Text

Medical Software Design: Enhancing Healthcare Delivery Through Technology

In the ever-evolving landscape of healthcare, the role of technology has become increasingly prominent, with medical software playing a pivotal role in enhancing patient care, streamlining workflows, and improving overall efficiency. In this article, we'll delve into the intricacies of medical software design, exploring the principles, challenges, and best practices associated with creating innovative solutions for the healthcare industry.

Introduction

Medical software encompasses a diverse range of applications, including electronic health records (EHRs), telemedicine platforms, diagnostic tools, and medical imaging software. Designed to meet the unique needs and regulatory requirements of the healthcare sector, medical software plays a crucial role in facilitating clinical decision-making, improving patient outcomes, and optimizing healthcare delivery.

Understanding Medical Software Design

Medical software design involves a multidisciplinary approach that integrates principles of user interface (UI) design, software engineering, data security, and regulatory compliance. It encompasses the entire software development lifecycle, from requirements gathering and prototyping to testing, deployment, and maintenance. Key considerations in medical software design include usability, interoperability, data integrity, and patient privacy.

Key Principles of Medical Software Design

User-Centered Design

Prioritizing the needs and preferences of end-users, including healthcare professionals and patients, is paramount in medical software design. User-centered design principles emphasize iterative feedback, usability testing, and continuous improvement to ensure that software solutions are intuitive, efficient, and user-friendly.

Interoperability

Interoperability refers to the seamless exchange of data between different healthcare systems and devices. In medical software design, interoperability standards such as HL7 (Health Level 7) and FHIR (Fast Healthcare Interoperability Resources) are essential for facilitating data sharing, care coordination, and interoperability across disparate systems.

Data Security and Privacy

Given the sensitive nature of health information, ensuring robust data security and privacy protections is critical in medical software design. Compliance with regulations such as HIPAA (Health Insurance Portability and Accountability Act) and GDPR (General Data Protection Regulation) is essential to safeguard patient data against unauthorized access, breaches, and misuse.

Scalability and Flexibility

Medical software solutions must be scalable and adaptable to accommodate evolving healthcare needs, technological advancements, and regulatory changes. Designing modular, flexible architectures enables seamless integration of new features, scalability to accommodate growing user bases, and customization to meet specific organizational requirements.

Clinical Relevance and Efficacy

Medical software should be designed with a deep understanding of clinical workflows, protocols, and best practices. Incorporating evidence-based guidelines, clinical decision support systems, and intuitive workflows enhances the clinical relevance and efficacy of software solutions, ultimately improving patient outcomes and safety.

Challenges in Medical Software Design

Regulatory Compliance

Navigating the complex landscape of healthcare regulations and standards, including FDA (Food and Drug Administration) regulations for medical devices and HIPAA requirements for data privacy, poses significant challenges in medical software design. Ensuring compliance with regulatory requirements while maintaining agility and innovation is a delicate balance for software developers.

Interoperability

Achieving seamless interoperability between disparate healthcare systems, legacy software platforms, and emerging technologies remains a significant challenge in medical software design. Inconsistent standards, proprietary data formats, and organizational silos hinder data exchange and interoperability, leading to fragmented care delivery and inefficiencies.

Usability and User Experience

Designing intuitive, user-friendly interfaces that meet the diverse needs of healthcare professionals and patients is a persistent challenge in medical software design. Balancing complexity with simplicity, providing context-sensitive guidance, and minimizing cognitive load are essential for enhancing usability and user experience.

Data Security and Privacy

Safeguarding patient data against security breaches, unauthorized access, and cyber threats is a constant concern in medical software design. Implementing robust encryption, access controls, audit trails, and security protocols is essential to protect sensitive health information and maintain patient trust.

Best Practices in Medical Software Design

Collaborative Approach

Engaging stakeholders, including healthcare providers, IT professionals, patients, and regulatory experts, in the design process fosters collaboration, ensures alignment with user needs, and enhances the relevance and effectiveness of medical software solutions.

Iterative Development

Adopting an iterative development approach, such as agile or iterative prototyping, allows for rapid feedback cycles, flexibility to adapt to changing requirements, and early identification of design flaws or usability issues.

User Feedback and Testing

Incorporating user feedback through usability testing, focus groups, and user interviews enables designers to identify pain points, gather insights, and iteratively refine the software interface and functionality to meet user needs and preferences.

