#Millwork Manufacturer

Text

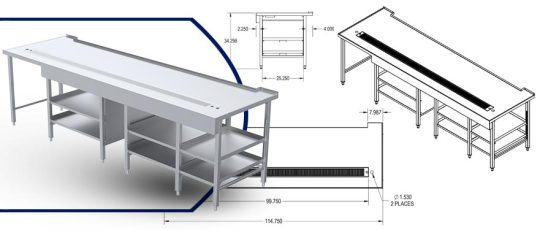

A furniture manufacturer, specializing in commercial kitchen furniture made of stainless steel partnered with Hitech CADD Services to develop millwork CAD drawings. A team of millwork engineers delivered detailed shop drawings that streamlined processing of all manufacturing orders and reduced overall design cycle time by 50%.

#millwork#millwork drafting#furniture manufacturer#millwork cad drawings#shop drawings#furniture#manufacturing

2 notes

·

View notes

Text

Manufacturing Software (MES) for Metal Fabrication, Millwork and Furniture

HitechDigital provides manufacturing software MES solutions that help streamline production process for metal Fabrication, millwork and furniture manufacturers.

0 notes

Text

General contractor

Website: https://www.bigbeams.com

Address: 1913A NW 40th Ct, Pompano Beach, FL 33064

Phone: +1 (954) 532-0262

Post & Beam is a supplier and installer for exterior millwork products, heavy timbers, and specialty wood applications. We maintain a high production millwork facility in Boynton Beach supported by the best carpenters in the industry.

Our millwork facility has an impressive array of specialty tools designed specifically for heavy timber work; articulating band saws, flitched beam mortise chain saws, heavy duty planers, sanders and specialty hand tools. We offer specialized skill, experience and equipment designed to handle heavy timbers and deliver efficient, high-end workmanship.

Our team has handled some of the most recognized commercial timber structures as well as an array of residential products for some of the most expensive real estate in South Florida.

We’ve become a one stop shop for assisting designers to create and engineer unique heavy timber structures and applications.

#Trim Carpentry#Finish Carpentry#Lifeguard tower#Heavy Timber Construction#Timber structures#Professional Carpenters#Exterior millwork#Miami lifeguard towers#Trim Carpentry Florida#Heavy Timber Manufacturing#trim carpentry supplier#finish carpentry contractors#trim carpentry supplier near me#trim carpentry near me#finish carpentry near me#professional carpenters near me#heavy timber manufacturing company#Trim Carpentry in Pompano Beach#Finish Carpentry in Pompano Beach#Lifeguard tower in Pompano Beach

1 note

·

View note

Text

Elevate Your New York Home: Transforming Spaces with Custom Cabinetry

What Is Custom Cabinetry?

Custom cabinetry is the pinnacle of precision, providing a truly one-of-a-kind solution for your home. Custom cabinetry ensures that no space is wasted or underutilized. Skilled craftsmen measure and design cabinets to fit seamlessly within your specific room dimensions, even accommodating difficult layouts.

Tailored Beauty and Style for Every Room!

Customized cabinetry is an art form that elevates the aesthetics of your home beyond basic functionality. Custom cabinetry provides individualized elegance and flair for every space, from the kitchen to the bathroom, the living room to the bedroom. Immerse yourself in a world of beautiful materials, delicate details, and one-of-a-kind finishes as you create an elegant and sophisticated space.

Maximize Storage Efficiency!

Personalized Storage for Everyday Life:

Living in the vibrant city of New York frequently means dealing with limited space. Custom built cabinets come to the rescue by optimising storage efficiency and generating inventive space solutions. Say goodbye to clutter and welcome to a well-organized and productive home, as custom cabinetry maximises every inch of available space by incorporating ingenious storage features, specialised sections, and customizable organisers.

Well Built, Durable and Value for Money!

Uncompromising Quality Materials and Construction:

Custom cabinetry is designed to last a lifetime. Skilled craftsmen use high-quality materials to ensure the greatest levels of durability and lifetime. Every component, from solid hardwoods to top-grade veneers, is carefully selected and expertly manufactured to provide a great product that withstands daily usage and preserves its beauty for years to come.

Boosting Property Value and Market Appeal:

Choosing custom cabinets is an investment in the value of your property. Exquisite craftsmanship, personalised design, and exceptional functionality improve not just your daily living experience but also the desirability and market appeal of your property. Custom cabinetry provides a strong selling factor when it comes time to sell, appealing potential buyers with its unique charm and tailored features.

The Right Choice for Long-Term Happiness

With custom cabinetry's transforming potential, elevate your New York home. Custom cabinetry brings your vision to life and creates a house that is both functional and exciting, from boosting aesthetics and maximising storage efficiency to exhibiting professional craftsmanship and allowing personalisation. Embrace the beauty of custom cabinetry as it transforms your living spaces and feel the difference it makes.

Furniture Design Knossos, Inc.

