#but the 'drywall' is much faster and cheaper

Text

A Comprehensive Guide to Basement Excavation Cost

Have you ever thought about how much space is beneath your home? You may need more storage space, a recreation area, or additional bedrooms and bathrooms to accommodate your growing family.

You can dig a new basement if you want to. Building contractors can lift your house from its foundation and excavate it, then pour a new basement foundation.

In this comprehensive guide, we’ll explore how much you’d need to budget for this project and the basement excavation cost factors you need to consider.

What is Basement Excavation?

Basement excavation is the process of removing rocks, dirt, and other debris to make room for a new basement. It is typically the initial step of building construction work, creating a hole where your new space will be constructed.

You can also excavate the basement after your existing house has been constructed. This process is more complex and requires skilled excavation contractors to dig into the soil and remove excavated debris without damaging the foundation or footings. It is generally more cost-effective to excavate before any part of the building is constructed.

Basement Excavation Cost

The cost for basement excavation in new construction can range from $12,000 up to $36,000. That’s roughly $10 to $20 a square foot.

If you plan to dig underground under an existing home, the average cost will be between $40,000 and $50,000. This is about $47-$100 per square foot.

When comparing costs, digging a new basement will cost slightly more than expanding a crawl space. A new basement measuring 1,000 square feet will cost between $22,500 and $45,000. The costs for crawl space extension range between $10,000 and $30,000.

Though crawl space expansion may seem cheaper than the cost to dig out an entirely new basement, you should still factor in all necessary expenses associated with basement construction.

Factors Affecting the Cost of Basement Excavation Project

Several factors influence the total cost of a full basement excavation project. Understanding these factors will help you plan and budget effectively:

Size of Excavation

Excavation projects that require large excavations require more time, labor of local contractors, and equipment which increases overall expenses significantly.

Cost: $75 to $150 per cubic yard of dirt removed.

Raising or Bracing

When excavating a basement, your home requires support to avoid structural damage. While hydraulic jacks offer faster and cheaper solutions, raising can compromise stability; bracing (underpinning) is more time-consuming but does preserve its structural integrity more fully than raising can.

Cost: Raising ($3,100 to $9,400); underpinning ($20,000).

Plumbing

Installing proper plumbing and drainage systems in your new basement is essential and should be taken into consideration when planning for your excavation costs.

Plumbing costs vary depending on the fixtures you want and the impact on the main sewer line. Drainage systems must be designed to keep the basement dry, especially in areas with a high water table.

Cost: Plumbing expenses for a new basement typically range from $1,000 to $3,000. Drainage systems can cost between $2,000 and $6,000, depending on local climate, soil conditions, and yard grading.

Permits

Every major construction project, including basement excavation, requires building permits. Permit costs depend on local building codes and regulations.

Cost: Budgeting around $1,200 to $2,000 for permits is a reasonable estimate.

Foundation

Once excavation and plumbing work has been completed, a concrete foundation must be laid. This includes pouring a concrete slab for foundation walls, floors, and footings.

Cost: Typically ranges from $10,000 to $30,000.

Unexpected Repairs

Excavating a basement involves foundation work, which may uncover existing issues. Unexpected repair costs may include foundation repairs, drywall repairs, or frame repairs.

Cost: Potential costs range from $2,100 to $7,800 for foundation repairs and $50 to $80 per square foot for other repairs.

Can you dig a basement deeper?

Yes, it is possible to dig a basement deeper by lowering its floor. Basement underpinning can increase the height of your basement without reducing square footage. This is an excellent option for those who wish to keep the existing space.

On the other hand, bench-footing involves digging out the crawl space to create a deeper basement, but it may result in a reduction of the overall square footage of the finished basement.

How to convert a crawl space into a basement?

Converting a crawl space into a basement involves the following steps:

Build a Scaffolding: Construct a supporting structure to support the weight of the home while the new foundation is being built.

Excavate the Crawl Space: Excavate the area beneath the house to create the basement space, which is normally eight feet deep.

Pour the New Foundation: For the basement, add four to six feet of concrete walls surrounding the house, establishing a firm link between the existing and new foundations.

Finish the Basement: Complete the full basement space and transfer the home onto the new foundation.

Monitor for Settling: Keep an eye on the foundation and basement for a few months to identify and address any potential issues.

Basement excavation offers a fantastic way to expand your property and boost its value. Make sure to consider the factors discussed above when getting basement cost quotations from local contractors.

source https://aspireconstructiongroup.co/blog/basement-excavation-cost/

1 note

·

View note

Text

The Benefits of Purchasing Construction Materials Online

Purchasing construction materials online has revolutionized the construction industry with convenience, cost-effectiveness, and a vast array of products. Online retailers offer an immense variety of materials, allowing for immediate access to buyers and dedicated support services, such as easier shipping, returns, and warranties. Furthermore, with the ability to shop for construction materials at any time and receive them within days, consumers can save on their transportation costs. Not to mention, they can compare prices in the convenience of their homes, in just a few clicks. By cutting out the “middleman”, they can get the material they need, faster and cheaper than ever before. Lastly, online purchases from global vendors are not limited by geographic boundaries, resulting in access to many more services and products than traditional purchases in a store.

Access to a Wide Range of Quality Products

With the internet, accessing quality construction products is easier than ever before. Online stores and auction houses carry a wide selection of building materials and equipment, ranging from lumber and drywall to tile, lighting, and flooring. These companies often have supply contracts with leading manufacturers, so customers can be sure they’re getting the highest quality materials and at the best prices. Online construction stores also offer competitive pricing on materials, so homeowners can get what they need at a price that fits their budget. Customers can easily browse and order through the convenience of online shopping, and they can also read customer reviews to ensure the product and store is dependable and trustworthy. At Builders' Marketplace, you can sell construction materials online.

Save Time and Money with Easy Transaction Processes

Shopping online for construction products is not only convenient, but it’s also much more affordable than shopping in stores. Most online suppliers offer free shipping on orders over a certain amount, as well as a range of discounts and promotions. This is especially beneficial for those who are in a rush to finish a project and don’t have the luxury to spend extra time in stores. With online stores, spending time and money on unnecessary trips to the store is eliminated, so projects can be completed faster and more efficiently without blowing the budget.

Create Accurate Cost Estimates without Leaving the Office

Shopping online for construction products also makes it much easier to create accurate cost estimates. Customers can easily compare prices between different online suppliers to determine which one is offering the most competitive price. Additionally, many online stores offer “virtual shopping carts” that allow customers to add items to their cart and accurately estimate the total cost of the project. This makes the process of creating budget estimates much easier than ever before.

Take Advantage of Special Online Deals and Discounts

By shopping online for construction products, customers often have the chance to take advantage of special deals and discounts. Many online retailers offer promotional codes or special pricing to customers who purchase items in bulk, so customers can save extra money each time they make a purchase. Seasonal or holiday sale items, along with clearance discounts, are also common, so customers can get the most from their transaction and stretch their budget further.

Enjoy Carefully Vetted Construction Products without the Hassle

Shopping for construction products online also eliminates the hassle of vetting products. Online stores are typically vetted by third-party organizations to ensure safety and quality, so customers can be confident they’re buying products from a dependable source. Customers can also easily compare products side-by-side to ensure they’re getting the best value for their investment.

Streamline Inventory Management and Build Sustainable Supply Chains

By shopping for construction products online, businesses can also streamline their inventory and build sustainable supply chains. Online stores make it easy for customers to keep track of what they need and when they need it, resulting in fewer trips to the store and a more efficient procurement process. This can also help businesses build sustainable supply chains with reliable suppliers who offer the most competitive pricing and delivery times.

Achieve Total Transparency about Product Specifications and Delivery Dates

Finally, shopping for construction products online helps to achieve total transparency with product specifications and delivery dates. Customers can easily read product descriptions and specifications, as well as reviews and customer feedback, so they can ensure they’re getting exactly what they need and when they need it. They can also easily track their shipment and get updates on when their order is expected to arrive. This helps eliminate buyer’s remorse by ensuring customers know exactly what they’re getting and when it will arrive.

Conclusion

In conclusion, purchasing construction materials online has many benefits. It enables businesses to compare prices, access thousands of products in a single place, encourages sustainability, provides easier access to materials, and facilitates secure financial transactions. Additionally, online shopping eliminates the need for on-site visits, resulting in time and money savings. Overall, purchasing construction materials online is a cost-effective, efficient, and convenient way to acquire the materials needed for a construction project.

