#automated guided vehicles

Text

Implementation of an Automatic Guiding Vehicle Solution Based on the Forlinx RK3568 SoM

Automated Guided Vehicles (AGV), also known as unmanned transport vehicles, are characterized by their significant feature of unmanned driving. AGVs are equipped with an automatic guidance system, which ensures that the system can automatically travel along a predetermined route without the need for manual guidance. They can transport goods or materials automatically from the starting point to the destination.

Depending on the navigation method, AGVs can be divided into various types, such as electromagnetic navigation AGVs, laser navigation AGVs, magnetic strip navigation AGVs, QR code navigation AGVs, and vision navigation AGVs.

Among various forms, visual navigation products are the most capable of applying AI technology. They can dynamically capture the surrounding environment image information through cameras, compare it with the stored images database, and after repeated comparisons, they can engage in deep learning to determine the current state and make decisions for the next steps of travel.

Key Features:

Automated Navigation: Through autonomous navigation technologies such as laser navigation, visual navigation, and magnetic navigation, robots can independently plan paths, avoid obstacles, and perform tasks.

Precision and Safety: It can operate on highly accurate paths to perform material handling and distribution tasks, reducing human errors and safety risks.

Multiple Payload Capacities: It can be designed and configured to accommodate different sizes and weights of goods or materials based on requirements.

Flexibility: Adaptability to different manufacturing and warehousing environments. It can easily adapt to different production and warehouse environments, allowing for adjustments in tasks and paths based on requirements.

Reduction of Labor Costs: The application of AGV can reduce manual labor and lower labor costs.

Improving Efficiency: Compared with traditional labor, it can greatly improve the efficiency of production and logistics.

The ARM architecture has several notable advantages in AGV (Automated Guided Vehicle), making it one of the widely adopted processor architectures.

Here are the key benefits of ARM in AGVs:

Low Power Consumption: The ARM processor architecture is known for its low-power characteristics, which is important for AGVs, which often need to run for long periods of time without interruption to perform material handling and distribution tasks.

High Performance: ARM processors offer a wide range of performance levels, from low-power embedded cores to high-performance multi-core processors, which can be selected according to the AGV's application requirements for efficient task execution.

Multi-core Support: The ARM architecture supports multi-core processor designs, which is beneficial for AGV applications that require parallel processing and complex calculations.

Rich Ecosystems: ARM is supported by a rich set of development tools, compilers, operating systems and software libraries, which make it easier to develop and deploy AGV applications.

Customizable: The ARM architecture allows hardware designers to customize the processor to meet the performance, power and size requirements of AGV applications based on specific needs.

Wide Range of Applications: ARM processors are widely used in a variety of applications, including embedded systems, mobile devices, IoT and automation, making it easier to access technical support and resources for adopting the ARM architecture in AGVs.

Cost-effectiveness: ARM processors are typically less expensive for cost-sensitive applications such as AGVs.

The Forlinx FET3568-C SoM is developed based on the Rockchip RK3568 processor, featuring a quad-core 64-bit Cortex-A55 architecture with a high frequency of up to 2.0GHz. This processor is a domestic application platform created by Rockchip specifically for the AIoT and industrial markets, offering high performance, low power consumption, and rich functionality.

AGV Application Advantages:

Powerful performance, combining GPU, NPU, and VPU in one.

Built-in NPU with 1TOPS arithmetic power to meet the demand for lightweight AI computing in the application process, supporting Caffe / TensorFlow / TF-Lite / ONNX / PyTorch / Keras / Darknet mainstream architectures, bringing convenience to machine learning.

Rich interface functionality, convenient for peripheral expansion, including 2 CAN FD interfaces, 4 independent USB interfaces (supporting up to USB 3.0), 3 SATA 3.0 controllers, and 2 built-in GMACs with support for RGMII/SGMII/QSGMII (2 MAC) interfaces, enabling dual gigabit Ethernet.

Support 1080p60fps H.264 and H.265 format hardware encoding; support dynamic bit rate, frame rate, and resolution adjustment.

The board has been subjected to severe ambient temperature tests, pressure tests, and long-term stability operation tests to ensure that it works stably and reliably.

Originally published at www.forlinx.net.

0 notes

Text

AMR & AGV: Clear Choice for Flexible Material Handling At The Warehouse

Why is Warehouse Robotic Automation Surging?

