Text

PEX Power Play: Surging from $7.6B to $11B - Transforming Automotive, Construction, and Solar Industries!

The Cross-Linked Polyethylene (PEX) market is poised for remarkable growth, with projections indicating a surge from USD 7.6 billion in 2023 to USD 11.0 billion by 2028, reflecting a noteworthy Compound Annual Growth Rate (CAGR) of 7.6% during the forecast period. This robust expansion is underpinned by several key factors that underscore the versatility and indispensability of PEX across various industries.

One significant driver of the PEX market's growth is the increasing demand within the automotive sector. PEX has found extensive use in wiring and cable applications, garnering prominence due to its excellent electrical insulation properties and durability. The automotive industry, particularly in the dynamic Asia Pacific region, is witnessing rapid evolution and expansion. As the demand for advanced wiring and cable systems continues to rise, PEX remains a preferred choice, ensuring robustness and reliability in the face of evolving automotive technologies.

Simultaneously, the construction industry has emerged as a crucial growth contributor to the PEX market. Applications such as pipes and wiring showcase PEX's flexibility, corrosion resistance, and ease of installation, making it an attractive option for various construction projects. This trend is particularly pronounced in Asia Pacific, where ongoing rapid urbanization and infrastructure development fuel the continued adoption of PEX in construction applications. The material's adaptability to diverse construction needs positions it as a cornerstone in the development of modern infrastructure.

Moreover, the global solar industry is playing a pivotal role in shaping the trajectory of the Cross-Linked Polyethylene market. The increasing need for plastic pipes in solar thermal systems is a key factor driving market growth. Cross-Linked Polyethylene pipes have proven to be well-suited for transporting heat transfer fluids in solar panels, owing to their exceptional thermal resistance and durability. With the world's increasing shift towards renewable energy sources, particularly solar power, the demand for PEX in the solar industry is poised for steady and sustained growth. This aligns with global efforts to promote sustainable and eco-friendly energy solutions.

The confluence of these factors positions Cross-Linked Polyethylene (PEX) as a versatile material that adapts seamlessly to the evolving needs of industries. Its inherent qualities such as durability, flexibility, and thermal resistance make it a preferred choice in diverse applications. The surge in demand within the automotive, construction, and solar sectors highlights PEX's cross-industry relevance and cements its status as a transformative material.

As industries increasingly prioritize sustainability and efficiency, PEX's role becomes even more crucial. In the automotive sector, where advancements are rapid and stringent standards prevail, the exceptional electrical insulation properties and durability of PEX make it integral to the industry's progress. Similarly, in construction, where the focus is on creating resilient and sustainable structures, PEX's corrosion resistance and ease of installation contribute significantly to project efficiency.

Looking ahead, the Cross-Linked Polyethylene (PEX) market is positioned to be a key player in the global materials landscape. The anticipated growth in the automotive, construction, and solar industries underscores the adaptability and resilience of PEX. Keeping abreast of these trends is essential for stakeholders aiming to harness the full potential of this versatile material.

Download PDF Brochure :

The Cross-Linked Polyethylene (PEX) market is not only witnessing substantial growth but is also intricately woven into the fabric of key industries. Its journey from USD 7.6 billion to USD 11.0 billion by 2028 is not just a numerical progression but a testament to its transformative impact across diverse sectors. As we navigate towards a future shaped by sustainable practices and technological advancements, Cross-Linked Polyethylene stands tall as a material of choice, ready to meet the challenges and opportunities that lie ahead.

0 notes

Text

Market Analysis: Adhesive Tapes Market Expected to Reach $110.6 Billion by 2028

Adhesive tapes, often viewed as an everyday convenience, play a crucial role in diverse industries, from construction and manufacturing to healthcare and electronics. This seemingly simple product boasts a complex global market worth billions, and its story is far from ordinary. Let's explore the Adhesive Tapes Market, examining its size, trends, growth, and exciting predictions for the future.

Industry Size: Sticking to Impressive Numbers

As of 2024, the global Adhesive Tapes Market was valued at USD 80.2 billion, and according to MarketsandMarkets, it's projected to reach USD 110.6 billion by 2028, witnessing a healthy CAGR of 5.6%. This impressive growth signifies the increasing reliance on these versatile bonding solutions across numerous sectors.

Market Trends: Innovation Takes Center Stage

Several key trends are shaping the Adhesive Tapes Market:

Technological Advancements: Continuous innovations are leading to tapes with enhanced functionalities, like higher temperature resistance, improved conductivity, and eco-friendly materials.

Sustainability Focus: Environmental concerns are driving the development of biodegradable and recyclable tapes, minimizing environmental impact.

Specialty Applications: Tapes are catering to niche applications in industries like medical devices, electronics, and aerospace, demanding high-performance characteristics.

E-commerce Boom: Growing online retail is fueling the demand for packaging tapes, creating opportunities for manufacturers.

Market Analysis: A Tapestry of Players and Products

The market comprises diverse players ranging from established global giants like 3M, Nitto Denko, and Avery Dennison to regional players and niche specialists. Tapes are segmented by:

Type: Single-sided, double-sided, transfer tapes, masking tapes, etc.

Material: Acrylic, rubber, silicone, paper, film, etc.

Application: Packaging, construction, automotive, healthcare, electronics, etc.

Market Demand: Where's the Stickiness Coming From?

Several factors are driving the demand for adhesive tapes:

Urbanization and Infrastructure Development: Growing infrastructure projects require high-performance tapes for construction and bonding.

Advancements in Healthcare: The healthcare industry utilizes specialized tapes for medical devices, wound care, and diagnostics, increasing demand.

Rise of Electronics: Miniaturization and complexity in electronics require sophisticated tapes for precise bonding and insulation.

Sustainability Concerns: Eco-friendly tapes cater to environmental awareness, creating a new market segment.

Market Growth: A Future Held Together by Innovation

With rising demand and continuous innovation, the Adhesive Tapes Market is poised for significant growth. Industry experts predict:

Expansion into Emerging Markets: Developing economies will witness increased demand for tapes due to infrastructure development and industrialization.

Growing Adoption in Specialty Applications: Tapes will cater to niche applications in areas like renewable energy and electric vehicles.

Focus on Smart Tapes: Tapes integrated with sensors and electronics will offer real-time monitoring and data collection capabilities.

Download PDF Brochure :

The Adhesive Tapes Market transcends its simplistic image, showcasing a dynamic and innovative landscape. With its diverse applications, constant advancements, and promising future, the market is poised to stick around for years to come, playing a vital role in various industries and shaping our everyday lives in ways we might not even realise.

0 notes

Text

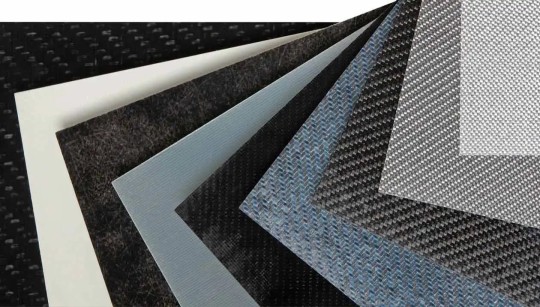

Unveiling the Dynamics of the Thermoplastic Composites Market

The thermoplastic composites market has been gaining significant traction in recent years, driven by advancements in materials science and the growing demand for lightweight and durable materials across various industries. In this article, we'll delve into the key aspects of the thermoplastic composites market, exploring its growth, applications, and notable trends.

