#Neoprene cable

Text

Fiber optic cable

Kabeltec is a Singapore leading supplier specialising in Flexible cable, Fiber, Crane, Coaxial & Neoprene cable, High-temperature cable, Electrical cable and wire, etc. for use in industrial, LAN, Solar, Welding, Data, Power Cable, Fiber optic cable and Communication cable.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#Power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#LAN cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

1 note

·

View note

Text

The Magic Of Coaxial, LAN, High-Temperature, And Communication Cables Revealed

The complexity of the many cables used in today’s linked world provides the foundation for faultless data transfer and communication.

Grasping the Fundamentals: The Coaxial Cable

A Revolution in Coaxial Technology

Coaxial cable stands out due to its unique structure; it is frequently called the “unsung hero” of communication. This cable has a core conductor, an insulating substance, a metallic shield, and an outside insulating layer for the best signal transmission. Strong and versatile, coaxial cable meets various technical demands, from transferring cable TV signals to high-speed internet traffic.

Putting Coaxial Cable to Work

Whether playing online games or watching your favorite show, the Coaxial cable quietly provides little signal loss and great bandwidth. Its versatility has made it an essential component of contemporary networking, finding use in fields as diverse as telecommunications and computer networks.

Finding Your Way Around the Web: The Importance of LAN Cable for Faultless Networking

Local Area Network (LAN) Cable

Modern networking would not be complete without local area network (LAN) cable, which promotes dependable local connectivity. Local area network (LAN) cables, such as Cat5e and Cat6, are essential for transferring data over small distances and are found in homes, workplaces, and data centers.

LAN Cable Versatility is shown

LAN cable provide high-speed data transfer and low-latency connectivity. LAN cables are essential in many different types of installations to get strong and reliable communication, from gaming rigs to professional office networks.

Coping with Extreme Heat: The Longevity of High-Temperature Cable Explored

High-Temperature Cable

High-temperature cables are the answer to problems caused by extreme heat. Specialized materials allow these cables to endure high temperatures without compromising signal quality. High-temperature aerospace, automobile, and industrial applications require these cables.

The Make-Up of High-Temperature Cable Unveiled

High-temperature cables are built with heat-resistant materials such as silicone rubber and fluoropolymers. They are essential in harsh industrial environments due to their composition, which protects against chemical corrosion and guarantees endurance to high temperatures.

Investigating Communication Cables: The Foundation of Communication

The Role of Communication Cables

The unseen threads that link people, companies, and countries worldwide are communication cables. These cables allow for transferring voice, data, and multimedia at previously unimaginable speeds and efficiency, whether subterranean communication cables or fiber optics laid underground.

The Importance of Communication Cables in the 5G Era

The cusp of a 5G revolution and communication cables will be essential in bringing about this new age of unparalleled connection. When laying the groundwork for future communication technologies, fiber optic communication cables are king, guaranteeing lightning-fast data transfers with almost no delay.

Conclusion

Communication, high-temperature, LAN, and coaxial cable are the threads that hold contemporary networking together. In today’s digital world, every kind of cable is essential to smoothly transferring data. As we move forward, it’s crucial to recognize the unseen but powerful function of these cables inefficiently and precisely linking our environment.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#Power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#LAN cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

1 note

·

View note

Text

High-temperature cable

Kabeltec is a Singapore leading supplier specialising in Flexible cable, Fiber, Crane, Coaxial & Neoprene cable, High-temperature cable, Electrical cable and wire, etc. for use in industrial, LAN, Solar, Welding, Data, Power Cable and Communication cable.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

0 notes

Text

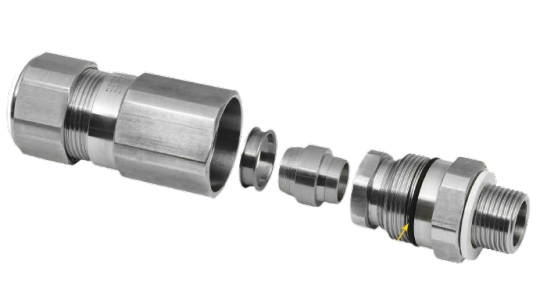

Exploring the Functionality of Key Cable Gland Components?

Introduction

Cable glands play a crucial role in ensuring the proper installation and functionality of electrical and data cables in various industries and applications. These glands not only provide a secure and waterproof seal around cables but also protect them from environmental factors such as dust, moisture, and chemicals. Understanding the components of cable glands is essential for ensuring their effectiveness and reliability in different settings. In this blog post, we will explore the functionality of key Cable gland components and their importance in cable management systems.

Body:

1.1. Cable Gland Basics:

Before delving into the components of cable glands, it's important to understand their basic structure and function. A cable gland, also known as a cable connector or fitting, is a device designed to attach and secure the end of a cable to an electrical or mechanical enclosure. It typically consists of a threaded body, a sealing element, and various other components that ensure a tight seal and provide strain relief for the cable.

1.2. Threaded Body:

The threaded body of a cable gland serves as the main housing for the gland assembly. It is usually made of metal, such as brass, stainless steel, or aluminum, although plastic versions are also available for less demanding applications. The threaded body is designed to screw into a corresponding threaded hole in the enclosure, providing a secure connection that prevents the gland from coming loose under vibration or tension.

