#Styrenic Polymers Market

Text

https://www.advancemarketanalytics.com/reports/34091-global-styrenic-polymers-market

Styrenic Polymers Market: Study Navigating the Future Growth Outlook

Advance Market Analytics released a new market study on Global Styrenic Polymers Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Styrenic Polymers Forecast till 2029*.

Styrenic polymer is formed by polymerization of styrene in the presence of vinyl group results. The styrene based resins are widely applicable in manufacturing wide variety of everyday goods, kitchen appliances, hospitals and school supplies. The styrenic polymers offer several facilities such are flexibility of materials and design in the field of medical industries. There has been significant rise in number of polymer production capacity with figure stood up to USD 10.8 million ton in global in 2016, the future for styrenic polymers looks promising. The major companies are introducing latest technology based styrenic polymers in Asia-Pacific and Middle East region as its demand is observed in electrical and electronics industries that consume a majority of styrenic polymers.

Key Players included in the Research Coverage of Styrenic Polymers Market are:

Bayer Material Science (Germany), Lanxess Ag (Germany), Saudi Basic Industries Corporation (Saudi Arabia), Nova Chemicals Corporation (Canada), ENI S.P.A, LG Chem Ltd. (South Korea), Ashland (United States), Styrolution Group GmbH (Germany), Ineos Group Ag (Switzerland), Asahi Kasei Corporation (Japan), Alpek Sab De Cv (Mexico), BASF(Germany),

What's Trending in Market: Rising Demand of styrenic polymers due to urbanization and industrialization.

increasing demand of styrenic polymers in automobile industry at South America region.

Challenges: Adverse Impact Due to Economic Uncertainties in Styrenic Polymers.

Opportunities: Introduction Of New Models and Technology Advancements Expected to Boost the Business Jet Market.

Rapid Technological Innovation Leads to Propel the Market.

Market Growth Drivers: Increase In Demand of Lightweight Materials in Consumer Goods Industries.

Rise In Demand Of Styrenic Polymers in Asia-Pacific Regions Fuelled Up The Market.

The Global Styrenic Polymers Market segments and Market Data Break Down by Type (Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Styrene Acrylonitrile (SAN), Methacrylate Butadiene Styrene (MBS), Methacrylate Acrylonitrile Butadiene Styrene (MABS), Styrene Methyl-Methacrylate (SMMA), Styrene Butadiene Styrene (SBS), Styrene Ethylene Butylene Styrene (SEBS), Others), Application (Medical, Building and Construction, Electrical and Electronics, Automotive Industry, Consumer Goods, Other), Process (Geometric, Fluid-Dynamic, Thermodynamic)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/34091-global-styrenic-polymers-market

To comprehend Global Styrenic Polymers market dynamics in the world mainly, the worldwide Styrenic Polymers market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

#Styrenic Polymers Market Overview#Size#Share#Trends#Scope#and Growth Predictions for 2022-2028 | 200 Pages Report#intellectualmarketinsights

0 notes

Text

#global styrenic polymer packaging market#styrenic polymer packaging research report#styrenic polymer packaging business research report#styrenic polymer packaging research insights#styrenic polymer packaging market overview#styrenic polymer packaging

0 notes

Link

Acrylic Emulsions Market is poised to grow at a CAGR of 5 % by 2027. Factors driving the Acrylic Emulsions Market are growing demand for water-based paints and input costs for solvent-based paints.

#acrylic emulsions market#acrylic polymer emulsion market growth#styrene acrylic emulsion polymer market share#acrylic polymer emulsion market share#styrene acrylic emulsion polymer market size#acrylic emulsions market size

0 notes

Text

Gum base

Gum base is the non-nutritive, non-digestible, water-insoluble masticatory delivery system used to carry sweeteners, flavors, and any other substances in chewing gum and bubble gum. It provides all the basic textural and masticatory properties of gum.

The actual composition of a gum base is usually a trade secret. The FDA allows 46 different chemicals under the umbrella of "gum base."[1][2] The chemicals are posted on their website. These chemicals are grouped into the following categories.

Synthetic coagulated or concentrated latices: Polymers such as butadiene-styrene, vinyl acetate, polyethylene, paraffin, and petroleum waxes are the most commonly used gum bases on the market today. They are petroleum-derived polymers which are designed to maximize elasticity and incorporate other components of the gum base as well as flavors and sweeteners in their chemical matrix.[3]

Plasticizing materials (softeners): These materials generally help to emulsify various chemical components that do not always bind to each other. They are generally medium-sized molecules and are frequently esters of tree resins and rosins.

Terpene resins: This specific subcategory is not fundamentally different from materials in the first two categories except it is a specific substance that can be produced both naturally and artificially.

Preservatives: The most common antioxidant preservative in gum, BHT, functions by scavenging free radicals (which spoil food) and sequestering them behind its sterically hindering tert-butyl groups.[4]

Natural coagulated or concentrated latices of vegetable origin: These include many of the resins such as chicle that were traditionally chewed as gum. It also includes natural waxes like beeswax and latex (natural rubber). These natural sources of gum base have largely been replaced by synthetic, petroleum-derived gum bases.

Gum bases for chewing gum are different from those for bubble gum. A bubble gum base is formulated with the ability to blow bubbles; it contains higher levels of elastomers or higher molecular weight polymers for this purpose. Gum bases for antacid use calcium carbonate as a filler, while gum bases for acid flavored gum use talc as a filler, since acids can react with calcium carbonate to produce carbon dioxide gas, which is undesirable.

Bubble gum usually contains 15–20% gum base, while chewing gum contains 20–25% gum base and sugar-free chewing gum contains 25–30% gum base.

Researchers at the University of Illinois at Urbana–Champaign and at Wm. Wrigley Jr. Company are studying the possibility of making gum base with biodegradable zein (corn protein).[5]

Large chewing gum manufacturers generally produce their own gum base in-house while small chewing gum producers usually buy gum base from third-party suppliers.