Understanding the Thermoplastic Composites Market

The thermoplastic composites market is witnessing robust growth, fueled by the versatility and superior performance characteristics of these materials. Companies across sectors such as aerospace, automotive, and construction are increasingly turning to thermoplastic composites for their unique combination of strength, flexibility, and recyclability.

The global thermoplastic composites market size was valued at USD 22.2 billion in 2020 and is projected to reach USD 31.8 billion by 2025, growing at a cagr 7.5% from 2020 to 2025. The thermoplastic composites industry is growing due to its properties such as recyclability, fast processing, ability to mould and remould, survival at higher temperatures. However, the demand for thermoplastic composites is expected to decline in 2020 due to COVID-19. The removal of restriction on cross country travel and recovery in the end-use industries will stimulate the demand for thermoplastic composites during the forecast period.

Key Drivers of Growth:

Lightweight Solutions: Thermoplastic composites offer a lightweight alternative to traditional materials, contributing to fuel efficiency in transportation and reducing overall structural weight.

Durability and Strength: The inherent strength of thermoplastic composites makes them ideal for applications where resilience and durability are crucial, such as in aircraft components and automotive parts.

Environmental Sustainability: With an increasing emphasis on sustainable practices, the recyclability of thermoplastic composites aligns with the global push for eco-friendly manufacturing processes.

Examples of Thermoplastic Composites in Action

To grasp the versatility of thermoplastic composites, let's explore a few notable examples:

Aerospace Innovations: Thermoplastic composites are extensively used in the aerospace industry for manufacturing aircraft components, including interior panels, structural elements, and even entire fuselages.

Automotive Advancements: Leading automotive manufacturers incorporate thermoplastic composites in the production of lightweight components, enhancing fuel efficiency without compromising on safety and performance.

Renewable Energy Solutions: In the renewable energy sector, thermoplastic composites find applications in wind turbine blades, where their strength and durability contribute to the overall efficiency and longevity of the equipment.

Distinguishing Thermoplastic from Thermoset Composites

A common point of confusion lies in understanding the difference between thermoplastic and thermoset composites. In essence, thermoplastic composites can be melted and reshaped multiple times without undergoing significant degradation, whereas thermoset composites undergo a one-time curing process and cannot be re-molded. The ability to be reshaped gives thermoplastic composites a notable advantage in terms of recyclability and flexibility in manufacturing processes.

Leading Thermoplastic Composite Manufacturers

Several key players dominate the thermoplastic composites market, contributing to its growth and innovation. Some notable manufacturers include:

Hexcel Corporation: Renowned for its advanced composites technology, Hexcel is a global leader in producing thermoplastic composites for aerospace and industrial applications.

Solvay S.A.: Solvay is a major player in the development and production of high-performance thermoplastic composites, catering to diverse industries, including automotive and healthcare.

Teijin Limited: Teijin is at the forefront of thermoplastic composite solutions, offering a wide range of materials suitable for various applications, from lightweight automotive components to advanced structural components in construction

Download PDF Brochure:

0 notes

Text

Silk Industry Unveiled: Navigating Challenges, Embracing Demand, and Charting Future Prospects in a $16.94 Billion Market

Silk, a luxurious and timeless fabric, has woven its way into the fabric of human history. While synonymous with elegance and opulence, the silk industry faces its unique set of challenges and opportunities. In this article, we delve into the main issues affecting the silk industry, the driving forces behind its high demand, the current market size in India, and the promising future that lies ahead.

The global silk market is projected to be valued at USD 16.94 billion by 2021, at a cagr 7.8% from 2016 to 2021. In this study, 2015 has been considered the base year and 2016 to 2021, the forecast period, to estimate the global market of silk. The growing demand in the Asia-Pacific, coupled with the growing demand for textile goods is expected to drive the global silk market during the forecast period.

High demand for silk

Despite challenges, silk maintains a robust demand globally. The allure of silk lies in its unmatched combination of softness, sheen, and breathability. It is a staple in the fashion industry, where designers and consumers alike appreciate its natural luster and luxurious feel. Moreover, silk's unique properties make it a sought-after material for a range of products, including bedding, accessories, and high-end garments.

Market size of silk in India

India, with its rich history of silk production, holds a significant position in the global silk market. As of [latest available data], the Indian silk industry contributes [market size] to the overall global market. The country is renowned for its diverse silk varieties, including Banarasi, Mysore, and Tussar silk. Factors such as cultural significance, craftsmanship, and a growing export market contribute to the thriving silk industry in India.

What is the main problem of the silk industry?

The silk industry encounters several challenges, and one of the primary concerns is the labor-intensive nature of silk production. From silkworm rearing to the delicate process of silk extraction, the industry heavily relies on manual work. Additionally, fluctuations in weather conditions and susceptibility to diseases among silkworms pose a constant threat, impacting silk production yields. Striking a balance between tradition and technological innovation is key to overcoming these challenges.

Download PDF Brochure :

Future of the silk industry

Looking ahead, the silk industry is poised for growth driven by technological advancements, sustainable practices, and evolving consumer preferences. Innovations in sericulture, such as automated silk harvesting and eco-friendly dyeing processes, aim to address long standing challenges. Moreover, the rising trend of eco-conscious consumers seeking sustainable and natural fabrics positions silk as a frontrunner in the future of textiles.

The silk industry navigates challenges with resilience, fueled by the enduring demand for this exceptional fabric. As technology continues to intersect with tradition, the silk industry stands at the cusp of transformative change, ensuring a bright and sustainable future.

0 notes

Text

Revolutionizing Lubrication: Exploring the Vibrant $36.7 Billion Base Oil Market

In this article we will discuss a brief overview of the importance of Base Oil in various industries. Mention its role as a crucial component in lubricants, hydraulic fluids, and other applications. Emphasize the growing demand for Base Oil across automotive, industrial, and manufacturing sectors.

The global base oil market was valued at USD 28.7 billion in 2020 and is projected to reach USD 36.7 billion by 2025, growing at 5.0% cagr during the forecast period. The growing demand for high-grade oils in the automotive industry is driving the base oil industry growth.

Drivers:

Increasing Demand in the Automotive Sector: Discuss how the automotive industry's growth, driven by rising vehicle production and sales, is boosting the demand for Base Oil in lubricants.

Technological Advancements: Highlight recent technological developments in the production of high-quality Base Oil, leading to improved performance and durability in end-use applications.

Expanding Industrial Activities: Explore how the expanding industrial landscape, especially in emerging economies, is contributing to the demand for Base Oil in various manufacturing processes.

Restraints:

Fluctuating Raw Material Prices: Address the challenge posed by fluctuating crude oil prices, impacting the overall production cost of Base Oil and subsequently affecting market stability.

Environmental Concerns: Discuss the environmental challenges associated with the production and disposal of Base Oil, and how the industry is addressing sustainability concerns.