2430 Brooklyn Queens Expy W, Queens, NY 11377, United States

+1 718-729-0404

2 notes

·

View notes

Text

What is strapping material and types of strapping material?

Strapping is securing and bundling packages and loads for storage and shipment. Different types of strapping materials are used to secure these cartons and other items. Various types of strapping materials are available in the market for different strapping and packaging needs. The strapping materials are made using different polymers, steel, and composite materials according to the need and demand. One should connect with the PET or PP Strap manufacturers in India according to their needs.

You will find strapping materials of various lengths, widths, and thicknesses to cater to different applications. The flexibility and tensile strength of the strapping materials also vary. All these qualities of strapping materials help in securely bundling several types of loads. Before buying the strapping materials from PP or PET Strap manufacturers in India, ask them about these qualities. Some of the most common applications of strapping materials are securing building or construction materials, securing products during shipping and transportation, securing finished goods for storage and supply, securing items at warehouses, and a few others.

Now that you know what strapping materials are and where they can be used, let’s know their types. After knowing the types of strapping material, you can choose the right strapping material for several applications. It will help you know which strapping material is used for which purpose, so let’s discover them.

Types of Strapping Materials

This blog shares the most common types of strapping materials used for multiple applications. They are:

Polypropylene Strap or PP Strap

Polyester Strap or PET Strap

Steel Strap

These three strapping materials are available with most PP strap manufacturers in India.

Polypropylene Strapping (PP Strap)

PP Strap is one of the most widely used straps for various applications. For applications that require light or medium strapping strength, polypropylene strapping is best for them. It is available in varied thicknesses, tensile strengths, widths, and colours. PP Straps are light in weight, making them suitable for bundling and sealing loads that are light in weight. They have several properties, like corrosion resistance, no deformation, and breaking strength. These qualities of PP Straps make them the perfect strapping material for holding products and items for a long time. Polypropylene Strapping material is mainly used in several applications like postal service, bailing hay, flooring, millwork, merchandise foods, and packing of frozen foods & meats.

Polyester Strapping (PET Strap)

PET Strap is the most common and highly durable strapping material among the multiple strapping materials. It is considered the best alternative to steel strapping because it is one of the strongest strapping materials with high tension. It is used to handle medium or heavy loads due to its several properties. It comes with several properties, like being resistant to UV rays, resistant to shocks, resistant to high temperatures, lightweight, and excellent stretch recovery.

Most PET straps are available in green colour as they are made using plastic bottles. But they are available in other colours too. You can ask the PET Strap manufacturers in India if they offer customized straps or not to get the desired colour. Most often, the PET straps are made using recycled materials only. Industries also use Polyester strapping because of their impact absorbing quality during the shipment. Some uses of polyester strapping material are in stabilizing heavy loads, palletizing heavy loads, and handling metals, bricks, tiles, pallets of bottles, and cans.

Steel Strap

It is one of those strapping materials used for a long time. We currently have several alternatives to steel strapping available in the market. Steel straps are mainly used for heavy loads or loads that require less stretching but high strength. Due to the zero stretchability, steel straps offer high tension, which is suitable for heavy materials. Like the above two strapping materials, steel straps are also available in different sizes, thicknesses, and widths. They come with different finishes like zinc-coated, glued, galvanized, and painted. Steel strapping is mainly used for several heavy-duty applications, like bundling metals, construction materials, securing metal containers, steel coins, railroad shipping, and packaging other heavy industrial equipment.

All these three strapping materials are widely used for packaging or bundling loads and items. If you need any of these strapping materials, go for OM Pack Strap. Being one of the best PET strap manufacturers in India, they offer heavy-duty, reliable pack straps at reasonable prices for several applications.

#PP Transparent Box Strapping#White Strap Roll#PP Strap Manufacturers in India#PET Strap Manufacturers in India#PP Box Strap Virgin

2 notes

·

View notes

Text

How to Dominate the Industry with Millwork Drafting Services from Synnoptech Cad Solutions

Synnoptech Cad Solutions emerges as a leading provider of millwork drafting services, offering comprehensive solutions tailored to meet the unique needs of each client.

Introduction to Millwork Drafting Services

Millwork drafting involves the creation of detailed technical drawings and plans for millwork components such as cabinets, moldings, doors, and windows. These drawings serve as blueprints for manufacturers, guiding them in the fabrication process. Synnoptech Cad Solutions specializes in providing high-quality millwork drafting services, assisting clients in bringing their design visions to life.

What are Millwork Drafting Services?

Millwork drafting services encompass the creation of precise and detailed drawings that outline the dimensions, materials, and specifications of millwork components. These drawings serve as a roadmap for manufacturers, ensuring that each piece is fabricated accurately to meet the client's requirements.

The utilization of millwork drafting services offers several benefits to clients, including:

Precision and accuracy: Millwork drawings created by experienced drafters ensure that each component is fabricated to exact specifications.

