s nearly no gap between valves and much smaller combustion chambers. The rebuilt heads will help make more power both in allowing greater air flow and higher compression. All of which will make Sacrebleu better than she was built, to continue showing taillights to all sorts of Hondas. ;)

#31#Sacrebleu#Boattail#Boattail Riviera#Buick Riviera#Riviera GS#Buick Riviera GS#Stage 1#Buick 455#Big Block Buick#Buick Big Block#455 Stage 1#Fast With Class#Bigger is Better#Size Matters#No Replacement for Displacement#Big Port Heads#Faster than your NA Honda

0 notes

Photo

1970 Oldsmobile 4-4-2 W-30 Facts ⬇️⬇️⬇️⬇️⬇️⬇️⬇️ Engine: 455ci/370hp W-30 V-8 Transmission: Turbo-Hydramatic 400 3-speed automatic Rearend: 3.23 gears and anti-spin differential Interior: Blue Strato buckets with Sports center console Wheels: 14×7 Super Stock II Tires: G70-14 Goodyear Polyglas white letter Special parts: W-30 package, OAI hood, Hurst Dual-Gate shifter 👴4️⃣4️⃣2️⃣👴4️⃣4️⃣2️⃣👴4️⃣4️⃣2️⃣ #olds #oldsmobile #442 #w30 #hotrod #musclecar #v8 #chevy #ford #mopar #car #classic #race #instagood #engine

170 notes

·

View notes

Text

4L80E Versus TH400: A Performance Guide

Before the 1990s, we can say life was pretty drab for the automobile industry. It was devoid of the term “smooth cruisin”. But, the invention of overdrive transmissions proved to be a game-changer. 4L80E Transmission was one of the heavy-duty series by General Motors designed for longitudinal configurations produced in 1991. This system allows for a car to run deep rear gears for tire-smoking or wheel hanging launches, thus, adding a semblance of highway cruising ability. This feature is one of the most vital reasons behind the popularity of 4L80E Transmission Rebuild Kits among horsepower fanatics.

Distinguishing Between 4L80E and TH400

Prior to the 1990s, the turbo- hydramatic, developed and produced by General Motors, was in use for a wide range of cars from GM and several other brands of automobiles. The biggest challenge was the 400/450 limit on horsepower. Other inventions with better horsepower compromised the durability of the system. The 4L80E transmission incorporates the durability of the TH400 with a better and smoother transmission. In addition to this, the high-torque capacity along with the electronically controlled transmission adds to the performance value of this system.

At the beginning of the 1990s, 4L80E Transmission rebuild kits and pre-installed systems were popularly used in 34- to 1- ton trucks and bigger SUVs. Since the new variant is modeled on the TH400, roughly 75 percent of its parts are replaceable by TH400. Additionally, the bell housing bolt pattern along with the flexplate is similar, so it bolts up to big- or small- blocks just like normal.

It basically uses the same internal components but just has the edge of the presence of an overdrive fourth gear with auto control shift points that gives the drives an extra grip, better control, and overall firmness over driving. The additional electronic control and overdrive facility adds an extra weight of 50 pounds. However, this doesn’t affect the functionality of the system in any way. Apart from this, the extra weight adds to the length (4 inches) with the trans mount located 112 inches rearward.

All in all, the improved transmission system is better and stronger than the original with a minimum improvement of 25 perfect on the overdrive.