Regulatory Challenges: Explore any regulatory hurdles or compliance issues that might pose constraints on the Base Oil Market's growth.

Opportunities:

Emerging Markets: Highlight potential growth opportunities in emerging markets where the demand for Base Oil is on the rise due to industrialization and increased manufacturing activities.

Innovative Applications: Discuss the exploration of new applications for Base Oil, such as in specialty lubricants or bio-based formulations, opening up avenues for market expansion.

Advancements in Production Processes: Explore how advancements in refining technologies and production processes are creating opportunities for efficiency improvements and cost reduction.

The Asia Pacific region is estimated to be the largest market for base oil in 2019. China, Japan, and India are the significant consumers of base oil in this region. Increasing GDP led by the rising industrial activities in the Asia Pacific region has increased the demand for base oil in this region. Furthermore, the growth of transportation, power generation, mining, and other sectors are responsible for the growth of the base oil market in the Asia Pacific.

Challenges:

Global Economic Uncertainties: Address how uncertainties in the global economic landscape may pose challenges to the Base Oil Market, affecting investment decisions and market dynamics.

Competitive Market Dynamics: Discuss the competitive nature of the market, with players constantly striving to innovate and differentiate their products.

Base Oil Market Players:

Chevron Corporation (US), Exxon Mobil Corporation (US), S-OIL CORPORATION (South Korea), Motiva Enterprises LLC (US), SK Innovation Co., Ltd. (South Korea), Royal Dutch Shell Plc (Netherlands), Neste Oyj (Finland), AVISTA OIL AG (Germany), Nynas AB (Sweden), Repsol S.A. (Spain), Ergon, Inc. (US), Calumet Specialty Products Partners, L.P. (US), H&R Group (Germany), Sinopec Corp. (China), PetroChina Company Limited (China), Saudi Aramco (Saudi Arabia), Abu Dhabi National Oil Company (ADNOC) (UAE), PT Pertamina (Persero) (Indonesia), Phillips 66 (US), Petroliam Nasional Berhad (PETRONAS) (Malaysia), GRUPA LOTOS S.A. (Poland), Sepahan Oil (Iran), GS Caltex Corporation (South Korea), and Hindustan Petroleum Corporation Limited or HPCL (India) are some of the leading players operating in the base oil market. These players have adopted the strategies of agreements, expansions, new product launches, acquisitions, collaborations, contracts, investments, and divestments to enhance their position in the market.

Download PDF Brochure :

This captivating exploration delves into the transformative trends shaping the world of lubrication. Unravelling the secrets of this thriving industry, where revolutions in technology and market demands are steering the course. From automotive advancements to sustainable solutions, discover the vibrant tapestry that defines the future of the Base Oil Market.

0 notes

Text

Carbon Nanotube Market Soars: Unravelling the Growth Trajectory

In the ever-evolving landscape of nanotechnology, the Carbon Nanotube (CNT) market is emerging as a key player, driving significant strides in various industries. As of 2023, the market stood at a noteworthy USD 1.1 billion, and projections indicate an impressive growth trajectory, with expectations to reach a staggering USD 2.3 billion by 2028, boasting a Compound Annual Growth Rate (CAGR) of 14.6%. Notably, the epicentre of this surge is the dynamic Asia Pacific region, which not only holds the largest share but is also anticipated to witness the highest CAGR during the forecasted period. Let's delve into the factors propelling this remarkable growth, with a special focus on the automotive, electronics, and semiconductors end-use industries.

Carbon nanotubes (CNTs) stand at the forefront of nanomaterial innovation, finding diverse carbon nanotubes applications across various industries. In electronics, their remarkable electrical conductivity makes them crucial for developing faster and more efficient electronic devices. The automotive industry benefits from CNTs due to their lightweight yet robust nature, enhancing structural integrity and contributing to improved fuel efficiency. Additionally, in medicine, CNTs play a pivotal role in drug delivery systems, ensuring targeted and precise treatment. These microscopic wonders also find application in materials science, reinforcing composites for stronger and more durable materials. As a versatile material, carbon nanotubes continue to push the boundaries of what's possible in fields ranging from materials engineering to medical technology.

Asia Pacific Leads the Charge:

The Asia Pacific region has emerged as the powerhouse of the Carbon Nanotube market, contributing significantly to the current and anticipated growth. As of now, it holds the lion's share of the market, and projections suggest that it will continue to dominate, registering the highest CAGR during the forecasted period. The robust expansion in this region is fueled by a confluence of factors, with increasing demand from key industries playing a pivotal role.

Driving Forces Behind the Growth:

Automotive Industry's Thirst for Innovation: One of the primary catalysts for the accelerated growth in the Carbon Nanotube market is the surging demand from the automotive sector. As the automotive industry undergoes a paradigm shift towards sustainability and innovation, carbon nanotubes are positioned as key enablers. Their lightweight yet robust nature makes them an ideal choice for enhancing the structural integrity of vehicles, leading to improved fuel efficiency and overall performance.

Electronics & Semiconductors Surge Ahead: In tandem with the automotive industry, the electronics and semiconductors sector is propelling the demand for Carbon Nanotubes. The unique electrical properties of CNTs position them as game-changers in electronics manufacturing. The pursuit of faster, more efficient electronic devices is steering the market towards increased adoption of carbon nanotubes, driving the industry's growth.

Download PDF Brochure :

The Future: A CNT-Powered Landscape:

As we navigate towards 2028, the projection of the Carbon Nanotube market at USD 2.3 billion underscores the transformative impact these nanomaterials are set to have on industries worldwide. With Asia Pacific at the helm, fueled by the automotive, electronics, and semiconductors sectors, the Carbon Nanotube market is on a trajectory that promises not just substantial economic value but also technological breakthroughs that will redefine various industrial landscapes.

The Carbon Nanotube market is not merely a statistical figure but a testament to the adaptability and indispensability of these nanomaterials in driving innovation. As we witness the surge in demand from key sectors in the Asia Pacific region, the journey of Carbon Nanotubes continues to unfold, promising a future where these microscopic wonders play a macroscopic role in shaping our world.

0 notes

Text

Electrical Steel Market Overview: Projected Growth and Key Drivers

Market Growth Projections

The electrical steel market is poised for substantial growth, with an estimated value of USD 40.6 billion in 2023, projected to reach USD 60.7 billion by 2028 at a commendable CAGR of 8.4%. This positive trajectory is underpinned by various factors, including the availability of essential raw materials such as silicon, crucial for electrical steel production, coupled with the global trends of urbanization and a burgeoning urban population. The rise in renewable energy adoption, particularly in wind and solar power, is anticipated to escalate the demand for electrical steel, integral to the manufacturing of generators. Additionally, the utilization of electrical steel in vital components like transformers and motors across diverse industries, including energy, automotive, and manufacturing, will contribute significantly to market expansion. Furthermore, the burgeoning electric vehicle market presents a new frontier for electrical steel production, given its indispensable role in electric motor manufacturing.

Challenges and Considerations

However, amid this optimistic outlook, challenges such as volatility in raw material prices and limited high-quality electrical steel supply pose potential impediments to market growth. Environmental concerns, technological constraints, and safety considerations also present noteworthy challenges. To maintain competitiveness, manufacturers and suppliers must prioritize strategic initiatives such as substantial investments in research and development, continuous improvement of production processes, and the adoption of sustainable practices.