Comprehensive Testing and Validation

Conducting thorough testing and validation, including functional testing, integration testing, and compliance testing, ensures the reliability, performance, and regulatory compliance of medical software solutions before deployment in clinical settings.

Continuous Improvement

Embracing a culture of continuous improvement and innovation enables organizations to stay abreast of emerging trends, address evolving user needs, and leverage technological advancements to enhance the quality, safety, and efficiency of medical software solutions.

Conclusion

In conclusion, medical software design plays a crucial role in shaping the future of healthcare delivery by harnessing the power of technology to improve clinical workflows, enhance patient care, and drive innovation. By adhering to principles of user-centered design, interoperability, data security, and regulatory compliance, software developers can create innovative solutions that empower healthcare professionals, engage patients, and transform the delivery of care.

0 notes

Text

ABB is a leading supplier of industrial robots and robot software, equipment and complete application solutions.

0 notes

Text

The integration of robotics into industrial environments has transformed manufacturing processes, enhancing productivity, efficiency, and safety. Robotics refers to the design, development, and implementation of robots capable of performing tasks autonomously or semi-autonomously.

0 notes

Text

Medical devices are essential tools that improve healthcare, enhance patient outcomes, and save lives. However, creating and bringing a medical device to market is a complex and highly regulated process. This comprehensive guide will walk you through the entire journey, from the initial idea to making a meaningful impact in the healthcare industry.

0 notes

Text

Custom Motor Manufacturers Discuss Facility Efficiency

In today's highly competitive industrial landscape, custom motor manufacturers are constantly seeking ways to enhance their operational efficiency to stay ahead of the curve. Efficient facilities not only drive down costs but also contribute to improved productivity and customer satisfaction. In this article, we delve into the strategies, challenges, and future trends surrounding facility efficiency in the realm of custom motor manufacturing.

1. Introduction to Custom Motor Manufacturers

Custom motor manufacturers specialize in designing and producing motors tailored to specific client requirements. These motors find applications in various industries, including automotive, aerospace, and robotics. Given the diverse nature of their clientele, custom motor manufacturers must maintain high levels of flexibility and adaptability in their operations.

2. Importance of Facility Efficiency

Efficiency is paramount for custom motor manufacturers due to several reasons. Firstly, it directly impacts production costs, with streamlined processes leading to lower expenses. Secondly, efficient facilities enable quicker turnaround times, allowing manufacturers to meet tight deadlines and customer demands effectively. Moreover, improved efficiency enhances overall quality control, ensuring that products meet stringent performance standards.

3. Factors Affecting Facility Efficiency

Several factors contribute to the efficiency of manufacturing facilities:

Equipment Maintenance

Regular maintenance of machinery and equipment is essential for preventing breakdowns and ensuring optimal performance. Custom motor manufacturers must implement robust maintenance schedules to minimize downtime and maximize productivity.

Workflow Optimization

Efficient workflow design is critical for minimizing bottlenecks and optimizing resource utilization. Manufacturers employ techniques such as value stream mapping and process reengineering to identify inefficiencies and streamline operations.

Employee Training

Well-trained personnel are key to maintaining operational efficiency. Providing employees with comprehensive training programs ensures that they possess the necessary skills and knowledge to perform their tasks effectively.

4. Strategies for Improving Facility Efficiency

Custom motor manufacturers employ various strategies to enhance facility efficiency:

Lean Manufacturing Principles

Implementing lean principles, such as just-in-time inventory management and continuous improvement, enables manufacturers to eliminate waste and improve process flow.

Automation Integration

Automation technologies, such as robotic assembly lines and computerized inventory systems, help streamline production processes and reduce manual labor requirements.

Energy Efficiency Initiatives

Adopting energy-efficient practices, such as upgrading to energy-efficient equipment and optimizing HVAC systems, not only reduces operating costs but also minimizes environmental impact.

5. Case Studies of Successful Efficiency Improvements

Several custom motor manufacturers have successfully improved facility efficiency through strategic initiatives. Case studies highlighting these success stories provide valuable insights into best practices and actionable strategies.

6. Challenges Faced by Custom Motor Manufacturers

Despite the benefits of efficiency improvements, custom motor manufacturers encounter various challenges in their quest for operational excellence. These challenges include technological complexities, supply chain disruptions, and regulatory compliance issues.