Robotics engineers have worked hard over the last few decades to integrate new technological developments, like artificial intelligence (AI) and the Internet of Things (IoT), with automated robotics technology. Innovative companies that have warehouses in their supply chains love the results that effective automation can bring.

What Sort of Robots Could Work in Your Warehouse?

Automated Guided Vehicles

Automated guided vehicles (AGVs) and their smaller cousins, automated guided carts (AGCs), transport inventory around your warehouse. They normally follow magnetic stripes or a track laid out on your warehouse floor.

For AGVs that don’t follow a track, they possess additional safety scanners that allow them to be used with manual vehicles. They’re also loaded with a map of your warehouse and the locations of all inventory.

AGVs work nights and weekends at the same cost as operating during the day, which improves warehouse efficiency and cuts costs. AGVs only require 8 minutes to recharge, which means they spend very little time out of commission.

Because of the amazing productivity and cost-saving capabilities of AGVs, the new system paid for itself just one year after installation.

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) are like AGVs in that they use sensor technology to deliver inventory around a warehouse. However, unlike AGVs, however they don’t require a set track or preset route between locations. AMRs understand their environment through the use of computers, onboard sensors and maps.

These small and nimble robots have the ability to identify the information on each package and sort it precisely. AMRs can move throughout the warehouse because they create their own routes based on the operation needed. They can reroute when necessary and avoid obstacles in their environment. These robots offer efficiency, accuracy and security during the sorting process.

AMR robots also help to cut down on redundant processes like sorting so that workers can take on more creative and collaborative roles. Humans are sometimes more prone to error when they find a task too boring. Today’s robots, on the other hand, deliver consistent accuracy regardless of how tedious a process is. As a result, warehouses enjoy a higher level of inventory accuracy.

Not only do AMRs help with the picking and sorting process, but they can also be used to conduct daily inventory cycle counts.

Original text: https://www.miwarobotics.com/post/amr-agv-clear-choice-for-flexible-material-handling-at-the-warehouse

1 note

·

View note

Link

#market research future#automated guided vehicle#auto-guided vehicle company#automated guided vehicle trend#guided vehicle technology

0 notes

Text

Automated Guided Vehicles Market Research Analysis, Strategies, Business Plan, Revenue, and Forecast 2030

The qualitative report Published by Exactitude Consultancy research on the Automated Guided Vehicles Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Automated Guided Vehicles market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Automated Guided Vehicles Market from a Global and Regional perspective.

The automated guided vehicles market is expected to grow at 7.9 % CAGR from 2024 to 2030. It is expected to reach above USD 3.8 billion by 2030 from USD 2.0 billion in 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/25120/automated-guided-vehicles-market/

#Automated Guided Vehicles Market Analysis#Automated Guided Vehicles Market Business#Automated Guided Vehicles Market Trends 2024-2030#Automated Guided Vehicles Market Size#Automated Guided Vehicles Market Growth#Automated Guided Vehicles Market Forecast 2030#Automated Guided Vehicles Market Technology#Automated Guided Vehicles Market Key Players#Automated Guided Vehicles Market CAGR#Market Scope#Automated Guided Vehicles Market Opportunity#Automated

0 notes

Text

Detailed Global Research Analysis on "Automated Guided Vehicle Market" | BIS Research

In the ever-evolving landscape of logistics and manufacturing, automation has emerged as a transformative force, enhancing efficiency, reducing costs, and improving overall operational capabilities. One key player in this automation revolution is the Automated Guided Vehicle (AGV) market.

Understanding Automated Guided Vehicles

Automated Guided Vehicles (AGVs) are autonomous mobile robots used for material handling and transportation within a facility. These vehicles are equipped with advanced navigation systems, sensors, and control mechanisms, allowing them to navigate predefined routes and interact with the environment without the need for human intervention. AGVs play a crucial role in streamlining internal logistics, from warehouses and distribution centers to manufacturing facilities.

The Global Automated Guided Vehicle Market accounted for 138,740 units in terms of volume in 2019 and is expected to reach 272,717 units by 2025. The market is anticipated to grow at a CAGR of 13.32% during the forecast period 2020-2025.

Market Dynamics and Growth Drivers

Rising Demand for Warehouse Automation:

The increasing demand for e-commerce and the need for efficient warehouse operations have fueled the adoption of AGVs.

