#Manufacturer of PTFE Lined Ball Check Valve

Text

PTFE Lined Ball Check Valve in Andhra Pradesh

Overview:

Flowline Valve is a Manufacturer and Supplier of PTFE Lined Ball Check Valve in Andhra Pradesh, India.

In piping systems, operators use a PTFE (Polytetrafluoroethylene) lined ball check valve to prevent backflow of fluids.

The valve consists of a ball inside a chamber with a hole or port for the fluid to pass through. The ball moves freely within the chamber, allowing flow in one…

View On WordPress

#Adoni#Amaravati#Anantapur#Chandragiri#Chittoor#Dowlaiswaram#East Godavari#Eluru#Exporter of PTFE Lined Ball Check Valve#Guntur#India#Kadapa#Kakinada#Krishna#Kurnool#Manufacturer#Manufacturer of PTFE Lined Ball Check Valve#Nagarjunakoṇḍa#Nellore#Prakasam#PTFE Lined Ball Check Valve#PTFE Lined Ball Check Valve in Ahmedabad#PTFE Lined Ball Check Valve in Andhra Pradesh#PTFE Lined Ball Check Valve in Gujarat#PTFE Lined Ball Check Valve in India#Rajahmundry#Rajamahendravaram#Sri Potti Sriramulu Nellore#Srikakulam#Supplier

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

FEP and UPVC Ball Valve

What is UPVC 3-Way Ball Valve? What is a Valve?

Taking a look at the humble pipe is a good place to start. It could be a pipe transporting water in your bathroom or a pipe carrying gas to your kitchen stove. A mechanism that controls how much liquid or gas flows through these liquid and gas pipes is required to function efficiently; this mechanism can be used to increase, decrease, or even stop the flow of fluid or gas. A valve is a mechanism that performs this function. They are mechanical switches that can turn pipes on and off as well as increase or decrease the flow of fluid/gas through them.

Now let's take a look at a few more examples from everyday life. To brush your teeth, you open a valve that lets pressurized water flow out of the pipe when you turn on the tap. Turning the tap more to one side typically reduces, stops, or increases the amount of water coming out (depending on the valve).

FEP Ball Valves:

The best type of ball valve to use for paper and pulp industries is the FEP-lined ball valve. At 10kg/cm2 pressure and 180°C operating temperature, it is capable of withstanding a pressure of 180°C. FEP-lined Ball Valves are ideal for slurries and viscous materials since they are non-sticky. Its unique properties make it superior to alloys.

In terms of its effects, FEP is similar to PTFE except for its soften-processed performance. Despite this, FEP can be quickly processed, welded, and re-molded into complex shapes. Welding and remodeling prospects, chemical and UV resistance, biocompatibility, and clear color are some of the unique properties of FEP.

PFA Ball Valve:

Many oil and gas industries utilize PFA-lined ball valves. PFA-lined valves can withstand temperatures up to 230°C at 10kg/cm2. PFA-lined valves have similar properties and qualities to FEP, but PFA is more temperature-resistant than FEP. In addition to their thermoplastic properties, PFA-lined valves offer a wide range of benefits. A thermoplastic material with the highest working temperature capacity is PFA. There is no fluoroplastic that can work continuously at a temperature higher than +260°C. It is possible to weld and re-mold it, with good permeability and outstanding chemical resistance. We are the PFA lined ball valve manufacturers in India.

What is UPVC 3-Way Ball Valve?

UPVC Ball Valve Manufacturers: The two ports of the PVC union ball valve are made up of two unions that can be disassembled and replaced at any time, making them easier to check and replace than common ball valves. An adjustable tightness, a low friction coefficient, ease of maintenance, and no leaks are some of the characteristics of a union ball valve. Furthermore, since the joints can be purchased separately, you can choose between threaded, socket, and standard joints. Although its single cost is higher than that of common ball valves, its replacement cost is lower.

Aira Euro Automation is the leading ball valve manufacturer in India. We offer various types of industrial valves like ball valves, butterfly valves, control valves, and many more.

0 notes

Text

Do You Have These Products?

The industry type we are talking about will never do anything with our requirement.

Thus, it becomes a deal that we learn through and expect the things to go the way expected.

Thus, have you ever needed Lined Pipes, Fittings, Valves and other such customized products?

Do share your thoughts, and now – We are going to share the product types you should have in place for the operations to get going.

Below are the products you can directly get out from AblazeLining!

Ball Valve

Ball Check Valve

Butterfly Valve

Lined Globe Valve

Diaphragm Valve

Flush Bottom Valve

Lined Swing Check Valve

Plug Valve

Full View Sight Glass

Double Window Type Sight Glass

Dip Pipe

PTFE Stirrer & Agitators

Feed Pipe

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined EQUAL TEE

Lined Concentric Reducer

Lined Equal Cross

Lined Unequal Cross

Lined Blind Flanges

Solid Spacer

Lined Spacer

If you are the person and need these products to conducting business operations at an ease, just make sure that you are switching to Ablaze Lining! They have been a leading and trustworthy Lined Pipes, Fittings, Valves and Customized Products’ manufacturer and supplier. They will also manage to serve you as per your requirement and needs. Make sure that you are filling in their contact form, and get to the every detail they have mentioned on their website. It will ensure you are having everything you need to have reasonable decision in place. On top of everything – They have served countless customers and always ensure the requirements clients use their products for taking on everything in the best possible manner. So, visit the recommendation for sure!

Final Thoughts

Thus, in case you are still looking for the Lined Swing Check Valve Manufacturer, the recommendation we talked about will do the best.

Just ensure to stick with the guide and take it as a reference.

These are the products we shared are what Ablaze Lining offers!

On a sweeter note – Thanks for the read, though!

0 notes

Photo

PTFE Lined Ball Valves Manufacturer in India

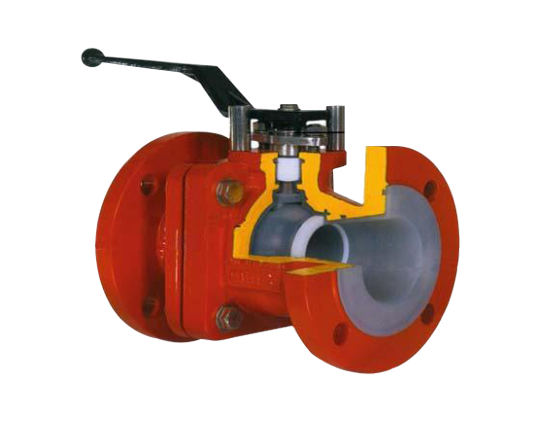

PTFE lined ball valves are devices designed to regulate the flow of fluids (including gases) by opening, closing, or moderately obstructing passageways in pipes. Lined ball valves have large- scale application over many various industries - for this reason they are vary widely in size, form and materials used depending on what they are going to be used for. They can be more or less simple, or they can be compound - in which case exceptional design is critical to how well they work.