1 note

·

View note

Text

Global Styrenic Block Copolymer Market to be Driven by Growing Demand for Green Construction Materials in the Forecast Period of 2022-2027

The new report by Expert Market Research titled, ‘Global Styrenic Block Copolymer Market Report and Forecast 2022-2027’, gives an in-depth analysis of the global styrenic block copolymer market, assessing the styrenic block copolymer market, based on its segments like products, applications, and major regions. The report tracks the latest trends in the industry and studies their impact on the overall market. It also assesses the market dynamics, covering the key demand and price indicators, along with analysing the market based on the SWOT and Porter’s Five Forces models.

Request a free sample copy in PDF or view the report summary@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market/requestsample

The key highlights of the report include:

Market Overview (2017-2027)

Historical Market Size (2020): About USD 8.1 billion

Forecast CAGR (2022-2027): 4.60%

Forecast Market Size (2026): Nearly USD 10.6 billion

The growth in the global market for styrenic block copolymer is being driven by the rising demand for styrene-butadiene-styrene (SBS). This can be associated with the rising demand for SBS from the polymer modification, footwear, construction, adhesives and sealant segments. The demand for SBS in the construction sector is being led by its applications in paving and roofing. This trend is further supported by rising construction and reconstruction activities around the world on account of rising urbanisation and industrialisation. Geographically, the Asia Pacific region is likely to account for a significant share of the market during the forecast period.

Industry Definition and Segmentation

Styrenic block copolymers refer to high-performance thermoplastic elastomers. These are specifically designed to increase product application and performance in end-use sectors. Styrenic block copolymers are thermally stable, crystal clear, and resistant, with little cytotoxic or mutagenic potential.

Explore the full report with the table of contents@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market

Based on product, the market can be segmented into:

Styrene-Butadiene-Styrene (SBS)

Styrene-Isoprene-Styrene (SIS)

Hydrogenated SBC (HSBC)

On the basis of application, the market divisions are:

Asphalt Modification

Wires and Cables

Polymer Modification

Adhesives and Sealants

Footwear

Others

The regional markets for styrenic block copolymer include:

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Latest News on Global Styrenic Block Copolymer Market@ https://www.expertmarketresearch.com/pressrelease/global-styrenic-block-copolymer-market

Market Trends

The growth in the global market for styrenic block copolymer is being positively influenced by applications in the medical equipment manufacturing sector. The increasing demand for medical equipment like tubing, bags, and IV drip chambers is driving the market forward. This can be attributed to the favourable properties of styrenic block copolymer which include high transparency, flexibility, good mechanical strength, kink resistance, and excellent UV and chemical resistance. Increasing medical spending and advancements in medical equipment technology are expected to further contribute to the growth of the market. Apart from this, the construction sector is projected to be a leading application segment owing to increasing investments in green building projects. This is likely to raise the demand for lightweight, environmentally friendly material like styrenic block copolymers, hence fuelling the growth of the market.

Key Market Players

The major players in the market are China Petrochemical Corporation, Asahi Kasei Corporation, JSR Corporation, Ineos Styrolution Group GmbH, Eastman Chemical Company, and Kumho Petrochemical, among others. The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

About Us:

Expert Market Research is a leading business intelligence firm, providing custom and syndicated market reports along with consultancy services for our clients. We serve a wide client base ranging from Fortune 1000 companies to small and medium enterprises. Our reports cover over 100 industries across established and emerging markets researched by our skilled analysts who track the latest economic, demographic, trade and market data globally.

At Expert Market Research, we tailor our approach according to our clients’ needs and preferences, providing them with valuable, actionable and up-to-date insights into the market, thus, helping them realize their optimum growth potential. We offer market intelligence across a range of industry verticals which include Pharmaceuticals, Food and Beverage, Technology, Retail, Chemical and Materials, Energy and Mining, Packaging and Agriculture.

Media Contact

Company Name: Claight Corporation

Contact Person: Steven Luke, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

City: Sheridan

State: Wyoming

Country: United States

Website: https://www.expertmarketresearch.com

Read More:

Health Insurance Market: https://www.digitaljournal.com/pr/global-health-insurance-market-is-expected-to-grow-steadily-at-cagr-of-6-in-the-forecast-period-of-2021-2026-2

Noninvasive Neuromodulation Market: https://www.digitaljournal.com/pr/global-noninvasive-neuromodulation-market-to-be-driven-by-technological-and-medical-advancements-in-the-forecast-period-of-2021-2026

Alumina Trihydrate Market: https://www.digitaljournal.com/pr/global-alumina-trihydrate-market-to-be-driven-by-the-versatility-and-application-flexibility-of-alumina-trihydrate-in-the-forecast-period-of-2021-2026

Food Dehydrators Market: https://www.digitaljournal.com/pr/global-food-dehydrators-market-to-be-driven-at-a-cagr-of-5-in-the-forecast-period-of-2021-2026

Glucuronolactone Market: https://www.digitaljournal.com/pr/global-glucuronolactone-market-to-be-driven-by-the-heightened-demand-for-the-product-in-the-pharmaceutical-sector-in-the-forecast-period-of-2022-2027

Also, Check Procurement Intelligence which provides you with Infallible research solutions.

*We at Expert Market Research always thrive to give you the latest information. The numbers in the article are only indicative and may be different from the actual report.

#Styrenic Block Copolymer Market#Styrenic Block Copolymer Market Size#Styrenic Block Copolymer Market Analysis#Styrenic Block Copolymer Market Report

2 notes

·

View notes

Text

Styrene Butadiene Rubber (SBR) Market Analysis: Assessing Growth Opportunities

Styrene Butadiene Rubber (SBR) stands as one of the most widely used synthetic rubbers globally, finding extensive applications across various industries. This blog delves into the dynamics of the SBR market, exploring its key drivers, diverse applications, emerging trends, and future growth prospects.