1.3. Sealing Element:

The sealing element is perhaps the most critical component of a cable gland, as it is responsible for creating a watertight and dustproof seal around the cable. Common sealing materials include neoprene, silicone, rubber, and thermoplastic elastomers (TPE). The choice of sealing material depends on factors such as the application environment, temperature range, and chemical resistance requirements.

1.4. Compression Nut:

The compression nut is used to compress the sealing element against the cable and the threaded body, forming a tight seal that prevents moisture and contaminants from entering the enclosure. It is typically made of metal and features internal threads that match those on the threaded body. By tightening the compression nut, installers can adjust the compression force applied to the sealing element, ensuring a secure and reliable seal without damaging the cable insulation.

1.5. Clamping Device:

Some cable glands feature a clamping device or mechanism designed to provide strain relief for the cable, preventing it from being pulled out of the gland or becoming damaged due to excessive bending or tension. This is especially important in dynamic applications where cables are subject to movement or vibration. Common types of clamping devices include rubber grommets, spiral cable glands, and adjustable clamps.

1.6. O-Ring or Washer:

In addition to the main sealing element, many cable glands incorporate an O-ring or washer at the interface between the gland and the enclosure. This secondary seal helps to further enhance the waterproof and dustproof properties of the gland assembly, especially in outdoor or harsh environments where moisture ingress is a concern. The O-ring or washer is typically made of rubber or silicone and is compressed between the gland and the mounting surface when the gland is installed.

Importance of Cable Gland Components:

2.1. Environmental Protection:

One of the primary functions of cable glands is to provide environmental protection for cables and electrical connections. By sealing the entry point of the cable into the enclosure, cable glands help to prevent moisture, dust, dirt, and other contaminants from entering sensitive equipment and causing damage or malfunction. This is particularly important in outdoor or industrial settings where cables are exposed to harsh conditions.

2.2. Safety and Reliability:

Proper cable gland installation ensures the safety and reliability of electrical and data systems by minimizing the risk of short circuits, electrical arcing, and equipment failure. By creating a secure and watertight seal around cables, cable glands help to prevent accidental contact with live conductors, reducing the risk of electrical hazards and fire.

2.3. Compliance with Regulations:

In many industries, compliance with regulatory standards and codes is mandatory to ensure the safety and integrity of electrical installations. Cable glands that are properly designed and installed according to industry standards help companies meet these requirements and avoid potential fines or legal liabilities. Common standards governing cable gland design and installation include the National Electrical Code (NEC), the International Electrotechnical Commission (IEC), and the European Union's Restriction of Hazardous Substances (RoHS) directive.

2.4. Long-Term Performance:

The quality and durability of cable gland components directly impact the long-term performance and reliability of cable management systems. High-quality materials, precision engineering, and rigorous testing ensure that cable glands can withstand the rigors of daily use and continue to provide effective sealing and strain relief over their operational lifespan. Investing in premium Cable gland components upfront can save time and money on maintenance and replacement costs down the line.

Conclusion:

Cable glands are essential components of electrical and data cable installations, providing protection, safety, and reliability in a wide range of applications. By understanding the functionality of key cable gland components such as the threaded body, sealing element, compression nut, clamping device, and O-ring or washer, installers can ensure the proper selection, installation, and maintenance of cable glands for optimal performance and compliance with industry standards. Whether in industrial, commercial, or residential settings, cable glands play a critical role in safeguarding equipment, infrastructure, and personnel against the hazards of environmental exposure and electrical faults.

0 notes

Text

Top PCP Cable Deals in India: Find the Best Prices

PCP cables are essential for various industrial and commercial applications, offering durability and reliability in power transmission. In this guide, we'll explore the top PCP cable deals available in India, helping you find the best prices for your electrical projects.

Understanding PCP Cables: PCP cables, also known as Polychloroprene or Neoprene cables, are widely used in industries due to their excellent resistance to oil, grease, chemicals, and abrasion. These cables are commonly employed in power distribution networks, machinery, equipment, and construction sites, ensuring uninterrupted power supply and safety.

Exploring the Best Deals:

Quality vs. Price: While searching for PCP cable deals, it's essential to strike a balance between quality and price. Look for reputable manufacturers offering high-quality PCP cables at competitive prices.

Bulk Purchase Discounts: Many suppliers offer discounts on bulk purchases, making it cost-effective to buy PCP cables in large quantities for extensive projects or stocking inventory.

Special Promotions: Keep an eye out for special promotions and sales events from reputable suppliers. These can provide opportunities to secure PCP cables at discounted rates or with added benefits.

Online Marketplaces: Explore online marketplaces and e-commerce platforms for a wide range of PCP cable options at competitive prices. Compare prices, read customer reviews, and take advantage of exclusive deals and offers.

Supplier Reputation: Prioritize suppliers with a proven track record of delivering high-quality PCP cables and excellent customer service. Check for certifications, warranties, and customer testimonials to ensure reliability.