Strategic Initiatives for Competitiveness

In terms of product types, Grain-oriented electrical steel emerged as the second-largest segment in 2022. This specialty steel, distinguished by its highly ordered crystal structure, holds a pivotal role in the production of electrical power transformers, generators, and other magnetic applications. The efficiency of Grain-oriented electrical steel in channeling magnetic flux in a single direction results in reduced energy losses during electrical transformation, translating to heightened efficiency and cost savings. This characteristic is particularly critical in applications involving the generation or transmission of large power quantities over considerable distances, such as in electrical power grids.

Application Focus: Inductors in Electronic Circuits

In the realm of applications, inductors secured the third-largest share in 2022. Inductors, electrical components storing energy in the form of a magnetic field when an electric current flows through them, find widespread use in electronic circuits, especially in power supplies, filters, and oscillators. The demand for electrical steel in inductors, despite their relatively larger size and cost compared to alternative cores, is on the rise due to the increasing prevalence of electronic devices in various industries, including automotive, healthcare, and telecommunications.

Request Sample Pages :

End-Use Industries and Power Sector

End-use industries also play a crucial role in shaping the electrical steel market, with the energy sector claiming the second-largest share in 2022. Electrical steel's pervasive use in power generation, transmission, and distribution, as well as its vital role in renewable energy technologies, positions it as a key component in the power sector. With the anticipated expansion of the power sector, driven by ongoing growth in public infrastructure, the demand for electrical steel is set to soar.

Geographical Dynamics: North America

Geographically, North America dominated the electrical steel market in 2022, with the United States and Canada leading the region's development. Industries such as automotive, energy and power, and consumer appliances are experiencing upward trends, leading to increased construction of industrial facilities and subsequently, heightened demand for electrical steel. Noteworthy players in this region include United States Steel Corporation, Cleveland-Cliffs Inc., and Silicon Steel. The shift towards electric vehicles in the automotive and locomotive industry further propels the demand for electrical steel, offering substantial opportunities for the North American market.

Download PDF Brochure:

Major Players and Market Strategies

Major players in the Electrical steel Market, such as ArcelorMittal, POSCO, Voestalpine AG, China Baowu Steel Group Corporation, Nippon Steel Corporation, United States Steel Corporation, Steel Authority of India, TATA Steel Limited, Thyssenkrupp AG, and JFE Steel Corporation, among others, are adopting strategic measures such as expansions, acquisitions, joint ventures, and new product developments to fortify their positions in the market. These initiatives underscore the industry's commitment to innovation and growth in a dynamic market landscape.

0 notes

Text

Calcium Carbonate Market Forecast, Industry Size and future outlook

Calcium carbonate, a chemical compound represented by the formula CaCO3, stands as a cornerstone in various industries. With a market valuation of USD 21.2 billion in 2019, expected to reach USD 28.3 billion by 2024, and a projected CAGR of 6.0% from 2019 to 2024, the calcium carbonate industry is on a trajectory of substantial growth. The global calcium calcium market, totaling 125,282.6 kilotons in 2018, is anticipated to register a CAGR of 4.4% between 2019 and 2024, showcasing its pervasive influence.

Forecast for the Calcium Carbonate Industry:

The forecast for the calcium carbonate industry is indeed promising. the market is set to witness robust growth, driven by factors such as the expanding construction industry, heightened environmental awareness, and widespread use in paper and pulp production. With a projected CAGR of 6.0%, the industry is positioned to meet the increasing demand for calcium carbonate across various sectors.

The Future Outlook for Calcium Carbonate:

Looking to the future, calcium carbonate is not merely a mineral; it is a force driving technological advancements. Its forecasted growth is buoyed by innovations in extraction and manufacturing processes. The eco-friendly attributes of calcium carbonate make it a sustainable choice, further solidifying its position as a key player in industries ranging from construction to healthcare.

How Big is the Calcium Carbonate Market?

The calcium carbonate market, with a valuation of USD 21.2 billion in 2019, reflects its substantial size and diverse applications. As the demand escalates from industries such as construction, healthcare, and plastics, the market is poised for significant expansion. This versatile mineral, extracted using techniques like mining and quarrying, is a cost-effective solution that addresses the needs of multiple sectors.

Importance in Manufacturing Industries:

Calcium carbonate's importance in manufacturing is underscored by its presence in various industries. In construction, it contributes to the strength of structures through its role in cement and concrete production. The paper and pulp industry relies on calcium carbonate as a crucial filler and coating material, enhancing paper quality.

In plastic manufacturing, it serves as a reinforcing agent, improving the mechanical properties of plastic products. Found in pharmaceuticals and utilized as a calcium supplement, calcium carbonate plays a vital role in the healthcare sector.

Download PDF Brochure :

The calcium carbonate market is positioned for remarkable growth. As it continues to evolve with technological advancements, the industry is not just a market force; it is a crucial element shaping the landscape of diverse manufacturing sectors globally.

0 notes

Text

Electronic Wet Chemicals Market in Semiconductor Innovation, Trends and Industry Size

The Electronic Wet Chemicals Market has witnessed substantial growth, driven by key factors that have spurred demand and adoption across various industries. The proliferation of electronic devices in consumer electronics, automotive, healthcare, and telecommunications has significantly contributed to this expansion. As these industries progress, there is a parallel need for sophisticated electronic components manufactured with precise wet chemical processes. Technological advancements, particularly in semiconductor and microelectronics manufacturing, have resulted in higher complexity in device architectures and materials, necessitating specialized wet chemicals for intricate processes.

Semiconductor Dominance: Precision in Manufacturing

The dominance of the semiconductor industry as the primary application for electronic wet chemicals is rooted in the indispensable role these substances play in semiconductor manufacturing intricacies. In this sector, where the creation of integrated circuits demands precise and complex processes, wet chemicals emerge as fundamental tools. These chemicals facilitate critical procedures such as etching, cleaning, and material deposition on silicon wafers with unparalleled accuracy, enabling the formation of intricate circuit patterns crucial to semiconductor functionality. Furthermore, the semiconductor realm demands utmost precision and uniformity, achieved through wet chemical processes that ensure consistent treatment across vast manufacturing scales. With a diverse range of semiconductor materials requiring tailored chemical solutions, these substances offer selectivity, allowing precise interactions while safeguarding other materials—a vital aspect in semiconductor patterning and layering. Surface preparation, a pivotal stage in semiconductor production to prevent defects, relies significantly on wet chemicals to meticulously clean and prepare surfaces for subsequent processing steps. Supported by an industry possessing extensive expertise and specialized infrastructure for handling these chemicals, the semiconductor sector's continuous quest for technological advancements further solidifies the critical reliance on electronic wet chemicals in driving innovation and progress within semiconductor manufacturing.