Understanding Styrene Butadiene Rubber (SBR):

Styrene Butadiene Rubber (SBR) is a synthetic elastomer derived from the copolymerization of styrene and butadiene. It exhibits excellent abrasion resistance, good aging properties, and versatility in processing, making it a preferred choice for numerous rubber applications.

Market Dynamics:

Automotive Tire Industry: The dominant use of SBR is in tire manufacturing due to its high abrasion resistance, good grip on road surfaces, and cost-effectiveness compared to natural rubber (NR).

Footwear and Industrial Rubber Goods: SBR is extensively used in footwear soles, conveyor belts, hoses, gaskets, and other industrial rubber products due to its durability, flexibility, and resistance to wear and tear.

Polymer Modification: SBR serves as a modifier in polymer blends and compounds, enhancing properties such as impact resistance, flexibility, and weatherability in plastics and other materials.

Construction and Infrastructure: SBR-based compounds are employed in construction materials such as seals, gaskets, and roofing membranes due to their weather resistance and sealing properties.

Applications Across Industries:

Automotive: Tire treads, sidewalls, automotive seals.

Footwear: Shoe soles, industrial rubber goods.

Polymer Blends: Impact modifiers, polymer blends.

Construction: Seals, gaskets, roofing membranes.

Market Trends:

Green Initiatives: The SBR market is witnessing a shift towards eco-friendly formulations, including bio-based SBR and recycled SBR materials, driven by environmental regulations and sustainability goals.

High-Performance Grades: Manufacturers are developing high-performance SBR grades with improved properties such as enhanced grip, reduced rolling resistance for tires, and better wear resistance for industrial applications.

Innovation in Blends: Blending SBR with other elastomers or additives to achieve specific performance characteristics, such as oil resistance, heat resistance, and electrical conductivity, is a growing trend in the market.

Future Prospects:

The global Styrene Butadiene Rubber market is poised for steady growth, fueled by the expanding automotive industry, infrastructure developments, and ongoing advancements in material science. Sustainable practices, technological innovations, and customized solutions will drive the market towards enhanced performance and environmental responsibility.

Conclusion:

Styrene Butadiene Rubber remains a cornerstone material in the rubber and polymer industries, catering to diverse applications with its exceptional properties and cost-effectiveness. Understanding market trends, consumer demands, and technological innovations will be crucial for stakeholders navigating the evolving SBR market landscape. As industries evolve, SBR's versatility and adaptability ensure its continued relevance and growth in meeting the demands of modern applications worldwide.

0 notes

Text

Plastic Injection Mold Florida

Florida is known for its fine weather and diverse groups of people who call it home. It is also a highly industrialized place, with many big manufacturing companies calling the state their home. One of the most important manufacturing companies in the state is plastic injection mold Florida, which uses melted plastic to produce parts and products for a variety of industries. Injection molding is a complex process that requires a great deal of skill and knowledge. It is used to make a wide variety of products, including consumer goods, automotive parts, and medical devices. Injection mold florida is a rapidly growing industry, with demand for this type of work rising significantly in recent years.

American Plastic Molds was founded in 2014 with the goal of helping local businesses get the industrial plastic products they need. This company offers a full range of services for plastic injection molding, including prototyping and tool design. They have a lot of experience, having worked on many projects in different industries. Their expertise allows them to provide high-quality products and services at a competitive price.

Another great company that provides quality plastic injection molding in Florida is American Plastic Molds. This second-generation, family-owned and operated business has been in operation for over 20 years. Their injection-molded products are in demand from the commercial and residential markets, as well as by a number of large companies in the aerospace, marine, defense, and automotive industries. The company has a strong focus on customer service, and they have some of the best machinery available in the industry to ensure that their customers are satisfied with their product.

Injection molding is a highly customizable and flexible process that can be used to create a wide variety of different products. Injection molding is a great option for producing high-quality parts, and it can be used to make everything from consumer products to industrial equipment. The benefits of this process include the ability to customize and adjust the part to fit the specific needs of the client, as well as the cost-effectiveness of the process.

Some of the most important things to consider when choosing an injection molding company are the materials that they use and their experience in creating tight tolerance parts. National Molding is an experienced injection molder that specializes in tight tolerance parts and close-tolerance injection molding. They have a comprehensive set of services, including 3D CAD design, in-house tooling, and production runs up to 1 million parts.

The company works with a wide range of polymers, often called resins, to meet the demands of various applications. Some of the most common materials include acrylonitrile butadiene styrene (ABS), polycarbonate, nylon, and high-impact polystyrene. They can also work with thermoplastic elastomers, acetal, and Ultem®. The company offers horizontal, vertical, insert, and over molding as well as secondary services such as box-build assembly, pad and screen printing, electroplating, hydro-dipping, laser etching, hot stamping, internal and external threading, and metal stamping.

1 note

·

View note

Text

Key Players and Competitive Landscape in the SBR Market

The Styrene Butadiene Rubber (SBR) market features several key players that dominate the global landscape. These companies are involved in manufacturing and supplying SBR for various applications across industries such as automotive, construction, footwear, and consumer goods.

Buy the Full Report for SBR Industry Capacity Forecast, Download a Free Report Sample

Here are some of the key players and their roles in the competitive landscape:

Synthos S.A.: Synthos is a leading European producer of synthetic rubber, including SBR. The company offers a wide range of SBR grades for applications such as tires, conveyor belts, footwear, and adhesives. Synthos operates production facilities in Poland and supplies its products to customers worldwide.

LANXESS AG: LANXESS is a global specialty chemicals company that produces synthetic rubber, including SBR, under its Performance Butadiene Rubbers business unit. The company offers SBR grades for tire manufacturing, polymer modification, and other industrial applications. LANXESS has manufacturing facilities in Europe, North America, and Asia.

Trinseo S.A.: Trinseo is a global materials solutions provider that manufactures and supplies SBR for various applications, including tires, footwear, and construction. The company offers a diverse portfolio of SBR grades tailored to meet customer requirements for performance, durability, and cost-effectiveness.