AGVs contribute to optimizing warehouse layouts, ensuring faster order fulfillment, and reducing operational costs.

Focus on Workplace Safety:

AGVs enhance workplace safety by reducing the need for human workers in potentially hazardous environments.

These vehicles are designed with advanced safety features, contributing to accident prevention and promoting a secure working environment.

Integration with Industry 4.0:

The Fourth Industrial Revolution, often referred to as Industry 4.0, emphasizes the integration of smart technologies into manufacturing processes.

AGVs play a vital role in this paradigm, aligning with the principles of connectivity, data exchange, and automation.

Efficiency and Cost Reduction:

AGVs contribute to operational efficiency by automating material handling tasks, leading to faster and more accurate processes.

The reduction in labor costs, improved resource utilization, and minimized errors contribute to overall cost savings.

Grab a Free Detailed Research Report on Automated Guided Vehicle Market Forecast.

AGV Market Trends

Adoption of Collaborative AGVs:

Collaborative AGVs, designed to work alongside human workers, are gaining popularity.

This trend promotes a flexible and adaptive approach to automation, allowing for seamless collaboration between humans and machines.

Integration of Artificial Intelligence (AI):

AGVs are increasingly incorporating AI and machine learning capabilities for enhanced decision-making and adaptability.

AI-driven AGVs can analyze data in real-time, optimize routes, and improve overall operational efficiency.

Customization and Flexibility:

Modern AGVs are designed to be modular and easily adaptable to different environments and tasks.

The ability to customize AGV functionalities allows businesses to tailor automation solutions to their specific needs.

Environmental Sustainability:

There is a growing emphasis on the environmental impact of industrial processes.

AGVs with energy-efficient designs and the ability to operate in eco-friendly modes contribute to sustainable logistics practices.

Challenges in the AGV Market

Initial Investment Costs:

The upfront investment required for implementing AGV systems can be a deterrent for some businesses in the Robotics and Automation Industry.

However, the long-term benefits often outweigh the initial costs, making it a strategic investment.

Integration with Existing Systems:

Integrating AGV systems with existing infrastructure and technologies can pose challenges.

Businesses need to ensure a seamless integration process to avoid disruptions in ongoing operations.

Maintenance and Downtime:

Like any machinery, AGVs require regular maintenance, and unexpected breakdowns can lead to downtime.

Proactive maintenance strategies and robust support systems are crucial to minimizing disruptions.

The Future of AGV Market

As technology continues to advance, the AGV market is poised for substantial growth and evolution. The integration of AGVs with emerging technologies like 5G, the Internet of Things (IoT), and advanced analytics will further enhance their capabilities. The focus on creating more agile, adaptive, and intelligent AGV systems will contribute to reshaping the future of material handling and logistics.

Conclusion

In conclusion, the Automated Guided Vehicle Industry represents a pivotal force in the ongoing automation revolution, transforming the way businesses approach material handling and logistics. As industries worldwide recognize the need for efficiency, safety, and adaptability, AGVs are emerging as indispensable allies in the quest for streamlined and future-ready operations.

The AGV market's trajectory reflects not only its current impact but also its potential to revolutionize how goods are handled, stored, and transported within industrial settings. As businesses navigate the complexities of modern logistics, the role of AGVs becomes increasingly significant in ensuring a seamless, efficient, and forward-looking approach to material handling.

#Automated Guided Vehicle Market#Automated Guided Vehicle Industry#Automated Guided Vehicle Market Report#Automated Guided Vehicle Market Research#Automated Guided Vehicle Market Size#Automated Guided Vehicle Market CAGR#Automated Guided Vehicle Market Share#Automated Guided Vehicle Market Trend#Automated Guided Vehicle Market Forecast#Automated Guided Vehicle Industry Analysis#BIS Research#Robotics and Automation

0 notes

Text

Powering Productivity: The Impact of Automated Guided Vehicle Market Solutions

In today's rapidly evolving industrial landscape, businesses are constantly seeking innovative solutions to enhance productivity and streamline operations. One such transformative technology making waves is Automated Guided Vehicles (AGVs). As industries embrace automation to stay competitive, the Automated Guided Vehicle Market has emerged as a key player in revolutionizing traditional logistics and material handling processes.