Nowadays, PTFE lined ball valves have been the necessary products in all kinds of corrosive industrial applications. However, there are only a limited lined ball valve manufacturers who reach the international standard. So when company buy this valve, they must called for the seller to show the certifications for production. Through this way company can avoid purchasing the uncertified products.

The primary functions of lined ball valves are important guidelines based on exactly what the industry wants with regard to their machines and equipments. They are available on a number of designs and sizes, plus they are manufacture from different materials, which imply that they offer a model for just about any project.

Aira 4Matic Global Valves is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined ball valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering Lined check valves for corrosive industrial applications. We have different size range of lined ball valves which are matched to all the industrial operations. We offer ball valves that are fire proof and also passed fugitive emissions testing standards.

1 note

·

View note

Text

Use of Valves in Water Industry

Industrial valves are widely used in engineering, manufacturing, commercial and scientific communities. The valve's primary function is to regulate water flow and pressure while also releasing air from the system. In the water segment, valves play a significant role. Many aspects of everyday mechanical systems, such as the HVAC and water system in an office, require water valves.

Characteristics of the Most Common Valves Used in the Water Industry

There are many type of industrial valves can be used in water industry but some most helpful valves are given as below.

Gate Valves- The most important valves in the distribution system are gate valves. The on/off control of gate valves is the most common use and also known as isolating valves. Gate valves stop liquid from flowing in both directions. Manual gate valves are most utilised in the pipe line system for their effective flow regulations. They're simple to set up and keep up with. Gate valves are low-cost and widely employed in the water, petroleum and many other industries due to their ability to cut through liquids.

Butterfly Valve- Butterfly valves can control, regulate or isolate large fluid flow effectively. Because it provides a 90-degree rotating motion for stoppage, the butterfly valve is also known as a quarter turn valve. They were frequently huge in size but short in length and light in weight. They only require a small amount of torque and space in comparison with any other valves.

Ball Valve- Ball valves are priority valves for fluid control. A ball rotates between two circular seats consisting of a kind of PTFE and co-polymer in ball valves. They are available in a tiny size range of 1/2" to 12". These valves are utilised in situations that require a higher level of pressure. Ball valves require less force to operate than gate valves, have a smaller size, and are lighter than gate valves. Ball valve manufacturers offer them in various type and specifications, most preferable Manual, Pneumatic and Electric Ball Valves.

Plug Valves- By rotating the conically tapered plugs inside the valve body, plug valves may control the flow. They have a very simple design with few parts, and they are very easy to maintain and repair. They have a cheap cost per head and a drip-tight seal.

Regulating Valves- Regulating valves are designed to provide for direct control of flow rate as well as significant control of process quantities, i.e. flow/pressure reduction. Regulating valves can sustain a large head loss and come with different control scenarios. These valves consist of a regulating unit that changes the flow cross-section and are used on trunk or industrial pipelines.

Vacuum Release Valves- These sorts of valves, as the name implies, release air during the filling and testing of pipes, as well as air that naturally accumulates in pipes. It enables air into the pipe when draining and ensures the pipeline's carrying capacity.

An Engipro solution is a leading provider of industrial valves including Gate Valves, Globe Valves, Ball Valves, Check Valves, Non-return Valves, Pressure Reducing Valves, and Shutoff Valves. If you need any type of valve or want to learn more about our company, we are always willing to help you with our heart and soul.

1 note

·

View note

Text

Use of Valves in Water Industry

Industrial valves are widely used in engineering, manufacturing, commercial and scientific communities. The valve's primary function is to regulate water flow and pressure while also releasing air from the system. In the water segment, valves play a significant role. Many aspects of everyday mechanical systems, such as the HVAC and water system in an office, require water valves.

Characteristics of the Most Common Valves Used in the Water Industry

There are many type of industrial valves can be used in water industry but some most helpful valves are given as below.

Gate Valves- The most important valves in the distribution system are gate valves. The on/off control of gate valves is the most common use and also known as isolating valves. Gate valves stop liquid from flowing in both directions. Manual gate valves are most utilised in the pipe line system for their effective flow regulations. They're simple to set up and keep up with. Gate valves are low-cost and widely employed in the water, petroleum and many other industries due to their ability to cut through liquids.

Ball Valve- Ball valves are priority valves for fluid control. A ball rotates between two circular seats consisting of a kind of PTFE and co-polymer in ball valves. They are available in a tiny size range of 1/2" to 12". These valves are utilised in situations that require a higher level of pressure. Ball valves require less force to operate than gate valves, have a smaller size, and are lighter than gate valves. Ball valve manufacturers offer them in various type and specifications, most preferable Manual, Pneumatic and Electric Ball Valves.

Plug Valves- By rotating the conically tapered plugs inside the valve body, plug valves may control the flow. They have a very simple design with few parts, and they are very easy to maintain and repair. They have a cheap cost per head and a drip-tight seal.

Regulating Valves- Regulating valves are designed to provide for direct control of flow rate as well as significant control of process quantities, i.e. flow/pressure reduction. Regulating valves can sustain a large head loss and come with different control scenarios. These valves consist of a regulating unit that changes the flow cross-section and are used on trunk or industrial pipelines.

An Engipro solution is a leading provider of industrial valves including Gate Valves, Globe Valves, Ball Valves, Check Valves, Non-return Valves, Pressure Reducing Valves, and Shutoff Valves. If you need any type of valve or want to learn more about our company, we are always willing to help you with our heart and soul.

1 note

·

View note

Text

Important Steps to Troubleshoot and Fix the Most Common Problems with AODD Pumps

Because of their simplicity, air operated double diaphragm pumps (AODD Pumps)are great for transfer applications. To achieve maximum performance, it is important to properly install and operate your pump. These six easy fixes will help you troubleshoot and fix common problems when your AODD is not working properly during installation and operation.

1.To Check The Air Inlet Size And Pressure.

A small airline is the most common error with AODD pumps. To operate at its best, the pump requires compressed air. An airline that is too small will deprive it of the fuel it needs. Larger AODD pumps (one-inch and more) require more compressed and longer air lines than their smaller counterparts. For the correct size air line for your pump, refer to the manufacturer's instructions and operation manual. It is a good rule of thumb to match the size of the air line hose to the size of the inlet port on AODD pumps. Explore the latest AODD Pumps at Antlia Engineering Works. They are the AODD Pump Suppliers Globally.

Your pump's performance can also be optimized by adjusting the inlet pressure. Diaphragm pumps work in a 1:1 ratio. The pump's inlet pressure is directly proportional to the pump's outlet pressure. 100 psi is the target outlet pressure for a 50 gpm 1 inch pump. The pump's inlet pressure must also be greater than or equal to 100psi.

The outlet fluid pressure is affected by fluid viscosity, system back pressure, and fluid viscosity. Too little back pressure can cause the pump to run slower and the ball checks may not be as quick. If the fluid pressure exceeds the air pressure, the pump may stall. An air regulator is required to regulate the incoming pressure to ensure that an AODD pump performs at its best. An air regulator and the correct size air line will resolve most of the problems associated with AODD pump installation.