0 notes

Photo

A classic #deuceandaquarter as it was meant to be - long, low, and wide. Bold, befinned, and brand new, the #Electra replaced the Roadmaster in 1959 and at first there were two versions - the 220” Electra and the bigger, plusher, 225” long Electra 225. In the days of “bigger is better,” what better way to say “best” than actually putting the length of the car in the name? The actual length changed to 219 inches in 1961 and the size would vary, but the #Electra225 label stuck until 1980; sometimes supplemented by “Limited,” a 1930s label. - The original ’59 was a radical break from the past, clean sides, trapezoidal canted fins, and new names - but over time, the Electra 225 would become a conservative mainstay of American luxury sedans. A Cadillac in Tri-shield garb, it rode the same C-body platform as the DeVille and the related, but typically even more conservative Oldsmobile 98. The first four seasons of Electras were a mixture of styles as fins gave way to space-age modern, but in 1963 the car settled into a slab-sided, understated Lincoln-influenced look. - 1964 was an evolution from 1963, but there were some key differences under the hood - primarily the replacement of Buick’s ancient Dynaflow with the Super Turbine 400 transmission - better known as the Turbo Hydramatic THM400. The Dynaflow, the first torque converter automatic, was designed to minimize driver involvement and the very obvious shifts of the early Hydra-Matic, which would have been amplified in the torque-tubes of 1940s #Buicks. - In practice, Dynaflows were almost like CVTs (indeed, Buick experimented with a friction-drive proto-CVT in the 1930s). Unless you were in “low,” the transmission was effectively always in high gear - which made it very smooth but equally inefficient. The Super Turbine wasn’t unique to Buick but it made the cars better performers and, although MPG was never the Electra’s forte, mileage also greatly improved. - Power came to the Super Turbine via the 401 (325hp) or optional 425 cid (340 hp) Buick V8s, pulling five hefty bodies (~4,200 lbs.) - a sleek coupe and convertible and a trio of 4-doors which shared Cadillac’s basic rooflines with slight modifications. https://www.instagram.com/oldmotors/p/BwHxrXlFxwg/?utm_source=ig_tumblr_share&igshid=1gs8q3w3erdhy

0 notes

Text

1978 Rolls Royce Silver Wraith Ii - $35,900.00

1978 Rolls Royce Silver Wraith II that was just painted 2 years ago by Wrights Customs in Cadillac Michigan where vehicle is located at our Show Room. This car runs and drives how it should, All Brake work just recently done by owner. Car has original Jack and Manual. See Video Here https://www.youtube.com/watch?v=xHXCZ0c8siw&feature=emb_logo The Rolls-Royce Silver Shadow is a luxury car produced in Great Britain in various forms from 1965 to 1980. The car was the manufacturer's response to claims that it was falling behind the times, and had lost contact with modern developments. It was the first Rolls-Royce to use a monocoque chassis, and to date has the largest production volume of any Rolls-Royce. Following in the manufacturer's tradition of building luxury vehicles, the standard wheelbase Silver Shadow measured 5.17 metres, or more accurately, 17.00 feet, in length, weighed 4,700 pounds, and had a base price of 19,700 dollars in the first year of production. The Silver Shadow was produced from 1965 to 1976, and the Silver Shadow II from 1977 to 1980. The design was a major departure from its predecessor, the Silver Cloud. This was the first single bow Rolls-Royce, in contrast to its predecessors' double bow designs. The cars exterior design was by Rolls-Royce's chief designer, John Polwhele Blatchley. Aside from a more modern appearance, the Silver Shadow introduced many new features such as disc rather than drum brakes, monocoque construction, and independent rear suspension, rather than the outdated live axle design of previous cars. The Shadow featured a 172 hp 6.2 L V8 from 1965 to 1969, and a 189 hp 6.75 L V8 from 1970 to 1980. Both powerplants were coupled to a General Motors-sourced Turbo Hydramatic 400 transmission, except on pre-1970 right-hand-drive models, which used the same 4-speed automatic gearbox as the Silver Cloud (also sourced from GM). The car's most innovative feature was a high-pressure hydraulic system licensed from Citroën, with dual-circuit braking and hydraulic self-levelling suspension. At first, both the front and rear of the car were controlled by the leveling system; the front levelling was deleted in 1969 as it had been determined that the rear levelling did almost all the work. Rolls-Royce achieved a high degree of ride quality with this arrangement. Initially, the long wheelbase model did not have a separate name, but in 1977, with the introduction of the Silver Shadow II, the longer car was dubbed the Silver Wraith II. The Wraith II is identified by all of alterations found on the Silver Shadow II and additionally an Everflex covered roof (also available as an option on the Silver Shadow II), a smaller rear opera-style window(some customers deleted the smaller back window and different wheel covers. Some Silver Wraith IIs were also fitted with electric divisions which took up the extra four inches of leg room in the rear. Vehicles fitted with the division are now considered highly desirable. This exceptional low mileage example is in top flite condition throughout. The Paint, brightwork, interior, woodwork, and seat leather all are in excellent condition as one would expect from such a low mileage car. The brakes were redone under the current owners care at the local Rolls Royce Service facility, so no worries there. This is one of the nicest Shadow Era Rolls we have had the opportunity to represent. This car is a desirable Left hand drive car that will provide years of service to the lucky new owner.