Acetic Acid: Cornerstone of Electronic Wet Chemicals

Acetic acid stands out as a leading type in the electronic wet chemicals market due to its multifaceted utility and compatibility across various critical processes within electronics manufacturing. Its versatility plays a pivotal role, serving diverse functions, including cleaning, etching, and surface preparation, owing to its potent solvent properties adept at efficiently removing contaminants. Moreover, its cost-effectiveness compared to specialized alternatives renders it an economically attractive choice, contributing significantly to its widespread adoption in the industry. In semiconductor manufacturing, acetic acid finds particular favor for its compatibility with crucial processes involved in etching and cleaning semiconductor materials, making it indispensable in the production of integrated circuits and semiconductor devices. The controlled chemical properties of acetic acid, such as its adjustability in acidity and concentration, allow for precise and targeted application throughout various stages of electronic component fabrication. Its relatively safer handling compared to stronger acids further bolsters its preference, balancing effectiveness with safety considerations. With an established history in electronic manufacturing, regulatory compliance, and proven effectiveness, acetic acid remains a stalwart choice, consistently maintaining its dominance as a preferred and widely used type within the electronic wet chemicals market.

Liquid Form Supremacy: Adaptable Solutions for Electronics Manufacturing

The pre-eminence of the liquid form within the electronic wet chemicals market arises from its multifaceted advantages that cater directly to the intricate needs of electronics manufacturing. Liquids offer unparalleled ease of handling and application, boasting fluidity that facilitates precise dispensing, controlled pumping, and meticulous regulation essential for delicate manufacturing processes. Their versatility shines through in their adaptability across a spectrum of applications, from cleaning and etching to deposition and surface treatment, providing solutions to diverse manufacturing needs within the electronics industry. Furthermore, liquids afford a level of precision and uniformity crucial in electronics, ensuring meticulous control over concentration, flow rates, and temperature, thereby safeguarding against variations that could compromise product quality. Compatibility with existing infrastructure is a significant boon, as most electronics manufacturing facilities are tailored to handle liquid chemicals, mitigating the need for extensive modifications. Their efficient heat transfer properties aid in temperature control, safeguarding sensitive electronic components from overheating. Moreover, their safer containment compared to gases and their established industry preference and standardization solidify their dominance as the largest segment in the electronic wet chemicals market, offering a combination of effectiveness, reliability, and adaptability sought after in electronics manufacturing.

Keyplayer of the Electronic Wet Chemicals Market

Key players in this market include Avantor Inc. (US), BASF SE (Germany), Cabot Microelectronics (US), Kanto Chemical Co. Inc. (Japan), Honeywell International, Inc. (US), Eastman Chemical Company (US), Linde Plc (Ireland), Solvay (Belgium), Fujifilm Corporation (Japan), Technic Inc. (US), and more

Request Sample Pages for a detailed insight:

Asia-Pacific: The Epicenter of Electronic Wet Chemicals Market

The Asia-Pacific region stands as the largest market for electronic wet chemicals, primarily driven by several interlinked factors that collectively fuel its dominance in this sector. A pivotal contributor to this status is the region's exponential growth as a global electronics manufacturing hub. Countries such as China, South Korea, Taiwan, and Japan have emerged as major centers for semiconductor fabrication and electronics assembly, consequently propelling substantial demand for electronic wet chemicals across various stages of manufacturing processes. Moreover, the Asia-Pacific region boasts an expanding consumer electronics market, fueled by a burgeoning middle class and increasing disposable income. This surge in demand for devices like smartphones, tablets, televisions, and other electronic gadgets directly correlates to the heightened need for wet chemicals in their production. Additionally, there has been a notable shift of semiconductor production to Asia-Pacific nations, further solidifying the region's pivotal role in driving the electronic wet chemicals market. This strategic relocation aligns with the region's expertise, infrastructural development, and capacity to cater to the soaring demand for semiconductors and electronic components. Collectively, these factors cement the Asia-Pacific region's position as the largest and most influential market for electronic wet chemicals, reflecting its pivotal role in the global electronics manufacturing landscape.

0 notes

Text

Epoxy Resin Market Growth Analysis Overview, Segmentation, Trends Report

The global Epoxy Resin Industry is experiencing a surge of growth, propelled by a multitude of factors. With a current market value of USD 12.9 billion, analysts predict it to reach a staggering USD 17.0 billion by 2028, boasting a robust 5.5% CAGR throughout the forecast period. This burgeoning market presents a plethora of opportunities for players across the value chain, but also demands an understanding of the key drivers, restraints, and challenges shaping its landscape.

Technological Advancements Fueling Growth:

One of the primary drivers of the Epoxy Resin Market is the constant technological innovation in resin formulations. Researchers are developing resins with enhanced properties, like superior mechanical strength, improved chemical resistance, and enhanced thermal stability. These advancements make epoxy resins the perfect fit for demanding applications in industries such as aerospace, automotive, and electronics. Additionally, the emergence of faster and more efficient curing technologies has streamlined production processes and increased productivity, further bolstering the appeal of epoxy resins in time-sensitive sectors.

Emerging Economies: Untapped Potential:

Emerging economies across Asia-Pacific, Latin America, and Africa are experiencing rapid industrialization, urbanization, and infrastructure development. This presents a fertile ground for the Epoxy Resin Industry, as industries like construction, automotive, electronics, and consumer goods flourish in these regions. The burgeoning middle class and rising disposable incomes further fuel the demand for epoxy resin-based products, creating a lucrative market for industry players.

Addressing the Challenges:

Despite the exciting opportunities, the Epoxy Resin Industry faces its share of challenges. Volatility in raw material prices, particularly for bisphenol A (BPA) and epichlorohydrin, can significantly impact production costs and profitability for manufacturers. Additionally, the availability of substitute materials like polyurethane and polyester resins poses a competitive threat, as they offer advantages like lower cost or better flexibility in some applications. Manufacturers must address these challenges by differentiating their products, focusing on unique strengths, and continuously innovating to maintain their competitive edge.

Navigating the Landscape:

To capitalize on the immense potential of the Epoxy Resin Industry, a comprehensive understanding of its segmentation, market share, and growth trends is crucial. Industry reports and research provide valuable insights into these aspects, enabling informed decision-making for manufacturers, distributors, and investors alike. This knowledge, coupled with an eye on current industry trends and developments, will allow stakeholders to strategically position themselves for success in this dynamic market.

Download PDF Market :

The Future of Epoxy Resins:

The Epoxy Resin Industry stands poised for sustained growth, driven by rising demand, technological advancements, and favorable economic conditions in emerging markets. By addressing the challenges and capitalizing on the opportunities, players within this industry can secure their place in a thriving and lucrative market.

0 notes

Text

Building the Future: Why 3D Printing is Poised to Revolutionize Construction

Imagine a world where houses are printed, not built. Where intricate concrete structures rise from the ground in a matter of hours, not weeks. Where sustainable materials seamlessly integrate with cutting-edge design, minimizing waste and maximizing efficiency. This isn't science fiction – it's the burgeoning reality of 3D printing in construction.

3D printing construction market is a goldmine waiting to be unearthed. It's projected to reach a staggering $ 1,575 million by 2024, growing at a cagr 245.9%, driven by a confluence of factors that are reshaping the very fabric of the construction industry.

Why 3D Printing is the Key to Sustainable Construction

Disruptive Innovation: 3D printing offers a paradigm shift in construction, enabling faster, cheaper, and more sustainable building methods. This has the potential to disrupt traditional players and create entirely new business models.