7. Future Trends in Facility Efficiency

The future of facility efficiency in custom motor manufacturing is characterized by advancements in technology and evolving market dynamics. Trends such as the Internet of Things (IoT) integration, predictive maintenance, and digital twinning are poised to revolutionize manufacturing processes and further enhance efficiency.

8. Conclusion

Efficient facility management is indispensable for custom motor manufacturers striving to maintain a competitive edge in the industry. By implementing proactive strategies, addressing challenges, and embracing emerging trends, manufacturers can optimize their operations and achieve sustained growth and success.

0 notes

Text

Outer Reef Technologies specializes in the development and production of innovative BLDC Motor Controllers.

A BLDC Motor Controller plays a crucial role in efficiently driving and controlling the performance of

brushless motors, offering advantages such as improved energy efficiency, reduced maintenance, and enhanced reliability.

0 notes

Text

Navigating Excellence: Project Management for Medical Devices

The development and launch of medical devices demand meticulous planning, coordination, and execution. Effective project management is the linchpin that ensures the seamless progression of a medical device from concept to market. In this article, we explore the critical aspects of project management for medical devices, emphasizing the strategies and methodologies that underpin successful outcomes in this highly regulated and dynamic field.

1. Defining Project Scope and Objectives

Establishing Clear Goals

The foundation of effective project management for medical devices lies in establishing clear and concise project goals. Define the scope, objectives, and desired outcomes. This clarity provides a roadmap for the project team, aligning their efforts with the overarching mission and ensuring everyone is on the same page.

Regulatory Considerations

Given the highly regulated nature of the medical device industry, project scope must encompass regulatory requirements. Identify and integrate regulatory milestones, approvals, and compliance checks into the project plan. This proactive approach minimizes delays and ensures adherence to stringent regulatory standards.

2. Building a Competent Project Team

Cross-Functional Collaboration

Assembling a competent and cross-functional project team is pivotal. Include professionals with expertise in regulatory affairs, product development, quality assurance, and manufacturing. A diverse team brings a spectrum of skills and perspectives, fostering innovative problem-solving and efficient execution.

Effective Communication

Open and transparent communication is the glue that holds a project team together. Regular team meetings, progress updates, and clear lines of communication facilitate collaboration and ensure that everyone is informed of the project's status, challenges, and successes.

3. Rigorous Risk Management

Identification and Assessment of Risks

Comprehensive risk management is a cornerstone of successful project management for medical devices. Identify potential risks early in the project life cycle. Conduct risk assessments to evaluate the likelihood and impact of each risk, enabling the development of mitigation strategies and contingency plans.

Adaptability to Regulatory Changes

In the dynamic landscape of medical device regulations, project managers must be adaptable. Keep a pulse on regulatory changes and integrate them into risk assessments. This foresight allows the project team to anticipate and navigate changes efficiently, minimizing disruptions to the project timeline.

4. Methodical Project Planning

Gantt Charts and Milestone Tracking

A well-structured project plan is essential for meeting deadlines and milestones. Utilize project management tools like Gantt charts to visualize the project timeline and allocate resources effectively. Clearly defined milestones enable the team to track progress and make data-driven decisions.

Resource Allocation and Budget Management

Strategic resource allocation and budget management are integral components of project planning. Ensure that the project team has the necessary resources to execute tasks efficiently. Regularly monitor budget adherence, making adjustments as needed to prevent financial constraints that could jeopardize the project's success.

5. Robust Quality Management Systems

Integration of Quality Assurance Practices

Quality management is paramount in the development of medical devices. Integrate robust quality assurance practices throughout the project life cycle. Implement verification and validation processes to ensure that the device meets regulatory standards and fulfills its intended purpose.

Documentation and Traceability

Maintain meticulous documentation and traceability throughout the project. Document key decisions, design changes, and validation activities. This practice not only ensures compliance with regulatory requirements but also provides a comprehensive record for audits and future reference.

Conclusion: Orchestrating Success in Medical Device Projects

Project management for medical devices demands a blend of strategic planning, regulatory acumen, and cross-functional collaboration. Successful projects hinge on clear goals, competent teams, rigorous risk management, methodical planning, and robust quality management systems. As the medical device industry continues to evolve, effective project management remains the compass that guides teams toward excellence, ensuring that innovative and compliant medical devices reach the hands of those who need them most.