from Cardaddy.com https://www.cardaddy.com/vehicles/vehicle/1978-rolls-royce-silver-wraith-ii-cadillac-michigan-21473932

0 notes

Text

How to Swap a 700R-4 Overdrive Transmission into a C10

We’ve all been there—cruising down the highway in an old truck, just wishing you had “another gear.” The hum of 3,000 rpm on the interstate can be concerning to those of us who constantly stare at the temperature gauge or perhaps the gas gauge, and the persistent strain can take its toll on an old-school engine. In our case, we’re working on a 1971 Chevrolet C10, which has a fresh 355ci small-block Chevy with aluminum heads and a sizable camshaft. While the engine had received some serious attention, the TH350 transmission was completely stock, aside from a stall converter to work with the big cam.

The truck ran pretty well, but had a few issues that were hard to pinpoint. Our concern came when it was time to really test out the new engine on a nice, straight back road. At wide-open throttle in low gear, the engine seemed to bog, and it never came to life, even with close to 400 hp on tap. It wouldn’t spin the tires, no matter how hard we tried. The engine was firing on all eight cylinders, but the truck felt like it was tied to a tree stump when we’d take off. As we were scratching our heads in disbelief that it wouldn’t do a burnout or set you back in the seat, we went out for one more testdrive, and the transmission finally let go. What we quickly realized was that the transmission was causing the bogging issues before it gave up.

The truth of the matter is that we wanted to upgrade to an overdrive transmission either way, and this breakage gave us the perfect opportunity to make it happen. The natural choice for our application was a GM 700-R4, a simple four-speed automatic based off of the long-running Turbo Hydramatic design. The .70:1 overdrive ratio would calm down our peppy small-block during highway cruising, and the lower 3.06:1 First gear ratio (compared to the TH350’s 2.52:1 First gear) would liven up the acceleration. Of course, we could’ve also opted for the 200-4R overdrive transmission, but they’re getting increasingly harder to find and not exactly known for their strength.

We were faced with a couple of options. Grab a core from the junkyard and have a local shop go through it with factory-style replacement parts, or buy an aftermarket unit. After some studying and price checking, we called up the folks at Phoenix Transmission Products in Weatherford, Texas. They offer transmissions for lots of applications, including Chrysler and Ford, and had plenty of options for GM transmissions, including several versions of the 700-R4.

After a conversation with Greg at Phoenix Transmission, we decided on the “SS” model, the street/strip version, rated for 450 hp and 500 lb-ft of torque. Phoenix Transmission modifies the transmission with high-load capacity sprags, high-energy friction and band, and increase pump volume and pressure. To keep us from piecing together the components, Phoenix Transmission offers a complete package for our C10, including the new transmission, a high-performance lock-up torque converter, a COMPUSHIFT Mini module, a G-Force crossmember, and a Lokar stainless steel TV cable, complete with the appropriate correction bracket for our Demon carburetor. That means the only thing we had to add to the kit was a new driveshaft and a few quarts of Dexron III transmission fluid, and our C10 was back on the road.

The final result of our transmission swap is a classic truck that hits the highway with ease, thanks to overdrive and a lock-up torque converter. It also lights the tires with ease now that the new transmission isn’t holding back the rowdy small-block. We were pleased with the simplicity of the swap, and the performance of the Phoenix Transmission-prepared 700-R4 is undeniable. Now it’s time to stretch the legs on our C10 with some longer trips and some more back road adventures.

Our 1971 Chevrolet C10 pickup was showing signs of concern, and eventually lost forward motion when something let go in the transmission. Add to that a leaking chrome transmission pan and less-than-desirable highway manners, and it was time to remove this antiquated three-speed transmission.

Another problem area that we wanted to resolve included the two-piece driveshaft. While it had been repaired with a new carrier bearing, it still isn’t an ideal setup for a high-performance application.

Our starting point is the driveshaft. It can be removed at the rear end, by loosening the four bolts that keep the U-joint in place. Then, the carrier bearing can be removed from the rear suspension crossmember, and finally the yoke can slide out of the transmission.

Next, we remove the three torque converter bolts that pass through the flexplate. The engine will usually try to spin, so we typically tap on the box-end wrench with a small hammer to get it broken loose.

The truck has a tubular transmission crossmember, which has easy access to the transmission mount bolts. While in this area, we can disconnect the vacuum line from the modulator valve, then we can move forward to disconnect the transmission fluid lines.

