#types of concrete batching plant

Text

How Does Concrete Batching Plant Works? Types Of Concrete Batching Plant

Concrete is the backbone of modern construction, and the process of producing high-quality concrete involves the use of a specialized facility known as a concrete batching plant. This essential infrastructure plays a pivotal role in ensuring the consistency and efficiency of concrete production. In this blog, we will delve into the inner workings of concrete batching plants, exploring their functions and the various types available, including mobile and stationary plants, cement silos, RMC plants, and WMM plants.

How Does a Concrete Batching Plant Work?

A concrete batching plant is a facility designed to combine various ingredients, such as aggregates, water, cement, and admixtures, to produce concrete in specified proportions. The process involves several key steps:

Aggregates Loading: The first step is to load aggregates into the plant. These aggregates, which can include sand, gravel, and crushed stone, are stored in bins.

Conveying System: The aggregates are then conveyed to the mixer using a conveyor belt or a skip hoist.

Cement and Admixture Addition: Cement and admixtures are stored in silos and added to the mixer in predetermined quantities to achieve the desired concrete mix.

Mixing: The ingredients are mixed thoroughly in the mixer to produce homogenous concrete.

Discharge: Once the mixing is complete, the concrete is discharged into transit mixers or directly into concrete pumps for transportation to the construction site.

Types of Concrete Batching Plants

Concrete batching plants come in various types, each designed to cater to specific construction needs. Let’s explore some common types:

Concrete is the backbone of modern construction, and the process of producing high-quality concrete involves the use of a specialized facility known as a concrete batching plant. This essential infrastructure plays a pivotal role in ensuring the consistency and efficiency of concrete production. In this blog, we will delve into the inner workings of concrete batching plants, exploring their functions and the various types available, including mobile and stationary plants, cement silos, RMC plants, and WMM plants.

How Does a Concrete Batching Plant Work?

A concrete batching plant is a facility designed to combine various ingredients, such as aggregates, water, cement, and admixtures, to produce concrete in specified proportions. The process involves several key steps:

Aggregates Loading: The first step is to load aggregates into the plant. These aggregates, which can include sand, gravel, and crushed stone, are stored in bins.

Conveying System: The aggregates are then conveyed to the mixer using a conveyor belt or a skip hoist.

Cement and Admixture Addition: Cement and admixtures are stored in silos and added to the mixer in predetermined quantities to achieve the desired concrete mix.

Mixing: The ingredients are mixed thoroughly in the mixer to produce homogenous concrete.

Discharge: Once the mixing is complete, the concrete is discharged into transit mixers or directly into concrete pumps for transportation to the construction site.

Types of Concrete Batching Plants

Concrete batching plants come in various types, each designed to cater to specific construction needs. Let’s explore some common types:

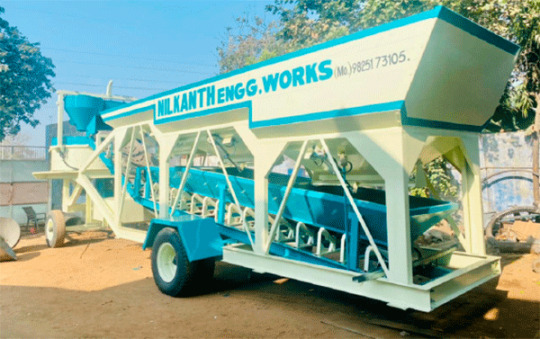

Mobile Concrete Batching Plant:

Portability: These plants are designed for on-site concrete production, making them ideal for projects with varying locations.

Compact Design: Mobile plants are compact and can be easily transported, offering flexibility in deployment.

Stationary Concrete Batching Plant:

Permanent Setup: Stationary plants are set up at a fixed location and are suitable for large-scale projects with consistent concrete demand.

High Production Capacity: They are capable of producing large quantities of concrete efficiently.

Cement Silo:

Storage of Cement: Cement silos are used to store cement, ensuring a constant supply for the batching plant.

Different Sizes: Silos come in various sizes to accommodate different project requirements.

RMC Plant (Ready-Mix Concrete Plant):

Instant Use: RMC plants produce ready-to-use concrete, eliminating the need for on-site mixing.

Quality Control: The centralized production ensures consistent quality and adherence to specifications.

WMM Plant (Wet Mix Macadam Plant):

Base Material Production: WMM plants are designed for the production of wet mix macadam, a base material used in road construction.

Precise Mixing: These plants ensure thorough mixing of aggregates with water and binding agents.

Conclusion

Concrete batching plants are the unsung heroes of construction, providing a reliable and efficient means of producing high-quality concrete. Whether it’s a mobile plant for on-the-go projects or a stationary plant for large-scale construction, the diverse types of batching plants cater to a wide range of construction needs. Additionally, ancillary equipment like cement silos, RMC plants, and WMM plants play crucial roles in enhancing the overall efficiency and quality of concrete production. Understanding the intricacies of these plants is essential for anyone involved in the construction industry, ensuring the successful execution of projects and the creation of durable and resilient structures.

#Tags:cement silo#concrete batching plant#concrete batching plants#mobile concrete batching plant#mobile concrete batching plants#RMC plant#Stationary Concrete Batching Plant#types of concrete batching plant

0 notes

Text

Do Androids Dream of Electric Jam? - Ch. 1: Let's Kill Tonight

Let's Kill Tonight - Next - Masterpost - [ AO3 ]

Rated M: guns, mild violence, suggestive, swearing - WC: 3388

"Let's kill tonight! Kill tonight! Show them all you're not the ordinary type." - Panic! at the Disco

The Reckoning

2122-11-01 : 18:39 UTC-8

The streets of Old Seattle have been left in shambles. The now-annual hundred year floods that began around the turn of the century have gradually made everything south of Madison Street officially uninhabitable.

Officially.

While the traditional brick and stone buildings of Old Seattle crumbled and dissolved in the rising brackish, toxic waters, most of the mid-century steel and glass buildings, designed to withstand earthquakes but not hurricanes, fared reasonably well. Their realsteel and concrete skeletons did, at least. The glass windows were all long-since blown out, decades of storms working to grind the remnants of the actual silicate-based glass into sand that clogged the overworked sump pumps installed in the late 2060s and early ‘70s’s and drove the city’s richest residents to abandon downtown, if not the planet altogether.

The only life left south of Madison were the families too poor to move, green and grey koi rumored to be from the old botanical gardens, and the thick-skinned ballard bullfrogs that ate them.

And The Reckoning.

“You’re late,” snapped a voice from the dark as he slid the salvaged synthsteel door shut behind himself.

He sighed in relief when the door closed silently. The Bear must’ve oiled the bearings since the last time they’d used this space and the creaking door in the supposedly hermetically sealed wreck had drawn nosy residents. “I know. I had to lose my tail, brother dear.” He looked around the room at their small—and growing ever smaller—resistance cell.

The tallest of the group looked ready to leap from his perch on top of what must’ve once been a kitchen island. He tugged at his sleeves, an old nervous habit from what the military used to call ‘shell shock.’ “Are you sure you weren’t followed?”

His twin’s firm hand on his shoulder halted his pissy retort before it could even begin. “Final check-in. Does everyone know where they need to be tomorrow night? The news drones will be out to cover the ceremony and we all need to be in place before they start.”

He nodded, “I’ll be at HQ with The Bear”—The Bear grinned and gave him two thumbs up—”Ready to divert the Catcher’s attention if he gets too close.”