Michelin Group: Michelin is one of the world's largest tire manufacturers and a major consumer of SBR for tire production. The company operates its own SBR production facilities and also sources SBR from third-party suppliers to meet its manufacturing needs. Michelin's expertise in tire technology and materials science contributes to its competitiveness in the SBR market.

SIBUR Holding: SIBUR is the largest integrated petrochemicals company in Russia and one of the leading producers of synthetic rubber, including SBR. The company operates SBR production facilities in Russia and supplies its products to customers in various industries worldwide.

Goodyear Tire & Rubber Company: Goodyear is a global tire manufacturer that utilizes SBR in its tire compounds for passenger cars, trucks, and aircraft. The company sources SBR from multiple suppliers and also produces its own SBR at select manufacturing facilities. Goodyear's reputation for quality and innovation contributes to its position in the SBR market.

JSR Corporation: JSR is a Japanese chemical company that produces synthetic rubber, including SBR, for various applications such as tires, automotive parts, and industrial goods. The company's expertise in polymer science and materials technology enables it to develop high-performance SBR grades to meet customer specifications.

Lanxess: Lanxess is a global specialty chemicals company and a leading manufacturer of synthetic rubber, including SBR. The company offers a wide range of SBR grades for applications such as tires, conveyor belts, and footwear. Lanxess operates production facilities in Europe, North America, and Asia-Pacific.

Versalis S.p.A. (Eni): Versalis, the chemical subsidiary of Eni, is a leading producer of synthetic rubber, including SBR. The company offers SBR grades for tire manufacturing, polymer modification, and other industrial applications. Versalis leverages its expertise in petrochemicals and polymer technology to meet customer demands for quality and performance.

Kumho Petrochemical Co., Ltd.: Kumho Petrochemical is a South Korean company that manufactures synthetic rubber, including SBR, for various applications such as tires, automotive parts, and industrial goods. The company's SBR products are known for their quality, consistency, and performance in demanding environments.

These key players compete on factors such as product quality, performance, reliability, innovation, and customer service to maintain their market position and gain a competitive edge in the global SBR market. Additionally, partnerships, collaborations, and strategic alliances with customers and suppliers are common strategies employed by SBR manufacturers to expand their market presence and meet evolving customer needs.

0 notes

Text

The ABCs of ABS: Unraveling the Characteristics and Uses of Acrylonitrile Butadiene Styrene (2023-2034)

This blog will focus on Acrylonitrile Butadiene Styrene (ABS). ABS is comprised of three monomers: Acrylonitrile, Butadiene, and Styrene. In this article, we'll look at how the polymer's unique properties work together to give ABS its exceptional strength, toughness, as well as the manufacturing process. The global Acrylonitrile Butadiene Styrene (ABS) market is likely to flourish at a moderate CAGR of 5.90% by the year 2034.

Introduction

Styrene Acrylonitrile has existed since the 1940s. While they improved toughness over pure styrene, their limits necessitated the addition of rubber (butadiene) as a third monomer. ABS consists of three major monomers: acrylonitrile, butadiene, and styrene.

Acrylonitrile contributes to ABS's chemical resistance and heat stability.

Butadiene enhances the toughness and impact strength of ABS.

Styrene provides ABS with rigidity and facilitates its processability.

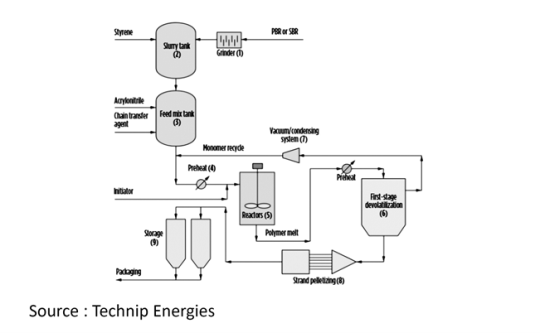

Manufacturing Process

ABS copolymers exhibit notable toughness, superior thermal resistance, and properties that surpass those of polystyrene plastics. ABS is produced through three distinct polymerization techniques: emulsion, suspension, and mass processes.

In the Mass Process, ABS is produced by the continuous copolymerization of styrene and acrylonitrile monomers with Polybutadiene Rubber (PBR) or Styrene-Butadiene Rubber (SBR) using a series of reactors, aided by organic peroxide. In a sequential process, chopped PBR or SBR is added to a slurry tank containing styrene monomer. The resultant mixture is then transferred to the ABS feed batch tank for complete rubber dissolution. This concentrated rubber solution is diluted with acrylonitrile, recycled monomer, and a chain transfer agent according to product requirements before preheating prior to entering the polymerization reactors.

Polymerization Section

The polymerization section employs a unique combination of plug flow and boiling stirred tank reactors arranged in series. Organic peroxide is introduced to initiate polymerization. This reactor setup allows precise control over various parameters such as rubber grafting, phase inversion, and molecular weight. Monomer conversion increases progressively throughout the reactor system, reaching final levels between 60% to 75%. Devolatilization is achieved through either extrusion or flash chamber methods.

Devolatization

In the extrusion devolatilization approach, the product from the last reactor undergoes stripping of unreacted monomers and byproducts in an extruder devolatilization system. Alternatively, the reactor product is subjected to volatile removal in a multistage flash devolatilization system operating under vacuum. Vapors are condensed, and the resulting mixture is recycled. The devolatilized polymer melts and then pelletizes and then dried.