0 notes

Text

This is the block that our son invented but it's from Greece and it was something he did in that era and it's somewhat interlocking because it was easy to use tons of buildings are made out of it and they're still up other buildings are gone and they do pour ground in it they have holes and they are cast with holes in them and they're not hard to make and the whole sometimes didn't line up but it's still very very strong and there was no laugh lead between it it was a glue and instead of a just motor and special mix and people try to replicate it and they can't do it perfectly but they come close and this is the point it should not be that hard to replicate but it is cuz we don't want you to and other people don't want you to but a ton of people should be aware that this block that is used in Florida is not very strong and not bullet resistant but the ones you see on the buildings in Greece and Rome have endured many many wars and horrific ones as you know and a lot of them are not even married and they're made out of regular concrete and extremely hard so please order up and we'll send it down there about 5000 PSI because we are not making it very strong ones and it's easy to make them and just cost more and 5,000 PSI is three times as strong no it's about twice as strong as regular block if you cast The block in the same manner but yes it's three times as strong and it's lighter because it's not as wide about 5 in wide and you need to have it changed on your plans and get the town to approve it before doing it and it does change the dimensions and some require you to re dimension it. And you can make a note not even dimensioned but it's the new block and the trust guy needs to know and they can change it at their shop but we are shipping a lot of this tonight we're getting orders already

Is a testament to his block design and the block concrete design because the mix on some of the buildings is the same it's not very high in PSI by comparison to the high strength block but what you see here is about 10,000 PSI but it is regular standard concrete mix it does have some fly ash in it which doesn't necessarily strengthen it and you have to reduce the acidity first and we have a process for that and if you want the higher strength block you must make a note of it when you're ordering it is a little bit more money and large of the block is some more it costs but these blocks are not very expensive and are cheaper than CMU by the sfca and they go up faster much faster and the machine can adapt to it and it puts it up fast as hell some people use brick machines because they can fit and these blocks are really easy to handle and they don't rip your hands apart and you can wear gloves or not and still use them as a wonderful product and a son should be committed and Florida will recover because of it a lot of people want to make little bunkers and all sorts of things safe rooms and it's perfect for it and we recommend it strongly these clones are at everyone and you can make it really really quick using the technique that we described it goes up very fast and you could use durock on the it's the ceiling joist or it's the trust choice you cut in durock and you coat the size of it and it's hard to get into believe it or not it can even coat it with with concrete and it makes it more resilient it's really really nice and it makes it waterproof too

A lot of people put the block on top of the door Rock but sideways and they buy the 4-in and they glue it together it makes it very very strong and it spans it almost and it doesn't move at all once it's cured it's hard as Stone and they make sure there's a positive connection meaning they cut the drywall out and they glue the stone together and he went ahead and did it and he figured out how to do it at the end of it he just opened the wall up and put them lock inside the wall and you have a 2x4 there but he put the rock on the inside and he had to put a new shower in so you might as well put the block on the inside and get a small shower and he didn't want to do that it's also way to keep your insulation value and it fools people then you dry all the outside of it it looks like nothing it's only like 5 in here hiding

Thor Freya

Well we started going on and on and it was like stop stop and we're young and we criticized but people shouldn't and we shouldn't it's a great presentation of our product but heck I'm doing it

Hera

Well she's a woman and wants me to talk and sometimes she doesn't want me to talk but she does and that's how it is but his talk is perfect and retrospect but really she wants to publish it because she wants people to buy stuff she wants them to buy this block and get it in we're suffering under the hamster all very gutteral

Zues

Olympus

0 notes

Text

so im just remaking this donations post bc the ones i have are so cluttered and im dying

so heres the rundown: im 2 months behind on rent, im being evicted and have to build a carport into a room at my moms house or else im homeless, and my dog arlo needs to go to the vet.

ive been saving up money to repair the room

this one to be specific. i have to clear it out, insulate, drywall, paint, repair all holes that cause water to leak in during rain (monsoon season is coming up so yikes) and finally pay an electrician to fix all exposed wires. its a huge project but is still cheaper than even a basic studio apartment. Because of this, im behind on rent, and my roommate/landlord is being lenient with me but i dont know for how much longer.

so im working, doing some translation work, and commissions, but im losing money faster than i can make it. this is all i have atm

then, theres arlo, this baby girl

shes been under the weather, poor appetite, diarrhea, mucus discharge from her bum, and seemingly random lacerations on her tummy and legs

the good news about this is that i have talked to a vet, and its nothing serious (thank god) but she still needs a full checkup, and its 80 just to walk in the door. now, there is a sort of credit system so i dont have to pay out of pocket right there, but it accumulates interest quickly, so depending on how long it takes to save up the money to pay it off, more will be needed.

so basically: shits fucked and i wanna die

1K notes

·

View notes

Photo

Are bamboo charcoal Air Purifying Bags useful?

One of the best ways to purify air naturally indoors is by using activated charcoal. It removes toxins, and gets rid of allergens and molds. Placing charcoal purifying bags in your home also removes bad odors giving clean air indoors. But, how effective is it?

Do bamboo charcoal air purifier bags really work?

Activate the charcoal bag by keeping under the sunlight. Activated bamboo charcoal air purifying bags work and not only they can get rid of some dust particles, mold spores but even cigarette smells and other bad odors. Since bamboo charcoal has a much larger surface area for absorbing impurities, they show better results. Activated bamboo charcoal has 10 times the surface area and so the structure is highly porous and thus absorbs many types of toxins including ammonia and formaldehyde.

Working of an activated bamboo charcoal bag

As air flows over the bag, the porosity of charcoal inside the bag creates a surface area that traps pollutant particles giving out clean air through a process called adsorption.

On a molecular level, adsorption is the process by which a solid holds gaseous molecules or of a liquid or solute as a thin film.

This solid material used for adsorption is a combination of porosity with high surface area.

Thus, Adsorption is the attraction of molecules onto the surface of a solid. While in the charcoal bag case, it commonly adsorbs household pollutants such as mold and unpleasant odors. Charcoal traps pollutants on the surface as dirty air passes over it, cleaning the air to circulate indoors. If you’re cleaning your house after a while, it's a great idea to place these charcoal air purifying bags in various corners to remove drywall dust from indoor air

Basic differences between regular charcoal and bamboo charcoal air purifying bags:

Regular charcoal Bamboo charcoal

low surface area for adsorption 10 times more surface area for adsorption

The air purification rate is slow Much faster at cleaning indoor air

Note: One gram of activated charcoal has approx 10,000 square feet of internal surface area. That’s why it is also used in some air purification filters.

Bamboo charcoal when activated has a bigger surface area per gram, that means it is more porous than regular charcoal for cleaning the air. It helps in removing excess humidity in the house.

Durability of a bamboo charcoal bag

A bamboo charcoal air purifying bag can last upto 2 years when being used indoors. After that, you can discharge the bag by mixing into the soil for the toxins and odors to break down and dissipate into the environment. They might not work as effectively in areas around construction sites. Otherwise, they work upto 2 years in a normal atmosphere indoors.

Best Bamboo Charcoal Air Purifier Bags (Reviews)

Air purifiers are great. Brands like AirOK have amazing reviews for their first ingenious air purification products. They have different bag sizes available for different room sizes. It is cheaper and a natural alternative in activated bamboo charcoal air purifying bags.

They have been tested and proven in different parts indoors for example for removing shoe odor, neutralising indoor room air, clearing dust particles, getting rid of mold spores, and cigarette smoke odors. They can also be used in car cabins. They last upto 2 years when refreshed regularly.

The best feature/quality of the Nature Fresh bamboo charcoal bag is that it has no scent at all, so it is a great choice for anyone suffering from allergies. This also makes them safe for pets.

The bags are usually designed with a small ringed hole or a loop to make it easy to place or hang them in any corner in your house. They are very effective in small indoor spaces like the bathroom or even if kept in a fridge. Because of the activated charcoal, they remove the smell in no time i.e within 2 or 3 hours. They are definitely best suited for your car, closets, drawers, refrigerator, and even kept inside shoes/gym bags.

The bags can even get rid of odors from new furniture such that there isn’t any discomfort in the house within the first day of using them. They are a good replacement for scented aerosol sprays. They dry up the air from excess humidity and give fresh air.

As a general conclusion and recommendation, bamboo charcoal air purifying bags do work to purify indoor air. For effective results, use the bag in small areas, or use more than one if the room size is large.

On a molecular level, adsorption is the process by which a solid holds gaseous molecules or of a liquid or solute as a thin film. This solid material used for adsorption is a combination of porosity with high surface area.

0 notes

Text

Vertical Wall Mount Rack Bracket: The Best Rack for Small Business

Many businesses only need a 1U server, a switch, router, and might not have enough space for a rack. Often this leads to the decision of purchasing a tower server which means they also buy a non-rack mount switch and router.

These are all excellent products to use, but it’s a bit harder to manage organizationally.

Usually, all of the networking equipment in a fast food restaurant is inside the manager’s office. These typically don’t have much space because the real-estate needs to be dedicated to food, workers, and customers.

Does rackmount equipment cost more?

The rack-mountable form factor doesn’t make your server faster, or necessarily cheaper. Still, pricing is relatively competitive.

Without considering the current sale, the rack mount server is about 9.3% more expensive. If you’re purchasing multiple servers the new cost compounds on itself and can become very significant, but you also would not be able to store as many in one rack. Purchasing additional racks can be even more costly.

How to mount the Vertical Wall Mount Rack Bracket?

Setup is easy enough. The bracket can be mounted on drywall with anchors or screwed directly into studs. Choosing where you set it up is what’s interesting.

Mixer/Amplifiers are usually light enough for their entire weight to be supported while mounted vertically under a desk. This means that you can install the bracket in an area that is convenient to access but still out of the way.

If you want to mount larger equipment horizontally, you’ll need to double down on the brackets. Full-sized servers should only be installed with four areas of support, meaning a bracket for the front and a bracket for the back. Using this method, as long as your desk is strong enough, you can have up to 4U of space to mount networking equipment.

When this equipment is mounted under the desk, it is effortless to route cables discreetly. The primary office computer is likely nearby, and if you need to route them through a wall, you can do so without wires being visible.

Mounting larger equipment with only one bracket is a breeze, but it might be more of a chore to manage cables. Whichever part of the wall you decide to place the IT equipment, it will likely be beneficial to have some zip ties or velcro straps to organize and direct cables.