Time and cost-effectiveness: Efficient drafting processes help streamline production, reducing both time and costs associated with fabrication.

Customization and flexibility: Clients have the flexibility to customize their millwork designs according to their preferences and project requirements.

Synnoptech Cad Solutions: An Overview

Synnoptech Cad Solutions is a leading provider of millwork drafting services, offering a wide range of solutions to clients across various industries. With years of experience and a team of skilled drafters, Synnoptech Cad Solutions has established a reputation for delivering high-quality drafting services tailored to meet the unique needs of each client.

Why Choose Synnoptech Cad Solutions for Millwork Drafting?

Several factors set Synnoptech Cad Solutions apart as the preferred choice for millwork drafting services, including:

Cutting-edge technology and software: Synnoptech Cad Solutions utilizes the latest CAD software and technology to create precise and detailed millwork drawings.

Experienced and skilled team: The team at Synnoptech Cad Solutions comprises experienced drafters with extensive knowledge and expertise in millwork drafting.

Commitment to quality and deadlines: Synnoptech Cad Solutions is committed to delivering high-quality drafting services within the stipulated deadlines, ensuring client satisfaction.

Initial consultation and project assessment: Synnoptech Cad Solutions conducts a thorough assessment of the client's requirements and project scope.

Design conceptualization and development: The drafting team collaborates with the client to conceptualize and develop the millwork design.

Drafting and revisions: Detailed millwork drawings are created, and revisions are made as per client feedback and requirements.

Finalization and delivery: Once the drawings are finalized, they are delivered to the client in the required format.

Future Trends in Millwork Drafting Services

The future of millwork drafting services is marked by advancements in technology, including the integration of automation and AI. Synnoptech Cad Solutions remains at the forefront of these trends, leveraging innovative solutions to enhance efficiency and quality in drafting processes.

For More Information

https://www.synnoptechcad.com/

+91-9924 333 633

Adress- D-810, Titanium Business Park, Behind Divya Bhaskar Press, Off Prahladnagar Road, Prahladnagar, Ahmedabad – 380015 SEND AN INQUIRY

Street - Eglinton Avenue, Toronto, ON - M4P 1A6

Related Topic: https://synnop.blogspot.com/2024/04/how-to-dominate-industry-with-millwork.html https://qr.ae/psAGHU

#millwork drafting#millwork shop drawings services#shop drawings services company#Millwork drafting services

0 notes

Text

The Evolution of Panel Saw CNC Machines

Introduction:

In the realm of woodworking and industrial manufacturing, precision, efficiency, and versatility are paramount. Over the years, the integration of Computer Numerical Control (CNC) technology has revolutionized various manufacturing processes, including woodworking. One significant advancement in this domain is the Panel Saw CNC machine. These machines have not only simplified the process of cutting large panels but have also ushered in a new era of precision and productivity in the woodworking industry.

Understanding Panel Saw CNC Machines:

Panel Saw CNC machines are sophisticated pieces of equipment designed for precise and efficient cutting of large panels such as plywood, particleboard, MDF (Medium-Density Fiberboard), and other engineered wood products. These machines utilize CNC technology, which involves the automation of cutting processes based on digital designs and instructions.

Key Features and Components:

Panel Saw CNC machines come equipped with several essential features and components to ensure accurate and efficient operation:

Cutting Head: The cutting head of a Panel Saw CNC machine holds the cutting tool, which could be a circular saw blade, a router, or a combination of both. These cutting tools are capable of making various cuts, including rip cuts, cross cuts, and angled cuts, depending on the requirements of the project.

CNC Control System: At the heart of every Panel Saw CNC machine lies its control system, comprising software and hardware components. The CNC software interprets digital design files (such as CAD drawings) and translates them into precise cutting instructions. Operators can input parameters such as cutting dimensions, tool paths, and cutting speeds through user-friendly interfaces.

Precision Drive Mechanism: To ensure accuracy in cutting, Panel Saw CNC machines are equipped with precision drive mechanisms. These mechanisms control the movement of the cutting head along the X, Y, and Z axes with high precision, allowing for intricate cuts and tight tolerances.

Material Handling System: Many Panel Saw CNC machines feature integrated material handling systems to streamline the loading and unloading of large panels. These systems can automatically feed panels into the cutting area and remove finished pieces, reducing manual labor and increasing efficiency.

Benefits of Panel Saw CNC Machines:

The adoption of Panel Saw CNC machines offers numerous benefits to woodworking businesses and manufacturers:

Precision: CNC technology ensures consistent and precise cuts, resulting in high-quality finished products with tight tolerances and minimal waste.

Efficiency: By automating the cutting process, Panel Saw CNC machines significantly reduce production times compared to manual methods. This increased efficiency translates to higher productivity and lower labor costs.