With a whisper of movement, the one on the countertop dropped to the floor, hefting a mean-looking tangle of wires protruding from a grey plastene casing. “I’ll be planting these babies all over the Quad.”

“Good. And I’ll be at Pike with my own batch.” They looked around the room. Two decades still hadn’t yet filled in the hole left by their missing comrade.

The late one now gripped the shoulder next to his. “We’ll keep him safe and away from the action.”

He blew out a sharp breath, rustling a tuft of his permanently unruly hair. “Yeah, I know,” he muttered, voice low. The room fell silent and The Bear wrapped his arm around him and gave him a squeeze. Finally, he looked up. “Meet up at Duke’s if you need repairs.” He nodded again.

“Let’s go.”

The Catcher

2122-11-03 : 07:15 UTC-8

Sharp, icy rain pounded against the synthsteel windows on the 219th floor. Noxious clouds gathered a hundred feet or so below, casting an eerie burnt orange glow over the upper floors that magnified and reflected the flashes of lightning from the storm. As dawn approached, the programming in the synthsteel took over, gradually shifting from an opaque matte silver to a translucent amber. Light strips embedded in the window frame gave the floor-to-ceiling panels a soft, warm glow, simulating sunrise.

As he slept, the diffused light began to illuminate Logan’s face and, after a few moments of the slowly increasing brightness, his eyes snapped open and he sat up, blinking against the light. He allowed his vision to adjust before fumbling at the nightstand for his visored eyeglasses, setting the frames in place and flipping back his blanket.

He stripped out of his pajamas, tucking the already disintegrating material into the recycler before brushing his teeth and changing into his more durable work suit. He knotted his tie with practiced ease and slipped through the door, his bed already made and folded back into the floor until nighttime. Out of habit, Logan touched the wall to deactivate the lights in his room before he realized they were already off, the room illuminated by the artificial sunrise streaming in through the windows. With a shrug, he double tapped the panel to open the door and join his brother for breakfast.

As the door slid open, the droning natter of the newsfeed vocaloid blasting from the dining room filled his ears. Janus must already be awake and listening to the news. For the countless time, he silently thanked the soundproofing in his room.

… “claim that the latest ash converter series now taking flight is expected to clear over 16% of the radioactive ash over parts of the Pacific Northwest, from as far north as Vancouver and south down to the former Bay Area. The effect on crashing bee and wasp populations is unclear. In related news, a number of civilians started a show of support for the artificial pollinators produced by RUR (https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwif5MqGlcz5AhWeAjQIHYrcDsgQFnoECB4QAQ&url=https%3A%2F%2Fen.wikipedia.org%2Fwiki%2FR.U.R.&usg=AOvVaw3YAkNn3UwvYOsZi052w8xa ) after the Human Kind Institute announced their findings that it will require an 89% reduction in ash to restore insect populations to their pre-Blast levels. Leon Resk, CEO of RUR Software Corp addressed the crowds. ‘We here at the RUR pledge to continue the production of our Flightsaver pollinators, ensuring support for the world’s food chains, with only nominal price increases for hive leases in order to maintain competitiveness and satisfy fiduciary responsibilities to our stakeholders and…’”

Logan rolled his neck as he made his way down the long hallway, wishing he could somehow turn off his hearing to avoid the corporate doublespeak. He did not understand how Janus could stomach it all, but his elder brother always insisted hiding from the news wouldn’t make it go away.

“… were met with protests when later that day the president of Evergreen Energy spoke during their observation of the fifty-fifth anniversary of the Blasts. Undeterred, she announced a new fifteen-year road map for the cleanup of the battery islands impacted on that historic day. ‘Evergreen Energy has never sought to point fingers or displace blame for the ecological impact of the American terrorists’ actions on that horrific day. On the contrary, EE takes its responsibility seriously and we pledge to Clean Up Our Mess and work to reduce precipitation toxicity by 13% over the next twenty years…’”

Logan rolled his eyes, wondering which came first, the vocaloid’s programming to uncritically replay these ludicrous public relations talking points or the loss of critical reading by the human reporters of the last century. Janus had shown him ancient recordings of humans reading the news. There hadn’t been much difference.

“And in other news, today marks the tenth anniversary of the Pike Place Massacre where three lives were lost during an artifice insurrection at RUR’s primary production plant. We mourn with the surviving families and credit the quick work of the loyal Model V artifices who responded with alacrity by physically decommissioning over 800 of the responsible artifices. Yesterday, a peaceful memorial was disrupted by the actions of a malfunctioning Model V that threatened the life of the Governor and her children. The artifice was quickly dispatched by one of the city's brave Catchers—“

The vid screen was filled with grainy over-zoomed footage captured by amateur and AI vid drones. It showed the Governor, bleeding and unconscious on the ground, an aide applying pressure to a gaping wound at her side. Two small children cowered behind a blurry figure dressed in black slacks and a jacket festooned with pockets, a dark indigo shirt peeking out. The figure grappled with a tall, heavily armed artifice dressed in black foam armor. The camera zoomed again, automatic facial recognition identifying the man as Sanders, L.

"House, news off, please," Logan instructed.

Janus raised an eyebrow over his data pad. "Someone woke up cranky this morning. Usually you get through your first cup before you've ordered House to stop playing the news."

"It's just the day," he muttered. "I hope you weren't actually watching that nonsense."

"Merely burning time until I had the opportunity to bask in the presence of my little brother, the brave Civilian Catcher of Seattle."

Logan rolled his eyes but smiled as he settled into his seat. He poured a cup from the teapot on the table and took a sip before leaning forward, sharp blue eyes peering at the tremor in his brother’s hand, the paleness on the unscarred side of his face, the long, dark shadows beneath his eyes. He took another slow sip of his tea and spoke into his cup. “I didn’t see you when I came in last night.”

Janus took a bite of his omelet and chewed slowly, swallowing with some effort. “I would characterize four AM as morning, not night.”

“So you did wait up.”

“Yes, he did,” Roman chastised, giving Janus a fondly admonishing look as he walked down the hall and settled into a seat next to him. Janus poured his tea. “Good morning, Logan,” he said brightly, shaking out his napkin and placing it carefully in his lap. He raised his tea cup in salute before taking a sip. “We were all relieved when you returned home safely.”

“Good morning, Roman.” Logan smiled at the artifice, his effusive words warming him as much as the tea. “Thank you.” He raised his cup in response to Roman’s little gesture and took another sip. “And thank you for managing to cajole my brother into eventually getting a bit of sleep.”

“‘It is a far, far better thing that I do, than I have ever done.’”

Janus laughed, raising Roman’s hand to kiss his fingers. “I know you know what that’s from, but did you think I wouldn’t?” Roman’s only response was a laugh, then he gave Janus’ hand a gentle squeeze and took another sip of his tea. Looking up at his brother over his tea cup, Janus frowned. “That Model V was classed as a level 9 threat.” He paused, trying his breakfast again. “You take too many risks, Lo.”

Logan chuckled quietly, “I take every precaution.” He finished his tea and poured a second cup. “You know that… they’re your precautions. It helps to have a robotics master for a brother.”

“‘Master’ is such a distasteful word…” Janus made a sour face and stirred a little extra rice milk into his cup. He winked at Roman. “I’d graciously accept ‘expert,’ ’prodigious genius,’ ‘world-renowned—’”

“Don’t you need to be young to be considered a prodigy?”