#server rack#server cabinet#network rack#rack server#home server rack#computer rack#wall mounted cabinet#network cabinet#home network rack#wall mount network rack#42u server rack#Wall Mount Rack#6u wall mount rack#2u wall mount rack#wall mount audio rack

0 notes

Photo

The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself https://ift.tt/2EWSK2p

Many of you have asked for tips and tricks to make installing an Ikea kitchen go more smoothly and look (and function) the best it possibly can. And the good news is that after installing three of them in a little over a year and a half (!!!), we have learned A TON about how to make things a little easier and help you end up with a better result. So settle in, I’ve got twenty tools & tips that can make all the difference.

First off, we like Ikea cabinets and have personally installed them in five rooms: our laundry room & bonus room at home, our beach house kitchen, and now these two duplex kitchens. We have lived with the ones in our home for nearly five years and they’re great. Not a single issue. They are smartly made, very durable, and they have a great 25-year warranty and a great price tag (often thousands cheaper than other options). They also come with many thoughtful features like soft close drawers that come standard and tons of customization options. So yeah, some Ikea furniture is known for feeling a little cheap and wobbly, but that has not been our experience with their cabinets AT ALL.

Ok, but back to the point of this post – tips and tools to make your Ikea cabinet install easier. Some of the tools I’m listing here are absolutely necessary and some are optional (they’ll just make the process easier, faster, and less frustrating). And as you read through this list, I think you’ll also get a pretty good sense of the steps (and curveballs) involved too, which I hope will help as well.

I’ll include a short bulleted list of everything at the end of the post too, that way you can use it as a tool checklist. But let’s just get right into it.

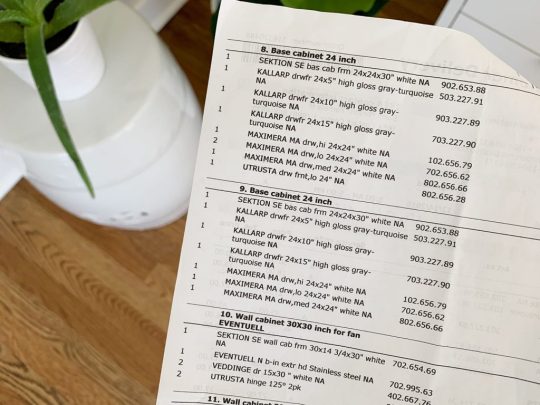

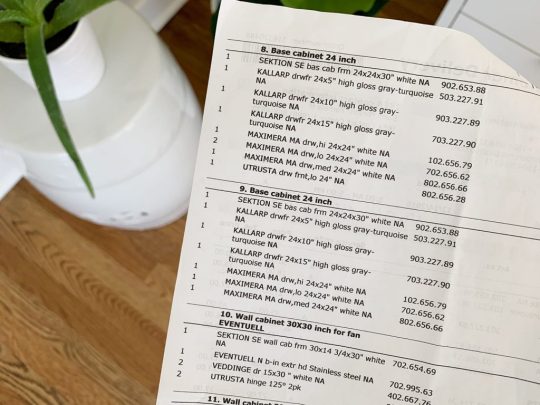

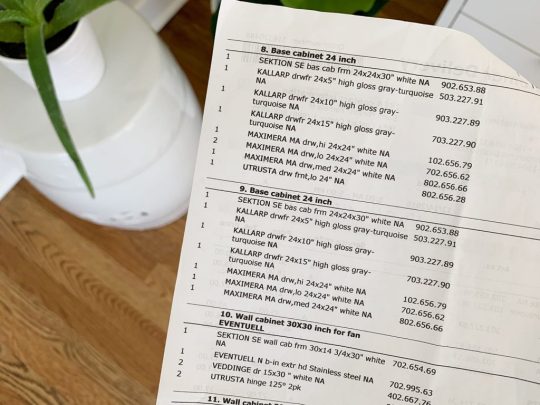

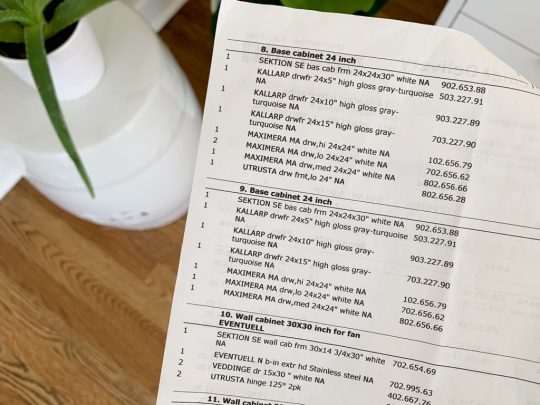

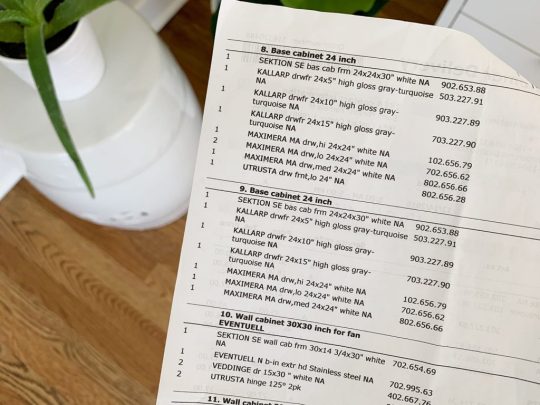

1. Your Itemized Receipt/Order

Before you build anything, you’ll want to take time to inventory and organize all of your boxes. We had over 200 boxes (!!!) delivered for our two duplex kitchens, so it helped to sort everything into piles beforehand.

We personally like to sort boxes by item (Sektion boxes over here, Maximera drawers over there, all of our cabinet fronts somewhere else, etc.) but you may find it helpful to sort yours by cabinet instead (ex: the box, drawer, hinges, and front for one cabinet all together in one pile – this is how Ikea breaks them up your order form). Either way you do it, this sorting process will help you identify any missing pieces and also make it faster once you start building.

2. Power driver (with Philips head)

This combo gets a lot of use in this install (especially the power driver/drill) – but they’re needed first to construct your cabinet boxes (Sektion pieces). We love constructing the boxes first because you quickly get to see the shape of your kitchen come to life.

And even though Ikea is known for their allen wrenches, you don’t use them AT ALL during a typical kitchen installation! So don’t worry about having lots of specialty drill bits. You just need a normal Phillips head to screw these puppies together.

3. Hammer

You’ll also need a hammer handy to nail the MDF backings onto the cabinet backs. It may also be useful if you need to tap any anchors into your drywall when it comes time to hang your cabinets.

4. Magnetic Drill Bit Holder

Having one of these on your drill can save you a lot of frustration while building your cabinets and drawers. You can buy one separately for about $2 or it often comes included in drill/driver sets like ours. It’ll magnetize your drill bits, meaning many of the screws that Ikea provides will stick to your drill handsfree (thanks to the magic of magnets). We found this VERY helpful when trying to screw into small spots that were too tight for our fingertips (we couldn’t reach in and hold the screw steady, so having a magnetized drill bit that held it for us was key).

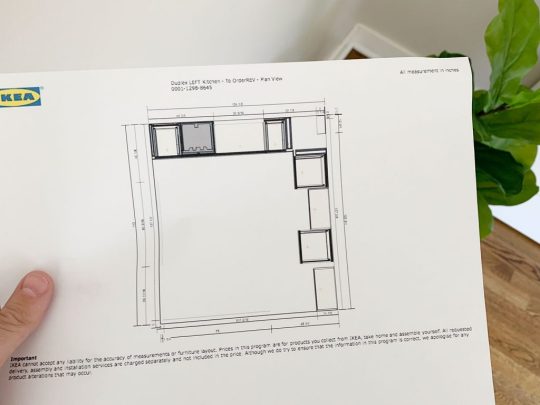

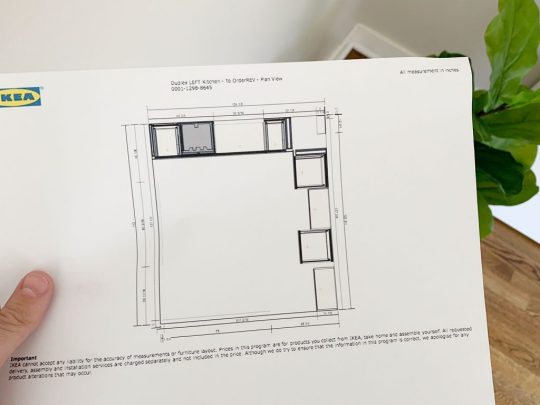

5. Measuring Tape

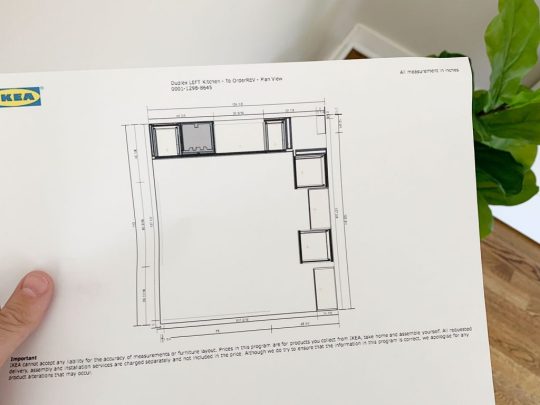

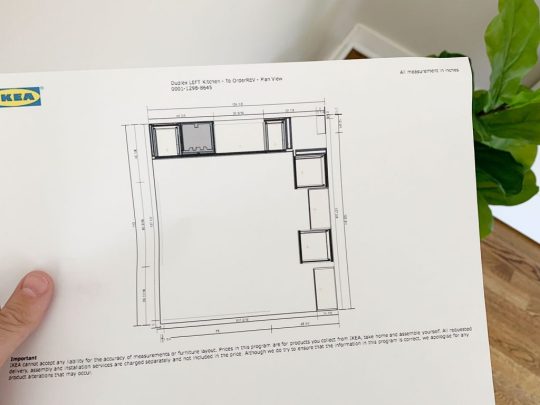

The next several tools are needed for attaching your cabinets to the wall. Whether you’re doing upper or lower cabinets, Ikea’s system uses a metal track (called the Sektion suspension rail) that you attach to your wall and then the cabinet boxes hang from these. The rail system is extremely handy because if you make sure the rail is level, your cabinets all hang from that and are guaranteed to be level! I know, it’s GREAT. The only time I don’t use their rail is when I don’t have a wall behind my cabinets, like if you’re doing an island. In that case I’ve built my own bases from 2×4″s, but more on that later.