The six bolts that hold the transmission to the engine usually require the use of a couple extensions and a swivel extension to have enough room to spin the ratchet. Before it’s completely loose, we roll our low-profile transmission jack in place and secure the transmission.

With everything out of the way, we did a mock-up on the G-Force Transmissions crossmember, which is part of the kit from Phoenix Transmission Products. While it does have massive humps for exhaust clearance, our particular truck needed some modifications to the exhaust for proper fitment.

For the sake of simplicity, we decided to completely remove the exhaust system. This isn’t necessary on all C10s, but it gave us a lot more room.

Phoenix Transmission builds several versions of GM’s 700-R4 automatic overdrive transmission, and we went with the PT700R4SS, which is the street/strip configuration. The transmission is rated for 450 hp, and takes all of the guesswork out of the swap. It comes out of the crate with a Lokar TV cable already installed.

The complete kit from Phoenix Transmission included a custom torque converter, built to match our camshaft specifications and rear end gear ratio. Since our application has a Comp Big Mutha’ Thumpr camshaft, it required a 2,800-stall speed.

The transmission comes with a new mount installed, as well as a new speedometer drive and new hardware throughout. The transmission has been run on Phoenix Transmission’s dyno, so it’s tested and ready to install.

Our transmission swap took place under a carport—no lifts or special equipment here. We did make use of a low-profile transmission jack, which made easy work of lifting the 700-R4 transmission into place.

Before we installed the transmission, we situated the G-Force crossmember between the framerails and then slid it backward. The tolerances are pretty tight on the crossmember, so having it hanging in place keeps us from having to fight with it.

We lined up the dowel pins and slid the transmission against the engine. Then, it was a matter of installing and tightening the six mounting bolts.

Now we can jack the transmission up a little more and then slide the transmission crossmember forward to line up with the mount. We used the supplied oval-shaped plate to strengthen the connection, as it features large slots for a wide range of adjustments.

With the crossmember bolted to the transmission, we can drill holes (if necessary) in the frame and then attach the crossmember to the frame.

Next, we attach the torque converter to the flexplate with three new torque converter bolts. Luckily, the Phoenix Transmission torque converter features dual-bolt patterns, so our existing flexplate worked perfectly.

Our existing transmission lines didn’t need any tweaking to fit into the new 700-R4 transmission. The original lines and fittings threaded into the female fittings, which were already installed by Phoenix Transmission.

Installing the pressure sensor is next on our to-do list. It’s provided with the kit and works with the COMPUSHIFT Mini to read line pressure, controlled by the TV cable. The sensor threads into the driver side of the transmission case, with a little bit of Teflon pipe tape on the threads. To access the port, you must first remove a brass plug.

Another piece of the puzzle is the speed sensor, part of the COMPUSHIFT system that makes easy work of configuring the transmission settings. The speed sensor connects to the transmission speedometer drive with a 1-foot speedometer cable. The big end threads into the transmission.

The small end of the short cable threads into the speed sensor. You can connect your mechanical cable to the other end of the sensor. Or if you’re using a digital speedometer, you can connect the purple wire with a white stripe in the speed sensor wiring harness to the “high side” of the speedometer wiring.

Now we can simply plug in the wiring harness. The pressure sensor and speed sensors have specific connectors and are clearly marked for easy installation.

Finally, we can snap the main harness plug into place and tidy up the wiring with a few zip ties. Be sure to keep all sensors, wires, and cables away from the exhaust.

Attaching the shifter linkage is a simple task. We reused the arm from our TH350 transmission, which goes along with the column-shift linkage.

Phoenix Transmission provides a new dipstick tube with the kit, so we carefully pressed it into place, being sure the bulge in the tube is seated against the case. It’s a nice, tight fit.

With the bottom side buttoned up, we can make the necessary changes to the exhaust system and prepare for a new driveshaft.

We wanted to swap the original two-piece driveshaft for a more reliable one-piece design. Most shops request measurement from center-to-center on the U-joints, so you can slide your old slip-yoke into the transmission to get a good measurement.

The new driveshaft came complete with new U-joints and a new slip-yoke. We simply slide the yoke into the transmission and then attach it to the rear end with the original U-joint straps and hardware.

Up top, we installed a Lokar throttle cable, as well as the provided TV cable kit (Phoenix PN PTVSYSBGD), which uses a special correction bracket on the throttle arm on the Demon carburetor for correct TV cable geometry. A small set screw keeps the rear cable bracket square and steady for consistent cable tension.