“Now, now, now, Logan…” Patton’s cheery voice couldn’t sound stern even if he’d tried. “You know your brother’s sensitive about his age,” he chirped as he set down a plate of toast and jam in front of Logan.

“Is this—” Logan picked up the tiny jar of preserves and tapped the side of it. The impact made a rare, almost echoing ting. “This is real fruit jam. In a glass jar.” He looked up at Patton and tilted his head. “This must have been exorbitant. How did—” Logan caught Janus’ silent eye movement down toward his data pad. “No, Pat… That was a gift! Those credits were meant for you to spend on something for you… an upgrade or an experience or—”

“Something that brought me joy,” Patton grinned at Logan, eyes almost literally twinkling. Logan had been quietly relieved when Janus had reverted that upgrade, returning Patton’s irises to their factory original ice blue. Whether it was the artificiality of the tiny lights, the colder gaze it gave the caretaker he remembered more strongly than even his own brother, or merely the reminder that Patton was not human, the twinkling LEDs pushed the artifice solidly over the edge of the uncanny valley.

Seeing the hurt in Patton’s eyes in the rare few times that Logan could force himself to actually meet them had not eased his discomfort.

Still grinning with that disarming warmth, Patton winked and smeared a small scoop of the blueberry preserves over Logan’s triangle-cut toast and arranged them on the plate along with his two bean curd eggs, sunny side up, shaped in a rough smile. He patted Logan’s shoulder. “And seeing you happy, Kiddo, brings me great joy.”

“But, Pat—”

“Please don’t be angry with me, Logan. I truly bought what I wanted to buy.” He tilted his head, bright eyes scanning Logan’s features. He tucked a strand of hair away from his eyes and grinned again. “You have a big day ahead.” After Logan finally took a bite and his eyes widened in pleasure at the taste of the genuine, fruit-based jam, Patton smiled and moved to the other side of the table to refill Janus’ tea.

“So we know Logan will likely have an appearance at the press conference later today. If he doesn’t find a way out of it, of course.” Logan hid his blush behind his tea cup as Patton pointed with his chin toward Janus’ datapad. “What do you have planned today? You have first years this semester, don’t you?” Patton winked again, a quiet laugh behind his words. “Ready to torture the future programmers of the world?”

If Roman laughed, he hid it well behind his napkin.

Janus raised a hand to his chest, mouth falling open in utterly shocked outrage. “I’m as soft as a kitten on those first years.” His expression broke into a smirk at Logan’s raised eyebrow. “It’s my grad students who need to mind their step.”

Patton looked equally unconvinced and he shared a knowing look with Logan as he passed his seat on the way back to the kitchen.

"Have you been modifying his programming again?" Logan had waited until Patton had left the room, but didn’t look up from his tea, frowning into the still-steaming liquid.

"No, of course not."

Logan set down his tea and hefted the tiny jar of jam in the center of his palm. The label was hand-lettered, and Logan could only imagine where they’d gotten the ink. Perhaps home grown, along with the berries for the jam itself. With the tip of his thumbnail, he tapped the side of the jar and the old-fashioned button-top in the center of the cap. The jar was solid glass, and he didn’t need to take a sample with his watch to know the lid was realsteel.

"He has good taste." Logan looked up, surprised by Janus’ sudden comment. Janus shrugged. “You think very loudly, you know.”

“Speaking of good taste,” Roman began, tea cup cradled in his hands. “Are we continuing the Philosophiae after your classes today?”

“Are you actually enjoying it?” Janus brushed the backs of his fingers over Roman’s cheek with a gentle laugh. “You could recite Descartes in twenty-six different languages.”

“Twenty-eight,” Roman and Logan said in unison. This was far from the first time the couple had discussed the topic.

Laughing, Roman covered Janus’ hand and held it against his own cheek. “But it’s so beautiful when you read it.” He met Janus’ eyes and smiled. “Please?”

It didn’t take long for Janus to relent. “Of course, my dear,” he murmured. “Your wish is my command,” he chuckled before pulling Roman closer and pressing a kiss against his other cheek and returning to his breakfast.

When Logan had finished eating and Roman had excused himself for his morning cello practice, he stood to take the remaining dishes to the kitchen. He frowned at his brother’s half-eaten meal. “Are you feeling alright, Jan?”

Janus chuckled, “I’m fine. Just a bit of nerves. We’re interviewing for the new department chair all afternoon and I’m dreading the semi-human interaction.”

“Well, maybe take another bite of the omelet.” He jerked his head toward the kitchen entry with a little smile. “You don’t want Patton to think you’re getting sick.” He laughed, “Or worse, that you don’t like his cooking.”

“No, we definitely wouldn’t want that,” he murmured, taking back his plate for a moment and finishing two more bites of his breakfast.

Logan’s comm buzzed in his ear and he tapped it twice, watching Janus finish his tea, then unhook his cane from the back of his chair and maneuver out of his seat. As he listened to his day’s assignment, he eyed the way Janus leaned heavily on it, skin paling around the edges where he clung to the hand grip.

“Congratulations on your successful completion of last night’s assignment,” the near-human vocaloid chirped into his ear. “You have been assigned a new artifice to locate and detain.” Logan’s visor projected a meter-wide image of the wanted artifice.

It was tall, with the lanky build and habitual slouch of a decommissioned Model V bot. Structurally, it was identical to the Model V Logan had fought last night, but this new one had been heavily modded, with implants around its eyes and joints, probably extra sensors and energy packs. It had also altered its hair, lengthening it from its military standard buzzcut until its black bangs hung over its eyes, shot through with a deep purple autodye. It wore synth armor over black pants and a heavy black hoodie with worn patches of patterned vid-scrambling paint.

The image appeared to have been taken at last night’s protests, and it caught the artifice throwing back a small EMP device toward an officer’s body cam before it could activate and disrupt its own systems.

“Do you accept this assignment?”

The automated recording waited in programmed patience for his vocal print to commit to the job. “What are the charges?”

After a beat, the vocaloid rattled off a long list of offenses, larceny, destruction of public property, unauthorized modification of an artifice, unauthorized self-modification of an artifice, trespassing… Logan interrupted its litany with a sharp, “Halt list.” He sighed. “Is this artifice charged with anything beyond property crimes?”

There was another brief silence followed by a short, almost disappointed, “No.”

“Who’s next on the list if I do not accept?” Logan scoffed when the program remained silent, awaiting his passcode. The roster of other bounty hunters was an open secret. Each had a code that would reveal their assignments to the rest of the group and they all tracked each other. It was the safest way to avoid encroaching on each other’s territory because the automated dispatcher was shit and everyone knew it. “Authorization Lima-Oscar-Golf-India-Charlie-November-Tree.”

“Authorized,” the vocaloid chirped. “Recent events have overtaxed the New Seattle Police Department’s Citizen Catcher program. If you do not accept this job, it will be offered to SPD Agent R. Deckard, badge number NEX-62019.”

“Fuck.” He finally looked up and noticed Janus watching his half of the conversation. “I accept the job,” he muttered at last. “Download the file. Out.” Logan tapped his comm to end the call.

Janus leaned against the doorway, one eyebrow raised. “And I thought you only collected bounties on murderers.”

Logan straightened his tie in the mirror as he spoke, unwilling—or unable—to meet his older brother’s eyes. ‘Deckard’s a sociopath. Last year he used a perception trigger on a Model C wanted for shoplifting. Fucker said he wanted to be sure its Asmov chips still worked and it wouldn’t fight back at decom.” Logan shuddered. The poor thing’s screams had echoed through the station and the rest of the cops had just ignored it. He checked his respirator, then his gun. “Better I take it in than some animal like that.”