For now, just know the measuring tape will be useful in determining exactly where in your kitchen you’re placing your cabinets – both side-to-side on each wall, and how high the rails need to be hung (Ikea provides guides for this in their instructions). You will probably want to have your kitchen plan/schematic from Ikea handy too.

6. Dremel Or Hacksaw

Once you know where each run of cabinets is going, you’ll need to cut your metal suspension rails to size. The rails are sold in 7 foot lengths, but if you only have 4 feet of cabinetry in one area – you only want 4 feet of rail.

You can cut these by hand with a hacksaw, but we find it much faster to use our Dremel Multi-Max with a metal cutting blade.

I typically mark my cut on a piece of painters tape and cut across the open top of one of our cabinet boxes (with a piece of cardboard to protect the cabinet underneath).

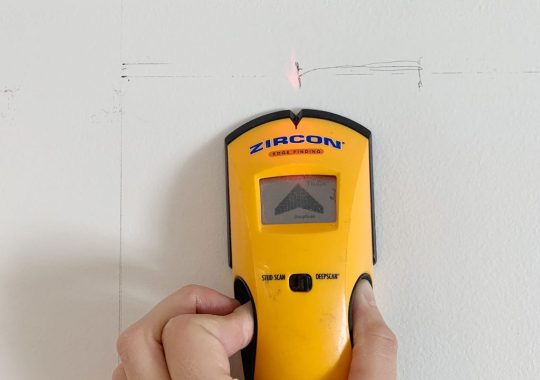

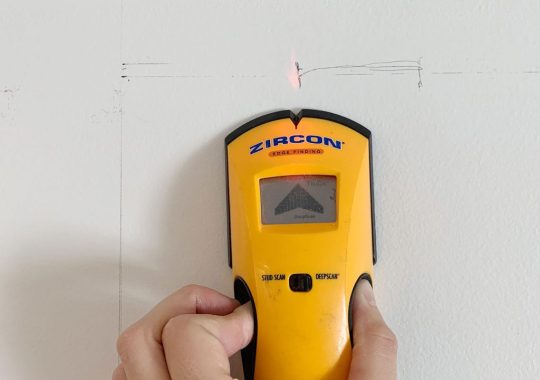

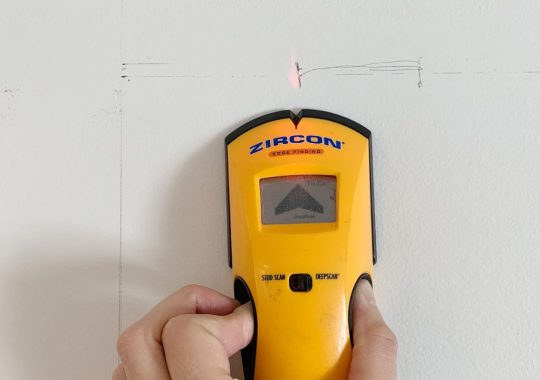

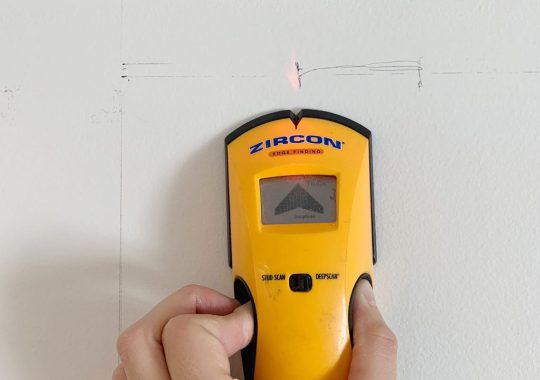

7. Stud Finder

You want to screw the rail into at least a few studs in your wall for maximum hold. So it’s smart to use a stud finder to locate and mark the studs that fall within the area you’re hanging the rail – that way you can be sure to go into them and get a nice firm hold. Since studs are typically 1.5″ thick, I like to mark the full width that my stud finder indicates, since you may not know exactly where the holes on the Sektion rail will line up.

8. Medium-Size Level

Once I know where my studs are, I hold my cut-to-size metal rail and, with a medium sized level (like this 24″ level) held against it, I mark the top line of my rail AND where the holes line up with my studs. I suggest amedium sized level for this just because they’re easier to wrangle during this step.

I also mark a few additional holes where I’ll use screws paired with anchors. I believe Ikea suggests at least having a screw every 12″ inches – but for short sections like this, I like to make sure I hit at least 2 studs and then have a screw at either end of the rail that goes into an anchor.

9. Heavy Duty Screws & Anchors

After some trial and error, we found that we like using these GRK Fastener Cabinet Screws to secure our rails into studs. They’re easy to drive, they hold really tight, and they include the star-head bit you need for them. We have tried other, cheaper “cabinet screws” and the heads kept breaking off. It was MADDENING.

We also like to have some anchors on hand too, like these E-Z Ancor packs that come with screws, for those additional support screws that we add.

10. Long Level

One of the biggest challenges we’ve found in this process is getting things level. Just because you’ve hung your rail level on the wall doesn’t prevent things like slopes in your floor or bows in your wall from chucking some additional curveballs in your direction. So your best defenses are a lot of patience and a nice long level, like this 4ft level we bought specifically for this task (after learning that it’s a lot harder to use a smaller level to solve these issues).

Your medium sized level will help with the process as well (especially in checking that each individual cabinet is level front-to-back) but you’ll want something bigger to check longer spans of cabinets. You could purchase an even longer level if you wanted, but they can start to get pricey, so we found a 4 foot long level to be sufficient, especially for checking across the gaps that you’ll leave for appliances like a 30″ stove or a standard 24″ dishwasher.

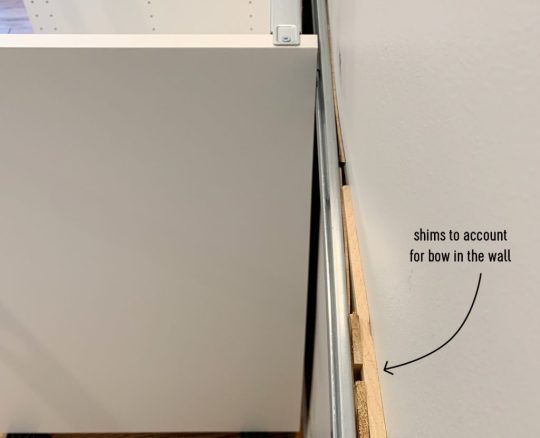

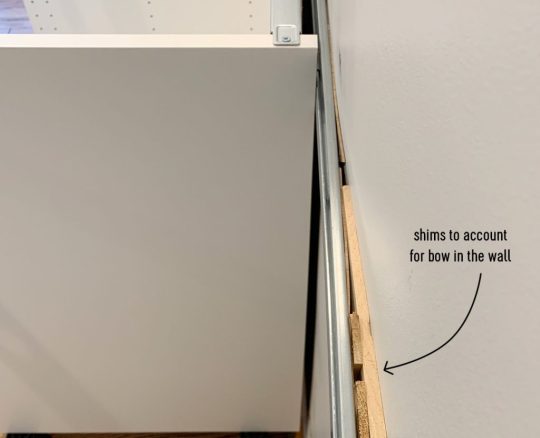

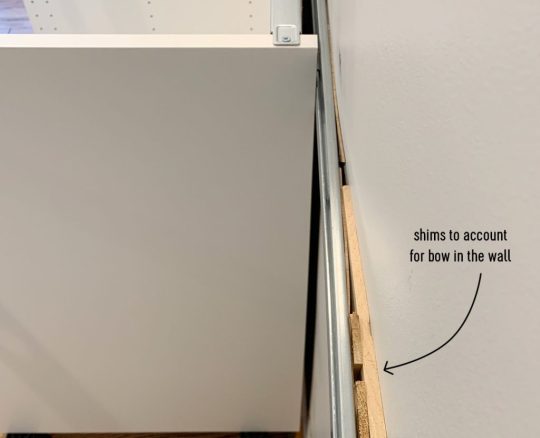

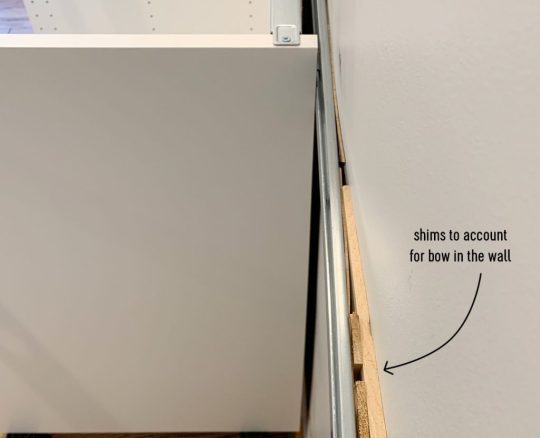

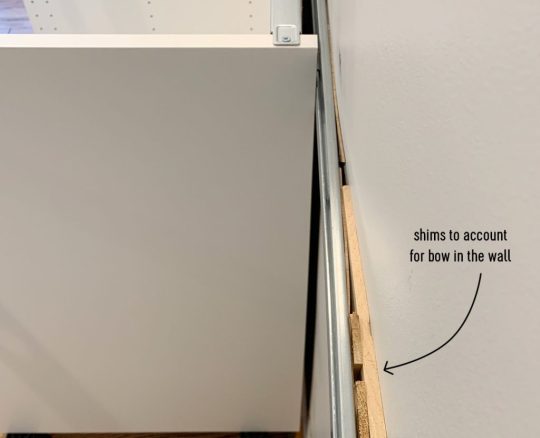

11. Shims

A lot of level issues can be corrected by twisting the adjustable plastic feet that come with your base cabinets, or by adjusting the placement of your metal rail. But if you’re dealing with bows in your wall (which you can find by placing your long level against it) you’ll want to have some wood shims on hand to place behind the metal rail. In these old houses, we had to use quite a few in a couple of places!