Before we crank the engine, we must adjust the TV cable. To do so, we go full throttle with the carburetor, and then pull out on the TV cable until it’s completely tight. Then, we can slide the cable end back as far as it can go, and tighten the small Allen-head set screw.

After adding some fluid to the transmission, we can fire it up and go through some of the settings on the COMPUSHIFT Mini. First, we confirm that line pressure changes with throttle input, and then we test the speed sensor with the rear end jacked up.

Then, we can calibrate the TPS Sensor by pulling the TV cable out and back in smoothly. Our truck has a carburetor on it, so there’s no actual TPS sensor on the engine. The throttle position is determined by the TV cable and its effect on line pressure.

Now we can go for a testdrive and adjust the default settings if needed. The COMPUSHIFT Mini allows us to control when the torque converter locks and unlocks, based on speed and throttle input (controlled by the TV cable). The lock-up torque converter will keep the 2,800-stall converter from slipping while cruising in overdrive.

The post How to Swap a 700R-4 Overdrive Transmission into a C10 appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/how-to-swap-700r-4-overdrive-transmission-into-c10/

via IFTTT

0 notes

Photo

New Post has been published on http://fastmusclecar.com/best-muscle-cars/1970-chevrolet-chevelle-ss-ls6/

1970 Chevrolet Chevelle SS LS6

VIN: 136370K186530

Engine: 454 LS6 V8

Transmission: Turbo-Hydramatic 400 3 Speed Automatic

Exterior Color: Cranberry Red

Mileage: 4,691

Starting bid: $104,930.00

BUY NOW ON EBAY.

We are at the top end of the spectrum here when it comes to muscle cars. All original, numbers matching and in pristine condition. This 1970 Chevrolet Chevelle SS LS6 has had a complete frame off restoration and comes with original window sticker, original Protect-O-Plate and two original build sheets. Condition wise, it’s probably as good as it gets and being a dealer sold vehicle you going to pay a bit more than a private sale, but on the flip side you should get more peace of mind with what you’re getting.

The listing doesn’t give exact production numbers, but a bit of sniffing around online gives 4,475 1970 LS6 454’s produced that year, but production numbers by paint code in general says there are no definitive productions numbers. Cranberry Red was probably one of the most popular with total production numbers that year being 26,515 in Cranberry Red for any Chevelle variant.

In any case, the red and white combination color scheme looks fantastic and with an LS6, this Chevelle ticks every box available for a pristine 1970 example. An F41 Special Performance Suspension with 3.31 gears also makes this example standout.

Prime condition 1970s Chevelle SS models with an LS6 are investment grade material and although you’re paying dealer prices here, cars like this will steadily increase their worth year on year. It’s that strange dichotomy where we wante muscle cars to be worth a lot, especially if you own one, but if you want to get your hands on one these days, especially in great condition with some tasty options, you’ve got to have deep pockets. As a classic muscle car, you simply can’t go wrong with the 1970s Chevelle SS.

BUY NOW ON EBAY.

More Muscle Cars For Sale – http://fastmusclecar.com/muscle-car-for-sale/

0 notes

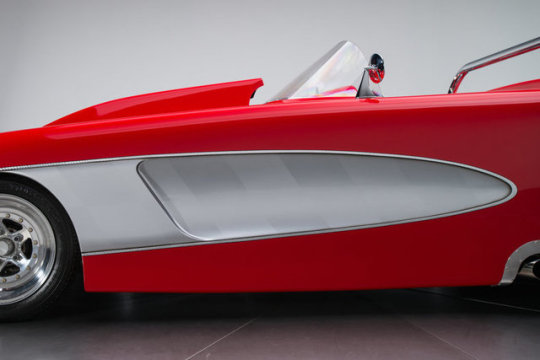

Photo

SOLD

1957 Chevrolet

Corvette

Ground Up Built Don Davis Corvette Street Rod 454 V8 Auto 4-link

SUMMARY

* The beneficiary of a detailed, professional build that was shepherded by Don Davis

* 454 cubic inch Chevrolet V8

* Turbo-Hydramatic 400 3-speed automatic transmission / Remote cooler

* Strange 9-inch rear axle / Custom housing

* Custom Don Davis chassis

* Custom suspension / Fully adjustable 4-link rear suspension

* Strange 4-wheel disc brakes / Rack-and-pinion steering

* 15-inch WELD wheels

* Composite flip-top body

* Vinyl interior

I would highly recommend RK Motors to anyone buying or selling their cars.

