Text

American Efficiency Services proudly stands at the forefront of eddy current measurement and testing. Our commitment to innovation, precision, and safety underscores every facet of our approach. As we continue to advance alongside evolving technology, our expertise in eddy current testing contributes to improved quality control and safety standards across various industries, setting a benchmark for excellence in non-destructive testing.

0 notes

Text

Exploring Eddy Current Measurement and Testing: A Comprehensive Overview | American Efficiency Services

Eddy current measurement and testing are non-destructive testing (NDT) techniques widely employed in various industries to inspect and evaluate the integrity of conductive materials. Named after the swirling currents induced by changing magnetic fields, eddy current testing is a powerful method for detecting flaws, cracks, and material inconsistencies without causing any damage to the tested object.

Understanding Eddy Currents:

Eddy currents are circulating currents that are generated in a conductor when subjected to a changing magnetic field. According to Faraday's law of electromagnetic induction, when a magnetic field varies within a conductor, it induces an electromotive force (EMF) and consequently generates circulating currents within the material. These eddy currents, in turn, create their own magnetic fields that interact with the original magnetic field, producing a variety of effects.

Principle of Eddy Current Testing:

Eddy current testing relies on the principles of electromagnetic induction. A coil carrying an alternating current is used to generate a magnetic field. When this coil is brought near a conductive material, eddy currents are induced in the material. The interactions between the induced eddy currents and the original magnetic field result in changes that can be detected and analyzed to provide information about the material being tested.

Key Components of Eddy Current Testing:

1. **Probe or Sensor:**

The probe, also known as the eddy current sensor, is a crucial component of the testing system. It contains the coil or coils responsible for generating the alternating magnetic field.

2. **Eddy Current Instrument:**

This instrument supplies the alternating current to the probe and measures the impedance or other electrical parameters affected by the presence of eddy currents. Modern instruments often use advanced signal processing techniques for enhanced sensitivity and accuracy.

3. **Display and Analysis System:**

The data collected by the eddy current instrument is typically processed and displayed in real-time. This system allows operators to interpret the results and identify any anomalies or defects in the material.

Applications of Eddy Current Testing:

1. **Surface Crack Detection:**

Eddy current testing is highly effective in detecting cracks, scratches, or other surface irregularities in conductive materials. It is commonly used in industries such as aerospace, automotive, and manufacturing.

2. **Material Sorting and Thickness Measurement:**

This technique is employed to sort materials based on their conductivity and to measure the thickness of conductive coatings on non-conductive substrates.

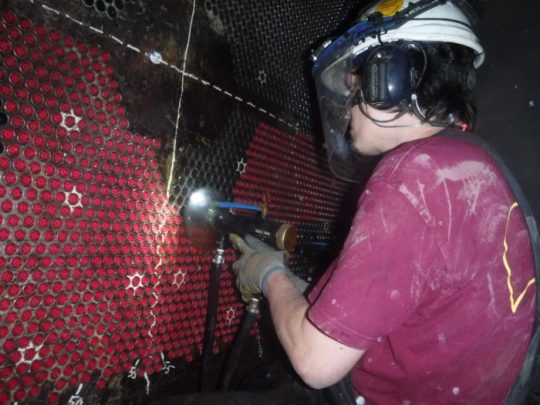

3. **Heat Exchanger Inspection:**

In industries like petrochemical and power generation, eddy current testing is used to inspect heat exchanger tubes for defects and corrosion, ensuring optimal performance and safety.

4. **Aircraft Component Inspection:**

Eddy current testing is widely utilized in the aviation industry to inspect critical components like turbine blades for cracks or defects, ensuring the safety and reliability of aircraft.

Advantages of Eddy Current Testing:

1. **Non-Destructive:**

Eddy current testing is a non-destructive technique, meaning it does not cause any harm to the tested material.

2. **High Sensitivity:**

It is highly sensitive to surface and near-surface defects, making it suitable for detecting small cracks and flaws.

3. **Rapid Inspection:**

The method allows for quick and efficient inspection of large areas, making it a valuable tool in various manufacturing and maintenance processes.

Conclusion:

American Efficiency Services proudly stands at the forefront of eddy current measurement and testing. Our commitment to innovation, precision, and safety underscores every facet of our approach. As we continue to advance alongside evolving technology, our expertise in eddy current testing contributes to improved quality control and safety standards across various industries, setting a benchmark for excellence in non-destructive testing.

0 notes

Text

In the pursuit of energy efficiency and cost savings, addressing air leakage is a fundamental step that should not be overlooked air leakage detectors are invaluable tools in identifying and rectifying these issues, ultimately leading to reduced energy consumption and lower utility bills. By investing in such technology, homeowners and businesses can contribute to a more sustainable future while enjoying the immediate benefits of a more energy-efficient living or working space. In the realm of American efficiency, the use of American Efficiency air leakage detectors stands out as a practical and effective solution for smarter energy management.

0 notes

Text

Air Leakage Detectors Can Save You Money on Energy Bills | American Efficiency

Introduction:

In an era where energy efficiency is paramount, homeowners and businesses alike are constantly seeking ways to reduce their energy consumption and cut down on utility costs. One often overlooked but significant factor contributing to energy wastage is air leakage. Uncontrolled air movement in and out of buildings can result in increased energy bills, as heating and cooling systems work harder to maintain a comfortable indoor environment. To combat this issue, the use of air leakage detectors, particularly those under the brand name "American Efficiency," has become a game-changer in enhancing energy efficiency and saving money on energy bills.

Understanding Air Leakage:

Air leakage, also known as infiltration or drafts, occurs when unconditioned air from outside enters a building or conditioned air escapes. This phenomenon is most common in older structures, but even newer buildings may experience air leakage due to poor construction or inadequate sealing. The primary areas where air leakage occurs include windows, doors, attics, and basements.