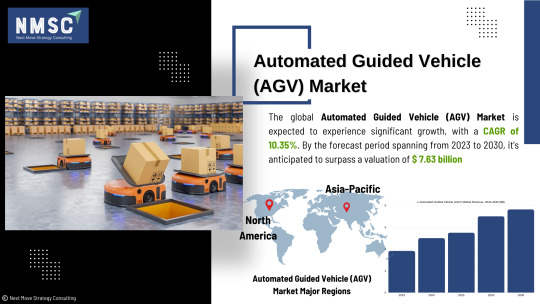

According to the study by Next Move Strategy Consulting, the global Automated Guided Vehicle Market size is predicted to reach USD 7.63 billion with a CAGR of 10.35% by 2030.

Request for a sample PDF report: https://www.nextmsc.com/automated-guided-vehicle-market/request-sample

Introduction to AGVs

Automated Guided Vehicles (AGVs) are self-guided vehicles designed to transport materials, goods, or products within a controlled environment without the need for human intervention. These vehicles utilize a combination of sensors, navigation systems, and onboard computers to navigate predefined routes and perform various tasks such as material transportation, picking, packing, and palletizing.

Benefits of AGV Market Solutions

The impact of AGV market solutions on productivity cannot be overstated. By automating repetitive and labor-intensive tasks, AGVs help businesses optimize resource utilization, reduce operational costs, and improve overall efficiency. With their ability to operate 24/7 without fatigue or error, AGVs significantly enhance throughput rates and accelerate cycle times, enabling businesses to meet growing demand and customer expectations.

Furthermore, AGVs contribute to a safer work environment by minimizing the risk of accidents and injuries associated with manual material handling. Equipped with advanced safety features such as obstacle detection, collision avoidance, and emergency stop mechanisms, AGVs prioritize employee welfare while maximizing operational uptime.

Applications of AGV Market Solutions

The versatility of AGVs makes them suitable for a wide range of industries and applications. In manufacturing facilities, AGVs are used to transport raw materials, components, and finished products between production lines, storage areas, and shipping docks. In warehouses and distribution centers, AGVs streamline order fulfillment processes by autonomously picking, packing, and palletizing goods for shipment.

Moreover, AGVs play a crucial role in the logistics and supply chain industry, where they are employed to handle material flow, inventory management, and order distribution in large-scale distribution centers and fulfillment operations. From automotive manufacturing plants to e-commerce fulfillment centers, AGVs are reshaping the way goods are handled, processed, and delivered across various industries.

Future Trends in the AGV Market

Looking ahead, the future of AGV market solutions appears promising. With advancements in artificial intelligence, machine learning, and robotics, AGVs are poised to become even more intelligent, agile, and autonomous. From collaborative robots that work alongside human operators to swarm robotics systems that coordinate complex tasks, the potential applications of AGV technology are limitless.

In addition, the integration of AGVs with emerging technologies such as Internet of Things (IoT), big data analytics, and cloud computing is expected to further enhance their capabilities and performance. By leveraging real-time data insights and predictive analytics, AGVs can optimize route planning, inventory management, and fleet coordination, resulting in greater operational efficiency and cost savings for businesses.

Challenges and Considerations

Despite the numerous benefits of AGV market solutions, there are several challenges and considerations that businesses must address when implementing AGV systems. These include upfront investment costs, integration with existing infrastructure and systems, maintenance and support requirements, as well as regulatory and safety compliance.

Moreover, the deployment of AGVs may require changes to workflow processes, employee training, and organizational culture, which can pose challenges in terms of adoption and acceptance. It is essential for businesses to carefully evaluate their specific needs, objectives, and constraints before investing in AGV technology to ensure a successful implementation and maximize return on investment.

Integration with Industry 4.0

One of the key drivers behind the widespread adoption of AGV market solutions is their seamless integration with the principles of Industry 4.0. AGVs serve as integral components of smart factories, where interconnected systems, machines, and processes communicate and collaborate in real-time to optimize production efficiency and quality. By leveraging technologies such as Internet of Things (IoT), artificial intelligence (AI), and cloud computing, AGVs can autonomously navigate dynamic environments, adapt to changing production demands, and exchange data with other connected devices and systems. This level of integration enables businesses to achieve unprecedented levels of automation, visibility, and control over their manufacturing operations, paving the way for greater competitiveness and resilience in the digital age.