Applications of Acrylonitrile Butadiene Styrene (ABS):

ABS (Acrylonitrile Butadiene Styrene) finds numerous applications across various industries. High impact grades are utilized in the production of travelling bags, helmets, furniture, sports goods, and automotive components, while medium impact grades are employed in radiator and air conditioner grills, heavy-duty domestic appliances, and control panels. Electroplating grades find their place in TV and radio knobs, bathroom fittings, refrigerator handles, and nameplates. High flow grades are ideal for housing domestic appliances, office equipment, and cabinets of electronic devices. High heat-resistant grades are utilized in automobile components and housing for electrical heaters and dryers. Transparent grades are sought after for areas requiring high transparency and impact strength, while impact modifier grades serve as modifiers for PVC compounding across various formulations. Glass-filled grades cater to applications demanding high flexural strength and stiffness, maintaining impact and tensile properties, while extrusion grades are used in refrigerator linings and luggage production.

Automotive

The automotive industry demands stringent standards from its materials. They must remain dimensionally stable and resist warping even when subjected to extreme stresses and significant temperature fluctuations.

Electronics & Electricals

ABS stands out in this regard due to its outstanding antistatic properties, providing a distinct advantage in meeting these requirements.

Appliances

ABS finds extensive applications in appliances, encompassing appliance control panels, housings for various devices such as shavers, vacuum cleaners, and food processors, as well as refrigerator liners, among others. Household and consumer goods represent the primary domains where ABS is widely utilized. Additionally, ABS is commonly employed in the manufacturing of keyboard keycaps.

Pipes & Fittings

ABS pipes and fittings are highly liked due to their ease of installation and rust resistance, making them a popular choice in a variety of applications.

Market Outlook:

ABS is an invariable thermoplastic polymer made up of three distinct monomers: acrylonitrile, butadiene, and styrene, which can change in proportion. They are also referred to as engineering plastics. Acrylonitrile provides chemical and thermal stability, styrene gives the plastic a glossy sheen, and butadiene provides strength and durability. These materials are widely used in the electronic appliance and automobile industries for vehicle and auto components production. The rapid growth of the medical business has increased demand for medical equipment, which is driving market growth. Furthermore, the growing construction and aerospace industries are predicted to significantly boost the ABS sector during the projection period. The global Acrylonitrile Butadiene Styrene (ABS) market is anticipated to reach approximately 15.7 million tonnes by 2034.

Acrylonitrile Butadiene Styrene (ABS) Major Manufacturers

Significant companies in the Global Acrylonitrile Butadiene Styrene (ABS) market are Formosa Chemicals and Fiber Corporation, LG Chem, LOTTE Chemical Corporation, Jilin Petrochemical Company, Toray Industries, CHIMEI Corporation, Tianjin Dagu Chemical Co., Ltd., and Others.

Challenges and Opportunities

While ABS possesses numerous advantageous properties, there are several restraining factors that could impact its market growth:

Environmental Concerns: ABS is derived from petrochemical sources, and its production and disposal can contribute to environmental pollution. Increasing environmental consciousness, combined with strict laws on plastic waste management and recycling, may present difficulties to the ABS market.

Competition from Alternative Materials: ABS faces competition from other engineering thermoplastics, such as polycarbonate (PC) and polypropylene (PP), which offer similar or enhanced properties in certain applications.

Conclusion:

Acrylonitrile Butadiene Styrene (ABS) is a versatile polymer with numerous useful applications. It is an essential in automotives and Electrical & Electronics industries owing to its unique set of properties. The surging demand for Acrylonitrile Butadiene Styrene (ABS) from Automotive, Home Appliances, Electrical & Electronics, and Building & Construction end-use industries, is anticipated to play a role in the demand-supply dynamics of the Acrylonitrile Butadiene Styrene (ABS) market.

0 notes

Text

Top 10 Plastics Market Size and Share Analysis

Top 10 Plastics Market report provides the broader perspective of the market place with its comprehensive market insights and analysis which eases surviving and succeeding in the market. This market report brings into focus plentiful of factors such as the general market conditions, trends, inclinations, key players, opportunities, and geographical analysis which all aids to take the business towards the growth and success. Moreover, Top 10 Plastics Market report explains better market perspective in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. Hence, the Top 10 Plastics Market report brings into the focus, the more important aspects of the market or Chemicals & Materials industry.

Top 10 Plastics Market, by Type (Polyethylene, Polypropylene, Polystyrene, Polyethylene Terephthalate, Polyvinyl Chloride, Polycarbonate, Acrylonitrile Butadiene Styrene, Polyoxymethylene, Polyamide, Polyurethane), End-Use Industry (Building & Construction, Electronics & Consumer, Automotive, Textile, Packaging), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America).

Download Free Sample Report: https://www.delvens.com/get-free-sample/top-10-plastics-market

Top players covered in the Top 10 Plastics Market report:

Arkema

BASF SE

Braskem

Celanese Corporation

Chevron Phillips Chemical Co., LLC

Covestro AG

Dow Inc

Ducor Petrochemicals

DuPont de Nemours, Inc

Eastman Chemical Company

Evonik Industries

Exxon Mobil Corporation

Formosa Plastic Corporation

INEOS

Lotte Chemical Corporation

Mitsui & Co. Plastic Ltd.

Reliance Industries Limited

Repsol

SABIC

Sumitomo Chemical Co., Ltd.

Toray Industries, Inc.

Top 10 Plastics Market Recent Developments:

In August 2023, A joint venture agreement was formed by the biopolymer manufacturer Braskem and SCG Chemicals to create bio-ethylene from bio-ethanol dehydration and to market Braskem's "I'm green" bio-based Polyethylene.

In June 2023, BASF set up a new polyethylene plant in Zhanjiang Verbund site in China. The brand-new facility, with a yearly capacity of 500,000 metric tons of PE, will meet China's rapidly expanding demand. In 2025, the facility is expected to begin operations.

The Top 10 Plastics Market size was estimated at USD 503.11 billion in 2023 and is projected to reach USD 777.21 billion in 2030 at a CAGR of 6.41% during the forecast period 2023-2030.