2.Check for Muffler Icing and Restrictions

Mufflers can be installed on AODD pumps and are recommended because they can produce high decibel levels at full speed. To operate the pump's air motor, compressed air is needed. Rapid temperature changes are caused by the compressed air entering the valve. It is then channeled through the pump's center section and exhausts through the muffler. The muffler exhaust temperature is below freezing and can lead to icing issues. This is more prevalent in environments with high humidity. Looking for AODD Pump Manufacturers In India.

Visit Antlia Engineering works, they manufacture all types of AODD Pumps.

If your pump is acting erratically, your inlet air contains high levels of moisture, or you can see the front of your muffler, these are indicators that your pump has icing issues. These solutions can help you eliminate icing issues and improve your pump's efficiency.

Pump the air pressure down

To operate at a lower speed (i.e.,. lower air pressure)

An exhaust port tube allows you to exhaust the air to remote locations

To collect condensation, add an air filter and a water catcher to your system.

To raise exhaust air temperature above freezing, install an air heater

To adjust the pressure dew point temperature, use an air compressor dryer

3.Checking Sealing Surfaces for Leaking

Leakage issues can occur with all types of pumps. These tips will ensure that your fluids remain in the pump and not the ground.

Follow the bolting pattern's illustration and torque the pump to the manufacturer's specifications.

When servicing your AODD pump, replace all PTFE o rings. Although PTFE can be used in many applications, it is not capable of returning to its original form after being compressed.

You can reduce the risk of leakage by properly torquing your pump according to the manufacturer's specifications and ensuring that sealing o-rings are replaced during service.

4. Ensure proper tubing and piping sizes

The flow rate of fluid required will determine the diameters of the pump's inlet and outlet ports. The size of the outlet and inlet hoses must be equal. This is a major concern because of the potential for cavitation, as well as the higher repair frequency and increased maintenance costs.

A pump that is 1 inch tall has a 1/2-inch inlet hose attached. The pump will not be capable of operating at its maximum capacity without cavitation. As the fluid viscosity increases, this risk is greater. To avoid cavitation, a pump of 1 inch should have an outlet and inlet hose of 1 inch. This will prevent costly and frequent repairs.

AODD pumps should have flexible inlet and outlet connections. This is preferable to hard plumbed installations. As the pump speed increases, vibration increases. Vibration increases with pump speed. This increases the possibility of hard-plumbed connections being loosened, which can lead to leakage.

5. PRIME - LOWER THE PUMP

AODD pumps are a popular choice for applications that require self-priming. The AODD pumps draw fluid by creating a low-pressure zone within the fluid bowls. This is less than the atmospheric pressure (14.7 psi). If the air pressure is too high, the pump will not changeover quickly enough to allow the fluid to flow into it.

This is solved by using the air regulator to reduce the air pressure entering an air valve and slow down the pump. The pump speed can be reduced to ensure that the fluid supplied has sufficient time to reach the pump. After this, the pump can operate at a faster speed by increasing the air pressure.

6. CLEAR ALL FLUID LINE RESERVATIONS

Clearing any fluid line restrictions is the final step in ensuring optimal pump performance. Limitations can lead to increased maintenance, pressure loss and potential cavitation. This issue can be fixed by removing the following:

Valves that are partially or fully closed

Line kinks or clogs

Too many hoses or too long a distance

These six steps will resolve most of the problems associated with AODD pumps. This will allow you to produce more and not spend time trying to fix it. If you need more help troubleshooting and repairing your AODD pump contact one of our experts.

For more details visit Antlia Engineering Works and know in detail about AODD Pumps as they are the Peristaltic Pump Manufacturers and supplier of the Pumps worldwide.

#AODDPumps#AODDPumpManufacturers#AODDPumpSuppliers#AODDPumpManufacturersInIndia#PeristalticPumpManufacturers

0 notes

Text

PTFE Lined Ball Check Valve Supplier in Kolkata

PTFE Lined Ball Check Valve Supplier in Kolkata:

Flowline Valve:

Flowline Valve is a well-established manufacturer and supplier in Kolkata, India, specializing in PTFE Lined Ball Check Valves, serving diverse industries with reliable products.

PTFE Lined Ball Check Valve Overview:

Function: Designed to control fluid flow in pipelines, particularly for backflow prevention, featuring a ball…

View On WordPress

#Ahritola#Alambazar#Archana#Badartala#Baghajatin#Bamboovila#Chetla#Colootola#Dharmatala#Exporter of PTFE Lined Ball Check Valve#Garfa#Gokhel Road#Jawpore#Jorasanko#Kasthadanga#Keoratala#Madrassa#Manufacturer of PTFE Lined Ball Check Valve#Naktala#Noapara#PTFE Lined Ball Check Valve#PTFE Lined Ball Check Valve Supplier in India#PTFE Lined Ball Check Valve Supplier in Kolkata#Rajabagan#Supplier of PTFE Lined Ball Check Valve

0 notes

Text

1 note

·

View note

Text

Uses of Valves

Some custom valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation.

Some are dedicated to fluid power applications, including solenoid, poppet, hydraulic, cartridge, and air logic valves. Others are for general pipeline applications or smaller-scale fluid systems and include plug, piston, pinch, globe, gate, disc, diaphragm, butterfly, and ball valves. Then there are valves designed to activate automatically in certain events including relief valves and check valves.

Some valves are so common that they are grouped by function, for example, boiler feedwater and blowdown control valves, faucet valves, float valves, double block and bleed valves, HVAC zone valves, or floor drain check valves. Some valves are so specialized that they may have only one or two applications, such as rotary solenoid valves used in excavators, or inverted vent check valves used in sewage systems and on ships.

As for pipeline valves, many can be thought of as suited either to blocking or throttling. A ball valve is better suited for on-off applications than it is for regulating flow. The same goes for gate and piston valves. For flow regulating, globe and butterfly valves are preferred choices, with globe valves being especially common. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). Other valve types usually introduce some loss in the valve owing to the need to place the components of the valve, actuating shafts, etc. directly in the stream and/or the need to redirect the direction of fluid flow.

Most pipeline valves are available with manual levers or handwheels which can be adapted to gear type actuators in larger sizes and fitted with electric or electro-pneumatic actuators for automatic control. Valves fitted with such actuators are sometimes called control or flow control valves in that with automatic actuation they can be integrated into control loops used for process automation. The phrase “control valve” is sometimes used to describe the valves used in hydraulic and pneumatic fluid power systems to actuate a ram, for example. Any valve can be a control valve, that is to say.

Any valves fitted with automatic actuators could be considered control valves, as they presumably would be tied in with remote process controllers. The same valve without the actuators would still be a globe valve, gate valve, etc. albeit one with manual control via handwheel or lever. Many control valves retain some form of manual control by which the valve can be opened and closed. Some valves are considered control valves if they have mechanical means of sensing flow rate, pressure, etc. and can adjust the valve through pilots, for example. In the smaller sizes, solenoid valves function as control valves. Many manufacturers will provide integrated valve and actuator combinations, for example, motorized ball valves.