#Chevrolet#american cars#europeon cars#automobile#german car#classic car#build car#restoration#v8#chevrolet v8

69 notes

·

View notes

Photo

Pontiac Firebird Transam Hardtop Coupé 1969 (4614) by Le Photiste Manufacturer: Pontiac Motors Division, Kansas City, Kansas - USA / General Motors Company, Detroit, Michigan - U.S.A. Type: Firebird TransAm Ram Air III (L-74) Hardtop Coupé Production time: September 1968 - September 1969 Production outlet: 634 / some sources 689 Engine: 6558cc GM Pontiac H.O. Ram Air III V-8 400 Big-Block OHV Power: 335 bhp / 4.800 rpm Torque: 583 Nm / 3.300 rpm Drivetrain: rear wheels Speed: 197 km/h Curb weight: 1560 kg Wheelbase: 108.1 inch Chassis:GM F-body platform box section frame and all-steel unibody (by Fisher) Steering: Saginaw variable-ratio power recirculating ball Gearbox: three-speed manual (heavy duty) / all synchromesh / floor shift Clutch: 10.4 inch single dry plate disc Carburettor: Rochester Quadra-jet 4-barrel downdraft Fuel tank: 70 liter Electric system: Delco 12 Volts 53 Ah Ignition system: distributor and coil Brakes front: 9.5 inch Delco-Moraine servo-assisted hydraulic discs Brakes rear: 9.5 inch hydraulic drums self-adjusting type Suspension front: independent ball joints, unequal length trapezoidal wishbones, upper control arms pivoted on rubber bushings, sway bar, low-rate coil springs + double-acting hydraulic telescopic shock absorbers Suspension rear: beam axle Hotchkiss type, Four Link |System, angle-mounted upper and lower radius arms, longitudinal low-rate semi-elliptic leaf springs + angle-mounted hydraulic telescopic shock absorbers Rear axle: live semi-floating type Differential: Salisbury type hypoid 3.55:1 Wheels: 5J x 14 inch steel discs Tires: F70 x 14 pressure tires Options: Muncie four-speed manual gearbox, Hurst floor shifter, Turbo Hydramatic two-speed automatic transmission, power windows, power seats, AM/FM Multiplex Stereo radio, Stereo Tape player, power antenna, Air Conditioning, Rally wheels, Rally clock, different axle ratios, heavy-duty coil springs, heavy-duty version shock absorbers, adjustable steering column, speed control device, “Instant-Aire” pump, child safety seat, custom sports steering wheel, console, whitewall tires, Safe-T-Track limited slip differential, tachometer, defogger, Circ-L-Aire heater, Soft-Ray tinted glass, Strato bucket seats, Special: - The Pontiac brand was introduced by General Motors in 1926 as the “companion” marque to GM's Oakland Motor Car line. The Pontiac name was first used in 1906 by the Pontiac Spring & Wagon Works and linked to Chief Pontiac who led an unsuccessful uprising against the British shortly after the French and Indian War. The Oakland Motor Company and Pontiac Spring & Wagon Works Company merged in November 1908 under the name of the Oakland Motor Car Company. The operations of both companies were joined together in Pontiac, Michigan (in Oakland County) to build the Cartercar. - "What Chevrolet can do, we can too," Pontiac thought, when Chevrolet released their Camaro, designed by Pontiac Motor Division General Manager John DeLorean. - They (heavily) shared the same coach work (the F-body platform), but with detailed changes, such as grille (twin grilles of a bumper-integral design), chrome trim strips, three vertical air slots on the front edge of the rear body panels and vent windows in the front. - Unfortunately the Camaro outsold the Firebird two to one in the beginning. - The Camaro and the Firebird were at the forefront of America's muscle car generation. - The 1969 Firebird TransAm Ram Air III (L-74) Series was available as this 2-door Hardtop Coupé and as 2-door Convertible (only 8 units built). - This first generation Firebird Transam Series (1967-1969), with its characteristic Coke bottle styling, was assembled in Lordstown (Ohio: 1967-1969), Van Nuys (California: 1968-1969) and in Norwood (Ohio: 1969). http://ift.tt/2yFy8XZ

0 notes