12. Jigsaw

When it comes time to install your sink base cabinet, you’ll need to make some holes for your plumbing. For smaller pipes like your water supply lines, you can just drill holes using a large drill bit (we used the 3/4″ bit in this set). But for things like your large drain pipe, you’ll either need to buy a larger hole bit or break out a jigsaw. Even though we don’t get the cleanest cut with it, the jigsaw gives us a little more wiggle room when placing the cabinet (since the drain pipe isn’t flexible like the supply lines) and we can also use it for other cuts like for exposing the outlets along the wall (the one below powers the garbage disposal under the sink).

Just be sure to make careful measurements before you cut. We usually put a layer of painters tape around the area we’re cutting. It allows us to mark our cut without marking the cabinet, plus the tape helps keep the white finish from cracking off. Either way, this stuff will all be hidden under the sink so it doesn’t have to look perfect.

13. Clamps

As you start to get your cabinets in place and leveled, you’ll want to secure any adjacent cabinets together. Ikea provides screws for doing this, but you’ll want to use some clamps (we like these 6″ bar clamps) to hold the cabinets tightly together before you begin screwing.

We didn’t get a picture of that process, but the clamps come in handy A LOT as an extra set of hands – like when we were installing this bracket for the exhaust hoods that we hung over the stoves.

14. Circular Saw and/or Table Saw

In addition to screwing cabinets together, you may find yourself attaching cover panels or filler pieces at some point. Cover panels go on exposed ends of cabinets (so you can’t see the metal rail they hang on) or, in our case, we used some large cover panels to create a box around the fridges at the duplex. So you’ll need some sort of larger saw to make long, straight cuts. Our cover panels were a bit too wide, so I used a circular saw to shave a few inches off one side.

I didn’t use a table saw for that panel because running an 8 foot tall panel that’s this wide across my table saw would’ve been tough. But for smaller pieces (like filler pieces that are only about 3 feet long) a table saw is often easier, especially if you’re only shaving off a little bit. But if that’s too pricey and you’ve got a steady hand, you can get by with the circular saw.

15. 2 x 4″ Boards

Every time we’ve installed an Ikea kitchen we’ve needed some 2×4″s at some point. At the beach house we used them to make some bases for the island cabinets.

Basically, they were just some boxes we made almost the same size as each cabinet (slightly narrower to account for the toekicks) that we secured to the floor using pocket holes. To drill the pocket holes, you can use something like a…

16. Kreg Jig

Now, a Kreg Jig isn’t absolutely necessary here, but I’ve had one for around nine years now so I’m accustomed to breaking it out for tasks like this. So while I’m a big fan of having one in your arsenal, I understand that you’ve just bought a new kitchen so tacking on another $99 tool to your budget isn’t always practical.

I did use it again for the duplexes to make more 2×4″s into boxes (this time for mounting the above-fridge cabinet away from the wall, so it sat closer to the front of the fridge).

The boxes acted as an extension of the wall. The top one was for mounting the metal rail, and the bottom one gave the base of the cabinet a spot to rest so it didn’t tip back wildly. They also gave us a way to mount that large cover panel to box in the fridge.

I guess I should add in here that a step ladder is also useful, so let’s officially put that on the list.

17. Manual Screwdriver

Once your cabinets and panels are hung, leveled, and secured to each other, the next part of the process is to add your doors and drawers. The instructions here are pretty self-explanatory and the main tool you need is a power driver to screw everything together. Our main word of warning is to pay close attention to screw placements when you’re assembling drawers! Depending on where each drawer goes in the stack (top, middle, or bottom) there are sliiiiight differences in the instructions. So while we find it most efficient to do multiple drawers at once, we still pay close attention – especially for the first few.

Ok, back to the manual screw drivers. One big part of installing doors and drawers is tweaking and adjusting them for even and level spacing. For this you’ll want to a regular ol‘ manual Philips head screwdriver. It can be kind of tedious and frustrating, but it’s worth taking your time with it. This video shows it in a bit more detail.

You also will want a flathead screwdriver for twisting the little piece of plastic that locks each cabinet onto the metal rail, which comes up earlier in the process.

18. Miter Saw

Tasks like cutting your 2×4″s or even your filler pieces will be made easier and faster by having a miter saw on hand (we own this miter saw). You’ll also find that it’s helpful when it’s time to cut and install your toekicks. Ikea’s sells toekicks to match your cabinet fronts and they clip on to the plastic feet you will have attached to the bottom of your base cabinets.

In our beach house kitchen we installed quarter round in front of the Ikea baseboards to help disguise some floor level issues, as well as using quarter round around the island where we built our own base (we used standard wood baseboard trim instead of the Ikea toekicks around the island). Meanwhile, we just used the Ikea toekicks in the duplex kitchens and the floors were more level (and we think the wood and blue cabinets were more forgiving than white ones) so we didn’t need to add quarter round and it looks great.

19. Nail Gun

In addition to using a nail gun to attach additional molding like quarter round if you’re adding that (again, the Ikea baseboards just snap on so you won’t need it for that) I also find a nail gun comes in handy sometimes for attaching small filler pieces. Especially in cases where they’re too thin to take a screw.

20. Others Tools

Real quick, here are some other items you may want to have on hand. Some I’ve mentioned or shown already, but haven’t officially listed:

Pen or pencil

Painters tape

Step ladder

Utility knife or scissors (for opening boxes faster!)

Crowbar (if you need to remove any baseboard or molding)

Broom, dustpan, and/or vacuum with a hose (we have this one)

Your Ikea Kitchen Installation Tool Checklist

As promised, here’s all of the items in one place so you can make sure you have everything you need on hand. I’ve organized it a bit differently than above, just to put like items together. You may have special circumstances for your project that require more, less, or other tools – but I’ve found this to be a pretty comprehensive set:

Your itemized receipt / order

Hammer

Manual screwdrivers

Crowbar

Measuring tape

Pen or pencil

Painters tape

Step ladder

Power driver

Drill bit set with magnetic bit holder & 3/4″ bit for plumbing holes

Dremel or Hacksaw

Stud finder

Medium level (24″)

Large level (48″)

Wood shims

Cabinet screws (roughly 4 per cabinet)

Screws with anchors (roughly 2 per cabinet)

Jigsaw

Circular saw and/or table saw

Miter saw

Utility knife or scissors

Nail gun

Clamps

2×4″s (optional)

Kreg Jig (optional)

Broom, dustpan, and/or vacuum with hose

Good luck and happy installing!

P.S. For other posts we’ve written about installing Ikea cabinets, here’s one about installing our laundry room cabinets 5 years ago, and another one about using Ikea cabinets to make a wall of built-ins for our bonus room.

*This post contains affiliate links*

The post The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself appeared first on Young House Love.

0 notes

Text

The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself

Many of you have asked for tips and tricks to make installing an Ikea kitchen go more smoothly and look (and function) the best it possibly can. And the good news is that after installing three of them in a little over a year and a half (!!!), we have learned A TON about how to make things a little easier and help you end up with a better result. So settle in, I’ve got twenty tools & tips that can make all the difference.

First off, we like Ikea cabinets and have personally installed them in five rooms: our laundry room & bonus room at home, our beach house kitchen, and now these two duplex kitchens. We have lived with the ones in our home for nearly five years and they’re great. Not a single issue. They are smartly made, very durable, and they have a great 25-year warranty and a great price tag (often thousands cheaper than other options). They also come with many thoughtful features like soft close drawers that come standard and tons of customization options. So yeah, some Ikea furniture is known for feeling a little cheap and wobbly, but that has not been our experience with their cabinets AT ALL.

Ok, but back to the point of this post – tips and tools to make your Ikea cabinet install easier. Some of the tools I’m listing here are absolutely necessary and some are optional (they’ll just make the process easier, faster, and less frustrating). And as you read through this list, I think you’ll also get a pretty good sense of the steps (and curveballs) involved too, which I hope will help as well.

I’ll include a short bulleted list of everything at the end of the post too, that way you can use it as a tool checklist. But let’s just get right into it.

1. Your Itemized Receipt/Order

Before you build anything, you’ll want to take time to inventory and organize all of your boxes. We had over 200 boxes (!!!) delivered for our two duplex kitchens, so it helped to sort everything into piles beforehand.