Environmental Sustainability

In addition to driving productivity gains and operational efficiencies, AGV market solutions also contribute to environmental sustainability by reducing energy consumption, emissions, and waste in industrial settings. Unlike traditional material handling equipment powered by fossil fuels or electricity, AGVs are often electrically powered and produce zero emissions during operation. Furthermore, AGVs are designed to optimize route planning and material flow, minimizing unnecessary movements and idle time, which translates to lower energy consumption and carbon footprint. By adopting AGV technology, businesses can align their operations with sustainability goals, reduce their environmental impact, and demonstrate corporate responsibility to stakeholders and customers alike.

Scalability and Flexibility

Another key advantage of AGV market solutions is their scalability and flexibility to adapt to evolving business needs and operational requirements. Unlike fixed conveyor systems or manual labor, which may be limited by physical constraints or labor availability, AGVs offer a modular and customizable solution that can be easily scaled up or down to accommodate changes in production volumes, product mix, or facility layout. Whether expanding production capacity, introducing new product lines, or reconfiguring warehouse space, businesses can leverage AGVs to quickly and cost-effectively adjust their material handling processes and workflows to meet changing market demands and business objectives. This scalability and flexibility not only future-proofs investments in automation but also enables businesses to stay agile and responsive in today's dynamic marketplace.

Collaborative Robotics

In recent years, there has been a growing trend towards collaborative robotics, where humans and machines work together in shared workspaces to enhance productivity, safety, and efficiency. AGVs play a crucial role in this paradigm by acting as collaborative robots that can interact with human operators, equipment, and infrastructure in a safe and efficient manner. By implementing AGVs with advanced sensors, vision systems, and control algorithms, businesses can create collaborative work environments where AGVs and human workers collaborate on tasks such as material handling, assembly, and quality control. This collaborative approach not only improves productivity and throughput but also enhances workplace safety, employee satisfaction, and overall operational performance.

Inquire before buying: https://www.nextmsc.com/automated-guided-vehicle-market/inquire-before-buying

Conclusion In conclusion, the adoption of AGV market solutions is transforming the way businesses operate and compete in today's digital economy. By harnessing the power of automation, connectivity, and intelligence, AGVs enable businesses to unlock new levels of productivity, efficiency, and agility across a wide range of industries and applications. From manufacturing and logistics to warehousing and distribution, AGVs are reshaping traditional material handling processes and driving innovation in industrial automation. As businesses continue to embrace digital transformation initiatives and Industry 4.0 principles, AGVs will play an increasingly critical role in driving operational excellence, sustainability, and competitiveness in the years to come.

0 notes

Text

Hello. Hope you're having a great day. When we evaluated which type of fully automated parking system we wanted to provide, we were especially interested in systems that are reliable, provide redundancy, and fast retrieval times.

If you look at what is available in the marketplace, the two main types of fully automated systems are what's called AGV, or autonomous guided vehicle and rack and rail, of which there are a couple different flavors. When we took this all into consideration, we selected the AGV system.

Here's why. Rack and rail systems have a lot of moving parts, and there is typically one traversing shuttle per level. If this shuttle goes down, there's no ability to retrieve vehicles on that level until restored.

Because there is only one shuttle per level retrieving vehicles, they tend to achieve slower retrieval times. With the AGV system, there are only eight moving parts on each robot, four wheels and four actuators picking up and setting down the vehicles on the platforms.

Hence, they're very reliable. We typically design these with multiple AGV robots on each level. If something happens to a robot, the other robots can pick up the slack and they can also be summoned from different levels if available. With multiple robots on each level, they can be parking and retrieving multiple vehicles simultaneously as well.

If you need faster retrieval times, all we have to do is program an additional AGV robot off site and add it to your garage. Additionally, with the AGV system, we have the ability to provide computer simulations for your specific property to ensure we can meet your peak hour demands. We partner with volley automation out of San Francisco and can tour you in an installation if you're interested.

Look forward to providing you with creative parking solutions.