Versatility: Panel Saw CNC machines can handle a wide range of panel materials and cutting tasks, making them suitable for diverse woodworking applications, from cabinet making to furniture manufacturing.

Scalability: With the ability to process large volumes of panels quickly and accurately, Panel Saw CNC machines enable woodworking businesses to scale their production capacity to meet growing demand.

Applications:

Panel Saw CNC machines find applications across various industries and woodworking sectors, including:

Cabinet Making: Precisely cut panels for constructing cabinets, shelves, and other storage solutions.

Furniture Manufacturing: Produce components such as tabletops, side panels, and drawer fronts with high precision and efficiency.

Architectural Millwork: Fabricate custom moldings, trim pieces, and architectural details for residential and commercial projects.

Sign Making: Create intricate designs and lettering on wood panels for signage and displays.

Conclusion:

Panel Saw CNC machines represent a significant advancement in the woodworking industry, combining the precision of CNC technology with the efficiency of panel cutting operations. By automating processes, enhancing precision, and increasing productivity, these machines empower woodworking businesses to deliver high-quality products while remaining competitive in today’s market. As technology continues to evolve, Panel Saw CNC machines are poised to play an increasingly integral role in modern woodworking and manufacturing processes.

0 notes

Text

Affordable Ways to Integrate Teak Wood Frames

Introduction

Teak wood brings a touch of elegance and warmth to any living space. As leading wooden door manufacturers in India, GSM Doors understand the allure of teak doors in Delhi and beyond. Not only do they exude natural beauty, but they also offer durability and strength that lasts for generations. Integrating teak into your home doesn't have to break the bank. In this blog, we'll explore affordable ways to incorporate these timeless pieces into your decor.

1. Enhance Your Entryway

The entryway sets the tone for your home's interior. Installing teak wood frames around your front door instantly elevates curb appeal and creates a welcoming atmosphere. Opt for a classic design with clean lines and rich hues to make a lasting impression. Teak doors in Delhi are renowned for their ability to withstand the elements, making them an ideal choice for outdoor use.

2. Upgrade Your Interior Doors

Interior doors play a crucial role in defining the aesthetic of each room. Replace plain, hollow-core doors with teak wood frames to add character and sophistication to your home. Whether you prefer traditional paneling or modern minimalist styles, there's a teak door design to suit every taste. Wooden door manufacturers in India offer a wide range of options to fit any budget, making it easy to upgrade your interior without breaking the bank.

3. Create Custom Furniture

Teak frames aren't just for doors – they can also be used to create custom furniture pieces that complement your decor. From bed frames and dining tables to bookshelves and cabinets, the possibilities are endless. Incorporating teak wood into your furniture adds natural beauty and timeless appeal to any room. Plus, teak's durability ensures that your investment will last for years to come, making it a cost-effective choice for budget-conscious homeowners.

4. Accentuate Architectural Features

Highlighting architectural features with teak frames adds visual interest and depth to your home's design. Whether it's framing windows, doorways, or built-in shelving units, teak wood adds a touch of luxury to any space. Opt for custom millwork to ensure a perfect fit and seamless integration with your existing decor. With its warm tones and natural grain patterns, teak wood enhances the beauty of any architectural element, creating a cohesive look throughout your home.

5. Incorporate Decorative Details

Small details can make a big impact when it comes to home design. Incorporate teak into decorative elements such as mirrors, picture frames, and wall art to add warmth and texture to your walls. These subtle touches tie the room together and create a cohesive look that showcases your attention to detail. Whether you prefer a rustic farmhouse aesthetic or a sleek modern vibe, teak wood accents add character and charm to any space.

Conclusion

In conclusion, integrating teak wood frames into your home doesn't have to be expensive. By focusing on key areas such as entryways, interior doors, furniture, architectural features, and decorative details, you can enhance your home's beauty and value without breaking the bank. As a leading wooden door manufacturer in India, GSM Doors is passionate about helping homeowners find affordable ways to incorporate teak wood into their decor. Contact us today to learn more about our wide range of teak doors and start transforming your home into a timeless sanctuary.

Also, read:

Why Teak Wood Doors are a Smart Choice?

Originally published at: https://gsmdoors.blogspot.com/2024/03/affordable-ways-to-integrate-teak-wood.html

0 notes

Text

Kolbe & Kolbe proposal to build workforce housing edges closer to reality

A Wausau business is one step closer to adding more than 100 housing units on the city's west side, after a Plan Commission meeting Wednesday.

Damakant Jayshi

A Wausau business is one step closer to adding more than 100 housing units on the city’s west side, after a Plan Commission meeting Wednesday.