Valve material can play an important role in valve selection especially when it comes to handling aggressive fluids, abrasive slurries, food products, and so on. Material concerns address not only the wetted parts but can extend to the materials of the valve body too. For instance, valves used for food processing need to resist caustic washdown chemicals and usually demand stainless steel even for exterior parts that do not contact the product. Some valves are lined to improve their resistance to corrosive fluids, etc. Check valves are sometimes lined with PTFE for improved operation and wear resistance. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. Ball valves, for example, are available in brass, stainless steel, polypropylene, and other plastics. So-called sanitary valves are fitted with quick disconnect flanges so that they can be removed from the pipeline easily for internal sanitizing, and are especially popular in the ball, butterfly, and plug designs. The valves themselves often have features which enable quick disassembly and reassembly. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves.

0 notes

Text

When Do You Need a China Butterfly Valve?

Before you choose a China butterfly valve there is some information you must acquire. You need to do this in order to make the best choice that will cover all your needs. There are many types of valves and each type has different models. This vast diversification has the role to cover all the needs that appeared over time. Every type has certain advantages and disadvantages over the others and you need to know what these are before choosing which one to use. A butterfly valve manufacturer will have at least three models which they produce and you must learn what makes them different.

In this article, you will find what are the advantages and disadvantages of a butterfly valve. You will understand in which situation they must be used and in which ones you should consider other types. After you understand this you can double-check your decision with the manufacturer right before buying. In this way, you can make sure that you have made the right decision. You can also learn from this article what are the different models of butterfly valves and what makes them special.

What Are the Advantages of a China Butterfly Valve?

The first thing you need to know is, how does a China butterfly valve works. The concept is easy to understand. A disk mounted on a shaft that can rotate. When the valve is closed the disk seals the pipe and stops the flow of the substance while opening the valve will allow it to flow around the disk. The only disadvantage that such a structure has is the fact that at large pressures the seal is not as efficient as other types, for example ball valves, which ability to seal is much better. On the other hand, this structure offers several advantages.

- Cost. The first one is its low cost. The amount of materials needed for the construction of this type of valve is very small. Together with the fact that the cost of the materials and the labor needed is very low for a butterfly valve manufacturer in China, it will result in a very small price that you need to pay for it.

- Flow regulation. Using this type of vale will allow you to regulate the volume of liquid that will flow through the pipe. This is a very useful ability and it is needed in a large range of applications. They can be used from small applications like taps to big projects like dams.

- Easy manipulation. While used in the optimal conditions this type of valve is the easiest to manipulate. It can be closed and opened very easy, while you also have very fine control over the process. Although other alternatives will allow you to regulate the flow of the valve, none will allow you the level of precision that a butterfly valve does.

What Are the Models Produced by a Butterfly Valve Manufacturer?

Every butterfly valve manufacturer will have some specialized models that are produced for certain purposes only. You can find them together with the standard ones on the manufacturer’s site. In this article will only be presented the most common models you can find on the market:

- Resilient seated. This model is used in the vast majority of low-pressure applications. You will find this model used in taps, in drainage systems, in air conditioning, and other such systems

- PTFE lined. This model is resistant to chemicals. It was developed as a solution to the applications that corroded the normal ones to fast. Now it is used in a large number of mediums. The PTFE lined butterfly valve can be used when dealing with salt, oxidants, acidic substances, and other chemicals that would degrade normal valves very fast.

- High performance. This type has appeared because the resilient seated valve cannot deal with high pressure and extreme temperatures. It is used in appliances that deal with steam or very cold water. It can also be used in high-pressure applications like jets of fuel or pressurized water.

- Triple offset. In the petroleum industry there appeared the problem of galling or scratches appearing very fast in the space between the seat and the disc of the valves. To eliminate this problem, this model of China butterfly valve was created. It resolved the problem because the disc comes in contact with the seat only at the moment of complete closure. By doing this, the accumulation of damage between them was reduced to an extreme.

0 notes

Text

Use of Valves in Water Industry

Industrial valves are widely used in engineering, manufacturing, commercial and scientific communities. The valve's primary function is to regulate water flow and pressure while also releasing air from the system. In the water segment, valves play a significant role. Many aspects of everyday mechanical systems, such as the HVAC and water system in an office, require water valves.

Characteristics of the Most Common Valves Used in the Water Industry

There are many type of industrial valves can be used in water industry but some most helpful valves are given as below.

Gate Valves- The most important valves in the distribution system are gate valves. The on/off control of gate valves is the most common use and also known as isolating valves. Gate valves stop liquid from flowing in both directions. Manual gate valvesare most utilised in the pipe line system for their effective flow regulations. They're simple to set up and keep up with. Gate valves are low-cost and widely employed in the water, petroleum and many other industries due to their ability to cut through liquids.

Butterfly Valve- Butterfly valves can control, regulate or isolate large fluid flow effectively. Because it provides a 90-degree rotating motion for stoppage, the butterfly valve is also known as a quarter turn valve. They were frequently huge in size but short in length and light in weight. They only require a small amount of torque and space in comparison with any other valves.

Ball Valve- Ball valves are priority valves for fluid control. A ball rotates between two circular seats consisting of a kind of PTFE and co-polymer in ball valves. They are available in a tiny size range of 1/2" to 12". These valves are utilised in situations that require a higher level of pressure. Ball valves require less force to operate than gate valves, have a smaller size, and are lighter than gate valves. Ball valve manufacturers offer them in various type and specifications, most preferable Manual, Pneumatic and Electric Ball Valves.

Plug Valves- By rotating the conically tapered plugs inside the valve body, plug valves may control the flow. They have a very simple design with few parts, and they are very easy to maintain and repair. They have a cheap cost per head and a drip-tight seal.

Regulating Valves- Regulating valves are designed to provide for direct control of flow rate as well as significant control of process quantities, i.e. flow/pressure reduction. Regulating valves can sustain a large head loss and come with different control scenarios. These valves consist of a regulating unit that changes the flow cross-section and are used on trunk or industrial pipelines.

Vacuum Release Valves- These sorts of valves, as the name implies, release air during the filling and testing of pipes, as well as air that naturally accumulates in pipes. It enables air into the pipe when draining and ensures the pipeline's carrying capacity.

An Engipro solution is a leading provider of industrial valves including Gate Valves, Globe Valves, Ball Valves, Check Valves, Non-return Valves, Pressure Reducing Valves, and Shutoff Valves. If you need any type of valve or want to learn more about our company, we are always willing to help you with our heart and soul.

0 notes

Text

A Premier Supplier of PTFE Lined Products

When it comes to industrial operations, if you switch to the crappy gadgets or appliances, things won’t work the way they are expected.

That’s how managing every aspect makes sure you are aligning with what is highly sought in place.

Thus, have you been in any situation wherein you required the tool to get started any industrial operation?