Conclusion: Finding the best deals on PCP cables in India requires careful consideration of various factors, including quality, price, discounts, promotions, and supplier reputation. By exploring different options and comparing prices, you can secure top-quality PCP cables at the best prices for your electrical projects. Trust reputable suppliers like IMT Cables to provide reliable solutions and competitive deals for your PCP cable needs.

0 notes

Text

10 Must-Have Car Accessories for an Ultimate Driving Experience

Are you looking to enhance your driving experience and take your car to the next level of comfort, convenience, and style? Look no further! We've curated a list of the best car accessories that will transform your vehicle into a luxurious haven on wheels. From cutting-edge technology to practical essentials, these accessories are designed to meet the needs of every driver. Let's dive in and explore the top 10 must-have best car accessories for an ultimate driving experience.

Dash Cam: Safety should always be a top priority on the road. A dash cam not only records your journey but also provides crucial evidence in case of accidents or disputes. With features like high-definition recording and night vision, a dash cam offers peace of mind and security while driving.

Bluetooth Car Kit: Say goodbye to tangled wires and hello to seamless connectivity with a Bluetooth car kit. Easily sync your smartphone to your car's audio system for hands-free calling, music streaming, and navigation. Stay focused on the road ahead while enjoying your favorite tunes or taking important calls.

Seat Covers: Protect your car's upholstery and add a touch of style with high-quality seat covers. Whether you prefer leather, fabric, or neoprene, there are endless options to suit your taste and budget. Choose from a variety of colors and designs to customize your interior and keep your seats looking fresh for years to come.

Car Organizer: Keep your vehicle neat and organized with a car organizer. From trunk organizers to seat-back organizers, these handy accessories help you store and access items such as groceries, toys, and roadside emergency supplies with ease. Say goodbye to clutter and hello to a tidier, more efficient driving experience.

LED Headlights: Upgrade your car's headlights with energy-efficient LED bulbs for improved visibility and safety on the road. LED headlights offer brighter illumination, longer lifespan, and lower power consumption compared to traditional halogen bulbs. Enhance your nighttime driving experience and stand out with stylish LED headlights.

Wireless Phone Charger: Never worry about running out of battery on the go with a wireless phone charger. Simply place your smartphone on the charging pad and enjoy convenient, cable-free charging while driving. Say goodbye to tangled cords and hello to effortless charging wherever you go.

Car Vacuum Cleaner: Keep your car clean and spotless with a portable car vacuum cleaner. Whether you're dealing with crumbs, pet hair, or dust, a compact vacuum cleaner makes quick work of tidying up your interior. Say goodbye to messy car floors and hello to a pristine driving environment.

Blind Spot Mirrors: Enhance your visibility and minimize blind spots with blind spot mirrors. Easily attach these small, convex mirrors to your side mirrors for a wider field of view and increased safety while changing lanes or parking. Stay aware of your surroundings and drive with confidence wherever you go.

Car Air Purifier: Breathe easier and enjoy fresher air inside your car with a car air purifier. These compact devices use advanced filtration technology to remove airborne contaminants, allergens, and odors, creating a healthier and more pleasant driving environment for you and your passengers.

Car Sunshade: Protect your car's interior from harmful UV rays and excessive heat with a car sunshade. Whether you're parked outside or driving under the sun, a sunshade helps prevent fading, cracking, and overheating of your dashboard, seats, and steering wheel. Keep your car cool and comfortable all year round with a durable and easy-to-install sunshade.

In conclusion, these 10 must-have car accessories are sure to enhance your driving experience and make every journey more enjoyable, safe, and convenient. Whether you're a tech-savvy driver or simply looking to upgrade your car's comfort and style, investing in these accessories is a smart choice. Visit MotoShield to explore a wide range of premium car accessories and take your ride to the next level today!

0 notes

Link

Check out this listing I just added to my Poshmark closet: Running Gear Phone Holder Arm Band Adjustable Strap Black Universally Compatible.

0 notes

Text

Welding Leads: Mastering the Craft

Welding leads are essential components that connect the welding machine to the electrode holder and the workpiece. These leads carry the electrical current necessary for creating the weld.

Welding leads play a crucial role in ensuring a strong and reliable connection between the welding equipment and the materials being welded. They are available in various lengths and materials to suit different welding applications. Proper maintenance and regular inspection of welding leads are necessary to prevent potential hazards and ensure efficient welding operations.

Understanding the importance of welding leads and their proper usage is vital for achieving high-quality and safe welds. We will explore the significance of welding leads, their different types, and the best practices for using and maintaining them in welding processes.

Understanding Welding Leads

Understanding Welding Leads is essential for anyone working in the welding industry. Welding leads, also known as welding cables, are vital components in any welding setup, as they carry the electrical current necessary for creating the weld. In this article, we will delve into the basic anatomy of welding leads, explore the different types and their uses, and discuss the common materials used for welding cables and connectors.

Basic Anatomy Of Welding Leads

Welding leads consist of several key components that allow for the transmission of electrical current from the welding power source to the welding equipment. The basic anatomy of welding leads includes:

- The conductor: This is the core component of the welding lead, responsible for carrying the electrical current. Copper is the most commonly used material for welding lead conductors due to its excellent conductivity.