We personally like to sort boxes by item (Sektion boxes over here, Maximera drawers over there, all of our cabinet fronts somewhere else, etc.) but you may find it helpful to sort yours by cabinet instead (ex: the box, drawer, hinges, and front for one cabinet all together in one pile – this is how Ikea breaks them up your order form). Either way you do it, this sorting process will help you identify any missing pieces and also make it faster once you start building.

2. Power driver (with Philips head)

This combo gets a lot of use in this install (especially the power driver/drill) – but they’re needed first to construct your cabinet boxes (Sektion pieces). We love constructing the boxes first because you quickly get to see the shape of your kitchen come to life.

And even though Ikea is known for their allen wrenches, you don’t use them AT ALL during a typical kitchen installation! So don’t worry about having lots of specialty drill bits. You just need a normal Phillips head to screw these puppies together.

3. Hammer

You’ll also need a hammer handy to nail the MDF backings onto the cabinet backs. It may also be useful if you need to tap any anchors into your drywall when it comes time to hang your cabinets.

4. Magnetic Drill Bit Holder

Having one of these on your drill can save you a lot of frustration while building your cabinets and drawers. You can buy one separately for about $2 or it often comes included in drill/driver sets like ours. It’ll magnetize your drill bits, meaning many of the screws that Ikea provides will stick to your drill handsfree (thanks to the magic of magnets). We found this VERY helpful when trying to screw into small spots that were too tight for our fingertips (we couldn’t reach in and hold the screw steady, so having a magnetized drill bit that held it for us was key).

5. Measuring Tape

The next several tools are needed for attaching your cabinets to the wall. Whether you’re doing upper or lower cabinets, Ikea’s system uses a metal track (called the Sektion suspension rail) that you attach to your wall and then the cabinet boxes hang from these. The rail system is extremely handy because if you make sure the rail is level, your cabinets all hang from that and are guaranteed to be level! I know, it’s GREAT. The only time I don’t use their rail is when I don’t have a wall behind my cabinets, like if you’re doing an island. In that case I’ve built my own bases from 2×4″s, but more on that later.

For now, just know the measuring tape will be useful in determining exactly where in your kitchen you’re placing your cabinets – both side-to-side on each wall, and how high the rails need to be hung (Ikea provides guides for this in their instructions). You will probably want to have your kitchen plan/schematic from Ikea handy too.

6. Dremel Or Hacksaw

Once you know where each run of cabinets is going, you’ll need to cut your metal suspension rails to size. The rails are sold in 7 foot lengths, but if you only have 4 feet of cabinetry in one area – you only want 4 feet of rail.

You can cut these by hand with a hacksaw, but we find it much faster to use our Dremel Multi-Max with a metal cutting blade.

I typically mark my cut on a piece of painters tape and cut across the open top of one of our cabinet boxes (with a piece of cardboard to protect the cabinet underneath).

7. Stud Finder

You want to screw the rail into at least a few studs in your wall for maximum hold. So it’s smart to use a stud finder to locate and mark the studs that fall within the area you’re hanging the rail – that way you can be sure to go into them and get a nice firm hold. Since studs are typically 1.5″ thick, I like to mark the full width that my stud finder indicates, since you may not know exactly where the holes on the Sektion rail will line up.

8. Medium-Size Level

Once I know where my studs are, I hold my cut-to-size metal rail and, with a medium sized level (like this 24″ level) held against it, I mark the top line of my rail AND where the holes line up with my studs. I suggest amedium sized level for this just because they’re easier to wrangle during this step.

I also mark a few additional holes where I’ll use screws paired with anchors. I believe Ikea suggests at least having a screw every 12″ inches – but for short sections like this, I like to make sure I hit at least 2 studs and then have a screw at either end of the rail that goes into an anchor.

9. Heavy Duty Screws & Anchors

After some trial and error, we found that we like using these GRK Fastener Cabinet Screws to secure our rails into studs. They’re easy to drive, they hold really tight, and they include the star-head bit you need for them. We have tried other, cheaper “cabinet screws” and the heads kept breaking off. It was MADDENING.

We also like to have some anchors on hand too, like these E-Z Ancor packs that come with screws, for those additional support screws that we add.

10. Long Level

One of the biggest challenges we’ve found in this process is getting things level. Just because you’ve hung your rail level on the wall doesn’t prevent things like slopes in your floor or bows in your wall from chucking some additional curveballs in your direction. So your best defenses are a lot of patience and a nice long level, like this 4ft level we bought specifically for this task (after learning that it’s a lot harder to use a smaller level to solve these issues).

Your medium sized level will help with the process as well (especially in checking that each individual cabinet is level front-to-back) but you’ll want something bigger to check longer spans of cabinets. You could purchase an even longer level if you wanted, but they can start to get pricey, so we found a 4 foot long level to be sufficient, especially for checking across the gaps that you’ll leave for appliances like a 30″ stove or a standard 24″ dishwasher.

11. Shims

A lot of level issues can be corrected by twisting the adjustable plastic feet that come with your base cabinets, or by adjusting the placement of your metal rail. But if you’re dealing with bows in your wall (which you can find by placing your long level against it) you’ll want to have some wood shims on hand to place behind the metal rail. In these old houses, we had to use quite a few in a couple of places!

12. Jigsaw

When it comes time to install your sink base cabinet, you’ll need to make some holes for your plumbing. For smaller pipes like your water supply lines, you can just drill holes using a large drill bit (we used the 3/4″ bit in this set). But for things like your large drain pipe, you’ll either need to buy a larger hole bit or break out a jigsaw. Even though we don’t get the cleanest cut with it, the jigsaw gives us a little more wiggle room when placing the cabinet (since the drain pipe isn’t flexible like the supply lines) and we can also use it for other cuts like for exposing the outlets along the wall (the one below powers the garbage disposal under the sink).

Just be sure to make careful measurements before you cut. We usually put a layer of painters tape around the area we’re cutting. It allows us to mark our cut without marking the cabinet, plus the tape helps keep the white finish from cracking off. Either way, this stuff will all be hidden under the sink so it doesn’t have to look perfect.

13. Clamps

As you start to get your cabinets in place and leveled, you’ll want to secure any adjacent cabinets together. Ikea provides screws for doing this, but you’ll want to use some clamps (we like these 6″ bar clamps) to hold the cabinets tightly together before you begin screwing.

We didn’t get a picture of that process, but the clamps come in handy A LOT as an extra set of hands – like when we were installing this bracket for the exhaust hoods that we hung over the stoves.

14. Circular Saw and/or Table Saw

In addition to screwing cabinets together, you may find yourself attaching cover panels or filler pieces at some point. Cover panels go on exposed ends of cabinets (so you can’t see the metal rail they hang on) or, in our case, we used some large cover panels to create a box around the fridges at the duplex. So you’ll need some sort of larger saw to make long, straight cuts. Our cover panels were a bit too wide, so I used a circular saw to shave a few inches off one side.

I didn’t use a table saw for that panel because running an 8 foot tall panel that’s this wide across my table saw would’ve been tough. But for smaller pieces (like filler pieces that are only about 3 feet long) a table saw is often easier, especially if you’re only shaving off a little bit. But if that’s too pricey and you’ve got a steady hand, you can get by with the circular saw.

15. 2 x 4″ Boards

Every time we’ve installed an Ikea kitchen we’ve needed some 2×4″s at some point. At the beach house we used them to make some bases for the island cabinets.

Basically, they were just some boxes we made almost the same size as each cabinet (slightly narrower to account for the toekicks) that we secured to the floor using pocket holes. To drill the pocket holes, you can use something like a…

16. Kreg Jig

Now, a Kreg Jig isn’t absolutely necessary here, but I’ve had one for around nine years now so I’m accustomed to breaking it out for tasks like this. So while I’m a big fan of having one in your arsenal, I understand that you’ve just bought a new kitchen so tacking on another $99 tool to your budget isn’t always practical.

I did use it again for the duplexes to make more 2×4″s into boxes (this time for mounting the above-fridge cabinet away from the wall, so it sat closer to the front of the fridge).

The boxes acted as an extension of the wall. The top one was for mounting the metal rail, and the bottom one gave the base of the cabinet a spot to rest so it didn’t tip back wildly. They also gave us a way to mount that large cover panel to box in the fridge.

I guess I should add in here that a step ladder is also useful, so let’s officially put that on the list.

17. Manual Screwdriver

Once your cabinets and panels are hung, leveled, and secured to each other, the next part of the process is to add your doors and drawers. The instructions here are pretty self-explanatory and the main tool you need is a power driver to screw everything together. Our main word of warning is to pay close attention to screw placements when you’re assembling drawers! Depending on where each drawer goes in the stack (top, middle, or bottom) there are sliiiiight differences in the instructions. So while we find it most efficient to do multiple drawers at once, we still pay close attention – especially for the first few.

Ok, back to the manual screw drivers. One big part of installing doors and drawers is tweaking and adjusting them for even and level spacing. For this you’ll want to a regular ol‘ manual Philips head screwdriver. It can be kind of tedious and frustrating, but it’s worth taking your time with it. This video shows it in a bit more detail.

You also will want a flathead screwdriver for twisting the little piece of plastic that locks each cabinet onto the metal rail, which comes up earlier in the process.