The Impact on Energy Bills:

The consequences of air leakage are directly reflected in energy bills. When outside air infiltrates a building, heating and cooling systems must compensate to maintain the desired indoor temperature. During colder months, warm air escapes, and cold air enters, forcing heating systems to work harder. Conversely, in warmer weather, cool air leaks out, and warm air infiltrates, causing air conditioners to operate more frequently. This continuous cycle leads to increased energy consumption and, subsequently, higher utility bills.

The Role of American Efficiency Air Leakage Detectors:

American Efficiency air leakage detectors play a crucial role in identifying and quantifying the extent of air leakage in a building. These devices use advanced technology to locate areas where uncontrolled air movement occurs. Thermal imaging, smoke pencils, and blower door tests are common methods employed by professionals to pinpoint air leakage sources. Once identified, necessary measures can be taken to seal these gaps and improve overall energy efficiency.

Benefits of Using American Efficiency Air Leakage Detectors:

1. **Cost Savings:** By addressing air leakage, property owners can significantly reduce their energy bills. The initial investment in American Efficiency air leakage detection and sealing is often outweighed by the long-term savings achieved through improved energy efficiency.

2. **Enhanced Comfort:** Sealing air leaks not only saves money but also enhances indoor comfort. A well-sealed building maintains a consistent temperature, providing a more comfortable living or working environment for occupants.

3. **Environmental Impact:** Reducing energy consumption contributes to a lower carbon footprint. By using American Efficiency air leakage detectors to improve energy efficiency, individuals and businesses can play a role in environmental conservation and sustainability.

4. **Increased Property Value:** Energy-efficient buildings are becoming increasingly attractive to potential buyers and tenants. Investing in American Efficiency air leakage detection and sealing can enhance the overall value of a property.

Conclusion:

In the pursuit of energy efficiency and cost savings, addressing air leakage is a fundamental step that should not be overlooked. American Efficiency air leakage detectors are invaluable tools in identifying and rectifying these issues, ultimately leading to reduced energy consumption and lower utility bills. By investing in such technology, homeowners and businesses can contribute to a more sustainable future while enjoying the immediate benefits of a more energy-efficient living or working space. In the realm of American efficiency, the use of American Efficiency air leakage detectors stands out as a practical and effective solution for smarter energy management.

0 notes

Text

Generator Inspection Procedures and Importance

Generator inspection is a crucial maintenance practice for industries and power generation facilities. Discover the significance of regular generator inspections, the key components to assess, and how they enhance operational efficiency and reliability. Explore the best practices and benefits of thorough generator inspections in this comprehensive guide. Contact us for more information 410-489-0613.

0 notes

Text

Enhancing Efficiency and Longevity: Condenser Tube Inspection and Cleaning Equipment

Introduction:

In the world of industrial processes, maintaining the efficiency of cooling systems is paramount. Condenser tubes play a crucial role in various industries, from power plants to chemical refineries, ensuring optimal heat exchange. To ensure the seamless functioning of these systems, regular condenser tube inspection and effective cleaning are essential. In this article, we delve into the significance of condenser tube inspection and explore the advanced cleaning equipment that keeps these vital components performing at their best.

The Importance of Condenser Tube Inspection:

Condenser tubes are susceptible to various issues that can compromise their efficiency. Over time, factors such as scaling, fouling, and corrosion can accumulate on the inner surfaces of these tubes, hindering heat transfer and increasing energy consumption. Regular condenser tube inspection enables early detection of these issues, preventing costly breakdowns, inefficiencies, and downtime.

Benefits of Routine Inspection:

Enhanced Efficiency:

Regular inspections identify performance-degrading factors, allowing for timely intervention and maintenance. This leads to improved heat exchange efficiency, reducing operational costs.

Extended Lifespan:

Early detection of corrosion or other damage can prevent the deterioration of condenser tubes, extending their lifespan and reducing replacement costs.

Energy Savings:

Clean and well-maintained condenser tubes require less energy to achieve the desired cooling effect, resulting in reduced energy consumption.

Reduced Environmental Impact:

Efficient cooling systems consume less energy, contributing to lower carbon emissions and a smaller ecological footprint.

Advanced Condenser Tube Cleaning Equipment:

Effective condenser tube cleaning is a critical aspect of maintaining system efficiency. As traditional cleaning methods prove inadequate, advanced equipment has emerged to address the challenges posed by modern industrial environments.

High-Pressure Water Jetting Systems:

Utilizing focused water jets at high pressure, these systems remove deposits and fouling from the tube walls without causing damage. They are versatile, suitable for various tube materials, and can restore optimal heat transfer efficiency.

Mechanical Tube Cleaning Systems:

These systems employ rotating brushes, scrapers, or projectiles to physically dislodge deposits from tube surfaces. They are highly effective for tough scaling and fouling, ensuring thorough cleaning.

Chemical Cleaning Systems:

Chemical cleaning solutions are designed to dissolve deposits and corrosion within condenser tubes. When used appropriately, they can restore tubes to near-original condition.

Robotic Cleaning Systems:

In complex or hard-to-reach environments, robotic systems can navigate tubes and perform cleaning tasks with precision. This technology minimizes human exposure to hazardous conditions and enhances cleaning accuracy.

Conclusion:

The integrity and efficiency of condenser tubes are integral to the smooth operation of various industries. Regular inspection and advanced cleaning techniques are pivotal to maintaining optimal heat exchange efficiency, reducing energy consumption, and extending the lifespan of these critical components. By embracing technological advancements in condenser tube cleaning equipment, industries can ensure reliable performance, operational cost savings, and a reduced environmental impact.

1 note

·

View note