0 notes

Text

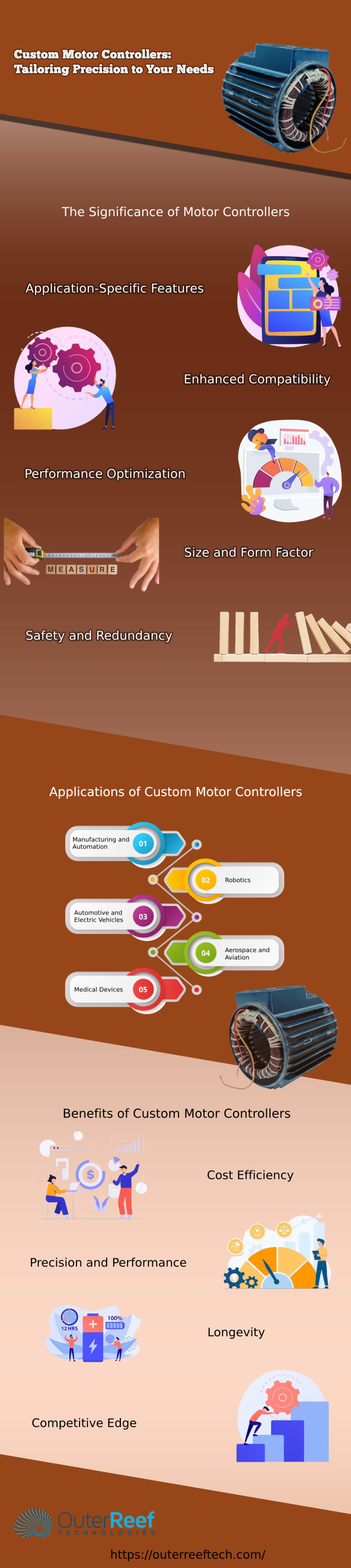

Beyond Off-the-Shelf: Unveiling the Advantages of Custom Motor Controllers

In the intricate world of motor control, the quest for optimal performance, precision, and adaptability has driven the evolution from off-the-shelf solutions to custom motor controllers. These tailor-made devices are engineered to meet specific application requirements, offering a spectrum of advantages that go beyond the limitations of standard controllers. This exploration delves into the unique benefits of custom motor controllers, showcasing why businesses are increasingly opting for bespoke solutions.

1. Tailored Performance for Specific Applications

The primary advantage of custom motor controllers lies in their ability to deliver tailored performance for specific applications. Unlike off-the-shelf controllers that provide generic solutions, custom controllers can be precisely configured to meet the unique demands of diverse industries, ensuring optimal efficiency and functionality.

2. Optimized Power Efficiency

Custom motor controllers enable optimization of power efficiency by fine-tuning parameters according to the requirements of the application. This level of customization ensures that the motor operates at peak efficiency, minimizing energy consumption and contributing to overall sustainability in power usage.

3. Enhanced Precision and Accuracy

Precision is paramount in many applications, such as robotics, manufacturing, and medical devices. Custom motor controllers allow for enhanced precision and accuracy by enabling adjustments to control algorithms, feedback mechanisms, and response times. This level of control is essential for applications where minute adjustments can make a significant difference.

4. Seamless Integration with Existing Systems

Off-the-shelf controllers may pose challenges when integrating with existing systems due to their standardized nature. Custom motor controllers, on the other hand, can be designed to seamlessly integrate with specific hardware and software architectures, ensuring compatibility and reducing the complexity of system integration.

5. Adaptability to Unique Environmental Conditions

Certain industries operate in challenging environmental conditions, such as extreme temperatures, humidity, or vibrations. Custom motor controllers can be designed with the necessary ruggedness and protection mechanisms to withstand these conditions, ensuring reliable operation in environments where off-the-shelf controllers might falter.

6. Cost-Efficiency in the Long Run

While the upfront costs of custom motor controllers may be higher than off-the-shelf alternatives, the long-term cost-efficiency is often superior. Custom controllers are precisely tailored to the application's needs, minimizing unnecessary features and components. This results in reduced maintenance costs, enhanced reliability, and a longer operational lifespan.

7. Flexibility for Future Upgrades

Custom motor controllers provide the flexibility needed for future upgrades and adaptations. As technology evolves or application requirements change, custom controllers can be easily reprogrammed or modified to accommodate these shifts, ensuring that the motor control system remains relevant and effective over time.

8. Optimal Space Utilization

Off-the-shelf controllers are designed with general form factors, which may not always align with the spatial constraints of specific applications. Custom motor controllers can be engineered to optimize space utilization, fitting seamlessly into compact or unique spaces within a given system.