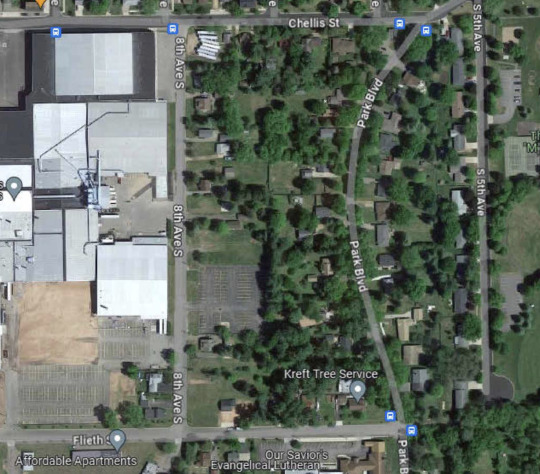

Kolbe & Kolbe Millwork Co. intends to build 108 multi-family housing units on company-owned property on the east side of 8th Avenue, just across the street from their main manufacturing plant.

Doing so requires changing the zoning from…

View On WordPress

0 notes

Text

Millwork shop drawings are detailed illustrations or diagrams that provide a comprehensive representation of custom millwork components for construction or manufacturing purposes.

0 notes

Text

Bentonville Arkansas Temple - Bentonville, Arkansas

by: @vcboarchitecture @cofjctemples

Exterior

O templo é uma estrutura de aço com exterior pré-moldado. O aço estrutural foi fabricado e instalado pela B&B Erectors de Dallas, Texas. O pré-moldado externo foi fabricado e instalado pela Gate Precast de Hillsboro, Texas.

O vidro artístico exterior foi projetado pelo Bovard Studio de Fairfield, Iowa, em conjunto com a VCBO Architecture. Holdman Studios de Lehi, Utah, fabricou o vidro artístico. Os principais designs do vidro artístico incluem a flor de dogwood, uma das primeiras flores da primavera na região. Sunbursts e desenhos de diamantes também são apresentados, reconhecendo o Arkansas como o lar da única mina de diamantes dos Estados Unidos. Os padrões vermelhos, amarelos e azuis lembram uma colcha, falando da herança americana da pequena cidade de Bentonville.

A principal árvore plantada no local é a árvore dogwood, junto com outras árvores e arbustos locais. A arquitetura paisagística foi fornecida pelo Ecological Design Group (EDG), localizado em Rogers, Arkansas. O empreiteiro paisagista é Superscapes of Carrollton, Texas.

Interior

Tapetes macios e dourados em tear largo projetados por Mannington Mills de Salem, Nova Jersey, são usados para áreas gerais e salas de instrução. Tapetes de lã de parede a parede projetados pela Rugs International of Georgia são usados nos quartos celestes, de selamento e de noivas. Os tapetes de área são renderizados em azuis, verdes, dourados e tons de rosa. A pedra geral usada para o piso é o mármore vagnelia extraído e fabricado na Turquia e instalado pela Peritia Stone de Waterloo, Iowa.

A pintura decorativa de interiores, projetada pela VCBO Architecture de Salt Lake City, Utah, apresenta tons suaves de azuis, verdes e dourados, com um toque de rosa para as flores de dogwood. Inclui vários padrões que lembram quilting e rendas para evocar a sensação americana de cidade pequena de Bentonville. A pintura decorativa foi feita pela Iconografia de Salt Lake City, Utah.

O vidro de arte interior foi projetado pelo Bovard Studio de Fairfield, Iowa, em conjunto com a VCBO Architecture e fabricado pela Holdman Studios. O vidro artístico interior é semelhante ao exterior, utilizando os mesmos padrões e cores.

As luminárias decorativas do templo são feitas de vidro, bronze e cristal. As luminárias de cristal foram projetadas por Schonbek (Swarovski) em Plattsburgh, Nova York, e as luminárias em todo o templo foram projetadas pela VCBO Architecture.

A incrustação decorativa de madeira repete os motivos de flor de dogwood, diamante e quilting encontrados em todo o templo. Millwork foi fabricado pela Masterpiece Millwork de Lindon, Utah.

As grades das fontes são postes verticais, uma reminiscência dos primeiros móveis americanos. Os materiais são bronze com acabamento em latão antigo e vidro. As grades foram fabricadas pela Smith Design and Manufacturing de Gunter, Texas.

As portas de entrada externas são de bronze com um painel central de vidro artístico e foram fabricadas por Ellison Bronze de Falconer, Nova York. As portas internas são de mogno e usam ferragens de bronze com acabamento em latão antigo. O motivo da flor dogwood também é usado aqui. A Masonite International de Tampa, Flórida, fabricou as portas, e as ferragens decorativas foram projetadas pela VCBO Architecture e fabricadas pela Luna Bronze de Heber City, Utah.

Os tetos foram construídos com placas de gesso, placas acústicas e gesso reforçado com fibra de vidro adicional. As molduras de coroa encontradas em todo o templo foram fabricadas pela Masterpiece Millwork. Todos os tetos foram projetados pela VCBO Architecture.