Although they generally incorporate additional materials, plastics are high molecular mass organic polymers. The majority of the time, they are synthetic and made from petrochemicals. However, the current emphasis on the environment has led to an increase in the number of plastics made from renewable resources, such as cellulosic from cotton linters and polylactic acid made from corn. Due to their comparatively low cost, simplicity of production, adaptability, and water resistance, plastics are now used in a wide variety of items. Plastic is used in everything, from basic items like paperclips to large ones like airplanes. Based on their availability and application, the top 10 most abundantly used plastics are polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide and polyurethane.

Plastic consumption is being driven by the food and beverage sectors' expanding requirement for packaging materials. product manufacturers seek packaging that guards against contamination and deterioration of product quality. Demand is being fuelled by plastic's ability to act as a shield between food products and the outside world. Moreover, their increased demand in textile, electrical and electronic, automotive, and consumer goods sectors is driving the growth of the market further.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/top-10-plastics-market

Top 10 Plastics Market Key Findings:

Based on type, the market is segmented into polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide, polyurethane. Polyethylene dominated the market in this segment owing to its extensive usage packaging, construction, electrical & electronics and construction. Moreover, the substitution of metal-based products with plastic based products is expected to drive the growth of polyethylene market further during the forecast period.

Based on end use industry, the market is segmented into building & construction, electronics & consumer, automotive, textile, packaging. Packaging dominated the market in this segment owing to the increased packaging demand from the rapidly growing food and beverages industry.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector, increased R&D activity, presence of major key players and easily available raw materials.

Top 10 Plastics Market Regional Analysis:

Asia Pacific to Dominate the Market

Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector and increased R&D activity within the region.

Moreover, the presence of major key players and availability of raw materials are expected to drive the growth of the market further during the forecast period.

Top 10 Plastics Market report involves use of latest tools and techniques for researching, analyzing and gathering of data and information. The market analysis here includes competitive study, product information analysis, applications, and region-wise analysis, competitor landscape, consumption and revenue study, cost structure analysis, price evaluation and revenue analysis up to 2030. This Top 10 Plastics Market report performs systematic gathering, recording and analysis of data about the issues related to the marketing of goods and services and serves the businesses with an excellent market research report. The global Top 10 Plastics Market report provides smart solutions to the complex business challenges and commences an effortless decision-making process.

Direct Purchase of the Top 10 Plastics Market Research Report at: https://www.delvens.com/checkout/top-10-plastics-market

Explore Related Reports:

Fire Protection Materials Market

Battery Recycling Market

Metal Foam Market

3D Printing Metals Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

#consulting company#strategic advisory firm#best market reports#market analysis reports#trending reports#syndicated reports#Top 10 Plastics Market#Top 10 Plastics#Top 10 Plastics Industry#Chemicals & Materials#Chemicals

0 notes

Text

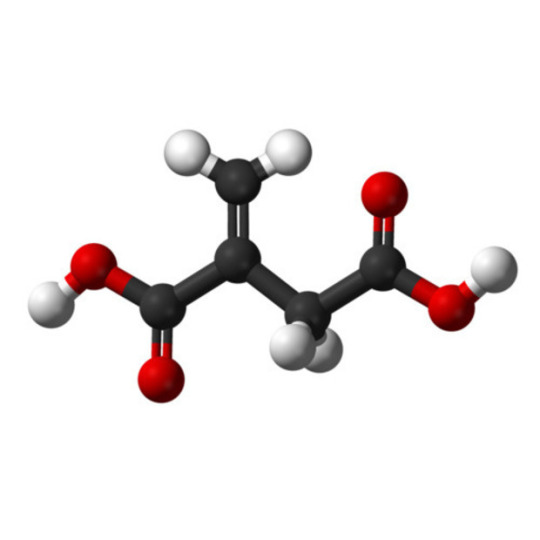

Analyzing the Global Methyl Methacrylate Market: Trends, Growth Drivers, and Industry Insights

Methyl Methacrylate: Properties, Synthesis and Industrial Uses of Methacrylate

Chemical Properties

Methyl methacrylate, commonly known as MMA, is an organic compound with the formula C5H8O2. It is a colorless, volatile liquid with an acrid odor. MMA is moderately soluble in water but highly soluble in most organic solvents such as alcohol, ether, acetone and dichloromethane.

The primary property of MMA is that it undergoes free radical polymerization, which leads to the formation of PMMA. During polymerization, the carbon double bonds in MMA monomers react to form long chains or polymers. This conversion of a low-molecular-weight liquid to a high-molecular-weight solid plastic through polymerization is the reason why MMA finds numerous industrial applications.

MMA polymerizes via a free radical mechanism initiated by heat, light or chemicals like peroxides. The polymerization is exothermic and needs to be controlled carefully. During industrial production of PMMA, monomers, polymers and residual reactants must be kept separate to avoid premature or uncontrolled polymerization.

Synthesis of MMA

Commercially, MMA is produced through the acetone cyanohydrin process, which involves the reaction of acetone and hydrogen cyanide to form acetone cyanohydrin. This intermediate is then reacted with methanol in the presence of an acid catalyst to yield MMA.

CH3COCH3 + HCN → CH3C(OH)CN + H2O

CH3C(OH)CN + CH3OH → CH2=C(CH3)COOCH3 + H2O

The overall reaction involves the replacement of the nitrile group in acetone cyanohydrin by a methoxy carbonyl group through acid-catalyzed esterification. Major process parameters are the selection of acid catalyst, temperature control and recovery of byproducts.

MMA can also be synthesized through the methacrylic acid process, which involves the carbonylation of acetylene to methacrylic acid, followed by esterification with methanol. However, the acetone cyanohydrin process is preferred industrially due to lower costs.

Industrial Uses of MMA

Some of the major industrial applications of MMA and PMMA are:

Plexiglas and Optical Materials - PMMA in the form of Plexiglas sheets finds widespread use as an alternative to glass in lighting fixtures, transport equipment, window panes and optical instruments. It offers advantages of lighter weight, thermal insulation and durability.