“Very well,” Janus’ voice was even and calm. “Are you trying to convince me?” Logan scowled at his own reflection. “Or yourself?”

“I need to go. Clock’s started.” Logan moved toward the door, but then turned around, his expression softer as he bowed his head. “See you tonight?”

“Always, Logan. Be safe.”

“Always,” he responded, eliciting a small smile from the elder brother. He turned and left, the door sliding shut behind him with a soft whoosh.

Without a sound, Patton stepped out from the hallway into the dining room and met Janus’ eyes. The human nodded once and Patton opened a secure comm line.

#Do Androids Dream of Electric Jam#ts logan#Logan Sanders#ts janus#Janus Sanders#ts remus#ts roman#ts patton#ts virgil#Model C Remus#Model C Roman#Model D Patton#Model V Virgil#ts lucas#Model X Lucas#tss#ts storytime#ts storytime 2022#sanders sides#ts fanfic#ts fanfiction#intrulogical#roceit#remile#very very background remile

11 notes

·

View notes

Text

Best Heavy Machinery Dealer

Team Engineers are authorised dealers for Volvo CE, SDLG and AJAX for Maharashtra.

We deal in all type of construction equipments including Backhoe Loaders, Batching Plants, Excavators, Graders, Pavers, PTRs, Transit Mixers, Vibratory Compactors, Wheel Loaders, Quick Couplers, Rock Breakers, Self Loading Concrete Mixers, Concrete Pumps & Dumpers. We provide after sales service for all our equipments and provide 100% genuine spares.

2 notes

·

View notes

Text

10 Must Know Facts Before You Buy A Concrete Plant

10 Must-Know Facts Before You Buy A Concrete Plant

Many people who manage construction work take the concrete batching plant on lease and use them until they do not finish their work. However, it proves to be quite costly as you will have to pay every time you use it, compared to those who have their own concrete plant.

Buying a plant over leasing from a concrete batching plant manufacturer in India is indeed a good choice if you are engaged in construction work regularly, as leasing can prove to be expensive for the same. However, buying a Portable concrete batching plant in India should not be done without any research. In this section, we have quoted some facts that you should know before buying a concrete plant. Let's have a look at them.

10 Facts That You Should Be Aware Of Before Buying A Concrete Plant

Fix Your Budget: Concrete batching plants are available at different price ranges. You must fix a budget according to the size of your construction business and the kind of construction work you get.

Type: Another important thing that you need to know is whether you want a mobile concrete plant or a stationary. Well, you can easily buy plants for Stationary concrete batching in India from Mobile concrete batching plant manufacturers as they offer a variety of concrete plants.

Size and Capacity: Choose a suitable concrete batching plant as per the size and capacity you are going to need. If you want a small concrete plant, then look for Compact concrete batching plant manufacturers.

Control Panel: Look for a concrete plant with easy handling so that laborers can work on it. There are multiple concrete batching plants with complex control panels, which are quite difficult to use.

After-Sales Service: After-sales service is a very important aspect to check for in a concrete plant manufacturer so that your issue can get rapidly resolved if any problem arises at the work site. Make sure your providers offer good after-sales service.

Equipment: Check all the essential equipment needed for concrete mixing before buying the concrete mixing plant to see whether they all are functioning properly or not.

Automatic: You can buy an automatic or a manual portable concrete batching plant in India according to your requirements. Choosing automatic or semi-automatic plants will be a good pick to reduce the effort and number of the human workforce at the site.

Dry or Wet Batching Plant: Another difference that you need to consider is whether the batching plant is for the dry or wet concrete mixture. Dry batching plants are more efficient compared to other types. You can get a plant that can work for wet as well as dry batching.

Power Consumption: Different concrete plants offer different power consumption. Make sure the plant you are going to buy is power efficient.

Reputed Seller: There are multiple concrete batching plant manufacturers in India, but you can not buy from any random seller. Do some research, and then choose the trusted and popular seller to expect good service.

Gather the right knowledge and make the right choice to enjoy the considerable benefits of buying a concrete plant.

2 notes

·

View notes

Text

Exploring Mobile vs. Inline Concrete Batching Plants: A Comprehensive Guide

Exploring Mobile vs. Inline Concrete Batching Plants: A Comprehensive Guide

In the dynamic world of construction, the selection of a concrete batching plant can greatly influence the efficiency and success of a project. Mobile Concrete Batching Plants and Inline Concrete Batching Plants represent two fundamentally different approaches, each catering to specific project needs. Here's an in-depth comparison to clarify their roles and benefits, enabling professionals to make informed choices tailored to their project demands.

Mobile Concrete Batching Plants: The Epitome of Mobility and Flexibility

Mobility and Operational Flexibility Mobile concrete batching plants are engineered for ease of transport and rapid relocation. This makes them the go-to choice for projects that require movement between various sites, such as highway construction or developments in remote locations. Their key advantage lies in their ability to swiftly adapt to changing project landscapes, offering unmatched flexibility for operations with shifting timelines or locations.

Efficient Setup and Dismantling Designed for quick assembly, mobile plants typically come pre-wired and mostly assembled. This design minimizes setup times and does not necessitate elaborate groundworks or foundations, which are both costly and time-intensive. This feature is particularly advantageous for projects with stringent deadlines or temporary site use.

Cost Efficiency For projects with a limited duration or those spread across multiple sites, mobile batching plants machines are a cost-effective solution. They significantly cut down the costs associated with transporting concrete from a stationary plant to various construction sites, thereby optimizing budget allocations.

Production Capacity Although mobile batching plant excel in efficiency, their output capacity is generally lower compared to their inline counterparts. They are ideal for smaller-scale projects or in scenarios where concrete demand fluctuates.

Operational Limitations Due to their compact size, mobile plants often have limited storage for aggregates and raw materials. This constraint may affect the diversity of concrete types that can be produced, potentially requiring more frequent resupply.

Inline Concrete Batching Plants: Optimized for High Volume Production

Superior Production Capability concrete batching plants are designed for permanent installation and are well-suited for large-scale industrial and commercial projects. These plants boast a high production capacity, capable of meeting continuous, substantial demands for concrete, thus facilitating large-volume output without interruptions.

Complex Setup Requirements Setting up an inline batching plan is a more involved process. It requires extensive site preparation, including the construction of durable foundations and infrastructure. This setup demands more significant initial investments and extended preparation time but results in a more stable and robust operation.

Expanded Material Storage With a larger footprint, inline batching plants offer considerable storage capacities for materials. This capacity allows for a wide variety of concrete mixes to be produced more efficiently and decreases the need for frequent restocking. Facilities typically include large cement silos, multiple bins for aggregates, and sophisticated systems for managing admixtures and other components.

Durability and Longevity Constructed for permanent operation, mini batching plants are robust and durable. They are designed to withstand prolonged usage, making them ideal for extensive projects that span several years.

Reduced Flexibility The primary drawback of inline batching plants is their immobility. Once installed, these plants cannot be easily relocated, which may pose challenges for firms undertaking projects at multiple or shifting locations.

Conclusion: Making the Right Choice

Deciding between a mobile and an inline concrete batching plant largely hinges on specific project criteria such as scope, duration, and site location. Mobile plants are preferred for their flexibility and cost-effectiveness in projects with dynamic requirements across multiple or temporary sites. Conversely, inline plants are more suitable for prolonged, large-scale projects where the higher initial investment can be amortized over time through efficient, high-volume production.