In fact, are you a business owner who has to do a lot with a wide range of Lined Pipes, Fittings, Valves and other such customized products?

If this is what you are considering, this is the right guide for you.

We will do the best to ensure you have the best information available.

Do ensure to stick with the guide and let’s get started.

When it comes to manufacturing and supplying a wide range of Lined Pipes, Fittings, Valves and other such customized products, all you have got to look just at Ablaze Lining since they are a thought-leader, expert, including a leading manufacturer and supplier of Fluoropolymer Lined Pipes, Fittings and Valves. The amazing thing you will note is – They have been a successful partner with leading companies across the world. They know what it takes to working in corrosion resistant company. Therefore, whatever requirement you have got, just make sure to visit the website and fill in the contact form. This will make things a lot easier and advantageous.

Products they offer are:

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined Equal TEE

Solid Spacer

Lined Spacer

Ball Valve

Ball Check Valve

Plug Valve

Full View Sight Glass

Thus, were you looking for the products that are designed in a way that can be used in highly corrosive applications?

If yes, the recommendation will do the best.

Final Thoughts

No matter if you need High Pressure Bellow Manufacturer in India or something, the thing that separates the recommendation than the others is the level of quality product they deliver.

On a sweeter note – Thanks for the read, though!

0 notes

Text

BENEFITS OF USING AODD PUMPS

Pumps play an important part in the success of a good sort of markets. From wastewater treatment to pharmaceutical production to carpet and chemical manufacturing, pumps keep many industries running at top speed.

Why Air Operated Double Diaphragm Pump (AODD) used so prominently in numerous differing types of industries? Because they provide advantages other sorts of pumps can’t. Keep reading to get the 16 benefits of using AODD pumps.

1. AODD PUMPS ARE RUN-DRY CAPABLE

AODD pumps are ready to dry out for an extended time without damage to the pump or its components. It’s quite common for pumps to dry out, especially in sump dewatering, tanker unloading or tank over applications.

Other sorts of positive displacement pumps could also be damaged by running dry and, ultimately, their service life is going to be shortened.

2. AODD PUMPS OFFER EFFICIENT SOLIDS HANDLING

Many AODD pumps can easily and efficiently handle solids-laden fluid without pump or product damage. Ball-valve units can handle solids up to just about 0.75” (19 mm) in diameter and flap-valve units can pass nearly line-sized semisolids.

3. AODD PUMPS DEADHEAD SAFELY

Deadheading occurs when the fluid pressure is adequate to the air inlet pressure powering the pump. When a valve on the fluid side of the pump is closed, the pump will build pressure until it's equal and stops pumping. When the valve is opened on the discharge fluid side of the pump, it'll start pumping again.

Many other pumping technologies require special controls or circulation loops to permit for the pump to deadhead. AODD pump is an excellent option for applications that are intermittent and need frequent deadheading.

4. AODD PUMPS WON'T SHEAR OUTCOME

AODD pumps are gentle on the merchandise being pumped and cannot froth or separate it. This is often critical when pumping many products which will be altered or ruined if sheared. For instance, many sorts of paints and coatings require a shear-sensitive pump; therefore the products aren't altered during the transfer. Other pumping technologies, like centrifugal and kit pumps, can shear products.

5. AODD PUMPS REQUIRE NO ELECTRICITY

AODD Pump Manufacturers in India require no electricity (rather, they require compressed gas to operate) and may be grounded for safe, reliable operation in explosive environments. This is often critical when pumping flammable liquids or when a pump is in an environment where fumes are present.

Certified models (like ATEX or UL Listed) are often confirmed safe when properly grounded. Because no electricity is required, additional certifications, costly permits and explosion-proof motors aren't needed, making pump found out simple and cost-effective.

Tip: Because AODD pumps don’t require electricity, they're portable.

6. AODD PUMPS HAVE A COFFEE INITIAL PRICE

In most cases, AODD pumps cost significantly but other positive displacement pump styles (like lobe, gear or progressive cavity). They also don't require expensive motors, controls or the necessity for expert installation.

When you consider the reliability and flexibility of AODD pumps make them a trusted workhorse of the industry, they're a bargain compared to other technologies.

7. AODD PUMPS ARE SELF-PRIMING

Unlike other pumping technologies, AODD pumps are self-priming and don't require positive inlet pressure (NPSHA) to prime.

They can pull a suction lift of up to 32 feet (9.8 meters) or be placed on the ground next to a tank and operate well with no inlet pressure or positive inlet pressure up to 10 feet (3 meters). If the inlet pressure is over 10 feet, consult the factory for guidance.

8. AODD PUMPS ARE OFTEN SUBMERSIBLE

If you're employed within the mining, wastewater, oil/gas or marine industries, you recognize the worth of pumps which it might be impossible to try to your job without them.

AODD pumps are often submerged completely and safely with no performance issues if:

The pump’s materials are compatible with the encompassing fluid the air exhaust port is above the liquid level so fluid doesn't enter the pump via the air exhaust

Tip: Because AODD pumps can pull suction lift, many users prefer to place the pumps above the liquid.

9. AODD PUMPS HAVE A SEALLESS DESIGN

AODD pumps don't use or require expensive mechanical seals to work. Instead, reciprocating elastomeric diaphragms and valve checks pull a product into the pump then push it out, causing a pumping motion.

This concept is extremely forgiving and really cost-effective.

10. AODD PUMPS HAVE VARIABLE FLOW AND HEAD PRESSURES WITHOUT SOPHISTICATED CONTROLS

With flow rates of up to 280 gpm (1,060 lpm), AODD pumps provide a good range of flows without costly, sophisticated controls. Standard 1:1 ratio AODD pumps can produce pressures up to 125 psi (8.6 bars).

Other ratios, like 2:1 high-pressure units which will produce pressures up to 240 psi (16.5 bar), are available. High-pressure units are usually utilized in applications requiring greater force, like injecting into a pressurized line.

11. AODD PUMPS HAVE EXCELLENT CHEMICAL AND TEMPERATURE RESISTANCE

AODD pumps are often manufactured out of a good range of materials in order that they can handle almost any fluid. Many pumps are offered with wetted component materials made up of chrome steel, Alloy C, cast iron, aluminium, polypropylene, PVDF and acetal. They will be fitted with FKM, PTFE, EPDM, Santoprene and nitrile materials so you'll select a unit that meets your chemical needs.

From a temperature standpoint, AODD pumps can easily handle heat up to 220 degrees Fahrenheit (104 degrees Celsius) and possibly beyond. They will also handle cold temperatures. When going over 220 degrees Fahrenheit (104 degrees Celsius) or below the melting point, consult the factory for guidance.

Tip: Reputable manufacturers will offer a chemical resistance guide to form sure you get the proper pump for your needs.

12. AODD PUMPS CAN HANDLE A GOOD VISCOSITY RANGE

AODD pumps can handle almost any fluid which will flow up to 90,000 cSt (415,500 SSU) and may be specifically fitted to realize even more.