9. Compliance with Industry Standards

Different industries have specific standards and regulations governing their operations. Custom motor controllers can be designed to comply with these industry standards, ensuring that the motor control system meets all safety, performance, and regulatory requirements relevant to the specific application.

10. Greater Control Over Security Features

In applications where security is a critical concern, such as in industrial automation or medical devices, custom motor controllers offer greater control over security features. This includes the implementation of encryption protocols, secure communication interfaces, and other measures to safeguard sensitive data and operations.

Conclusion: Tailored Excellence in Motor Control

The advantages of custom motor controllers extend far beyond the capabilities of off-the-shelf solutions. By offering tailored performance, optimized efficiency, and adaptability to unique application requirements, custom controllers stand as a testament to the pursuit of excellence in motor control technology. As industries continue to demand precision, flexibility, and efficiency in their motor control systems, the era of custom solutions is poised to play a pivotal role in shaping the future of electromechanical systems.

0 notes

Text

This guide comprehensively navigates the journey of medical device development, covering the entire process from conceptualization to real-world impact. It addresses crucial aspects of design and regulation, offering insights into the intricate world of creating medical devices. Topics include ideation, prototyping, testing, regulatory compliance, and ultimately, the transformative impact these innovations can have in the healthcare industry.

https://outerreeftech.com/blogs/news/from-idea-to-impact-the-complete-guide-to-medical-device-design-and-regulation

0 notes

Text

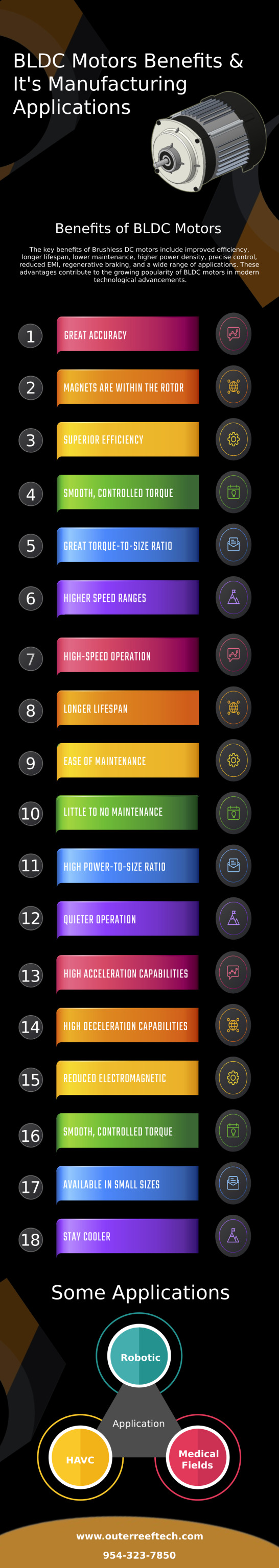

BLDC Motors Benefits: BLDC motors offer high efficiency, durability, and low maintenance due to the absence of brushes. They provide precise speed control, compact design, and reduced electromagnetic interference, making them ideal for various applications.

Manufacturing Applications: BLDC motors find widespread use in industries like automotive (electric vehicles), industrial automation, medical equipment, consumer electronics, HVAC systems, aerospace, and renewable energy. Their compact size, efficiency, and reliability make them a preferred choice for diverse manufacturing applications.

0 notes

Text

Precision in Motion: The Role of BLDC Motor Controllers in Robotics

In the realm of robotics, where precision and accuracy are paramount, Brushless DC (BLDC) motor controllers emerge as indispensable components, playing a pivotal role in achieving unparalleled levels of motion control. As we delve into the intricate world of robotics, this article explores how BLDC motor controllers contribute to precision in motion, enabling advancements in the field and expanding the possibilities of what robots can achieve.

1. Unmatched Precision in Speed Control

A. Fine-Tuned Speed Regulation

BLDC motor controllers excel in providing unmatched precision in speed control, allowing robotic systems to execute movements with incredible accuracy. This level of control is crucial in scenarios where precise and predictable motion is required, such as in manufacturing and assembly processes.

B. Adaptive Speed Adjustments

The adaptive nature of BLDC motor controllers enables robots to make instantaneous speed adjustments based on the task at hand. This adaptability is particularly beneficial in applications where the robot needs to switch between tasks with varying speed requirements seamlessly.