Automotive and Aircraft Industries - MMA is used to manufacture canopies, light covers, glazing panels and translucent roof panels for aircraft, vehicles, trains and boats. PMMA offers crash resistance, high optical clarity and weatherability.

Paints and Coatings - MMA or blends of MMA and styrene are used as monomers in paints and coatings for their resistance to solvents, weathering and aging. Applications include automotive finishes and industrial flooring.

Adhesives - MMA based adhesives bond plastics, metals, wood, ceramics and composites. They offer high adhesion strengths along with heat, chemical and water resistance.

Acrylic Fibers - Polymerization of MMA leads to acrylic fibers used in textiles and apparels. They mimic the feel and appearance of wool but are cheaper and easier to maintain.

Medical Devices - PMMA is approved by FDA for applications such as bone cement, breast implants and contact lenses due to its biocompatibility and durability.

In summary, methyl methacrylate serves as a vital building block monomer in the synthesis of PMMA, which then finds diverse industrial applications leveraging its outstanding material properties. Strict process control during MMA production and polymerization is needed for safety and maximal output.

0 notes

Text

Styrenic Polymer Packaging Market by Product, Types, Procedure, Application, End-user Global Forecast to 2029

Industry Analysis

Data Bridge Market Research analyses that the styrenic polymer packaging Market was valued at USD 5.53 billion in 2021 and is expected to reach USD 9.08 billion by 2029, registering a CAGR of 6.4 % during the forecast period of 2022 to 2029.

Data Bridge market report covers an array of aspects of the market analysis which today’s businesses call for. This market document also defines a chapter on the global market and allied companies with their profiles, which provides important data pertaining to their insights in terms of finances, product portfolios, investment plans, and marketing and business strategies. This market research report is generated with a nice blend of industry insight, talent solutions, practical solutions and use of technology to advance user experience. An outstanding Data Bridge market report puts light on many aspects related to Materials and Packaging industry and market.

Market Insights and Scope

Styrenic polymers are economical plastics that contain many plastic products with styrene as their primary building block. Due to their amorphous structure, these polymers can be quickly processed well above their softening point and over a varied temperature range. Styrenic polymers do not have a different melting point than other partly crystalline polymers. Styrenic polymers allow faster processing of these polymers and high dimensional stability and outstanding mechanical properties.

Additionally, the credible Styrenic Polymer Packaging Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Materials and Packaging industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Industry Segmentation

The styrenic polymer packaging market is segmented based on products and end-user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Products

Polystyrene (PS)

Acrylonitrile Butadiene Styrene (ABS)

Expanded Polystyrene (EPS)

Unsaturated Polyester Resin (UPR)

Styrene-Butadiene Rubber (SBR)

Other Polymers

Application

Building and construction

Automotive industry

Packaging

Medical

Electrical and electronics

Consumer goods

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-styrenic-polymer-packaging-market

Market Country Level Analysis

The countries covered in the styrenic polymer packaging market report is

U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-styrenic-polymer-packaging-market

Industry Share Analysis

Some of the major players operating in the styrenic polymer packaging market are:

BASF SE (Germany)

Lanxess A (Germany)

SABIC (south Arabic)

Dow (U.S)

Chimei (Taiwan)

LG Chem (South Korea)

Chevron Philips Chemical Company (U.S)

RocketReach.co (U.S)

Versalis SpA (Italy)

NOVA Chemicals Corporate (Canada)

Synthos (Poland)

INEOS Styrolution Group GmbH (Germany)

PS Japan Corporation (U.S)

Kraton Corporation (U.S)

An influential Styrenic Polymer Packaging Market research report displays an absolute outline of the market that considers various aspects such as product definition, customary vendor landscape, and market segmentation. Currently, businesses are relying on the diverse segments covered in the market research report to a great extent which gives them better insights to drive the business on the right track. The competitive analysis brings into light a clear insight about the market share analysis and actions of the key industry players. With this info, businesses can successfully make decisions about business strategies to accomplish maximum return on investment (ROI).

Get TOC Details: https://www.databridgemarketresearch.com/toc/?dbmr=global-styrenic-polymer-packaging-market

Browse Related Reports@

Global 1, 4-Cyclohexanedimethanol Dibenzoate Market

Global Plant Hydrocolloids Market

U.S. Tahini Market

Asia-Pacific Hydroxyl-Terminated Polybutadiene (HTPB) market

West Africa Shisha Tobacco Market

Global Orthostatic Hypotension Drugs Market

Europe Customer Journey Analytics Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Styrenic Polymer Packaging Market-by Product-Types-Procedure-Application-End User-Global-Forecast to-2029#Styrenic Polymer Packaging Market-Global Opportunity-Analysis and-Industry-regional#Styrenic Polymer Packaging Market-Growth-Competition-Scenario-Outlook#Styrenic Polymer Packaging Market-Insights-Country-Share-Competitors-Research-Study#Styrenic Polymer Packaging Market-Demands-Size-Share-Top Trends-Report-to-2029#Styrenic Polymer Packaging Market Value-Segmentation-CAGR rate-Future Trends#Styrenic Polymer Packaging Market-drivers-advantages-restraints-challenges#Styrenic Polymer Packaging Market-Leading Brands-Business-Materials and Packaging#Styrenic Polymer Packaging Market-Growing Popularity-Traffic-DBMR

0 notes

Text

Exploring the Biomedical Applications of Itaconic Acid in Drug Delivery and Biomaterials

Itaconic Acid: A versatile platform chemical gaining significance

Production and Applications of Methylenesuccinic Acid

Itaconic acid is produced through fermentation of carbohydrates like glucose, sucrose or molasses by fungi species Aspergillus itaconicus or Ustilago maydis. The process involves fungi growth in aqueous medium containing nutrients and sugars followed by acidification to extract methylenesuccinic acid. The medium is then filtered and purified using ion-exchange or crystallization to achieve high purity methylenesuccinic acid. Some key players involved in commercial production of methylenesuccinic acid include Itaconix Corporation, Qingdao Kehai Biochemistry Co., Ltd. and Zhejiang Guoguang Biochemistry Co., Ltd. Current global production capacity of methylenesuccinic acid stands at over 50,000 tons per year.