0 notes

Text

Home Window Replacement: Transforming Homes with Efficiency and Elegance

Improve the efficiency of your home with new house windows from Muhler. The perfect home window replacement can change the look and improve the efficiency of your home. If your house windows and doors are in poor condition and affecting your electricity bills each month, it may be time to consider replacements. If your Charleston house windows are older and showing signs of age, replacement windows are a great way to improve your home’s appearance. If your doors are in bad repair, that can significantly affect your home’s overall appearance. Are you looking to add more value to your home? This is all the more reason to purchase new house windows and doors.

A home isn’t a home without windows and doors. A door is more than just an entryway. Windows are more than a way to let in the fresh air. With the right style and color, your choice of home replacement windows and replacement doors can really make a bold statement. They can also add significant value to your home and are an excellent investment in window installation and custom window replacement in Charleston, Mount Pleasant, SC, and surrounding areas.

Muhler has it all when it comes to doors and windows. We have various doors (aluminium-clad bi-fold, custom entry, fiberglass) and house windows (custom-built, energy-efficient, impact-resistant, mahogany) to suit your needs. We also carry many of the best brands, such as Sierra Pacific, Jeld-Wen, Lepage Millwork, Bildau & Bussmann. Here are some of the available choices from Muhler’s windows and doors.

Type Of Home Window Replacement

VINYL WINDOWS: Vinyl windows can help protect your family and home in a storm. More importantly, purchasing vinyl windows will help strengthen your home's integrity. During a hurricane, impact windows are designed to remain intact even when cracked. Rather than glass shattering across the floor, impact windows will hold the shards of glass within the interlayer. We offer Vinyl windows from All American Window Company (AAWC), Jeld-Wen, PGT, Viwinco, and Sierra Pacific.

SIERRA PACIFIC WINDOWS: Sierra Pacific windows are made with high-quality, select woods that protect against moisture and insects. The finishes on these house windows have greater surface hardness, scratch resistance, and color retention. To improve energy efficiency and reduce seal failures, the insulated glass uses the revolutionary No-Metal TrueWarm® Edge polymer structural foam spacers.

JELD-WEN: Jeld-Wen is one of the largest windows manufacturers in the U.S. Jeld-Wen has an extensive portfolio of window options across styles such as awning, casement, single-hung, double-hung, bay, bow, and more. They also have various window frame material options, such as vinyl, aluminum, and wood. If you want to replace your windows and doors, look no further than Muhler.

Benefits of Home Window Replacement:

Energy Efficiency: One of the primary reasons homeowners opt for window replacement is to improve energy efficiency. Older windows may have single-pane glass or inefficient seals that allow heat transfer, leading to increased energy bills. Modern energy-efficient windows, equipped with double or triple-pane glass, low-emissivity coatings, and advanced framing materials, provide better insulation and reduce energy consumption, contributing to a more sustainable and cost-effective home.

Enhanced Comfort: Upgrading to new windows can significantly enhance the comfort levels within a home. Improved insulation keeps the cold air out during winters and prevents excessive heat from entering during summer. This results in a more consistent and comfortable indoor temperature, reducing the need for constant adjustments to your heating or cooling systems.

Aesthetic Appeal: Home window replacement offers an excellent opportunity to update a home's overall look and feel. New windows come in various styles, colors, and materials, allowing homeowners to choose options that complement their architectural style and personal preferences. The enhanced curb appeal adds value to the property and creates a positive impression on visitors.

Considerations for Home Window Replacement:

Window Styles and Materials: Before embarking on a window replacement project, it's crucial to consider the various window styles and materials available. Common window styles include double-hung, casement, sliding, and bay windows. Similarly, materials such as vinyl, wood, aluminum, and fiberglass each have their advantages and considerations. The choice should align with the homeowner's preferences, budget, and maintenance requirements.

Professional Installation: While some homeowners may attempt to replace windows as a DIY project, it is advisable to hire professionals for installation. Proper installation ensures the windows function optimally, provide a proper seal and offer the expected energy efficiency. Professional installers have the expertise and tools to handle the intricacies of window replacement, reducing the risk of issues like air leaks and water infiltration.

Energy Efficiency Ratings: When selecting replacement windows, homeowners should consider energy efficiency ratings, such as the U-factor and Solar Heat Gain Coefficient (SHGC). A lower U-factor indicates better insulation, while a lower SHGC value signifies reduced heat gain. Understanding these ratings helps homeowners make informed decisions based on the climate in their region and their specific energy-saving goals. For more information, visit us at https://www.muhler.com/windows-and-doors-replacementat s/

0 notes

Text

According to IMARC Group latest report titled “North America Secondary Wood Products Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2028”, offers a comprehensive analysis of the industry, which comprises insights on North America Secondary Wood Products market share. The report also includes competitor and regional analysis, and contemporary advancements in the market.

The North America secondary wood products market size reached US$ 216.9 Billion in 2022. Looking forward, IMARC Group expects the market to reach US$ 244.3 Billion by 2028, exhibiting a growth rate (CAGR) of 1.9% during 2023-2028.