- The insulation: Surrounding the conductor is the insulation, which protects the conductor from external elements and prevents electrical shocks. Rubber, PVC, or neoprene are often used as insulation materials for welding leads.

- The jacket: The outermost layer of the welding lead, the jacket provides additional protection and durability. It is typically made of a heavy-duty material such as EPDM (Ethylene Propylene Diene Monomer) rubber to withstand harsh working conditions.

Types Of Welding Leads And Their Uses

Welding leads come in various types, each designed for specific welding applications. Understanding the different types of welding leads and their uses is crucial for achieving optimal welding results. The common types of welding leads include:

- Work lead (ground lead): This type of welding lead is connected to the workpiece and provides the return path for the electrical current during the welding process.

- Electrode lead (torch lead): The electrode lead connects the welding machine to the welding torch or electrode holder, allowing the current to pass through the welding electrode to create the weld.

- Battery lead: Battery leads are used in welding setups powered by a battery source, commonly found in automotive welding applications.

Common Materials For Welding Cables And Connectors

The materials used for welding cables and connectors are critical for ensuring the safe and efficient transmission of electrical current. Common materials for welding cables and connectors include:

Material

Characteristics

Copper

High electrical conductivity, flexibility, and durability, making it ideal for welding leads.

Brass

Used for connectors and clamps due to its corrosion resistance and electrical conductivity.

Aluminum

Lightweight and cost-effective, suitable for certain welding lead applications.

Credit: fsmdirect.com

Welding Leads: Mastering The Craft Essentials

Welding leads are an essential component in the welding process that requires careful consideration and attention. To master the craft of welding, it's important to understand the significance of selecting the right lead, maintaining and caring for its longevity, and practicing safety measures. Let's explore these essentials in detail.

Importance Of Selecting The Right Lead

Selecting the right welding lead is crucial for ensuring a smooth and efficient welding process. The lead serves as the pathway for the electrical current to travel from the welding machine to the welding gun, making it a critical component in the welding setup. Factors such as the amperage rating, length, and insulation of the lead must be considered to ensure compatibility with the specific welding application.

Maintenance And Care For Longevity

Proper maintenance and care are essential for ensuring the longevity of welding leads. Regular inspection for wear and tear, cleaning of the lead connections, and proper storage can significantly extend the lifespan of the leads. Following manufacturer's guidelines for maintenance and storage is also important to prevent premature deterioration of the leads, ultimately saving time and money in the long run.

Safety Practices With Welding Leads

- Always wear appropriate protective gear when handling welding leads to prevent injuries from electrical hazards.

- Inspect the leads for any signs of damage or deterioration before each use to prevent potential electrical shocks or short circuits.

- Properly grounding the welding equipment and leads is crucial to minimize the risk of electrical hazards in the work environment.

- Avoid coiling or kinking the lead to prevent damage to the insulation and conductors, ensuring safe and reliable operation during welding tasks.

Advanced Techniques For Welding Leads

When it comes to welding, having the right leads is crucial for achieving quality results in your project. Advanced techniques for welding leads can enhance the efficiency, safety, and overall performance of the welding process. Let's delve into some advanced welding lead techniques and how to adapt leads for different welding methods along with problem-solving solutions for faulty leads.

Adapting Leads For Different Welding Methods

Adapting welding leads for different methods is essential for optimizing the welding operation. It involves understanding the specific requirements of each welding method and customizing the leads accordingly. Whether it's TIG welding, MIG welding, or stick welding, the leads should be adapted to match the power supply, electrode type, and welding position. Here's a quick overview of adapting leads for different welding methods:

- Identify the specific requirements of the welding method.

- Choose the appropriate lead length and gauge for the welding process.

- Ensure the leads have the necessary insulation and protection for the specific welding environment.

Problem-solving With Faulty Leads

Faulty leads can disrupt the welding process and pose safety risks. It's crucial to be able to identify and troubleshoot lead-related issues to ensure a smooth welding operation. Here are some problem-solving techniques for addressing faulty leads:

- Regularly inspect and maintain the leads to identify any signs of wear or damage.

- Use a multimeter to test the continuity and integrity of the leads.

- Address any loose connections or damaged insulation promptly to prevent issues during welding.

Optimizing Current For Superior Welds

Optimizing the current for superior welds is crucial to achieving high-quality and durable welds. By understanding and manipulating the amperage and voltage in welding, welders can effectively adjust the current to suit different metals, resulting in impeccable welds.

Understanding Amperage And Voltage In Welding

Amperage and voltage are two critical components in the welding process. Amperage, measured in amps, determines the amount of current flowing through the welding lead, while voltage, measured in volts, controls the heat intensity generated by the electric arc.

Calculating The Correct Current For Various Metals

When welding different metals, it is essential to calculate the correct current to achieve optimal results. Each metal has its own specific requirements in terms of current and voltage to create strong and reliable welds. This can be achieved by considering factors such as metal thickness, welding position, and the type of joint being welded.

Expanding Skills With Welding Leads

Welding leads are essential tools for any welding professional, helping to achieve precision and quality in various projects. As welders gain experience, they can expand their skills by mastering the use of welding leads for specialized projects and exploring innovative applications in modern fabrication.