Using weighted valve balls and oversizing the pump will help when pumping very viscous products. Gravity-feeding the merchandise into the pump is additionally ideal.

13. AODD PUMPS ARE EASY TO CLEAN/SANITIZE

AODD pumps are simple to disassemble and clean. Some can undergo a clean-in-place (CIP) process where the pumps are often flushed and sanitized without being disassembled.

14. AODD PUMPS MEET REQUIRED CERTIFICATION STANDARDS

AODD pumps can accompany a good range of certifications and standards to satisfy the requirements of users across the world. Some common certifications are:

• 3-A

• EHEDG

• CE

• UL Listed

• ATEX

• FDA Compliant

• 1935/2004 Food Contact Materials Standard

• EAC

• ABS Marine

• ISO 9001

• ISO 14001

15. AODD PUMPS ARE PORTABLE

Depending on the pump size and material, they will be lightweight and moved easily. Some plant manager’s cart-mount pumps for straightforward mobility and application versatility.

16. AODD PUMPS ARE EASY to put in

AODD pumps don't have to be laser-aligned and don't require complex controls to work effectively—they simply need air supply to power the pump. The pump is often controlled with a valve on the fluid discharge or by controlling the air coming into the pump. Accessories, like filter/regulator units, are affordable and straightforward to feature to the pump.

There are so many best diaphragm pump manufacturers available in India.

#AODD Pump#Diaphragm Pump Manufacturers#Aodd Pump Manufacturers in India#Air Operated Double Diaphragm Pump#Peristaltic Pump#Hose Pump

0 notes

Text

Valves

We are the dealers, distributors, and stockists of all types of Domestic and Industrial valves.

We are multibrand one-stop solutions for your Industrial Valves: AUDCO, L&T, SANT, LEADER, ZOLOTO, WJ, NETA, DRP, VEESON, KALPANA, KIRLOSKAR, KARTAR ETC.

Valves Dealer -Distributors -Stockist -U.K & Sons

We have full range of valves for all types of Industries

We have IBR and NON-IBR Valves for Oil, Gas, Petrochemical, Sugar, Cement Industries.

Valve and types

Water Line, Water Treatment Plants, HVAC, Firefighting we have ISI and NON- ISI Valve, in Cast Iron, Gun Metal, Brass, Bronze, and in Stainless Steel

For High Temperature Industries we have Forged Steel, Cast Steel Valves

ITEM

TYPE

DESCRIPTION & MATERIAL OF CONSTRUCTION (MOC)

GATE VALVE

Hand Wheel Operated Gate Valves

Features

Wedge: Gate valves can be provided with a solid wedge or flexible wedge or on special request of the customer.

End Detail: Screwed ( BSP threads and NPT Threads), Socket-Weld and Flange-Ends

Flange-end gates valves are suitable for BS10 Table-D / Table E / TableF Table H and as per ASA Class 150 / Class 300 / Class 600 / Class 900 or on customer demand. We can also supply male-female flanges.

Functions: Valve can be supplied with a manually operated lever, Pneumatic actuator, limit switch or electric actuator.

Special Arrangements: We can supply valves with the by-pass arrangement, flow indicator and in rising stem.

Seal: Graphite asbestos, lubricated asbestos, gland packing or as requested by customer.

Other Specifications: All companies have different manufacturing, dimension, and technical data, we request to go through these specifications before ordering as these data keep changing due to continuous research and development.

Gear Operated Gate valves

Features

Wedge: Gate valves can be provided with a solid wedge or flexible wedge or on special request of the customer.

End Detail: Screwed ( BSP threads and NPT Threads), Socket-Weld and Flange-Ends

Flange-end gates valves are suitable for BS10 Table-D, E, F, H and as per ASA Class 150, 300, 600, 900 or on customer demand. We can also supply male-female flanges.

Functions: Valve can be supplied with a manually operated lever, Pneumatic actuator, limit switch or electric actuator.

Special Arrangements: We can supply valves with the by-pass arrangement, flow indicator and in rising stem.

Seal: Graphite asbestos, lubricated asbestos, gland packing or as requested by customer.

Other Specifications: All companies have different manufacturing, dimension, and technical data, we request to go through these specifications before ordering as these data keep changing due to continuous research and development.

GLOBE VALVE

Hand Wheel Operated Globe Valves

Features

Globe valves - Cast Steel Outside Screw & Yoke Type

Globe valves - Bronze

Globe valves - Gun Metal

Globe valves - Forged Steel

Globe valves - Stainless Steel

Globe valves - Cast Iron Outside Screw & Yoke Type

Globe valves - bolted bonnet

Globe valves - Screwed in bonnet

Globe valves - Rising Stem

Globe valves - Screwed

Globe valves - Flanged as per BS10 Table D / Table E / Table F / Table H / and as per ASA Class 150 / Class 300 / Class 600 / Class 900.

Globe valves - IBR / Non IBR

Functions: Valve can be supplied with a manually operated lever / Pneumatic actuator / limit switch / electric actuator.

Globe valves - Marine Industries

Gear Operated Globe Valve

Features

Globe valves - Bronze

Globe valves - Gun Metal

Globe valves - Forged Steel

Globe valves - Stainless Steel

Globe valves - Cast Iron Outside Screw & Yoke Type

Globe valves - bolted bonnet

Globe valves - Screwed in bonnet

Globe valves - Rising Stem

Globe valves - Screwed

Globe valves - Flanged as per BS10 Table D / Table E / Table F / Table H / and as per ASA Class 150 / Class 300 / Class 600 / Class 900.

Globe valves - IBR / Non IBR

Functions: Valve can be supplied with a manually operated lever / Pneumatic actuator / limit switch / electric actuator.

Globe valves - Marine Industries

CHECK VALVE

Swing Check Valve

Features

Check Valves - Gun Metal

Check Valves - Brass

Check Valves - Bronze

Check Valves - Cast Iron

Check Valves - Forged Steel

Check Valves - Cast Steel

Check Valves - Investment Casting

Check Valves - Stainless Steel 304, 304l, 316

Check valves - swing type reflux valve

Check valves - Non Return Valve flap type

Check valves - wafer type NRV

Check valves - Spring type dual plate type

Check valves - non slam

Type of Pattern - Straight type, Right Angle Pattern

Type of Inlet - Straight Inlet, Right Angle Inlet

Type of Seat - Renewable Seat

Type of Disc - Renewable Disc

Trim Detail - SS 410

Gland Packing - Graphited Asbestos, Lubricated Asbestos

End Details - Screwed ( BSP Threads, NPT Threads), Socket-weld, Flange-end as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Flanged Detail - Flat Face / Raised Face / Male- Female Type.