Cost Optimization: Imagine reducing material waste by up to 70% and slashing labor costs by automating repetitive tasks. 3D printing unlocks these possibilities, leading to significant cost savings and enhanced profitability.

Unlocking New Markets: From remote locations to disaster-stricken areas, 3D printing makes construction accessible in previously unthinkable scenarios. This opens doors to untapped markets and expands your reach exponentially. The use of 3D printing materials is increasing due to the increasing demand for custom-made materials for a specific application, wherein manufacturers develop a niche and superior materials by modifying their properties as per the requirements.

Sustainability Champion: 3D printing utilizes recycled materials and minimizes energy consumption, aligning perfectly with environmental goals and ESG initiatives. This resonates with environmentally conscious consumers and investors alike.

Beyond the Hype: Challenges and Opportunities

While the potential is undeniable, challenges exist. Scalability, regulatory hurdles, and the need for skilled personnel are areas that require immediate attention. However, with the right approach, these obstacles can be overcome:

Invest in Research and Development: Continuously refine printing technologies, explore new materials, and develop efficient printing processes to overcome scalability limitations.

Forge Strategic Partnerships: Collaborate with government agencies, research institutions, and construction companies to create a supportive ecosystem for 3D printing adoption.

Upskill Your Workforce: Train your team on 3D printing technology and design software to ensure smooth implementation and maximize efficiency.

3D printing construction market presents a strategic opportunity to:

Diversify your portfolio: Invest in 3D printing technology companies, develop your own printing capabilities, or partner with established players in the space.

Optimize your supply chain: Utilize additive manufacturing to streamline production, reduce inventory costs, and create custom building components on-site.Traditional construction relies on a linear supply chain, with materials flowing from quarries to factories to warehouses and finally to the site. This creates bottlenecks, delays, and excess inventory. 3D printing flips the script, transforming construction into an additive process.

Lead the sustainability charge: Position your company as a leader in sustainable construction by embracing 3D printing technology and its eco-friendly benefits.

Download PDF Brochure :

By understanding the potential and challenges of 3D printing in construction, business owners can make informed decisions and capitalize on this transformative technology. The future of construction is being written, and it's time to start printing the next chapter.

0 notes

Text

Unveiling the Impact and Potential of the Molded Pulp Packaging Market

In the dynamic landscape of packaging solutions, one sustainable hero is quietly stealing the show – Molded Pulp Packaging. This eco-friendly warrior has captured the hearts (and minds) of industries seeking both effective and environmentally responsible packaging.

The Size and Growth:

The global molded pulp packaging market was valued at a staggering USD 4.6 billion in 2022 and is projected to reach USD 5.7 billion by 2027, growing at a healthy 4.3% CAGR. This impressive growth trajectory underscores the rising tide of environmental awareness and the increasing demand for sustainable alternatives.

The Niche of Molded Fiber:

Within the broader realm of pulp packaging, the molded fiber market stands out as a shining star. Currently valued at USD 3.5 billion in 2019, projected to reach USD 4.4 billion by 2024, molded fiber stands apart for its versatility and eco-credentials. This segment has carved its niche across diverse industries, from food and beverages to electronics and automotive, indicating a robust and promising future.

The Sustainable Allure:

Derived from recycled materials like newspapers and cardboard, molded pulp offers a guilt-free alternative to traditional packaging. Its eco-friendly composition, coupled with the ability to be molded into various shapes and sizes, makes it a knight in shining armor for all your protective packaging needs. From safeguarding delicate electronics to preserving the freshness of food and beverages, molded pulp is the versatile and environmentally responsible hero the packaging world needs.

Affordability Meets Sustainability:

One of the most compelling aspects of molded pulp packaging is its cost-effectiveness. Utilizing recycled materials and a relatively simple manufacturing process, molded pulp strikes a balance between affordability and sustainability. This makes it an attractive option for businesses looking to adopt green practices without breaking the bank, proving that sustainability doesn't have to come at a premium.

The Dominant Consumer:

While packaging needs vary across industries, the food and beverage sector takes the crown as the largest consumer. As consumer preferences increasingly lean towards sustainable choices, the demand for eco-friendly packaging solutions like molded pulp continues to rise.

Global Pulp Supplier Leadership:

Molded pulp packaging market comprises major players such as players Huhtamaki Oyj (Finland), Bordrene Hartmann A/S (Denmark), Genpack LLC(US), James Cropper 3D products Ltd., PrimWare-by Prim Link Solutions (US), Sonoco Products Co. (US) and UFP Technologies (US), Sabert Corporation (US), Fabri-Kal(US), Pro-Pac Packaging(Australia), and others are covered in the molded fiber pulp packaging market. Expansions, acquisitions, joint ventures, and new product developments are some of the major strategies adopted by these key players to enhance their positions in the Molded pulp packaging Market.

Download PDF Brochure :

The molded pulp packaging market is not just a trend, it's a revolution. Its eco-friendly attributes, combined with cost-effectiveness, position it as a true frontrunner in the packaging solutions arena. As industries embrace the need for environmentally responsible practices, molded pulp is poised to play an increasingly significant role in shaping the future of packaging, one sustainable package at a time.

0 notes

Text

The Rise of Antimicrobial Plastics Market: Trends, Technologies, and Applications

In recent years, the Antimicrobial Plastics market has experienced a significant surge, driven by evolving consumer preferences and advancements in technology. This blog post will delve into the key trends, cutting-edge technologies, and diverse applications that have propelled the growth of this market. From healthcare to packaging, antimicrobial plastics are making their mark, addressing concerns related to hygiene and safety. Let's explore the dynamic landscape of the Antimicrobial Plastics market.

The market size was USD 41.7 billion in 2022 and is projected to reach USD 64.8 billion by 2028, at a CAGR of 7.7%, between 2023 and 2028. Antimicrobial plastics are a pivotal innovation in the materials industry, offering enhanced protection against harmful microorganisms. The incorporation of antimicrobial agents during the manufacturing process makes these plastics effective in inhibiting the growth of bacteria, viruses, and fungi on surfaces.

Key Trends Shaping the Antimicrobial Plastics Market

Sustainable Solutions: As sustainability gains prominence, the market has witnessed a shift towards eco-friendly antimicrobial plastics. Manufacturers are increasingly focusing on developing biodegradable options to meet the growing demand for environmentally responsible products.

Integration in Healthcare: The healthcare sector has emerged as a significant adopter of antimicrobial plastics. With the increasing emphasis on infection control, medical equipment, and surfaces made from these materials contribute to creating safer environments in healthcare facilities.

Advancements in Nanotechnology: Nanotechnology plays a crucial role in enhancing the antimicrobial properties of plastics. The integration of nanoparticles with antimicrobial capabilities has opened up new possibilities for creating highly effective and long-lasting antimicrobial plastic products.

Technologies Driving Antimicrobial Plastic Innovations

Silver Nanoparticles Technology: Silver nanoparticles have proven to be a game-changer in the development of antimicrobial plastics. Their ability to disrupt microbial cell membranes has led to the creation of durable and efficient antimicrobial plastic products.