Free Consultation Call at (661) 430-3244 or visit us at https://theautomatedparkingcompany.com

#parkingautomation #parkingautomatedsolutions #desigmcustomparking #carparkingstackers #constuctiondevelopers #parkingengineersolutions #parking #newparkingsystem

Robotic Parking, Robotic Parking Garage, Puzzle Parking, Automated Parking, Automated Parking System, Automated

#agv parking#the automated parking company#automated parking systems#puzzle parking#puzzle parking system company#agv parking system#agv vs rr parking systems#Autonomos Guided Vehicle vs rack and rail parking systems#puzzle parking system#puzzle parking system cost#puzzle parking system price#puzzle parking systems

0 notes

Text

Revolutionizing Logistics: The Unprecedented Rise of Automated Guided Vehicles in the Next Decade

In an era marked by technological advancements and the relentless pursuit of efficiency, the Automated Guided Vehicle (AGV) Market is poised for an extraordinary journey from 2024 to 2032. As industries worldwide continue to embrace automation, AGVs stand out as key players in revolutionizing logistics, manufacturing, and warehousing. This article delves into the forecasted trends, innovations, and market dynamics that will shape the AGV landscape over the next eight years.

The Rise of Automation in Industry:

The global industrial landscape is undergoing a paradigm shift, with automation emerging as a driving force for increased productivity and cost-effectiveness. AGVs, equipped with advanced sensing and navigation technologies, are at the forefront of this transformation, offering a versatile solution for material handling and transportation within industrial settings.

Get a sample: https://www.econmarketresearch.com/request-sample/EMR00508

Market Growth Drivers:

Several factors contribute to the projected exponential growth of the AGV market. Increased demand for streamlined and efficient material handling processes, the need for labor cost reduction, and a growing emphasis on workplace safety are some of the primary drivers. AGVs offer a compelling solution to these challenges, providing a seamless blend of automation, precision, and adaptability.

Technological Advancements in AGVs:

The forecasted period is expected to witness significant advancements in AGV technology. Enhanced sensor capabilities, artificial intelligence, and machine learning algorithms will empower AGVs to navigate complex environments, optimize routes, and interact safely with humans and other equipment. These technological strides will not only improve operational efficiency but also contribute to a safer and more collaborative working environment.

Diverse Applications Across Industries:

AGVs are versatile tools with applications spanning various industries. In manufacturing, AGVs play a pivotal role in material transport, reducing downtime and increasing overall production efficiency. Warehousing and logistics companies are adopting AGVs for order picking, goods transportation, and inventory management, leading to faster fulfillment processes. The healthcare sector is also leveraging AGVs for tasks such as hospital logistics and medication delivery, showcasing the broad spectrum of applications for these automated systems.

Smart Warehousing and Intralogistics:

The next decade will witness a transformation in warehouse operations, driven by the integration of smart AGV solutions. AGVs will not only optimize storage and retrieval processes but will also contribute to real-time data analytics for efficient inventory management. Smart intralogistics powered by AGVs will create interconnected and adaptive warehouse ecosystems, ensuring rapid response to changing demands and minimizing errors.

Collaborative and Autonomous AGVs:

The evolution of AGVs includes a shift towards collaboration and autonomy. Collaborative AGVs will work alongside human workers, enhancing productivity and safety. Autonomous AGVs, on the other hand, will navigate without human intervention, making them ideal for repetitive and standardized tasks. The combination of collaborative and autonomous capabilities will result in more flexible and adaptable AGV systems.

Environmental and Cost Considerations:

The AGV market is also responding to the global emphasis on sustainability. Manufacturers are developing eco-friendly AGV models with energy-efficient features, reducing both operational costs and environmental impact. As businesses strive for greater sustainability, AGVs are positioned to play a crucial role in minimizing waste and energy consumption in material handling processes.

Challenges and Solutions:

While the AGV market is poised for substantial growth, challenges such as initial investment costs, system integration complexities, and workforce adaptation to automation may arise. However, industry players are actively addressing these challenges by developing user-friendly interfaces, providing comprehensive training programs, and offering scalable solutions to accommodate businesses of all sizes.

Global Market Dynamics:

The AGV market's growth is not limited to specific regions; it is a global phenomenon. North America, Europe, Asia-Pacific, and other regions are witnessing increased adoption of AGVs across various industries. The market dynamics are shaped by regional trends, regulatory environments, and the unique demands of different industries in each geographic location.

Future Outlook:

As we navigate the forecasted period from 2024 to 2032, the AGV market's trajectory is one of promise and potential. The integration of advanced technologies, collaborative approaches, and a commitment to sustainability positions AGVs as indispensable tools for industries seeking efficient, safe, and cost-effective material handling solutions. The next eight years are poised to witness a transformative journey, marking the ascendancy of AGVs as the cornerstone of automated logistics and manufacturing processes.