0 notes

Text

Advanced Concrete Pumping Services in Karachi

youtube

Ready Mix Concrete Karachi

Ready mix concrete is a type of concrete that is manufactured in a batch plant according to a set-engineered mix design. This type of concrete is delivered to a worksite by truck-mounted transit mixers. In Karachi, ready-mix concrete is popular due to its efficiency and convenience for construction projects. Here are some key points about ready-mix concrete in Karachi:

Quality and Consistency: Ready-mixed concrete offers consistent quality and uniformity, which is critical for structural integrity and durability.

Time-Saving: The use of ready-mix concrete can significantly reduce the time required for mixing and preparing concrete at the construction site.

Reduced Wastage: With ready-mix concrete, there's less material wastage compared to on-site mixing.

Customized Mixes: Ready-mixed concrete can be tailored to meet specific construction requirements, including different strengths, workability, and setting times.

Ready Made Concrete Karachi

Ready-made concrete, often referred to as pre-mixed or ready-mix concrete, is essentially the same product. It's prepared in a batching plant and transported to construction sites. The main benefits include:

Convenience: Ready-made concrete is pre-mixed and ready for immediate use, saving time and labor costs.

Precision: The mixing process is automated, ensuring precise proportions of cement, sand, aggregate, and water, resulting in high-quality concrete.

Availability: In Karachi, several suppliers offer ready-made concrete, ensuring a steady supply for ongoing construction projects.

Concrete Pump Karachi

Concrete pumps are essential for large-scale construction projects in Karachi, allowing for the efficient placement of concrete. There are two main types of concrete pumps:

Boom Pumps: These pumps use a robotic arm (boom) to deliver concrete to hard-to-reach areas, making them ideal for high-rise buildings and large construction sites.

Line Pumps: These are versatile pumps that use flexible hoses to deliver concrete horizontally or vertically, suitable for smaller projects or where space is limited.

Benefits of using concrete pumps include:

Efficiency: Faster placement of concrete, reducing labor costs and project timelines.

Precision: Accurate delivery of concrete to the desired location, minimizing wastage.

Safety: Reduced risk of manual handling and transportation of concrete, improving site safety.

Concrete Transit Mixer Karachi

Concrete transit mixers are trucks equipped with rotating drums used to transport and mix concrete from the batching plant to the construction site. In Karachi, these mixers are a common sight on construction sites due to their advantages:

Mobility: They enable the transportation of concrete over long distances without compromising its quality.

Continuous Mixing: The rotating drum ensures that the concrete remains homogeneous and prevents it from setting during transit.

Versatility: Suitable for various types of concrete, including standard, lightweight, and high-performance mixes.

In Karachi, companies offering ready-mix concrete and related services typically provide a comprehensive range of solutions, including concrete pumps and transit mixers, to meet the diverse needs of the construction industry.

0 notes

Text

Why are ReadyMix Concrete Products a Good Option for Inexperienced Contractors?

Experience does help you learn a lot. The years you work enhance the level of knowledge related to your job and everything associated with it. However, if experience plays a crucial role, how can beginners get their jobs done? For instance, how is a concrete contractor supposed to deliver if he begins his career a few days or weeks back? Well, there are many solutions available for this. The best readymix company has already introduced ready-mix products that concrete contractors can use right away.

Ready Mix Products:

What are ready-mix products? Concrete constructions are a result of the use of materials, techniques, and efforts. Concrete is not the only material used for concrete construction. Aggregates, adhesives, epoxies, waterproof compounds, etc., are mixed. The tricky part in this matter is the right quantity to be mixed for a concrete construction compound. Young concrete contractors might make a mistake during this. As a result, the construction quality could be poor. On the other hand, using ready mix products can drive away this concern.

Better Solutions:

Ready mix companies have already identified the right formula. This appropriate formula is the best solution for concrete construction. For instance, the ready-mix products save time and effort. Along with this, the downtime of these products is lower than the manually produced mixes. The best ready-mix producer company uses the right methods and develops these products with care in its concrete ready mix plant. As a result, these products enhance the quality of construction along with the longevity of the structure. Click here to learn more.

On-Site Batch Plants:

These days, concrete companies try to take things further. Instead of just providing ready-mix products for concrete construction, these companies provide on-site batch plants. These batch plants can produce tonnes of concrete per hour. Moreover, these on-site plants are managed and maintained regularly so that they perform efficiently enough all the time. As a result, these are in high demand. Inexperienced or newly recruited concrete contractors can utilize this service well.

About Martin Concrete:

Martin Concrete is a ready-mix concrete company that offers products, services, and assistance for all types of concrete construction. The company has been a prominent name in the industry, with years of experience and expertise. Martin Concrete provides much-needed assistance to its customers. Therefore, it is always in high demand.

Check out more at https://www.martinconcrete.com/

Original Source: https://bit.ly/44LFFUZ

0 notes

Text

Ready Mix Concrete Plant in Punjab

Proc Tech Machineries India Pvt. Ltd. Is a Services of Ready Mix Concrete Plant in Punjab.

Proc Tech Machineries India Pvt. Ltd. Is Manufacturer, Exporter and Supplier of Industrial Rotary Dryers, Air Classification Plants, Chilly Processing Plants, Asphalt Drum Mix Plants, RMC Plants, Turmeric Processing Plants, Waste Type Pyrolysis Plants, Jaggery Plants, Coriander Processing Plants, and more.

Our RMC plants feature silos and bins for cement and aggregates, weigh batchers, high-efficiency mixers, and advanced computerized systems for precise control.

Renowned for durability and accuracy, our RMC plants guarantee consistent performance and long-term satisfaction.

With strategic business insights and professional proficiency, we have established ourselves as a leading enterprise in the industry.

Equipped to handle diverse project requirements, our plant ensures prompt delivery without compromising quality.

Whether for residential constructions or commercial projects, our ready mix concrete sets the groundwork for your success in construction.

Features:

An efficient concrete model mixer to provide appropriate longevity and uniformity

Ensure high caliber

Quantity concrete supply computerized batching plant: Produce consistently high-quality concrete with a range of capacities. Extremely productive

Proc Tech Machineries India Pvt. Ltd. Is a Services of Ready Mix Concrete Plant in Punjab and including location like Ludhiana, Amritsar, Jalandhar, Patiala, Bathinda, Mohali, Pathankot, Hoshiarpur, Moga, Batala, Phagwara, Firozpur, Sangrur, Kapurthala, Rajpura, Fatehgarh Sahib, Gurdaspur, Khanna, Malerkotla, Barnala, Sirhind-Fategarh, Abohar, Muktsar, Faridkot, Rupnagar.

For further details, please feel free to contact us.

0 notes

Text

Transforming Construction Processes with Concrete Batching Plants

In the field of construction, efficiency, precision, and reliability are paramount. One pivotal innovation that has fundamentally transformed construction processes is Concrete Batching Plants. These plants, encompassing various types such as concrete mixing plants, batching equipment, cement batching plants, and ready-mix concrete plants, have revolutionized the landscape of construction operations worldwide.

Enhancing Efficiency with Concrete Mixing Plants

Concrete mixing plants serve as the cornerstone of modern construction projects, facilitating the seamless blending of constituent materials to produce high-quality concrete. By incorporating cutting-edge technology and advanced automation, these plants ensure precision in proportioning raw materials such as aggregates, cement, and water, resulting in a consistent and uniform mixture. The integration of state-of-the-art control systems enables real-time monitoring and adjustment, optimizing the production process and minimizing waste. As a result, construction timelines are significantly shortened, and operational costs are effectively reduced, driving unprecedented efficiency in project execution.