Tailoring Leads For Specialized Projects

Welding leads can be customized and adapted to suit the specific needs of various welding projects. Whether it's working with different materials, creating unique designs, or navigating challenging angles, welders can tailor welding leads to their precise requirements. By understanding how to modify and adjust leads for specialized projects, welders can enhance their capabilities and tackle a diverse range of welding tasks with confidence and precision.

Innovative Uses Of Welding Leads In Modern Fabrication

In today's advanced fabrication processes, welding leads are being utilized in innovative ways to optimize efficiency and productivity. From automated welding systems to robotic applications, the integration of welding leads has revolutionized modern fabrication techniques. By staying updated on the latest advancements in welding technology and techniques, welders can harness the full potential of welding leads to accomplish complex projects with precision and reliability.

Frequently Asked Questions On Welding Leads

What Are The Different Types Of Welding Leads?

Welding leads can include electrode holder leads, work clamp leads, and power supply leads. Each type serves a specific purpose in the welding process, ensuring a safe and efficient work environment.

How Do I Choose The Right Welding Leads For My Project?

Select welding leads based on the type of welding being done, the power source, and the specific requirements of the project. It's crucial to consider factors such as length, material, and insulation to ensure optimal performance.

Why Is Proper Maintenance Important For Welding Leads?

Regular maintenance of welding leads is essential to prevent damage, ensure safety, and maintain optimal performance. This includes inspecting for wear and tear, cleaning, and proper storage to extend the lifespan of the leads.

What Safety Precautions Should I Follow When Using Welding Leads?

When using welding leads, it's crucial to wear protective gear, inspect leads for damage, and ensure proper grounding. Following safety guidelines and regulations is essential to prevent injury and maintain a safe working environment.

Conclusion

Welding leads are essential for creating strong and durable joints in various metalworking projects. By using the right welding leads, you can ensure precision, efficiency, and safety in your welding operations. Investing in high-quality welding leads can ultimately save time, money, and resources while delivering superior results.

https://www.youtube.com/watch?v=CoPykUYYjdE

Read the full article

0 notes

Text

10 Clever Ways to Tuck Away TV Wires in Your Living Area

Achieving an aesthetically pleasing living space often means finding innovative ways of eliminating visual distractions, and one common culprit is the snarl of wires accompanying your TV setup. Fear not, here are some discreet ways to hide those pesky TV wires, elevating the visual appeal of your living room while maintaining practicality in your home decor.Camouflaging with Cable Concealers:A quick and easy solution involves utilizing cable concealers. These slender, paintable channels adhere to your walls, effectively camouflaging wires and seamlessly blending with the surrounding paint. Available in various sizes, they ensure a snug fit for any cable arrangement.

Sleek Socket - The Original & Patented Dual Side-by-Side Ultra-Thin Outlet Concealer w/Cord Concealer Kits, Two 3 Outlet Power Strips, Two 8-Ft Cords, Universal Size (Ideal for Behind a Couch or Bed)$39.95

ECHOGEAR Wire Hiders for TV On Wall - White Cable Management Kit Hides Wires Behind The Wall- Includes 2 Pass Throughs, Locking Brackets, and Hole Saw Drill Attachment Easy Install$21.99

In-Wall Cable Management Kits:For those willing to embark on a slightly more ambitious project, in-wall cable management kits offer a sleek alternative. This involves creating a concealed channel within your wall, requiring a bit of DIY effort but resulting in a polished, professional look with no visible cables.Furniture with Built-in Cable Management:Invest in furniture designed specifically to conceal cables. Entertainment units or desks with integrated cable management systems can keep your wires out of sight, offering a tidy appearance without compromising on accessibility.

ECHOGEAR TV Cord Hider for Wall Mounted TV - Dual Outlet in Wall Cable Management Kit for Power Cables & Low Voltage Wires - Includes Template, Saw, & Low Profile Extension Cord$69.99 (less 22%)

Strategic Use of Cord Clips and Holders:Opt for cord clips and holders to secure your wires discreetly. These come in various designs, including adhesive clips and adjustable holders, offering flexibility in organizing your cables along the back of furniture or walls.

Cable Management Box 3 Pack with 16 Cable Clips Set-Large & Medium & Small Wooden Style Cable Organizer Box to Hide Wires&Power Strips | Cord Organizer Box | Cable Organizer for Home & Office $31.99 (less 30%)

Neat Bundling with Zip Ties and Velcro Straps:A budget-friendly option involves bundling cables with zip ties or velcro straps. Gather them together and affix them to the back of your furniture or along the wall for an effective and straightforward cable management solution.

Cordinate Fabric Cord Cover, 6 ft, Hides Cables, Great for Lamps, Light Fixtures, and Desks, Cable Management, Easy Installation, Champagne$11.47

Decorative Cable Sleeves for a Stylish Touch:Elevate your wire-hiding strategy with decorative cable sleeves. These fabric or neoprene sleeves not only conceal cables but also introduce a touch of style to your space. Choose a sleeve that complements your decor for an integrated and polished look.