Conclusion:

The Automated Guided Vehicle market is on the cusp of a revolutionary decade, with innovation, collaboration, and efficiency at its core. As industries embrace automation to stay competitive in the global market, AGVs emerge as a beacon of progress, offering a seamless blend of technology and practicality. The forecasted period from 2024 to 2032 promises to be a testament to the transformative power of AGVs, reshaping the way we think about logistics, manufacturing, and the future of industry.

Read more details: https://www.econmarketresearch.com/industry-report/automated-guided-vehicle-market/

0 notes

Text

Data Bridge Market Research analyzes that the global automated guided vehicle market was valued at USD 2.4 billion in 2022 and is expected to reach USD 3.8 billion by 2030, registering a CAGR of 6.01% during the forecast period of 2023-2030. “Automotive segments” account for the highest market share due to the increasing usage of software as a service tool among the consumer. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

0 notes

Text

https://www.omaada.com/blogs/93057/Automated-Guided-Vehicles-Market-Report-Trends-and-Industry-Forecast-2023

Automated Guided Vehicles Market Report, Trends and Industry Forecast 2023-2028

0 notes

Video

youtube

10 Ton Agv Carts Exported Singapore Factory, Automated Guided Transporter

0 notes

Text

MIWA Robotics - The World’s Leading Automated Guided Vehicle Manufacturers

MIWA Robotics is the world’s leading tech company specializing in logistics robot intelligent systems. With its partner-Mushiny AI, we have businesses in more than 20 developed countries and regions. We have shipped over 3000 AGV/AMRs since establishment. Our Goods-to-Person AGV/AMR solution was developed by our key founders of the company, most of whom are former Amazonians.

AGV solutions are the way of the future when it comes to the supply line. Not only in storage, but also with management and distribution. Robotics have taken the world by storm and automated guided vehicles (AGVs) have become incredibly popular in the way we manage our warehouses.

6 Reasons to implement a warehouse AGV

1. Flexible loading options

AGVs can adapt to the size and makeup of your packages or parcels. They are highly customizable and updatable. This includes the weight they can withstand as well as size and configuration.

2. Cleaner and quieter

AGVs require less maintenance and produce less noise pollution. They are extremely clean and quiet. One of their most important features is that, since they can operate independently, you can program them to work in off-hours. This last feature gives you greater control over noise contamination and how it affects your workforce.

3. Easy to install

Like most of its family members, drones, robotic vacuum cleaners, and all those AI-supplemented tools, AGV warehouse systems are incredibly easy to install, configure, and modify. They are adaptable to any space and can be updated to meet new challenges and growth issues.

4. Sleek and more lean

You will no longer have to deal with conveyor belts that are static and partly cemented into space. AGVs give your warehouse an open design that you can take advantage of. Automated Guided Vehicles are programmed to return to their charging station when necessary, usually scheduled during downtime in operations. Their road, the highway they use during hours of operation, is cleared whenever you need it.

5. Lower staff cost

Your overhead, when it comes to training and retaining, suddenly decreases. You no longer need a huge workforce to manually pick and pack items or transport and sort them. AGVs are a great investment that pays dividends for years to come.

6. More efficient, safer

AGVs are robots – they are guided by smart technology and constantly update algorithms. Today’s automated guided vehicles have cameras, WiFi connectivity, collision sensor, laser-guided mechanism, and dozens of other tools that reduce the possibility of safety violations. They are human error-proof.

Why You Need AGVs

All warehouses can benefit from AGVs – either on a grand scale or on a much lower one. They help maintain your competitive edge and adapt rapidly to challenges. They are a one-time investment that gives your team greater leeway when it comes to the things they can do and the contracts they can take. We can also offer leasing options if it suits your operations better. MIWA Robotics partners with multiple AGV vendors to provide you units that meet your unique requirements. Contact us today to learn how AGVs might benefit your business.

https://www.miwarobotics.com/post/miwa-robotics-the-world-s-leading-automated-guided-vehicle-manufacturers

1 note

·

View note

Link

0 notes

Quote

Global Tugger Automated Guided Vehicle Market was valued at USD 537.50 Million in 2021 and is expected to reach USD 891.74 Million by the year 2028, at a CAGR of 7.5%

Tugger Automated Guided Vehicle Market- Global Industry Analysis and Covid-19 Impact | IMR

0 notes