Streamlining Operations with Batching Equipment

Central to the success of concrete batching plantsis the utilization of sophisticated batching equipment. These precision instruments meticulously weigh and dispense each component of the concrete mix, ensuring accuracy and reproducibility. Equipped with advanced sensors and monitoring mechanisms, batching equipment maintains tight control over the mixing process, guaranteeing the adherence to stringent quality standards. By eliminating manual intervention and human error, these automated systems enhance operational reliability and consistency, empowering construction teams to deliver superior results with confidence.

Maximizing Productivity with Ready-Mix Concrete Plants

In the field of rapid construction, ready-mix concrete plants stand as a testament to innovation and efficiency. These facilities produce pre-mixed concrete formulations tailored to specific project requirements, offering unparalleled convenience and flexibility to construction contractors. By centralizing the production of concrete off-site, ready-mix plants minimize on-site labor and equipment requirements, thereby optimizing resource utilization and enhancing productivity. Furthermore, the stringent quality control measures implemented in these plants ensure that each batch of concrete meets or exceeds industry standards, guaranteeing exceptional performance and durability in construction applications.

Optimizing Resource Utilization with Aggregate Batching

The efficient management of aggregates, a fundamental component of concrete production, is imperative for the success of any construction endeavor. Aggregate batching systems play a pivotal role in optimizing the utilization of these essential materials, ensuring precise dosing and blending to achieve the desired concrete mix properties. By utilizing advanced algorithms and algorithms, aggregate batching systems minimize material wastage and maximize resource efficiency, thereby reducing environmental impact and promoting sustainability in construction practices.

Conclusion

Concrete batching plants represent a paradigm shift in the construction industry, offering unparalleled levels of efficiency, precision, and reliability. From concrete mixing plants to ready-mix concrete plants, these innovative facilities have redefined the way construction projects are executed, enabling stakeholders to achieve unprecedented levels of productivity and cost-effectiveness. By harnessing the power of automation, advanced technology, and rigorous quality control measures, concrete batching plants have emerged as indispensable assets in the modern construction toolkit, driving progress and innovation across the globe.

Name: Coninfra Machinery Pvt.Ltd

Website: https://www.coninfra.in/

Address: 504, Sahitya Business Park, Nr. Keshav Hero Showroom , S.P Ring Road Nikol, Ahmedabad - 382350, INDIA

Phone No: +91 90999 41311

Faqs

What is a Concrete Batching Plant?

A Concrete Batching Plant is a facility that combines various ingredients to form concrete, such as water, aggregates, sand, cement, and additives. These ingredients are mixed in specific proportions to produce concrete of desired quality and consistency.

How does a Concrete Batching Plant work?

A Concrete Batching Plant works by first feeding the various ingredients into the batching equipment, where they are measured and mixed according to the predetermined recipe. Then, the mixed concrete is discharged into trucks or directly into concrete mixers for transportation to construction sites.

What are the benefits of using a Concrete Batching Plant?

Using a Concrete Batching Plant offers several benefits including:

> Improved efficiency and productivity in concrete production.

> Consistent quality control, ensuring uniformity in concrete properties.

> Reduced wastage of materials due to accurate batching.

> Flexibility to produce different types and grades of concrete according to project requirements.

> Enhanced safety measures in handling and mixing concrete ingredients.

What are the different types of Concrete Batching Plants?

Concrete Batching Plants come in various types based on their design, capacity, and mobility. Common types include:

> Stationary Concrete Batching Plants: Fixed in one location and suitable for large-scale projects.

> Mobile Concrete Batching Plants: Portable and easily movable, ideal for temporary construction sites.

> Compact Concrete Batching Plants: Space-saving designs suitable for small to medium-sized projects.

> Dry Mix Concrete Plants: Batch plants where all the ingredients are mixed except water, which is added at the construction site.

> Wet Mix Concrete Plants: Batch plants where all ingredients are combined with water before being discharged.

How to choose the right Concrete Batching Plant for my project?

Choosing the right Concrete Batching Plant involves considering factors such as:

> Project requirements including the volume and type of concrete needed.

> Available space for installation and operation.

> Accessibility to raw materials and transportation logistics.

> Budget constraints and long-term maintenance requirements.

> Environmental regulations and emission standards.

> Potential for future expansion or scalability of the plant.

0 notes

Text

Case Studies: Successful Applications of Different Concrete Batching Plant Types

Concrete batching plants play a pivotal role in the construction industry, providing the essential ingredient for any building project – concrete. However, not all concrete batching plants are created equal. Various types cater to different project requirements, offering unique advantages and applications. In this blog, we’ll delve into real-world case studies to showcase the successful applications of different types of concrete batching plant.

1. Mobile Concrete Batching Plants: The On-the-Go Solution

Case Study: Rapid Bridge Construction Project

In a rapidly developing urban area, a construction company faced the challenge of building a series of bridges within tight deadlines. The solution? Mobile concrete batching plants. These compact and transportable units allowed the construction team to set up temporary concrete production facilities near each bridge site. This not only minimized transportation costs but also significantly reduced the project timeline, showcasing the flexibility and efficiency of mobile batching plants.

2. Stationary Concrete Batching Plants: Stability for Large-Scale Projects

Case Study: High-Rise Residential Tower

For a high-rise residential tower construction, where a consistent and large supply of concrete was needed, a stationary concrete batching plant proved to be the ideal choice. The constant production capabilities of stationary plants ensured a steady flow of high-quality concrete, meeting the demands of the vertical construction. The stationary plant’s robust structure and advanced automation contributed to a smooth and uninterrupted construction process.

3. Dry Mix Concrete Batching Plants: Water-Saving Solution

Case Study: Desert Highway Construction

In a desert environment where water scarcity is a critical concern, a construction project required a concrete batching solution that minimized water usage. Dry mix concrete batching plants, with their pre-measured components and minimal water requirements, became the go-to choice. The project not only met its sustainability goals but also experienced enhanced durability in the concrete structures due to the controlled mixing process.

4. Wet Mix Macadam Plants: Precision in Specialized Projects

Case Study: Hydroelectric Dam Construction

The construction of a hydroelectric dam demanded precision in concrete mix design to ensure the structural integrity of the dam. Wet mix Macadam plants, with their ability to achieve a high level of homogeneity and precision in mixing, were instrumental in meeting the project’s stringent specifications. The consistent quality of the concrete produced played a crucial role in the success of the dam construction.

5. Compact Concrete Batching Plants: Urban Redevelopment

Case Study: City Center Renovation

In the heart of a bustling city center undergoing redevelopment, space constraints were a major challenge. Compact concrete batching plant, with their small footprint and efficient design, allowed for on-site concrete production without disrupting the surrounding urban activities. This case study highlights how compact plants are tailored for projects in confined spaces, offering a localized solution to the concrete supply needs of urban redevelopment initiatives.

In conclusion, the success of a construction project often hinges on choosing the right concrete batching plant type. These case studies exemplify how different plant types cater to diverse project requirements, demonstrating the adaptability and efficiency of modern concrete production methods. Whether it’s a mobile plant for on-the-go projects or a stationary plant for large-scale developments, the key lies in aligning the plant type with the specific demands of the construction endeavor.