Polymer Coating Techniques: Polymer coating technologies have evolved to provide a protective layer on plastic surfaces, preventing the adhesion and growth of microorganisms. This innovative approach ensures long-lasting antimicrobial effects.

Download PDF Brochure:

Applications Across Industries

Packaging Industry: Antimicrobial plastics have found widespread application in the packaging industry. From food packaging to medical product packaging, these materials contribute to extending the shelf life of products and ensuring hygiene.

Consumer Goods: The incorporation of antimicrobial plastics in the production of consumer goods, such as household items and electronics, addresses the need for maintaining a clean and germ-free environment.

The Antimicrobial Plastics market is on an upward trajectory, driven by a confluence of trends, technological advancements, and diverse applications. As industries continue to prioritize hygiene and safety, the demand for antimicrobial plastics is poised to grow. This blog post has provided a comprehensive overview of the key aspects shaping the rise of the Antimicrobial Plastics market, from sustainable solutions to cutting-edge technologies. Stay tuned as this dynamic market continues to evolve and innovate.

0 notes

Text

Unveiling the Future: Activated Carbon Fiber (ACF) Revolutionizing Electric Steel Manufacturing

In the dynamic landscape of steel manufacturing, a silent revolution is underway. Activated Carbon Fiber (ACF) is emerging as a game-changer, ushering in a new era of efficiency and sustainability in the electric steel sector. For industry professionals – executives, managers, and analysts – navigating this transformative wave is essential. Let's delve into the world of ACF, exploring its growth trajectory, key players, and the pulse of emerging trends that are reshaping the steel industry.

Growth Potential of ACF in Electric Steel:

The Activated Carbon Fiber (ACF) market is experiencing unprecedented growth, fueled by the demand for superior air and water purification processes across industries. In the realm of steel manufacturing, ACF is becoming indispensable for enhancing the quality of steel production. The market's projected compound annual growth rate (CAGR) indicates a robust trajectory, promising exciting prospects for the foreseeable future.

Key Players Steering the ACF Revolution:

Kuraray Co., Ltd.: A pioneering force in the ACF market, Kuraray leads with a diverse range of activated carbon products, catering to various industrial applications, including the steel sector.

Toyobo Co., Ltd.: Renowned for its advanced ACF solutions used in gas masks, water purification, and industrial applications, Toyobo is a key player shaping the landscape.

Awa Paper & Techno Co., Ltd.: This Japanese firm stands out for its ACF products, particularly in environmental applications such as air and water purification.

Sutong Carbon Fiber Co., Ltd.: Positioned prominently in China, Sutong Carbon Fiber contributes significantly to the ACF market, particularly in the Asia-Pacific region.

Unveiling Emerging Trends:

Innovations in Material Science: Ongoing research is yielding advanced ACF with enhanced adsorption capacities, making it a more effective ally in steel manufacturing processes.

Customization for Specific Applications: A trend towards tailoring ACF products to suit the unique requirements of the steel industry is gaining momentum, ensuring optimal performance in gas and liquid purification.

Sustainable Solutions: With environmental concerns taking center stage, ACF manufacturers are aligning their solutions with the steel industry's push towards greener practices.

The spotlight on electric steel production is intensifying in key regions:

Asia-Pacific: Led by China and other Asian nations, the electric steel sector in this region is flourishing, driven by rapid industrialization and a commitment to sustainable steel manufacturing practices.

Europe: In response to stringent environmental regulations, the European steel industry is embracing electric steel production methods, shaping a sustainable future.

Download PDF Brochure :

Challenges and Opportunities on the Horizon:

Challenges:

High Production Costs: The initial investment in ACF technology can pose challenges, particularly for smaller steel manufacturers.

Market Fragmentation: The ACF market's numerous players can lead to fragmentation and potential difficulties in standardization.

Opportunities:

Regulatory Support: Favorable regulatory environments supporting sustainable practices present opportunities for ACF adoption in the steel industry.

Rising Awareness: Growing awareness of the benefits of ACF in enhancing steel production quality and reducing environmental impact creates avenues for market growth.

0 notes

Text

Suiting Up for Safer Tomorrows: Exploring the Booming $12.3 Billion Protective Clothing Market

The world of work is evolving, and so is the need for protecting those on the frontlines. Enter the protective clothing market, a rapidly growing sector safeguarding workers across diverse industries from head to toe. But just how big is this market, and what forces are driving its ascent? Buckle up, as we delve into the world of protective apparel, exploring its size, key drivers, segmentation, challenges, opportunities, and future trends.

Market Size and Growth: A Booming Landscape

The Protective Clothing Market is projected to reach USD 12.3 billion by 2025, at a CAGR of 6.9% from USD 8.8 billion in Upcoming years.

Market Drivers: A Cocktail of Safety, Regulation, and Innovation

Heightened awareness of worker safety: As the importance of employee well-being takes center stage, businesses are increasingly investing in high-quality protective gear.

Stringent regulations: Governments are enacting stricter safety standards, mandating the use of protective clothing in specific industries.

Emerging trends and niche applications: From the rise of biohazard suits in the healthcare sector to flame-retardant apparel in the energy industry, specific needs are driving innovation in protective clothing design.

Market Segments: A Diverse Spectrum of Needs

The protective clothing market is a tapestry woven from various segments:

By Type: Chemical-resistant suits, flame-retardant gear, high-visibility clothing, and cut-resistant garments cater to diverse hazards.

By Application: Healthcare, construction, manufacturing, chemical processing, and firefighting are just a few examples of industries with unique protective clothing needs.

By Region: Asia-Pacific currently dominates the market, followed by Europe and North America, with regional regulations and industrial landscapes influencing demand.

Key Players: Weaving the Fabric of Safety

The key market players profiled in the report include as 3M Company (US), E.I. du Pont de Nemours and Company (US), Ansell Limited (US), Kimberly Clark Corp (US), Teijin Limited (Japan), Sioen Industries (Belgium), and Lakeland Industries, Inc. (US).

Challenges and Opportunities: Navigating the Terrain

Despite its promising outlook, the protective clothing market faces hurdles:

Cost concerns: High-quality gear can be expensive, posing challenges for smaller businesses and developing countries.

Sustainability concerns: Disposable protective clothing generates significant waste, prompting the need for eco-friendly alternatives.

Technological limitations: Developing materials that offer superior protection while remaining comfortable and breathable is an ongoing challenge.

However, these challenges also present opportunities:

Technological advancements: Research into self-healing fabrics, nanomaterials, and smart clothing opens doors for increased protection and functionality.

Growing demand for customization: As workplaces become more diverse, the need for tailored protective solutions tailored to specific needs presents a lucrative market.

Focus on sustainability: Developing reusable and biodegradable protective clothing can attract environmentally conscious consumers and businesses.

Future Trends: Gearing Up for Tomorrow

The future of protective clothing is brimming with possibilities:

Integration of smart technologies: Sensors embedded in garments could monitor vital signs, environmental hazards, and even fatigue levels, enhancing worker safety and well-being.

Personalization and customization: 3D printing and advanced tailoring techniques could lead to perfectly fitting protective gear adapted to individual needs and preferences.