Standard - ISI / Non-ISI / IBR / Non-IBR

Check valves - Single plate flap type

Lift Type Check Valve

Features

Non Return Valves - Gun Metal

Non Return Valves - Brass

Non Return Valves - Bronze

Non Return Valves - Cast Iron

Non Return Valves - Forged Steel

Non Return Valves - Cast Steel

Non Return Valves - Investment Casting

Non Return Valves - Stainless Steel 304 / 304l / 316,

Non Return Valves - steel bolted cover swing type

Non Return Valves - steel pressure seal cover swing type

Non Return Valves - wafer

Non Return Valves - dual plate

Non Return Valves - non slam

Non Return Valves - flap type

Type of Pattern - Straight type / Right Angle type

Type of Inlet - Verticle / Horizontal / Angle / curved Inlet

Type of Seat - Renewable Seat

Type of Disc - Renewable Disc

Trim Detail - SS 410

Gland Packing - Graphited Asbestos / Lubricated Asbestos

End Details - Screwed ( BSP Threads, NPT Threads), Socket-weld / Flange-end as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Flanged Detail - Flat Face / Raised Face / Male- Female Type.

Standard - ISI / Non-ISI / IBR / Non-IBR

Single Plate Wafer Check Valve

Features

NRV - single plate swing check vale

NRV - swing type

NRV - Flangeless wafer type

NRV - flap type

Type of Pattern - Staright type

Inlet - Verticle / Horizontal

Body Detail - Dusctile Iron / SS 304 / SS 316 / Carbon Steel / Mild Steel

Type of Seat - EPDM/ Nitrile / Natural Rubber /Renewable Seat

Type of Disc - Carbon Steel + Ni Plate

Trim Detail - SS 410

Gland Packing - Graphited Asbestos, Lubricated Asbestos

End Details - Suitable for Flange as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Standard - ISI / Non-ISI / PN 10 / PN 16 / IBR / Non-IBR

Daul Plate Wafer Check Valve

Features

Reflux Valves - Double Plate swing type

Reflux Valves - Dual Plate Check Valves

Reflux Valves - Dual Plate wafer check valve

Reflux Valves - dual plate

Reflux Valves - wafer type spring loaded dual plate check valve

Reflux Valves - Dual flap type check valves

Body Detail - Dusctile Iron / SS 304 / SS 316 / Carbon Steel / Mild Steel / Cast Iron IS 210 Gr FG 200

Type of Seat - EPDM/ Nitrile / Natural Rubber /Renewable Seat

Type of Disc - Carbon Steel + Ni Plate / SS 304 /CF8 / SS 316 / CF8M

Trim Detail - SS 410

Spring and Pin- SS 304 (CF8M)

Gland Packing - Graphited Asbestos, Lubricated Asbestos

End Details - Suitable for Flange as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Standard - PN 10/ PN16 / PN25 / Class 125 / Class 150 / Class 300 / Class 600

BALL VALVE

2Piece Ball Valves

Features

Ball valves: Standard Bore / Full Bore

Ball Valve - Gun Metal

Ball Valve - Brass

Ball Valve - Bronze

Ball Valve - Cast Iron

Ball Valve - Forged Steel

Ball Valve - Cast Steel

Ball Valve - Investment Casting

Ball Valve - Stainless Steel 304 / 304l / 316,

Type of Pattern - Lever Operated / Gear Operated/ Electric Actuaotor / Pneumatic Operated / Limit Switch

Type of Inlet - Screwed / Socket-weld/ Flangend

Type of Seat - Renewable PTFE / Teflon / Carbon filled Seat

Type of Disc - Renewable Disc

Trim Detail - SS 410

Gland Packing - Graphited Asbestos / Lubricated Asbestos / teflon ring

End Details - Screwed ( BSP Threads, NPT Threads), Socket-weld / Flange-end as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Flanged Detail - Flat Face / Raised Face / Male- Female Type.

Standard - ISI / Non-ISI / IBR / Non-IBR

3 Piece Ball Valve

Features

Ball valves: Standard Bore / Full Bore

Ball Valve - Gun Metal

Ball Valve - Brass

Ball Valve - Bronze

Ball Valve - Cast Iron

Ball Valve - Forged Steel

Ball Valve - Cast Steel

Ball Valve - Investment Casting

Ball Valve - Stainless Steel 304 / 304l / 316,

Type of Pattern - Lever Operated / Gear Operated/ Electric Actuaotor / Pneumatic Operated / Limit Switch

Type of Inlet - Screwed / Socket-weld/ Flangend

Type of Seat - Renewable PTFE / Teflon / Carbon filled Seat

Type of Disc - Renewable Disc

Trim Detail - SS 410

Gland Packing - Graphited Asbestos / Lubricated Asbestos / teflon ring

End Details - Screwed ( BSP Threads, NPT Threads), Socket-weld / Flange-end as per BS 10 Table D / Table E / Table F / Table H and as Per ASA Class 150 / Class 300 / Class 600 / Class 900.

Flanged Detail - Flat Face / Raised Face / Male- Female Type.

Standard - ISI / Non-ISI / IBR / Non-IBR

BUTTERFLY VALVE

Wafer Type Butterfly Valve

Features

Butterfly Valve - SANT

Butterfly Valve - AUDCO

Butterfly Valve - C&R

Butterfly Valve - ZOLOTO

Butterfly Valve - L&T

Butterfly Valve - Leader

Butterfly Valve - KSB

Body Description - Cast Iron is 210 Gr FG-200 / Ductile Iron / SG Iron as per IS : 1865 / Stainless Steel CF 8 / Stainless Steel CF 8m

Pressure Rating - PN 10 / PN 16 / PN20 / PN25 / class 150 / class 300 / class 600 / class 900

Product Description - Wafer Type / flangeless butterfly valve

Type of Seat - Nitrile / EPDM / Natural Rubber / Renewable seat

Type of Disc - Cast Iron powder coated / SG Iron / SS 304 / CF8 / SS 316 /CF8M

Stem - Stainless Steel SS - 410 / SS 304 CF8 / SS 316 CF8M

End Details - Suitable for flange as BS 10 Table D / Table E / Table F / Table H and as per Class 150 / class 300 / class 600 / class 900

Type of Operation - Hand Lever / Gear Operated / Pneumatic Actuator / Limit switch / Electric Actuator

Lugged Type Butterfly Valve

Other Models :

Butterfly Valve - SANT

Butterfly Valve - AUDCO

Butterfly Valve - C&R

Butterfly Valve - ZOLOTO

Butterfly Valve - L&T

Butterfly Valve - Leader

Butterfly Valve - KSB

Body Description - Cast Iron is 210 Gr FG-200 / Ductile Iron / SG Iron as per IS : 1865 / Stainless Steel CF 8 / Stainless Steel CF 8m

Pressure Rating - PN 10 / PN 16 / PN20 / PN25 / class 150 / class 300 / class 600 / class 900

Product Description - Wafer Type / Sandwitch type butterfly valve

Type of Seat - Nitrile / EPDM / Natural Rubber / Renewable seat

Type of Disc - Cast Iron powder coated / SG Iron / SS 304 / CF8 / SS 316 /CF8M

Stem - Stainless Steel SS - 410 / SS 304 CF8 / SS 316 CF8M

End Details - Sandwitch type Suitable for flange as BS 10 Table D / Table E / Table F / Table H and as per Class 150 / class 300 / class 600 / class 900

Type of Operation - Hand Lever / Gear Operated / Pneumatic Actuator / Limit switch / Electric Actuator

STEAM TRAP

Inverted Bucket Type Steam Trap

Features :

Type of Pattern - Vertical

Body Material cum Standard - Cast Iron IBR 86 to 93 Gr.A

Description - Bolted cover

Trim - SS AISI304

End Details - Inlet Female BSP Parallel threads to BS 21.