18. Miter Saw

Tasks like cutting your 2×4″s or even your filler pieces will be made easier and faster by having a miter saw on hand (we own this miter saw). You’ll also find that it’s helpful when it’s time to cut and install your toekicks. Ikea’s sells toekicks to match your cabinet fronts and they clip on to the plastic feet you will have attached to the bottom of your base cabinets.

In our beach house kitchen we installed quarter round in front of the Ikea baseboards to help disguise some floor level issues, as well as using quarter round around the island where we built our own base (we used standard wood baseboard trim instead of the Ikea toekicks around the island). Meanwhile, we just used the Ikea toekicks in the duplex kitchens and the floors were more level (and we think the wood and blue cabinets were more forgiving than white ones) so we didn’t need to add quarter round and it looks great.

19. Nail Gun

In addition to using a nail gun to attach additional molding like quarter round if you’re adding that (again, the Ikea baseboards just snap on so you won’t need it for that) I also find a nail gun comes in handy sometimes for attaching small filler pieces. Especially in cases where they’re too thin to take a screw.

20. Others Tools

Real quick, here are some other items you may want to have on hand. Some I’ve mentioned or shown already, but haven’t officially listed:

Pen or pencil

Painters tape

Step ladder

Utility knife or scissors (for opening boxes faster!)

Crowbar (if you need to remove any baseboard or molding)

Broom, dustpan, and/or vacuum with a hose (we have this one)

Your Ikea Kitchen Installation Tool Checklist

As promised, here’s all of the items in one place so you can make sure you have everything you need on hand. I’ve organized it a bit differently than above, just to put like items together. You may have special circumstances for your project that require more, less, or other tools – but I’ve found this to be a pretty comprehensive set:

Your itemized receipt / order

Hammer

Manual screwdrivers

Crowbar

Measuring tape

Pen or pencil

Painters tape

Step ladder

Power driver

Drill bit set with magnetic bit holder & 3/4″ bit for plumbing holes

Dremel or Hacksaw

Stud finder

Medium level (24″)

Large level (48″)

Wood shims

Cabinet screws (roughly 4 per cabinet)

Screws with anchors (roughly 2 per cabinet)

Jigsaw

Circular saw and/or table saw

Miter saw

Utility knife or scissors

Nail gun

Clamps

2×4″s (optional)

Kreg Jig (optional)

Broom, dustpan, and/or vacuum with hose

Good luck and happy installing!

P.S. For other posts we’ve written about installing Ikea cabinets, here’s one about installing our laundry room cabinets 5 years ago, and another one about using Ikea cabinets to make a wall of built-ins for our bonus room.

*This post contains affiliate links*

The post The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself appeared first on Young House Love.

0 notes

Text

The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself

Many of you have asked for tips and tricks to make installing an Ikea kitchen go more smoothly and look (and function) the best it possibly can. And the good news is that after installing three of them in a little over a year and a half (!!!), we have learned A TON about how to make things a little easier and help you end up with a better result. So settle in, I’ve got twenty tools & tips that can make all the difference.

First off, we like Ikea cabinets and have personally installed them in five rooms: our laundry room & bonus room at home, our beach house kitchen, and now these two duplex kitchens. We have lived with the ones in our home for nearly five years and they’re great. Not a single issue. They are smartly made, very durable, and they have a great 25-year warranty and a great price tag (often thousands cheaper than other options). They also come with many thoughtful features like soft close drawers that come standard and tons of customization options. So yeah, some Ikea furniture is known for feeling a little cheap and wobbly, but that has not been our experience with their cabinets AT ALL.

Ok, but back to the point of this post – tips and tools to make your Ikea cabinet install easier. Some of the tools I’m listing here are absolutely necessary and some are optional (they’ll just make the process easier, faster, and less frustrating). And as you read through this list, I think you’ll also get a pretty good sense of the steps (and curveballs) involved too, which I hope will help as well.

I’ll include a short bulleted list of everything at the end of the post too, that way you can use it as a tool checklist. But let’s just get right into it.

1. Your Itemized Receipt/Order

Before you build anything, you’ll want to take time to inventory and organize all of your boxes. We had over 200 boxes (!!!) delivered for our two duplex kitchens, so it helped to sort everything into piles beforehand.

We personally like to sort boxes by item (Sektion boxes over here, Maximera drawers over there, all of our cabinet fronts somewhere else, etc.) but you may find it helpful to sort yours by cabinet instead (ex: the box, drawer, hinges, and front for one cabinet all together in one pile – this is how Ikea breaks them up your order form). Either way you do it, this sorting process will help you identify any missing pieces and also make it faster once you start building.

2. Power driver (with Philips head)

This combo gets a lot of use in this install (especially the power driver/drill) – but they’re needed first to construct your cabinet boxes (Sektion pieces). We love constructing the boxes first because you quickly get to see the shape of your kitchen come to life.

And even though Ikea is known for their allen wrenches, you don’t use them AT ALL during a typical kitchen installation! So don’t worry about having lots of specialty drill bits. You just need a normal Phillips head to screw these puppies together.

3. Hammer

You’ll also need a hammer handy to nail the MDF backings onto the cabinet backs. It may also be useful if you need to tap any anchors into your drywall when it comes time to hang your cabinets.

4. Magnetic Drill Bit Holder

Having one of these on your drill can save you a lot of frustration while building your cabinets and drawers. You can buy one separately for about $2 or it often comes included in drill/driver sets like ours. It’ll magnetize your drill bits, meaning many of the screws that Ikea provides will stick to your drill handsfree (thanks to the magic of magnets). We found this VERY helpful when trying to screw into small spots that were too tight for our fingertips (we couldn’t reach in and hold the screw steady, so having a magnetized drill bit that held it for us was key).

5. Measuring Tape

The next several tools are needed for attaching your cabinets to the wall. Whether you’re doing upper or lower cabinets, Ikea’s system uses a metal track (called the Sektion suspension rail) that you attach to your wall and then the cabinet boxes hang from these. The rail system is extremely handy because if you make sure the rail is level, your cabinets all hang from that and are guaranteed to be level! I know, it’s GREAT. The only time I don’t use their rail is when I don’t have a wall behind my cabinets, like if you’re doing an island. In that case I’ve built my own bases from 2×4″s, but more on that later.

For now, just know the measuring tape will be useful in determining exactly where in your kitchen you’re placing your cabinets – both side-to-side on each wall, and how high the rails need to be hung (Ikea provides guides for this in their instructions). You will probably want to have your kitchen plan/schematic from Ikea handy too.

6. Dremel Or Hacksaw

Once you know where each run of cabinets is going, you’ll need to cut your metal suspension rails to size. The rails are sold in 7 foot lengths, but if you only have 4 feet of cabinetry in one area – you only want 4 feet of rail.

You can cut these by hand with a hacksaw, but we find it much faster to use our Dremel Multi-Max with a metal cutting blade.

I typically mark my cut on a piece of painters tape and cut across the open top of one of our cabinet boxes (with a piece of cardboard to protect the cabinet underneath).

7. Stud Finder

You want to screw the rail into at least a few studs in your wall for maximum hold. So it’s smart to use a stud finder to locate and mark the studs that fall within the area you’re hanging the rail – that way you can be sure to go into them and get a nice firm hold. Since studs are typically 1.5″ thick, I like to mark the full width that my stud finder indicates, since you may not know exactly where the holes on the Sektion rail will line up.

8. Medium-Size Level

Once I know where my studs are, I hold my cut-to-size metal rail and, with a medium sized level (like this 24″ level) held against it, I mark the top line of my rail AND where the holes line up with my studs. I suggest amedium sized level for this just because they’re easier to wrangle during this step.

I also mark a few additional holes where I’ll use screws paired with anchors. I believe Ikea suggests at least having a screw every 12″ inches – but for short sections like this, I like to make sure I hit at least 2 studs and then have a screw at either end of the rail that goes into an anchor.

9. Heavy Duty Screws & Anchors

After some trial and error, we found that we like using these GRK Fastener Cabinet Screws to secure our rails into studs. They’re easy to drive, they hold really tight, and they include the star-head bit you need for them. We have tried other, cheaper “cabinet screws” and the heads kept breaking off. It was MADDENING.

We also like to have some anchors on hand too, like these E-Z Ancor packs that come with screws, for those additional support screws that we add.

10. Long Level

One of the biggest challenges we’ve found in this process is getting things level. Just because you’ve hung your rail level on the wall doesn’t prevent things like slopes in your floor or bows in your wall from chucking some additional curveballs in your direction. So your best defenses are a lot of patience and a nice long level, like this 4ft level we bought specifically for this task (after learning that it’s a lot harder to use a smaller level to solve these issues).

Your medium sized level will help with the process as well (especially in checking that each individual cabinet is level front-to-back) but you’ll want something bigger to check longer spans of cabinets. You could purchase an even longer level if you wanted, but they can start to get pricey, so we found a 4 foot long level to be sufficient, especially for checking across the gaps that you’ll leave for appliances like a 30″ stove or a standard 24″ dishwasher.

11. Shims

A lot of level issues can be corrected by twisting the adjustable plastic feet that come with your base cabinets, or by adjusting the placement of your metal rail. But if you’re dealing with bows in your wall (which you can find by placing your long level against it) you’ll want to have some wood shims on hand to place behind the metal rail. In these old houses, we had to use quite a few in a couple of places!

12. Jigsaw

When it comes time to install your sink base cabinet, you’ll need to make some holes for your plumbing. For smaller pipes like your water supply lines, you can just drill holes using a large drill bit (we used the 3/4″ bit in this set). But for things like your large drain pipe, you’ll either need to buy a larger hole bit or break out a jigsaw. Even though we don’t get the cleanest cut with it, the jigsaw gives us a little more wiggle room when placing the cabinet (since the drain pipe isn’t flexible like the supply lines) and we can also use it for other cuts like for exposing the outlets along the wall (the one below powers the garbage disposal under the sink).