Focus on sustainability and circularity: Biodegradable materials, closed-loop recycling systems, and upcycling initiatives will be crucial in minimizing the environmental footprint of protective clothing.

Download PDF Reports :

Protective Gear for a Safer Tomorrow

The protective clothing market is not just about safeguarding workers; it's about shaping a future where safety, innovation, and sustainability go hand in hand. As technology advances and regulations evolve, we can expect even more sophisticated and specialized gear to emerge, protecting the workforce and paving the way for a safer, healthier, and more productive world.

0 notes

Text

Cultivating Growth: Navigating the Booming Agricultural Films Market

The global agricultural landscape is facing unprecedented challenges. A burgeoning population, shrinking arable land, and increasingly erratic weather patterns are putting immense pressure on food security. Fortunately, amidst these obstacles, innovation is flourishing, and one technology is quietly revolutionizing the field: agricultural films.

These versatile plastic sheets, used in greenhouses, mulching, and silage storage, are no longer simply a passive barrier. They're evolving into sophisticated tools, enabling farmers to maximize yields, protect crops, and optimize resource usage. Understanding the dynamic agricultural films market is crucial for anyone involved in modern agriculture, from farmers to investors.

A Market Sowing Seeds of Success:

The global agricultural films market is estimated to reach a staggering US$18.2 billion by 2028, growing at a compound annual growth rate (CAGR) of 6.9%.

This explosive growth is fueled by:

Rising food demand: With the world population projected to reach 9.7 billion by 2050, agricultural productivity needs to significantly increase.

Controlled environment agriculture: Greenhouses and vertical farms utilizing agricultural films offer greater crop control and resilience against climate fluctuations.

Water conservation: Mulching films reduce water evaporation, a critical advantage in drought-prone regions.

Sustainable agriculture: Biodegradable and recycled film options are gaining traction, addressing environmental concerns.

Delving into the Diverse Landscape:

The agricultural films market is a tapestry woven from various types of films, each serving a distinct purpose:

Greenhouse films: These create controlled environments, regulating temperature, humidity, and light for optimal crop growth.

Mulching films: These suppress weeds, retain moisture, and regulate soil temperature, boosting crop yields and minimizing water usage.

Silage films: These preserve the nutritional value of fodder for livestock, minimizing waste and maximizing animal feed efficiency.

Emerging Trends for Future Harvests:

The agricultural films market is constantly evolving, embracing cutting-edge technologies to enhance efficiency and sustainability. Some exciting trends include:

Smart films: Embedded sensors monitor environmental conditions and adjust film properties in real-time, optimizing crop growth.

Biodegradable and compostable films: Addressing plastic waste concerns, these films decompose naturally, returning nutrients to the soil.

Nanotechnology: Incorporating nanoparticles into films enhances their strength, durability, and pest resistance.

Download PDF Brochure :

Taking Root in the Market:

Whether you're a farmer seeking to optimize your operations or an investor interested in a burgeoning industry, understanding the agricultural films market presents exciting opportunities. By staying informed about the latest trends and technologies, you can leverage the power of these versatile films to cultivate a more secure and sustainable agricultural future.

0 notes

Text

Unveiling the Dynamics of the Metal Nanoparticles Market

In the realm of nanotechnology, metal nanoparticles have emerged as integral components with applications spanning various industries. From healthcare to electronics, these microscopic wonders are shaping the future of technology. In this article, we'll explore the dynamics of the metal nanoparticles market, answering pertinent questions and shedding light on the trends, challenges, and key players in this dynamic landscape.

The global Metal Nanoparticles Market was valued at USD 2.4 billion in 2021 and is projected to reach USD 4.2 billion by 2026, growing at a cagr 11.5% from 2021 to 2026. Growing application areas of metal nanoparticles coupled with increasing demand for gold nanoparticles in the pharmaceutical & healthcare industry are major factors expected to drive the growth of the metal nanoparticles market globally. Also, the rapid growth of the healthcare sector is one of the other factors expected to drive the growth of the global market for metal nanoparticles.

The Most Used Metal Nanoparticles

1. Silver Nanoparticles:

Renowned for their exceptional antimicrobial properties, silver nanoparticles have found a significant foothold in healthcare, textiles, and electronics.

2. Gold Nanoparticles:

Valued for their stability and compatibility, gold nanoparticles play a pivotal role in drug delivery, imaging, and catalysis applications.

3. Iron Oxide Nanoparticles:

With magnetic properties, iron oxide nanoparticles are indispensable in biomedical applications, including imaging and targeted drug delivery.

Limitations of Metallic Nanoparticles

While the advantages of metal nanoparticles are vast, they are not immune to challenges:

1. Toxicity Concerns:

Certain metal nanoparticles may pose toxicity risks, prompting careful consideration of their impact on human health and the environment.

2. Stability Issues:

The stability of metal nanoparticles can be compromised under specific conditions, affecting their performance and versatility.

3. Cost Considerations:

The production of certain metal nanoparticles, particularly those involving precious metals, can be cost-intensive, influencing their widespread adoption.

Challenges and Trends in the Metal Nanoparticles Market

Trends

1. Integration in Healthcare:

Metal nanoparticles are increasingly integrated into medical applications, promising groundbreaking advancements in diagnostics, imaging, and drug delivery within the healthcare sector.

2. Sustainable Synthesis:

A growing trend in the market is the exploration of eco-friendly and sustainable methods for synthesizing metal nanoparticles, addressing environmental concerns.

Challenges

1. Regulatory Hurdles:

Navigating regulatory frameworks remains a significant challenge for the widespread adoption of metal nanoparticles in various industries.

2. Safety Concerns:

Addressing concerns related to the safety and potential environmental impact of metal nanoparticles is crucial for their sustained usage.

Download PDF Brochure :

Opportunity: Metal nanoparticles as emerging green catalysts

Green nanotechnology is defined as the technology applied for building clean technology by which one can reduce the potential risks of environment and also improve human health conditions. It is linked with the implementation of products of nanotechnology and its process of manufacturing. Green nanotechnology synthesizes new nanoproducts with improved properties in such a way that they can substitute some of the existing low-quality products. The main motive of developing new nanoproducts is to enhance sustainability and also to make them more environment friendly. In particular, nanoscale materials (e.g., metal nanoparticles) can be defined as those having characteristic length scale lying within the nanometric range, that is, in the range between one and several hundreds of nanometers. Within this length scale, the properties of matter are sufficiently different from individual atoms/molecules or from bulk materials.

Market Players

Major players operating in the global metal nanoparticles market include American Elements (US), Nanoshel LLC (US), Nanostructured & Amorphous Materials (US), EPRUI Nanoparticles & Microspheres (China), US Research Nanomaterials (US), Tanaka Holdings (Japan), Meliorum Technology (US), Nanocomposix (US), BBI Group (UK), Sigma-Aldrich (US), and Nanocs (US) among many others.

The metal nanoparticles market is marked by innovation, challenges, and a constant quest for improvement. As technology advances and our understanding deepens, these microscopic wonders continue to shape the future across industries, promising both opportunities and responsibilities. Stay tuned for more updates on this dynamic and ever-expanding field!

1 note

·

View note