2. Highly Responsive Position Control

A. Sub-Millimeter Accuracy

BLDC motor controllers, integrated with advanced position sensing technologies, deliver sub-millimeter accuracy in position control. This precision is essential in applications where the robot must interact with delicate components or execute intricate tasks with precision, such as in medical robotics.

B. Dynamic Position Adjustments

The dynamic capabilities of BLDC motor controllers empower robots to make swift and dynamic position adjustments. This is instrumental in scenarios where the robot needs to navigate complex environments or respond to changing conditions in real-time.

3. Reduced Vibrations for Stability

A. Vibration-Free Performance

The inherently smooth operation of BLDC motor controllers translates to vibration-free performance. In robotics, where stability is paramount, this feature ensures that the robot can execute tasks with minimal vibrations, enhancing the overall performance and accuracy of the system.

B. Enhanced Tool Precision

In applications where robots are equipped with tools or manipulators, reduced vibrations contribute to enhanced tool precision. This is crucial in fields such as surgery, where robotic systems are increasingly utilized for minimally invasive procedures.

4. Optimal Energy Utilization

A. Efficiency in Energy Consumption

BLDC motor controllers optimize energy utilization, ensuring that robotic systems operate efficiently. This is particularly important in robotics applications where battery life or energy efficiency is a critical factor, such as in autonomous drones or mobile robotic platforms.

B. Extended Battery Life

The energy-efficient design of BLDC motor controllers contributes to extended battery life in robotic systems. This is advantageous in scenarios where robots need to operate for prolonged periods without frequent recharging or power source replenishment.

5. Adaptability to Varied Loads

A. Efficient Handling of Variable Loads

BLDC motor controllers exhibit a high level of adaptability to varied loads. This means that robotic systems can efficiently handle changes in payload or external forces, maintaining precise control even in dynamically changing conditions.

B. Dynamic Load Adjustments

The ability to dynamically adjust to varying loads allows robots to perform tasks that involve lifting, manipulating, or transporting objects of different weights. This adaptability is crucial in applications ranging from logistics to material handling.

6. Reduced Wear and Tear for Longevity

A. Minimal Mechanical Friction

Unlike traditional motors with brushes, BLDC motors experience minimal wear and tear due to the absence of mechanical friction. This characteristic contributes to the longevity of robotic systems, reducing maintenance requirements and downtime.

B. Extended Operational Lifespan

The extended operational lifespan of robotic systems equipped with BLDC motor controllers ensures a reliable and cost-effective solution for industries. This is particularly beneficial in sectors where continuous operation and reliability are critical factors.

7. Seamless Integration into Complex Systems

A. Advanced Control Algorithms

BLDC motor controllers often come equipped with advanced control algorithms, facilitating seamless integration into complex robotic systems. This allows for a higher degree of customization and adaptability, enabling the robot to perform intricate tasks with precision.

B. Compatibility with Robotics Frameworks

The compatibility of BLDC motor controllers with popular robotics frameworks and software platforms ensures ease of integration. This compatibility streamlines the development and deployment of robotic systems, reducing the time and resources required for implementation.

Conclusion

In conclusion, the role of BLDC motor controllers in robotics is transformative, elevating the precision and capabilities of robotic systems to unprecedented levels. From fine-tuned speed regulation and sub-millimeter position accuracy to reduced vibrations and adaptability to variable loads, BLDC motor controllers are the driving force behind the evolution of robotics.

As industries continue to push the boundaries of what robots can achieve, the precision in motion offered by BLDC motor controllers becomes increasingly crucial. Whether in manufacturing, healthcare, or autonomous systems, the seamless integration of BLDC motor controllers empowers robots to perform with the utmost precision, opening new frontiers of possibility in the field of robotics.

0 notes

Text

Outerreef's BLDC motors stand out for their precision control, high efficiency in power conversion, reduced friction and heat loss, minimal maintenance needs, and an impressive torque-to-size ratio. These features collectively make them a reliable and efficient choice for a wide range of applications, meeting the demands of modern technology and industry standards.

0 notes

Text

Project Management For Medical Devices

We leverage our understanding and knowledge of FDA requirements, ensuring you that your project plan is compliant with the regulations, thereby increasing your chances of getting your device FDA approved.

Click here to learn everything about a successful and efficient project management plan for medical device development.

https://outerreeftech.com/pages/project-management-for-medical-devices

0 notes