Body / Bonnet -Cast Iron as per IBR 86 to 93 Gr.A

Syphon Pipe - Mild Steel

Bucket / other Trim Material - Stainless Steel AISI410 / 304

Gasket - Compressed Asbestos Fibre IS:2712 Gr.C

Fasteners - Mild Steel

TD-3

Thermodynamic Steam Strap Valve

Features

Type of Body - Bronze IBR 282(a)(iv) Gr.B / Forged Stainless Steel FSS (AISI410)

Type of Seat - Renewable seat Stainless Steel AISI410

Type of Disc - Renewable disc Stainless Steel AISI410

Type of Cover - Stainless Steel AISI410

Type of Strainer - Stainless Steel AISI304

Type of Trim - SS AISI410

End Details : Screwed Female BSP Taper Threads to BS 21 / Socket Welded Ends as per ASME B-16.11

Pressure Testing - Hydraulic Test Pressure - 500 Psig.Hyd.

Steam Test Pressure - 250 Psig.Hyd.

Maximum Working Pressure - Max.BOP 250 Psig.(17.58Kg/cm²) at 435°F (225°C)

STRAINER

"Y" Type Strainer

Features

Such types of strainers are named after their shape and are usually used for filtration of any type of Fluid and Oil.

Product Description - Y Strainer / Y Type Strainer / Y shape Strainer

Type of Body - Mils Steel, Cast Iron, SG Iron, Cast Steel, Stainless Steel

Type of Mesh - SS 304 / SS 316 / CF8 / CF8M

Drain Plug - Bronze / SS / IBR 282(a)(iv) Gr.B / AISI410 / NON IBR

Gasket - Compressed Asbestos Fibre / teflon / nitrile

Type of End - Threaded as per BSP / NPT / Socket Weld / Flanged ends as Per Table D / Table E / Table F / Table H / class 150 / class 300/ class 600 / class 900

Type of Mesh hole - Diamond / round / square or as per customer demand

Mesh Size - SS 304 Screen having 1.2 mm dia perforation / as per standard of various companies / custom perforation can be ordered as per the usage

Application - Water / oil / steam

Product Design - Standard / Custom fabrication on order as per customer demand

"T" Type Strainer

Features

Such types of strainers are named after their shape and are usually used for filtration of any type of Fluid / Oil / Steam /Gas.

Product Description - T strainer / T Type Strainer / T Filter

Type of Body - Mils Steel, Cast Iron, SG Iron, Cast Steel, Stainless Steel

Type of Mesh - SS 304 / SS 316 / CF8 / CF8M

Drain Plug - Bronze / SS / IBR 282(a)(iv) Gr.B / AISI410 / NON IBR

Gasket - Compressed Asbestos Fibre / teflon / nitrile

Type of End - Flanged ends as Per Table D / Table E / Table F / Table H / class 150 / class 300/ class 600 / class 900

Type of Mesh hole - Diamond / round / square or as per customer demand

Mesh Size - SS 304 Screen having 1.2 mm dia perforation / as per standard of various companies / custom perforation can be ordered as per the usage

Application - Water / oil / steam

Product Design - Standard / Custom fabrication on order as per customer demand

Sluice Valve

Rising Spindle/Non-Rising Spindle

Special Features :

Product Description - Solid Wedge Gate Sluice Valve / CI Sluive Valve / Sluice Valve / Wedge Gate valve

Type of Body - Cast Iron IS 210 Gr FG 200

Product standard - IS 14846 / Non ISI /ISI

Pressure Rating - PN 10 / PN 16

Stem - Rising / Non Rising Stem

Bonnet - Bolted Bonnet - Inside Screw / Bolted Bonnet - Outside Screw & Yoke Type Rising Stem

Type of Seat - Renewable seat

Type of Disc - Solid wedge

Trim - Cu-Alloy Rings, stem SS (12 Cr.12)

Gland Packing - Jute & Hemp / Rubber

End Details - Flanges as per IS:1538 FF drilled

Cap / Gland / Bonnet / Thrust Plate / Body /

Wedge / Handwheel / -Cast Iron

Screw / Bolts / Nuts - Carbon Steel /Stainless Steel AISI 410

Body Seat / Wedge Ring / Wedge Nut - Leaded Tin Bronze

Gasket - Rubber / compressed Asbestos Fiber /

Handwheel Nut / Yoke Sleeve Nut / Stem /

Gland / Back Seat Bush - SS AISI410 / Gun Metal

Yoke Sleeve - Aluminium Bronze

Type of arrangment - Hand Lever / gear operated / pneumatic actuator / limit switch

Pressure Reducing Valve

Pilot Operated R Type Reducing Valve

Features

Product Description - Cast Iron Pilot-Operated Pressure Reducing Valve / PRV /Pressure Reducing Valve / Bronze Pressure Reducing Valve

Type of Pattern - Straight Type

Type of Body Material - Cast Iron IBR 86 to 93 Gr.A / Bronze IBR 282(a)(iv) Gr.B

Definition - Pilot operated R-type Outlet pressure range available 5/60 psig / 20/80 psig / 40/125 psig / Spring Loaded outlet pressure range available 5/60 psig, 20/80 psig, 40/125 Psig

Type of Trim - SS AISI410 / Monel

End Details - Flanges as per BS 10 Table F / Screwed female BSP Taper threads to BS 21.

Body, Bonnet, Bottom Cover, Spring Discs - Cast Iron

Diaphragm Cover, Adjusting Screw, Plugs,

Ring Guide - Bronze as per IBR 282(a)(IV) Gr.B

Diaphragm - Stainless Steel AISI304

Spring - Spring Steel as per IBR 307 to 314

Nipples / Pilot Valve - Stainless Steel as per AISI410

Gasket - Compressed Asbestos Fibre as per IS:2712 Gr.C

Piston Rings - Manganese Bronze

Body Seat Ring / Main Valve / Liner - S.S. / Cast Monel as per AISI410 / Ni-Cu Alloy steel

Strainers - Brass / S.S. as per IS:410 / AISI304

Fasteners - Mild Steel

Cap - Aluminium Casting

Pressure Adjusting Screw / Tommy Bar / Fastener - Mild Steel

Read the full article

#valves#butterflyvalves#globevalves#ballvalves#sluicevalves#plugvalves#gatevalves#nrv#checkvalve#pressurereducingvalves

0 notes