Secondary wood products encompass a broad range of goods derived from the processing and transformation of primary wood materials. These products include furniture, cabinets, architectural millwork, and a variety of building materials such as doors, flooring, and moulding. The production of secondary wood products capitalizes on the durability and aesthetic versatility of wood, catering to both functional and design needs across residential and commercial spaces. A distinct advantage of these products is their contribution to sustainability; they often utilize wood that might otherwise be discarded, optimizing the use of forest resources. This industry plays a pivotal role in the economy by providing commodities essential to construction and interior design, supporting forestry management, and contributing to environmental stewardship through resourceful manufacturing practices.

Market Trends:

The North America secondary wood products market is majorly driven by the resurgence in construction and remodeling activities, particularly in the United States and Canada. Along with this, the growing consumer spending power and a shift towards sustainable and eco-friendly building materials are significantly supporting the market. In addition, technological advancements in wood processing have introduced greater efficiency and customization, allowing producers to cater to diverse consumer preferences and expanding the scope of applications for wood products.

Moreover, the emerging trend towards 'green' construction, with an increased emphasis on materials that contribute to healthier indoor air quality and have a lower carbon footprint, is favoring the market. Apart from this, trade policies and agreements within the region further support the market, facilitating smooth cross-border commerce of wood products and bolstering the industry's expansion. Furthermore, the adoption of innovative practices, such as the integration of smart technology in product design and the use of reclaimed wood, is creating a positive market outlook.

Competitive Landscape:

The competitive landscape of the market has been studied in the report with the detailed profiles of the key players operating in the market.

Ashley Furniture Industries

Steelcase

HNI Corporation

Herman Miller

Weyerhaeuser Company

North America Secondary Wood Products Market Segmentation:

Our report has categorized the market based on country and type.

Breakup by Country:

United States

Canada

Breakup by Type:

Wood Furniture

Office Furniture

Household & Institution

Wooden Kitchen, Cabinets and Countertops

Others

Engineered Wood Products

Plywood

OSB

Particle Board

Others

Secondary Paper Products

Paper Products

Paperboard Containers

Others

Key highlights of the report:

Market Performance (2017-2022)

Market Outlook (2023-2028)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major

market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

Americas:- +1 631 791 1145 | Africa and Europe:- +44-702-409-7331 | Asia: +91-120-433-0800, +91-120-433-0800

0 notes

Text

Get Expert Millwork Drafting Services | Boost Efficiency Today!

Need precise millwork drafting services? Our experts ensure accuracy & speed. Elevate your projects. Contact now! Millwork drafting services offer several benefits to architects, interior designers, contractors, and manufacturers. By outsourcing drafting tasks to experienced professionals, businesses can streamline their production workflows, reduce errors, and optimize material usage.

#architectural modelling services#bar and restaurant shop drawing services#photorealistic rendering services#millwork shop drawings services

0 notes

Text

Sustainable Luxury: The New Trend In Custom Furniture Design

Embracing Sustainability In Luxury Furniture

In the world of luxury custom furniture, a remarkable transformation is taking place. As environmental consciousness becomes paramount, discerning consumers are seeking out brands that deliver not only high-end design and quality but also demonstrate a commitment to eco-friendly practices. This shift is reshaping the luxury furniture market, infusing it with a refreshing sustainable ethos.

The Intersection Of Luxury And Sustainability

Luxury furniture has always been synonymous with superior quality and exquisite craftsmanship. Today, however, the definition has expanded to include sustainability. From sourcing materials responsibly to implementing energy-efficient manufacturing processes, luxury custom furniture brands are redefining 'luxury' by integrating sustainability into their ethos.

Materials Matter: Eco-Friendly Choices In Luxury Custom Furniture

The choice of materials plays a significant role in sustainable luxury furniture. Brands are increasingly opting for responsibly sourced woods, recycled metals, and eco-friendly fabrics. These materials don't just reduce environmental impact; they infuse each piece of custom wood furniture with a unique story, enhancing its appeal to the conscious consumer.

Craftsmanship That Respects The Environment

Sustainable luxury furniture isn't just about materials; it's also about how those materials are transformed into finished products. Custom furniture designers are leading the charge, leveraging energy-efficient manufacturing processes, and waste reduction initiatives, and championing local craftsmanship. They're doing more than creating beautiful pieces; they're respecting and preserving our environment.

The Consumer's Role In Sustainable Luxury

As consumers, our purchasing decisions can drive change. By choosing sustainable luxury furniture, we support brands that prioritize environmental stewardship, encouraging the industry as a whole to move towards more sustainable practices. Each piece of furniture isn't just a functional item; it's a statement of our commitment to preserving the planet.