Cord & Chain Cover, 6.5 feet, Dupioni Faux Silk Fabric, Hook-and-Loop Strip Close- Use for Chandelier, Lighting, Wire Sleeve (Red)$15.95

Strategically Placed Furniture and Decor:Use your furniture strategically to camouflage cables. Position decorative items, such as plants or stylish boxes, to hide cable entry points and subtly redirect attention away from the wires.Concealing Behind Wall-Mounted Shelves:Opt for wall-mounted shelves to not only provide additional storage but also to discreetly hide wires. Place your cable box, gaming consoles, or other devices on the shelves, and subtly route the cables behind or within the shelves.DIY Artwork or Photo Collages with Hidden Channels:Infuse creativity into your cable management solution by incorporating it into artwork or a photo collage. Design a piece that seamlessly integrates a discreet cable channel, transforming your cable organization into a unique and personalized part of your decor.Embrace Wireless Technology:Embrace the wireless era by opting for devices that support wireless connectivity. Many modern TVs, sound systems, and streaming devices offer wireless options, minimizing the need for visible cables altogether. If you’re lucky to be renovating, measure out the power socket to be placed directly behind the TV to hide even the power cord from view.Bidding farewell to TV wires need not be a daunting task, it’s an opportunity to enhance the overall aesthetics of your living space. Whether you choose subtle channels, furniture with built-in cable management, or unleash your creativity with DIY solutions, concealing TV wires can transform your room into a sophisticated haven. Pick the method that aligns with your style and space, and relish in a living room that seamlessly blends visual appeal with functionality.

Read the full article

1 note

·

View note

Text

Synthetic Rubber: Versatility Beyond Natural Rubber - A Blog by IHR Insights

Introduction:

Rubber is an essential material with a wide range of applications, from automotive tires to industrial machinery and consumer goods. While natural rubber has been the traditional source, synthetic rubber has become increasingly important due to its versatile properties and adaptability to various industries. In this blog, we will explore the different types of synthetic rubber and their diverse applications in our daily lives.

Types of Synthetic Rubber:

Styrene-Butadiene Rubber (SBR):

• SBR is the most widely used synthetic rubber due to its excellent abrasion resistance and good aging properties.

• Applications: Automotive tires, conveyor belts, shoe soles, and industrial hoses.

Polybutadiene Rubber (BR):

• BR is highly resilient and has low hysteresis, making it an ideal choice for low rolling resistance in tires.

• Applications: Tires, golf balls, and footwear.

Ethylene Propylene Diene Monomer (EPDM):

• EPDM is known for its outstanding weather and ozone resistance.

• Applications: Automotive weather-stripping, roofing membranes, and cable insulation.

Applications of Synthetic Rubber:

1. Automotive Industry:

Tires: Various types of synthetic rubber are used in tire manufacturing to enhance grip, durability, and fuel efficiency.

Seals and Gaskets: NBR, CR, and EPDM are used in engine components for their resistance to heat, oil, and weathering.

2. Consumer Goods:

Footwear: SBR, BR, and NBR are used in shoe soles and athletic shoes for their wear resistance and cushioning properties.

Wetsuits: Neoprene is the preferred material for wetsuits, offering buoyancy and insulation for water sports enthusiasts.

3. Industrial Applications:

Conveyor Belts: SBR and NBR are used for their abrasion resistance and durability in material handling systems.

Hoses and Tubing: Various types of synthetic rubber are used in hoses and tubing for their flexibility and resistance to chemicals and heat.

Read more from our Synthetic Rubber Market study.

Conclusion:

Synthetic rubber has revolutionized various industries by providing versatile solutions that meet specific needs, whether it's improving the performance of tires, ensuring the longevity of building structures, or enhancing the comfort of footwear. As technology advances, the development of new types of synthetic rubber continues, ensuring that this essential material remains an integral part of our modern world.

– Analyst Team

IHR Insights

[email protected]

0 notes

Link

Features: 40" (1m) Neoprene Cable Management Sleeve with Zipper & Buckle - 1.2" (3cm) Diameter - Computer/PC Power/Network/AV Cord Cover/Manager - Flexible Cable Organizer Wrap - Black Cable Management Sleeve | Zipper | Built-in Exit Holes PROFESSIONAL CABLE SLEEVE Ideal for office, home office & desktop workstation to easily organize & conceal cables with this Neoprene cable management sleeve; Provide a clean professional look; Just wrap the sleeve around the cable bundle & fasten the zipper CUSTOMIZABLE SOLUTION This 39.4" (1m) sleeve with 1.2" (3cm) diameter has built-in connector buckles allowing you to daisy-chain additional sleeves as required; For under computer/PC desk, multiple monitor setups, power cords, classrooms; Built-in holes DURABLE AND FLEXIBLE SLEEVE Cable manager made from rugged Neoprene rubber prevents wear & tear due to extended use, foot traffic or damage by pets; Flexible Neoprene to easily position/route around corners/bends; Sturdy zipper & buckles for frequent use Specifications: Environmental Operating Temperature 0°C to 40°C (32°F to 104°F) Storage Temperature 0°C to 40°C (32°F to 104°F) Humidity 30%RH ~ 60%RH Packaging Information Package Height 3.9 in [100.0 mm] Package Length 7.9 in [20.0 cm] Shipping (Package) Weight 3.9 oz [110.0 g] Package Width 7.9 in [20.0 cm] Physical Characteristics Color Black Product Height 1.2 in [30.5 mm] Product Length 39.4 in [100.0 cm] Weight of Product 3.8 oz [108.0 g] Product Width 1.2 in [30.5 mm] Materials Neoprene Rubber Manufacturer Part No: WKSTNCMZP Brand: StarTech Product Type: - UPC 065030889940 Product Family: - Shipping Weight: 0.1 kg PB Part No: CABSTT5243684 Product Model: - Warranty: 12 months * * Warranty period is as stated above unless the manufacturer has chosen to specify a longer period. All warranties are return to base unless otherwise specified. Why is there a reasonable price displayed? Discover the reason behind our incredibly reasonable prices! At our company, we prioritize your satisfaction and work tirelessly to offer you access to top-notch brands without breaking the bank. Our commitment to minimizing profit margins enables us to deliver affordability without compromising on quality. Shop with confidence and explore a wide range of reputable products at budget-friendly rates. Your satisfaction is our priority! #