#compact concrete batching plant#concrete batching plants#Dry mix concrete batching plants#mobile concrete batching plants#Stationary Concrete Batching Plant#types of concrete batching plant#Wet Mix Macadam Plants

0 notes

Text

A Simple Analysis of Concrete Batching Plant Price

In the world of construction, efficiency and cost-effectiveness are paramount. Concrete batching plants play a pivotal role in ensuring seamless operations and high-quality output. However, understanding the cost breakdown of different types of batching plants is crucial for informed decision-making. Let’s delve into the intricacies of this essential aspect.

Types of Concrete Batching Plants

1. Stationary Concrete Batching Plants: These plants are characterized by their fixed structure and are ideal for large-scale construction projects. The cost breakdown includes expenses related to land acquisition, initial setup, and maintenance.

2. Mobile Concrete Batching Plants: Offering unparalleled flexibility, mobile plants are suitable for projects requiring frequent relocation. Their cost breakdown typically comprises transportation expenses, installation costs, and ongoing maintenance.

3. Compact Concrete Batching Plants: Designed for small to medium-scale projects, compact plants combine efficiency with space-saving features. The cost breakdown involves factors such as equipment purchase, site preparation, and operational expenses.

Factors Influencing Costs

1. Capacity: The production capacity of a batching plant significantly impacts its cost. Higher capacity plants entail greater initial investment but offer economies of scale in the long run.

2. Technology and Features: Advanced technologies and additional features like automation, computerized control systems, and environmental protection measures contribute to the overall cost.

3. Maintenance and Operating Costs: Regular maintenance, spare parts availability, and energy consumption are ongoing expenses that need to be factored into the cost analysis.

Optimizing Cost Efficiency

1. Comparative Analysis: Conducting a comprehensive comparison of different types and models of batching plants helps in identifying the most cost-effective option tailored to specific project requirements.

2. Lifecycle Cost Assessment: Considering the lifecycle cost, including initial investment, operational expenses, and potential resale value, provides a holistic view of the financial implications.

3. Supplier Evaluation: Choosing a reputable supplier with a track record of delivering quality equipment and reliable after-sales support is crucial for minimizing unforeseen costs and ensuring long-term efficiency.

Understanding the cost breakdown of concrete batching plants empowers construction professionals to make informed decisions, maximize productivity, and optimize resource utilization. To explore further insights into enhancing construction efficiency and reducing costs, delve into our comprehensive guide. Read more for a deeper understanding.

0 notes

Text

Supplier of Paver Block Making Machine in Ahmedabad

Company Overview:

Robexo Industries is a leading Manufacturer and Supplier of Paver Block Making Machine in Ahmedabad, Gujarat, India.

The company specializes in manufacturing fly ash and fully automatic bricks, interlocking bricks, paver blocks, concrete hollow and solid block machines, vibrating table sets, automatic batching plants, and silos for concrete raw materials.

Contractors utilize a Paver Block Making Machine in construction to produce concrete or cement paver blocks. The machine comprises a mold into which they pour a concrete or cement mixture, compact it, and cure it to form durable paver blocks of various shapes, sizes, and designs.

Paver block making machines can produce various types of blocks, including interlocking bricks, concrete blocks, I-shaped pavers, curved pavers, and block pavers, offering flexibility to suit different construction needs.

Paver Block Making Machines boast customizable molds, automatic operation, high production capacity, durability, versatility, user-friendly interfaces, and energy efficiency.

During operation, the machine loads raw material into a mold, applies hydraulic pressure to shape it, extracts the block, and initiates curing.

Applications:

Paver Block Making Machines find applications across various construction projects, including driveways,

sidewalks, patios, pathways, parking areas, landscaping features, and other paved surfaces in residential,

commercial, and municipal settings.

Geographical Coverage:

Robexo Industries serves as a Supplier of Paver Block Making Machine in Ahmedabad, Gujarat, India, and

surrounding areas including Sanand, Vani, Kathawada, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol,

Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala, and Vatva.

Interested parties can contact Robexo Industries for inquiries or additional information

Read the full article

#automaticbatchingplants#Bakrol#Changodar#concretehollowandsolidblockmachines#Dhandhuka#Dholka#driveways#Exporter#fullyautomaticbricks#India#interlockingbricks#Kadi#Kalol#Kanbha#Kathawada#Kerala#Kujad#landscaping#Manufacturer#Naroda#Odhav#parkingareas#pathways#patios#paverblocks#Rakhial#Sanand#sidewalks#Singarva#Supplier

0 notes

Text

Concrete Batching Plant Manufacturer and Suppliers in India

The Concrete batching plant is an equipment that efficiently combines the various ingredients to make up concrete. The ingredients are sand, aggregate, water, air, cement, fly ash, and silica fume. These ingredients are mixed at different ratios depending on the final type of desired concrete. There are two main types of Concrete batching plants, which are the dry mix and the wet mix plants. A concrete batching plant is a machine in which ingredients of concrete are mixed and blended homogeneously to obtain concrete of desired strength and quality. The plants can be used wet or dry and has a wide array of configurations and production types including Ready Mix, Precast & Prestressed, Central Mix, and RCC. Because these plants offer total automation, superior performance, high production rates, and the highest quality manufacturing, they are very advantageous. As the volume drops through the maximum pressure field, the material is modelled into a solid compact sheet or flakes of ingredients.

For more details clicks here - https://www.indiantradebird.com/product/concrete-batching-plant

0 notes

Text

Ready Mix Concrete Supplier Near Me

The Ultimate Guide to Finding the Perfect Ready Mix Concrete Supplier Near You

Introduction

In the world of construction, time is money. Whether you're a contractor working on a large-scale project or a homeowner tackling a DIY renovation, one thing remains constant: the need for reliable and high-quality ready mix concrete. But with so many suppliers out there, how do you find the right one for your specific needs? Fear not, because in this comprehensive guide, we'll walk you through everything you need to know to locate the perfect ready mix concrete supplier near you.

Understanding Ready Mix Concrete

Before diving into the process of finding a supplier, it's essential to understand what ready mix concrete is and why it's such a crucial component in construction. Ready mix concrete, also known as RMC, is precisely mixed at a batching plant and delivered to the construction site in a ready-to-use condition. This eliminates the hassle of on-site mixing and ensures consistent quality and strength in the finished product.

Factors to Consider

When searching for a ready mix concrete supplier, several factors should influence your decision:

Quality: The quality of the concrete directly impacts the strength and durability of your project. Look for suppliers with a reputation for producing high-quality mixes using premium materials.

Reliability: Timely delivery is essential in the construction industry. Choose a supplier known for their reliability and punctuality, ensuring that your project stays on schedule.

Experience: An experienced supplier is more likely to understand your needs and provide tailored solutions. Look for companies with a proven track record and years of experience in the industry.

Variety of Mixes: Different projects require different types of concrete mixes. A supplier that offers a wide variety of mixes, including specialty blends for specific applications, can meet your project's unique requirements.

Customer Service: Exceptional customer service can make all the difference, from initial inquiries to post-delivery support. Choose a supplier that values clear communication and prioritizes customer satisfaction.

Researching Suppliers

Now that you know what to look for, it's time to start researching suppliers in your area. Here are some effective strategies:

Online Search: Start by conducting an online search for ready mix concrete suppliers in your vicinity. Visit their websites to gather information about their services, products, and contact details.

Reviews and Testimonials: Reading reviews and testimonials from previous customers can provide valuable insights into the reputation and reliability of a supplier. Look for feedback on factors such as product quality, delivery efficiency, and customer service.