Just be sure to make careful measurements before you cut. We usually put a layer of painters tape around the area we’re cutting. It allows us to mark our cut without marking the cabinet, plus the tape helps keep the white finish from cracking off. Either way, this stuff will all be hidden under the sink so it doesn’t have to look perfect.

13. Clamps

As you start to get your cabinets in place and leveled, you’ll want to secure any adjacent cabinets together. Ikea provides screws for doing this, but you’ll want to use some clamps (we like these 6″ bar clamps) to hold the cabinets tightly together before you begin screwing.

We didn’t get a picture of that process, but the clamps come in handy A LOT as an extra set of hands – like when we were installing this bracket for the exhaust hoods that we hung over the stoves.

14. Circular Saw and/or Table Saw

In addition to screwing cabinets together, you may find yourself attaching cover panels or filler pieces at some point. Cover panels go on exposed ends of cabinets (so you can’t see the metal rail they hang on) or, in our case, we used some large cover panels to create a box around the fridges at the duplex. So you’ll need some sort of larger saw to make long, straight cuts. Our cover panels were a bit too wide, so I used a circular saw to shave a few inches off one side.

I didn’t use a table saw for that panel because running an 8 foot tall panel that’s this wide across my table saw would’ve been tough. But for smaller pieces (like filler pieces that are only about 3 feet long) a table saw is often easier, especially if you’re only shaving off a little bit. But if that’s too pricey and you’ve got a steady hand, you can get by with the circular saw.

15. 2 x 4″ Boards

Every time we’ve installed an Ikea kitchen we’ve needed some 2×4″s at some point. At the beach house we used them to make some bases for the island cabinets.

Basically, they were just some boxes we made almost the same size as each cabinet (slightly narrower to account for the toekicks) that we secured to the floor using pocket holes. To drill the pocket holes, you can use something like a…

16. Kreg Jig

Now, a Kreg Jig isn’t absolutely necessary here, but I’ve had one for around nine years now so I’m accustomed to breaking it out for tasks like this. So while I’m a big fan of having one in your arsenal, I understand that you’ve just bought a new kitchen so tacking on another $99 tool to your budget isn’t always practical.

I did use it again for the duplexes to make more 2×4″s into boxes (this time for mounting the above-fridge cabinet away from the wall, so it sat closer to the front of the fridge).

The boxes acted as an extension of the wall. The top one was for mounting the metal rail, and the bottom one gave the base of the cabinet a spot to rest so it didn’t tip back wildly. They also gave us a way to mount that large cover panel to box in the fridge.

I guess I should add in here that a step ladder is also useful, so let’s officially put that on the list.

17. Manual Screwdriver

Once your cabinets and panels are hung, leveled, and secured to each other, the next part of the process is to add your doors and drawers. The instructions here are pretty self-explanatory and the main tool you need is a power driver to screw everything together. Our main word of warning is to pay close attention to screw placements when you’re assembling drawers! Depending on where each drawer goes in the stack (top, middle, or bottom) there are sliiiiight differences in the instructions. So while we find it most efficient to do multiple drawers at once, we still pay close attention – especially for the first few.

Ok, back to the manual screw drivers. One big part of installing doors and drawers is tweaking and adjusting them for even and level spacing. For this you’ll want to a regular ol‘ manual Philips head screwdriver. It can be kind of tedious and frustrating, but it’s worth taking your time with it. This video shows it in a bit more detail.

You also will want a flathead screwdriver for twisting the little piece of plastic that locks each cabinet onto the metal rail, which comes up earlier in the process.

18. Miter Saw

Tasks like cutting your 2×4″s or even your filler pieces will be made easier and faster by having a miter saw on hand (we own this miter saw). You’ll also find that it’s helpful when it’s time to cut and install your toekicks. Ikea’s sells toekicks to match your cabinet fronts and they clip on to the plastic feet you will have attached to the bottom of your base cabinets.

In our beach house kitchen we installed quarter round in front of the Ikea baseboards to help disguise some floor level issues, as well as using quarter round around the island where we built our own base (we used standard wood baseboard trim instead of the Ikea toekicks around the island). Meanwhile, we just used the Ikea toekicks in the duplex kitchens and the floors were more level (and we think the wood and blue cabinets were more forgiving than white ones) so we didn’t need to add quarter round and it looks great.

19. Nail Gun

In addition to using a nail gun to attach additional molding like quarter round if you’re adding that (again, the Ikea baseboards just snap on so you won’t need it for that) I also find a nail gun comes in handy sometimes for attaching small filler pieces. Especially in cases where they’re too thin to take a screw.

20. Others Tools

Real quick, here are some other items you may want to have on hand. Some I’ve mentioned or shown already, but haven’t officially listed:

Pen or pencil

Painters tape

Step ladder

Utility knife or scissors (for opening boxes faster!)

Crowbar (if you need to remove any baseboard or molding)

Broom, dustpan, and/or vacuum with a hose (we have this one)

Your Ikea Kitchen Installation Tool Checklist

As promised, here’s all of the items in one place so you can make sure you have everything you need on hand. I’ve organized it a bit differently than above, just to put like items together. You may have special circumstances for your project that require more, less, or other tools – but I’ve found this to be a pretty comprehensive set:

Your itemized receipt / order

Hammer

Manual screwdrivers

Crowbar

Measuring tape

Pen or pencil

Painters tape

Step ladder

Power driver

Drill bit set with magnetic bit holder & 3/4″ bit for plumbing holes

Dremel or Hacksaw

Stud finder

Medium level (24″)

Large level (48″)

Wood shims

Cabinet screws (roughly 4 per cabinet)

Screws with anchors (roughly 2 per cabinet)

Jigsaw

Circular saw and/or table saw

Miter saw

Utility knife or scissors

Nail gun

Clamps

2×4″s (optional)

Kreg Jig (optional)

Broom, dustpan, and/or vacuum with hose

Good luck and happy installing!

P.S. For other posts we’ve written about installing Ikea cabinets, here’s one about installing our laundry room cabinets 5 years ago, and another one about using Ikea cabinets to make a wall of built-ins for our bonus room.

*This post contains affiliate links*

The post The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself appeared first on Young House Love.

0 notes

Text

The Tools (And Tricks) You Need To Install An Ikea Kitchen Yourself

Many of you have asked for tips and tricks to make installing an Ikea kitchen go more smoothly and look (and function) the best it possibly can. And the good news is that after installing three of them in a little over a year and a half (!!!), we have learned A TON about how to make things a little easier and help you end up with a better result. So settle in, I’ve got twenty tools & tips that can make all the difference.

First off, we like Ikea cabinets and have personally installed them in five rooms: our laundry room & bonus room at home, our beach house kitchen, and now these two duplex kitchens. We have lived with the ones in our home for nearly five years and they’re great. Not a single issue. They are smartly made, very durable, and they have a great 25-year warranty and a great price tag (often thousands cheaper than other options). They also come with many thoughtful features like soft close drawers that come standard and tons of customization options. So yeah, some Ikea furniture is known for feeling a little cheap and wobbly, but that has not been our experience with their cabinets AT ALL.

Ok, but back to the point of this post – tips and tools to make your Ikea cabinet install easier. Some of the tools I’m listing here are absolutely necessary and some are optional (they’ll just make the process easier, faster, and less frustrating). And as you read through this list, I think you’ll also get a pretty good sense of the steps (and curveballs) involved too, which I hope will help as well.

I’ll include a short bulleted list of everything at the end of the post too, that way you can use it as a tool checklist. But let’s just get right into it.

1. Your Itemized Receipt/Order

Before you build anything, you’ll want to take time to inventory and organize all of your boxes. We had over 200 boxes (!!!) delivered for our two duplex kitchens, so it helped to sort everything into piles beforehand.

We personally like to sort boxes by item (Sektion boxes over here, Maximera drawers over there, all of our cabinet fronts somewhere else, etc.) but you may find it helpful to sort yours by cabinet instead (ex: the box, drawer, hinges, and front for one cabinet all together in one pile – this is how Ikea breaks them up your order form). Either way you do it, this sorting process will help you identify any missing pieces and also make it faster once you start building.

2. Power driver (with Philips head)

This combo gets a lot of use in this install (especially the power driver/drill) – but they’re needed first to construct your cabinet boxes (Sektion pieces). We love constructing the boxes first because you quickly get to see the shape of your kitchen come to life.

And even though Ikea is known for their allen wrenches, you don’t use them AT ALL during a typical kitchen installation! So don’t worry about having lots of specialty drill bits. You just need a normal Phillips head to screw these puppies together.

3. Hammer

You’ll also need a hammer handy to nail the MDF backings onto the cabinet backs. It may also be useful if you need to tap any anchors into your drywall when it comes time to hang your cabinets.

4. Magnetic Drill Bit Holder

Having one of these on your drill can save you a lot of frustration while building your cabinets and drawers. You can buy one separately for about $2 or it often comes included in drill/driver sets like ours. It’ll magnetize your drill bits, meaning many of the screws that Ikea provides will stick to your drill handsfree (thanks to the magic of magnets). We found this VERY helpful when trying to screw into small spots that were too tight for our fingertips (we couldn’t reach in and hold the screw steady, so having a magnetized drill bit that held it for us was key).

5. Measuring Tape