0 notes

Link

Check out this listing I just added to my Poshmark closet: Nike Metcon 3 AMP 'Gold' Cross Training Shoes 9.

0 notes

Text

Installation of the seal of a dishwasher pump

Modern household dishwashers are designed to provide years of trouble-free service before requiring maintenance. However, because the flexible surface of the neoprene pump seal is in constant contact with the rotating motor shaft, wear and tear occurs - and this seal is one of the first parts to break after extended use. To be on the safe side, this seal needs to be replaced as soon as you notice any accumulation of water under the unit. Aside from being a nuisance to mop the kitchen floor, water splashing on an electric motor is a potential shock hazard.

Turn off the breaker switch on the panel that supplies power to the dishwasher. Tape the switch to the panel with a piece of tape so no one can turn on the power while you are working.

Close the water shut-off valve under the sink. Loosen the clamp on the waste hose with a screwdriver. Pull the hose off the garbage disposal or the sink drain pipe, whichever applies.

Remove the two screws that secure the access panel to the bottom front of the dishwasher. Remove the plate and set it aside. Using an adjustable wrench, disconnect the braided water inlet hose from the inlet valve on the left side of the opening.

Loosen the screws and remove the electrical box cover plate on the right side of the opening. Note the orientation of the electrical wires and unscrew the wire nuts to separate the wires. Use channel pliers to remove the nut securing the electrical cable to the control box mounting plate. Pull out the conduit.

Open the dishwasher door and remove the screws from the bracket under the front of the countertop. Lower the dishwasher by lifting the unit slightly and turning the leveling pads on the front corners clockwise upward.

Slide the dishwasher out of the recess. Place a folded blanket behind the dishwasher. Tilt the dishwasher and place it on its back on the blanket. This will reveal the drain valve and pump motor on the bottom of the unit.

Squeeze the wiring harness plugs on the sides and pull them out of the drain valve and pump motor sockets. Remove the bolt securing the retaining rod to the motor using a nut driver.

Loosen the hose clamp securing the water chamber hose to the pump housing with the nut driver. Pull off the hose. Loosen the pump connector at the left, inner corner of the water chamber, followed by the pump housing clamp at the bottom. Lift out the pump and motor assembly and place it on the countertop.

Call the Emergency Plumber in Southend-on-Sea. We are your right contact partner. Call us now, 01702668129.

0 notes

Text

Ankle Straps for Cable Machines- Ankle Cuff For Leg Workout Cable Pulley Equipment Machine- Cable Straps For Men And Women adjustable with velro strap

Cable Straps For Men And Women

SUPERIOR GLUTES: Ankle straps can be used for cable machines and Glutes Exercise equipment and can help firm up your glutes workout. These ankle cuffs are effective for exercise machines for legs, especially if you use these leg straps for exercises such as inner and outer thigh contractions, leg extensions, cable kickbacks, hip abduction, and cable lunges, to improve your leg game!

PREIMUM QUALITY: Roubst double D-rings, reinforced seams, and an ideally balanced padding set our premium foot straps apart from the competition and provide not only more safety than standard models, but also outstanding and incomparable wearing comfort.

FUNCTIONALITY: Not only will our cable machine attachments help you strengthen your lower body, but our ankle cuffs were designed with a longer strap, so it can hug the ankle tightly, enabling you to lift more weights. Our cable straps also have two reinforced D-Shape on either side, to give you maximum support and the peace of mind that the strap shouldn't come undone while lifting. That’s why these cable attachments for gym are the ideal straps fitness trainers love!