Ask for Recommendations: Reach out to colleagues, friends, or industry contacts who have experience with construction projects. They may be able to recommend reputable suppliers based on their own experiences.

Visit Batching Plants: If possible, visit the batching plants of potential suppliers to assess their facilities and production processes firsthand. This can give you a better understanding of their capabilities and quality control measures.

Get Quotes: Once you've narrowed down your list of potential suppliers, request quotes from each of them. Compare pricing, delivery options, and any additional services offered to make an informed decision.

Making the Final Decision

After thorough research and consideration, it's time to choose the right ready mix concrete supplier for your project. Remember to prioritize factors such as quality, reliability, and customer service over price alone. A slightly higher upfront cost may be worth it in the long run if it ensures a smoother and more successful construction process.

Conclusion Finding the perfect ready mix concrete supplier near you doesn't have to be a daunting task. By understanding your requirements, conducting thorough research, and prioritizing key factors such as quality and reliability, you can confidently select a supplier that meets your needs and exceeds your expectations. With the right supplier by your side, you'll have the foundation for a successful and durable construction project.

1 note

·

View note

Text

The Rise of Concrete Pumping Services and Volumetric Concrete Suppliers

Two innovations that have significantly transformed the building landscape are volumetric concrete suppliers and concrete pumping services. Both technologies offer unique benefits and have revolutionized how concrete is prepared, delivered, and used in construction projects.

Volumetric concrete from Volumetric concrete suppliers near me involves the use of mobile concrete batching plants, known as volumetric concrete mixers. These units are effectively mobile factories that carry all the necessary ingredients for concrete—cement, water, sand, and aggregates—and mix them on-site. This approach provides a stark contrast to traditional methods where concrete is mixed at a central batching plant and transported in a drum mixer.

Benefits of Volumetric Concrete

Fresh Concrete on Demand

Volumetric mixers produce concrete on-site, ensuring the mixture is fresh and has not begun to cure or set during transportation. This leads to stronger, more durable concrete.

Customization and Flexibility

Since the concrete from Readymix concrete supplier near me is mixed on the spot, adjustments can be made to the mix design according to specific project needs without waste or additional costs.

Increased Efficiency

The ability to produce concrete by Readymix concrete supplier near me on demand means no delays due to under ordering or waiting for additional deliveries. Projects can proceed faster and more smoothly.

The Role of Concrete Pumping Services

Concrete pumping is a method used to transport freshly mixed concrete to specific locations on a construction site, unreachable by conventional means. Concrete pumps come in various types including boom pumps, line pumps, and stationary pumps, each serving different purposes.

Advantages of Concrete Pumping

Access Hard-to-Reach Areas

Concrete pumping services can deliver concrete to high-rise locations or sites with limited access without compromising the quality or workability of the concrete.

Speed and Efficiency

Pumping concrete is much faster than traditional methods of transportation and placement. This reduces labor costs and accelerates the construction timeline.

Reduced Labor Intensity

Manual labor for concrete placement is significantly reduced, minimizing human error and fatigue, and enhancing safety on the job site.

Consistent Quality

Concrete pumps deliver a steady flow of concrete, which can be critical for certain applications like laying foundations, ensuring a uniform and consistent finish.

Combining Volumetric Mixers with Concrete Pumps: A Construction Game-Changer

Integrating volumetric concrete delivery by Volumetric concrete suppliers near me with pumping services streamlines the construction process even further. Concrete can be mixed precisely to specifications and then pumped immediately to where it's needed. This synergy not only improves logistical efficiency but also enhances the overall integrity and quality of the structure.

#readymix concrete supplier near me#concrete pumping services#volumetric concrete suppliers near me#concrete suppliers near me

0 notes

Text

Concrete Convenience: Your Guide to Ready Mix Services

Introduction

In the realm of construction, convenience and efficiency are paramount. One essential element in many construction projects is concrete, the backbone of structures. Ready mix concrete services have emerged as a solution to streamline the process of concrete procurement and usage. This essay aims to provide a comprehensive guide to ready mix services, exploring their benefits, the process involved, and why they're gaining popularity in construction projects worldwide.

Understanding Ready Mix Concrete

Before delving into the specifics of ready mix services, it's crucial to understand what ready mix concrete is. Ready mix concrete, also known as RMC, is a pre-mixed blend of cement, aggregates, water, and additives, produced in a batching plant and delivered to construction sites in a ready-to-use form. This eliminates the need for on-site mixing, reducing labor requirements and ensuring consistency in quality and performance.

Benefits of Ready Mix Concrete

Ready mix concrete offers numerous advantages over traditional on-site mixing methods, including:

Consistency: Ready mix concrete is produced in controlled environments using precise formulations and quality control measures, ensuring uniformity in composition and performance. This results in higher quality finishes and greater durability of structures.

Time-Saving: Ready mix concrete eliminates the need for on-site batching and mixing, saving valuable time during the construction process. With just-in-time delivery, construction crews can focus on placement and finishing tasks without delays or interruptions.

Cost-Effectiveness: While ready mix concrete may involve higher upfront costs compared to on-site mixing, it ultimately proves to be cost-effective by reducing labor requirements, minimizing material wastage, and improving construction efficiency. Additionally, the precise measurement of ingredients in batching plants helps optimize material usage and minimize excess.

Versatility: Ready mix concrete can be customized to meet specific project requirements, including strength, slump, and durability characteristics. This versatility makes it suitable for a wide range of construction applications, from residential foundations to commercial buildings and infrastructure projects.

Quality Assurance: Ready mix concrete suppliers adhere to strict quality control standards and testing protocols to ensure that the delivered product meets industry specifications and regulatory requirements. This provides peace of mind to contractors and project owners regarding the performance and durability of the concrete used in their projects.

Accessing Ready Mix Services

Accessing ready mix services is a straightforward process, typically involving the following steps:

Project Planning: The first step in accessing ready mix services is to assess the concrete requirements of your project, including the type and volume of concrete needed, the desired strength and durability specifications, and any special considerations such as admixtures or additives.

Supplier Selection: Research and identify reputable ready mix concrete suppliers in your area, taking into account factors such as experience, reputation, quality control measures, and proximity to the construction site. Obtain quotes from multiple suppliers to compare pricing and services.

Order Placement: Once you've selected a ready mix concrete supplier, place an order for the required quantity and specifications of concrete for your project. Provide detailed information about the delivery location, access points, and any site-specific requirements or constraints.

Delivery and Placement: On the scheduled delivery date, the ready mix concrete supplier will dispatch a fleet of transit mixers to transport the concrete to your construction site. The concrete is discharged directly from the mixer trucks into forms or placement areas, where it is then consolidated, leveled, and finished by construction crews.

Quality Control: Throughout the delivery and placement process, the ready mix concrete supplier may conduct quality control tests and inspections to verify the consistency and performance of the concrete. This helps ensure that the delivered product meets the specified requirements and standards.

Conclusion

Ready mix concrete services offer a convenient and efficient solution for construction projects of all sizes and scales. By providing pre-mixed concrete tailored to project specifications, ready mix services streamline the construction process, reduce labor requirements, and ensure consistent quality and performance. As the construction industry continues to evolve, the demand for ready mix concrete services is expected to grow, driven by the need for faster, more cost-effective, and sustainable construction solutions. By understanding the benefits and process of accessing ready mix services, construction professionals can optimize their projects and achieve success in today's competitive marketplace.

0 notes