The Benefits Of Sustainable Luxury Furniture

Choosing sustainable luxury furniture comes with a host of benefits. Firstly, it helps conserve our planet's resources by using materials that are responsibly sourced or recycled. Secondly, it supports local craftsmanship and promotes ethical labor practices. Thirdly, each piece of sustainable furniture carries a unique story of its origin and creation, adding a depth of meaning that goes beyond aesthetics. Lastly, it allows consumers to express their values through their purchasing choices, making a statement about their commitment to environmental preservation.

The Future Of Luxury Is Sustainable

The trend towards sustainable luxury furniture signals a significant evolution in the industry. It shows that it's possible to create stunning, high-quality pieces while also respecting our environment. As we move forward, sustainability is set to become an even more integral part of what defines 'luxury' in furniture design. True luxury considers not just the present, but the future as well.

This shift in the luxury furniture market stands as proof that luxury and sustainability can indeed go hand in hand, creating a new era of conscious consumerism that is here to stay. So next time you're seeking luxury custom furniture, remember - choosing sustainability doesn't mean compromising on style or quality. It simply means you're part of a change that's bigger than all of us.

Furniture Design Knossos, Inc.

Address: 2430 Brooklyn Queens Expy W, Queens, NY 11377, United States

Phone: +1 718-729-0404

0 notes

Text

Exploring the Cutting Edge: A Comprehensive Guide to CNC Machines

Introduction:

In the realm of manufacturing and engineering, the advent of Computer Numerical Control (CNC) machines has revolutionized the way industries produce parts and components. These machines, driven by computer programs, offer unparalleled precision, efficiency, and versatility. From automotive to aerospace, from furniture to medical devices, CNC machines have become indispensable tools in modern manufacturing processes. This article delves into the intricacies of CNC machines, exploring their functionalities, applications, and significance in today’s industrial landscape.

Understanding CNC Machines:

CNC machines are automated devices programmed to execute precise machining operations based on digital instructions. Unlike conventional manual machines, which require constant supervision and manual input, CNC machines operate autonomously once the program is initiated. These machines rely on Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to generate the necessary instructions for cutting, drilling, milling, or shaping raw materials such as metal, wood, plastic, and composites.

Types of CNC Machines:

CNC machines come in various types, each tailored to specific machining tasks and materials. Some of the commonly used CNC machines include:

CNC Milling Machines: Utilized for cutting and shaping solid materials, CNC milling machines employ rotary cutters to remove material from a workpiece. They are ideal for producing complex shapes and contours with high precision.

CNC Lathes: These machines rotate a workpiece on its axis while a cutting tool moves along the material to create symmetrical parts. CNC lathes are widely used in cylindrical machining operations and are capable of producing intricate designs with ease.

CNC Plasma Cutters: Designed for cutting through electrically conductive materials, such as steel and aluminum, CNC plasma cutters utilize a high-velocity jet of ionized gas to melt and sever the material.

CNC Laser Cutting Machines: Employing a focused laser beam to vaporize or melt materials, CNC laser cutting machines are adept at producing intricate cuts with minimal material wastage. They are commonly used in industries requiring high-precision cutting, such as electronics and signage.

CNC Routers: These machines are equipped with rotating cutting tools and are primarily used for shaping and engraving materials like wood, plastic, and foam. CNC routers find extensive applications in woodworking, cabinetry, and prototyping.

Applications of CNC Machines:

The versatility of CNC machines enables their deployment across a myriad of industries and applications. Some notable applications include:

Automotive Manufacturing: CNC machines play a pivotal role in producing precision components for vehicles, including engine parts, chassis components, and interior fittings.

Aerospace Industry: CNC machining is integral to aerospace manufacturing, facilitating the production of lightweight yet robust components for aircraft, satellites, and spacecraft.

Medical Device Fabrication: CNC machines are employed in crafting intricate medical devices and implants with utmost precision, ensuring compatibility and functionality.

Electronics Production: CNC machining is utilized in manufacturing circuit boards, casings, and intricate components for electronic devices, ensuring high-quality and consistency.

Architectural Millwork: In the construction and architectural industries, CNC machines are utilized for crafting custom moldings, decorative panels, and intricate woodwork.

Significance of CNC Machines:

The adoption of CNC machines has revolutionized manufacturing processes by offering unparalleled precision, repeatability, and efficiency. By automating machining operations, CNC machines reduce labor costs, minimize material wastage, and accelerate production timelines. Moreover, their ability to handle complex geometries and tight tolerances makes them indispensable tools for industries demanding superior quality and reliability.

Conclusion:

In conclusion, CNC machines represent the pinnacle of precision engineering, empowering industries to achieve new heights of productivity and innovation. From automotive to aerospace, from healthcare to consumer electronics, CNC machines continue to drive technological advancements and reshape the landscape of modern manufacturing. As industries embrace automation and digitalization, the role of CNC machines in shaping the future of manufacturing remains paramount, promising endless possibilities and opportunities for growth.

0 notes