VALUE PAIR: With us, you'll be receiving a pair of two ankle straps to broaden your range of workouts! Our comfort is unmatched, keeping you free and clear of pain while you get those thighs and glutes EXACTLY where you want them to be. These ankle straps for cable machines and are made from soft neoprene padding that cushions above and below the ankle

GREAT FOR ALL: Ankle wraps can be used by both men and women for cable machine workout equipment, ankle straps for weight lifting, ankle straps for resistance bands, ankle straps for your glute’s workout, glutes machine, glutes workout machine and almost any weight exercise machine. Our Adjustable leg straps for exercise were developed to be used on workout machines for home gym and on as traditional gym accessories, giving you that added resistance needed to conquer

#gym#fitness#gym life#bodybuilding#boxing#gymlover

Blaze

0 notes

0 notes

Text

Instrumentation Cable Glanding and Termination

Introduction

Instrumentation cable glanding and termination is a crucial aspect of industrial installations and automation systems. These processes involve securing and connecting cables in harsh environments to ensure reliable and uninterrupted data transmission. Whether it's in oil refineries, power plants, chemical processing plants, or manufacturing facilities, proper cable glanding and termination are essential for the efficient operation of instrumentation and control systems. In this comprehensive guide, we will delve into the intricacies of instrumentation cable glanding and termination, discussing the best practices, key components, and the significance of maintaining signal integrity.

Understanding Instrumentation Cables

Instrumentation cables are specialized cables designed to transmit signals between instruments, sensors, and control devices in industrial settings. They carry crucial data, such as temperature, pressure, flow, and other process variables, to control rooms or data acquisition systems for analysis and decision-making. These cables are commonly exposed to harsh conditions, including extreme temperatures, chemicals, moisture, and mechanical stress. Therefore, proper glanding and termination are vital to protect the cables from environmental factors and maintain their performance.

The Importance of Cable Glanding

Cable glanding is the process of providing a secure and watertight seal around the point where the cable enters an enclosure or termination device. This is essential for several reasons:

Environmental Protection: Glanding ensures that moisture, dust, and other contaminants cannot infiltrate the cable's core or the equipment, safeguarding against potential damage and signal loss.

Safety: Proper glanding prevents the risk of electrical shock by insulating and securing the cable's conductors.

Compliance: Many industries have strict regulatory requirements regarding cable installations, and proper glanding is often a necessity to comply with safety and environmental standards.

Glanding Components and Techniques

Several components are involved in the glanding process:

Gland: The gland is the main component responsible for sealing the cable entry point. It is typically made of brass, stainless steel, or plastic and features an adjustable design to accommodate various cable diameters.

Locknut: The locknut secures the gland in place by threading onto the enclosure or termination device.

Seal: The seal, often made of neoprene or rubber, provides a watertight connection between the gland and the cable.

Earth Tag: In applications where grounding is critical, an earth tag is used to connect the cable's metallic armor or shielding to the grounding system, preventing electrical hazards and reducing electromagnetic interference.

Glanding techniques vary based on the type of cable and the environment. Common glanding methods include:

Compression Gland: This method involves compressing the seal against the cable by tightening the gland's cap. The compression ensures a tight seal and excellent strain relief.

Extrusion Gland: Typically used with armored cables, the extrusion gland compresses the seal and grips the cable's armor, providing additional mechanical strength.

Displacement Gland: In this method, the seal displaces within the gland body as the cap is tightened, creating a tight seal around the cable.

Understanding Termination in Instrumentation Cables

Termination refers to the process of connecting the cable's conductors to the terminals or devices within the control system. A proper termination is crucial to ensure a stable electrical connection, minimal signal loss, and long-term reliability.

Types of Termination

Several types of terminations are commonly used in instrumentation cables:

Crimp Termination: In crimp termination, the cable's conductors are inserted into a terminal or connector, and a crimping tool is used to compress the connector, creating a secure and gas-tight connection.

Screw Termination: Screw terminals are popular in control panels and junction boxes. They involve clamping the cable's conductors under screws to establish a solid electrical connection.

Insulation Displacement Connection (IDC): IDC terminations are widely used in multi-pair cables. This method involves a connector with small blades that pierce the cable's insulation, making direct contact with the conductors.

Solder Termination: In solder termination, the cable's conductors are tinned with solder, and then they are soldered to the terminal or connector, creating a permanent and reliable connection.

Best Practices for Instrumentation Cable Glanding and Termination

To ensure a successful glanding and termination process, adhere to these best practices:

Choose the Right Components: Select glands, seals, and terminations suitable for the cable type, diameter, and the environmental conditions.

Proper Cable Preparation: Clean and strip the cable's outer sheath carefully, ensuring the conductors are undamaged and ready for termination.

Maintain Bend Radius: Avoid sharp bends or excessive stress on the cable during installation to prevent signal attenuation and damage to conductors.

Thorough Inspection: Perform visual inspections of glanding and termination to verify that the components are properly fitted and aligned.

Test the Connection: After completing the process, test the cable's connectivity and verify signal integrity to ensure optimal performance.

Conclusion

In conclusion, proper instrumentation cable glanding and termination are paramount for industrial automation systems and process control applications. By providing environmental protection, ensuring safety, and complying with industry standards, glanding and termination processes play a crucial role in maintaining robust connectivity and signal integrity. Choosing the right components, employing suitable techniques, and following best practices will lead to reliable and efficient cable installations, contributing to the overall success of industrial operations.

#Instrumentation cable glanding and termination#cable glanding#cable glanding and termination#Understanding Instrumentation Cables#Instrumentation cables

0 notes

Link

Check out this listing I just added to my Poshmark closet: Leatherology Leather Henderson Laptop/Briefcase.

0 notes