Uses in Polymers and Specialty Chemicals Manufacturing

Being a dicarboxylic acid, methylenesuccinic acid serves as an important building block chemical for polymers and specialty chemicals. It finds significant usage in manufacturing of synthetic latex, superabsorbent polymers, chelating agents and copolymers for diverse applications. As a comonomer for acrylate or methacrylate polymers, methylenesuccinic acid improves water-absorbency and acid-base properties. Its copolymers with acrylates and styrene are used in paper coatings, adhesives, thickeners and dispersants. Methylenesuccinic acid also acts as a complexing agent for heavy metal ions and is used in industrial and agricultural chelating formulations.

Potential in Novel Therapeutic Applications

Novel applications of itaconic acid are being researched in the medical field as well. Some studies have revealed its anti-fungal, antibacterial and anti-viral properties. Research is in progress to develop itaconate derivatives with enhanced bioactivity against multi-drug resistant pathogens. Methylenesuccinic acid is also known regulate inflammatory responses in human body by inhibiting certain enzymes. This makes it a potential candidate for developing novel anti-inflammatory pharmaceuticals. Exploratory trials indicate it may assist in managing conditions like diabetes, neurodegeneration and cancer. Though in early stages, these therapeutic applications open up completely new frontiers for methylenesuccinic acid if successfully commercialized in future.

To conclude, with its unique structural attributes and bio-based origin, methylenesuccinic acid has emerged as a very important specialty platform chemical with broad scope across industries. Backed by steady growth in end-use markets and rising sustainability emphasis, the methylenesuccinic acid industry is rightly positioned for significant expansion globally in the coming years. Ongoing R&D and commercial initiatives also point towards novel product concepts and applications further accentuating the industrial relevance of this multifaceted organic acid.

0 notes

Text

Emulsion Polymers Market to Attain the Value of US$54.9 Billion by 2023

The global emulsion polymers market is poised for significant expansion between 2023 and 2031, driven by the increasing demand for environmentally friendly and cost-effective polymer solutions across various industries. Emulsion polymers, also known as latex or water-based polymers, find extensive applications in coatings, adhesives, textiles, paper, and construction materials due to their versatility, stability, and ease of use.

In 2022, the global industry was valued at US$ 28.8 billion. It is anticipated to grow at a Compound Annual Growth Rate (CAGR) of 6.7% from 2023 to 2031, reaching US$ 51.7 billion by the end of 2031.

Emulsion polymers are colloidal dispersions of polymers in water, stabilized by surfactants. They offer several advantages over solvent-based polymers, including low VOC emissions, improved safety, and ease of handling. The market for emulsion polymers is witnessing steady growth, driven by the growing emphasis on sustainable manufacturing practices and regulatory compliance.

Discover Valuable Insights: Download the sample of our Emulsion Polymers Market - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1705

Market Segmentation:

By Service Type: Manufacturing, Formulation, Application

By Sourcing Type: Acrylics, Styrene-Butadiene Latex, Vinyl Acetate Polymers, Others

By Application: Paints & Coatings, Adhesives & Sealants, Paper & Paperboard, Textiles & Nonwovens, Others

By Industry Vertical: Construction, Automotive, Packaging, Textile, Paper & Printing, Others

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Mature market with a strong presence of key players and a focus on sustainable coatings and adhesives.

Europe: Stringent environmental regulations drive the adoption of water-based polymer solutions across various industries.

Asia Pacific: Rapid industrialization, urbanization, and infrastructure development fuel the demand for emulsion polymers in emerging economies such as China, India, and Southeast Asian countries.

Latin America and Middle East & Africa: Growing construction activities and increasing investments in infrastructure projects contribute to market growth in these regions.

Market Drivers and Challenges:

Drivers:

Growing demand for eco-friendly and low-VOC polymers

Increasing use of emulsion polymers in architectural coatings and adhesives

Technological advancements in polymerization techniques

Rising consumer awareness regarding sustainable products

Challenges:

Volatility in raw material prices

Intense competition from alternative technologies

Regulatory challenges and compliance requirements

Limitations in performance compared to solvent-based polymers in certain applications

Market Trends:

Focus on Bio-Based Emulsion Polymers: Rising interest in bio-based and renewable polymer feedstocks to reduce environmental footprint and dependency on fossil fuels.

Development of High-Performance Formulations: Introduction of emulsion polymers with enhanced properties such as improved adhesion, abrasion resistance, and weatherability to meet the evolving needs of end-users.

Customization and Tailored Solutions: Increasing demand for customized polymer formulations tailored to specific application requirements and performance criteria.

Future Outlook:

The emulsion polymer market presents lucrative opportunities for growth driven by increasing environmental awareness, stringent regulations, and the shift towards sustainable solutions. Market players are expected to focus on innovation, research, and development to introduce novel products and capture a larger market share.

Key Market Study Points:

Analysis of market dynamics including demand-supply trends and pricing fluctuations

Assessment of regulatory landscape and its impact on market growth

Evaluation of key market segments and growth drivers

Identification of emerging applications and untapped market opportunities

Competitive Landscape:

Key players in the emulsion polymers market include:

BASF SE

Dow Inc.

Arkema Group

Synthomer plc

Celanese Corporation

These companies leverage strategic partnerships, mergers & acquisitions, and investments in research and development to maintain their competitive edge and expand their market presence globally.

Capitalize on the booming Emulsion Polymers Market! Buy your research report now - https://www.transparencymarketresearch.com/checkout.php?rep_id=1705<ype=S

Recent Developments:

Introduction of sustainable and bio-based emulsion polymers

Strategic collaborations for technology transfer and market expansion

Investment in advanced manufacturing facilities and process optimization

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes