#china cnc milling machine suppliers

Text

Top Aluminum CNC Machining Service in China

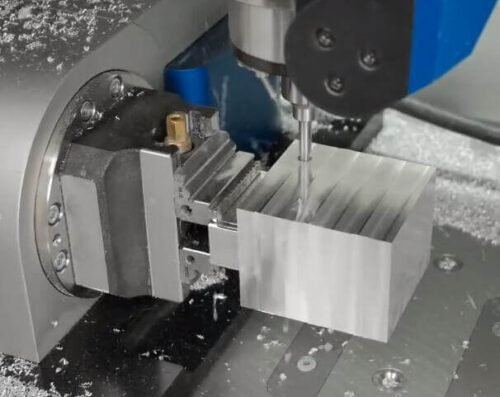

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Video

vimeo

TH MAchine Tools 2024 Corporate Vid Full Length from Byron Lippiatt on Vimeo.

At TH Machine Tools, business is about building relationships that last. Focusing on quality, we are confident to put our name on the machines we sell.

We specialize in new, used and reconditioned machines for fabrication, manufacturing, and engineering. Our vast portfolio includes conventional press brakes, guillotines, plate rolls, metal workers, lathes, mills, drills, band saws, welding machines and much more.

We also keep a finger on the pulse of the industry by constantly expanding our horizons with top CNC brands for our range of CNC fibre laser cutters, plasma cutters, machining centres, turning centres, press brakes and guillotines.

At TH Machine Tools we understand the need for affordable products of the best possible quality. Which is why our suppliers are carefully selected from across Europe, the East and America, namely: HURCO from the USA; SYIL from China; Sahinler, Isitan, LFSS and Bekamak from Turkey. And our own TH Machine Tools brand from China and Taiwan, ensuring quality, affordability, service, backup and spares.

We are based in Hartbeespoort and our 3000m3 warehouse offers a workshop area equipped with overhead cranes, loading bays, spares and tooling storage areas, an engineering shop, toolroom, boilermaker shop, offices and a large showroom area.

Our carefully selected staff, bring their unique contribution to unify and consolidate a well-defined work force, through love, care and dedication, assuring professional service and a long-term commitment to our customers.

TH Machine Tools is constantly evolving and adapting to the market needs and requirements, remaining consistent, rooted in faith, have withstood all the storms over the past 30 years, and still pursuing our goal to supply the industry with reliable new and used machines.

From Cape Town to Zimbabwe, Thabazimbi to Mozambique, Free State to Windhoek, you will find our name tag on quality machines across the continent.

TH Machine Tools – For Machines That Work!

0 notes

Text

PinnacleMetalFab: Trailblazers in Metal Fabrication Tools and Equipment Manufacturing

Originally Published on: SpendEdge |Top 5 Metal Fabrication Tools and Equipment Manufacturers | SpendEdge

In the realm of towering skyscrapers and intricate machinery, metal fabrication tools play a pivotal role in crafting sheet metal, nuts, bolts, springs, and wires. These tools, utilized in metal fabrication shops, mold and structure metal components through cutting, burning, welding, machining, forming, and assembling. Lathes, boring machines, milling machines, and drilling machines are commonplace in this intricate process. The metal fabrication process, whether manual or automated, has undergone a transformative evolution, particularly post the fourth industrial revolution, witnessing a significant shift towards automation and the integration of IoT systems. The adoption of IoT is anticipated to propel the global metal fabrication equipment market's growth, creating synergy between manufacturing and information management systems.

##Pioneers in Metal Fabrication Tools and Equipment Manufacturing

###Trumpf A stalwart in metal fabrication equipment, Trumpf, a family-owned powerhouse, stands among the world's largest machine tool suppliers. With production facilities spanning Germany, France, the UK, China, Japan, and the US, Trumpf offers a diverse product and service portfolio, encompassing laser cutting machines, marking systems, punching machines, bending machines, and more. The company's commitment to Industry 4.0 solutions is evident through its $30 million investment in a technology center in Chicago in 2017.

###Shenyang Machine Tool As the largest machine tool and equipment manufacturer in China, Shenyang Machine Tool is a global leader in metal fabrication equipment. Boasting a comprehensive range of tools for cutting, milling, boring, and drilling, the company's annual production exceeds 80,000 small and large equipment. A Berlin-based R&D center ensures top-notch product design and performance accuracy.

###Amada Headquartered in Kanagawa, Japan, Amada is a global player in metal processing equipment and machinery, specializing in metal cutting, forming, punching, and shearing equipment. With over 8,000 employees worldwide, Amada not only provides metal fabrication tools but also offers software solutions for machine automation and training. Their innovative 3kW ENSIS product enables continuous processing of thin-to-thick materials without a lens change.

###Okuma Originating as Okuma Noodle Machine in 1898, Okuma has evolved into a renowned machine tool builder. Producing CNC lathes and machining centers, Okuma is recognized for excellence and groundbreaking technologies. Reporting revenues of $1.45 billion in 2016, the company continues to push the boundaries of CNC machine tools.

###DMG Mori Seiki Formed through a strategic partnership between Deckel-Maho-Gildemeister and Mori Seiki, DMG Mori Seiki has grown into one of the world's largest suppliers of machine and metal fabrication tools. Operating under the name DMG Mori, the Japanese company has developed over 200 models of CNC lathes and machining centers since its establishment.

Delve into comprehensive insights on key players in the metal fabrication tools and equipment market, along with dynamic market trends, pricing models, procurement challenges, and sourcing insights in SpendEdge’s forthcoming report on the global metal fabrication equipment market.

Contact us.

0 notes

Text

DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS

BRIGHT-TOOLS offers premium DIN 69893 (ISO 12164) HSK-F tool holders, designed for high-speed cutting applications. Our HSK-F tool holders provide exceptional stability and cutting accuracy, ensuring superior performance even under the most demanding conditions. With BRIGHT-TOOLS HSK-F tool holders, customers can achieve greater precision, efficiency, and profitability in their machining processes.

WHAT TYPES OF MACHINES ARE DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS SUITABLE FOR?

HSK-F tool holders are suitable for high-speed spindles in CNC machines. These tool holders are specifically designed for applications that require high-performance, high-precision, and high-speed cutting operations. HSK-F tool holders provide optimal stability and accuracy during machining processes, making them suitable for various machines such as milling machines, lathes, grinding machines, and drilling machines. The HSK-F system ensures effective transmission of torque, enhanced cooling capabilities, and reduced tool vibration, resulting in improved machining precision and surface finish.

HOW TO ENSURE PROPER MAINTENANCE AND CARE FOR DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS?

To ensure proper maintenance and care for HSK-F tool holders, follow these steps:

1. Regularly inspect the tool holders for any signs of wear, damage, or contamination.

2. Clean the tool holders with a non-abrasive solvent after each use to remove chips, dust, and dirt.

3. Lubricate the tool holders with a recommended oil or grease to prevent rust and maintain smooth operation.

4. Store the tool holders in a clean, dry, and climate-controlled environment to protect them from moisture and temperature fluctuations.

5. Follow manufacturer recommendations for tightening and loosening the tool holders to prevent overtightening or undertightening.

1 note

·

View note

Video

youtube

Management of Wheat Silos(www.immy.cn)Integrated Flour mill EPC services provider: www.immy.cnIn wheat maize barley,millet,durrum etc production, the requirements for moistening time are relatively strict. If the moistening time is too short, the endosperm will not be completely soft, the endosperm structure will be uneven, and the rolling distance will not be easy to adjust during grinding. The grinding will not be thorough and the screening will be difficult. If the wheat moistening time is too long, the moisture on the surface of the wheat will evaporate, causing the moisture on the surface of the wheat to dry out and become easily broken, affecting the milling performance. https://www.immy.cn/blog/management-of-wheat-warehouse-in-flour-mill-1

WUXI HASEN IMPORTAND EXPORT CO.,LTD is a general solution service provider and project system integration service provider with grain and oil equipment technology research and development, engineering design, manufacturing, installation,training and commissioning, project contracting as business main structure. Products including energy saving roller mill,high plansifter, purifier,wheat scourer,wheat peeler,wheat washer,branbrush,bran finish,maize embryo remmoval,degerminator,flow balance,micro feeder(weight in loss feeder,diffrential micro feeder),rotary sifter,vibro sifter,packing machine,double shaft paddle mixer,quantitative weighing scale, paper bag packing machine,impact detacher,hammer mill(water drop pulverizer).suction duct,aspiration separator,moisture controller,single(double)bin control(inspection)sifter,CNC grooving machine,fluting machine,auto stack robot machine,vibro discharger, bran outlet discharger,color sorter,LAB mill,scraper conveyorbucket elevator,air locker,cyclone pipe,PLC control system.dampener, flour dryer.flour refeeder,conveyor feeder.pre cleaning sifter,pulse dust collector,quantitative flow scale,heavy duty combined sifter XMTS,gate, gravity grading destoner(stone removal),rotary screen. ETC flour mill equipment&machine.

We are leading Integrated wheat maize flour mill engineering equipment manufacture EPC turnkey project services provider from 100 to 3000TPD in China, Inquiry us if you need high standard Full Auto Flour Mill Line from 100-5000 tons per a day. Hope to be your valued supplier for life time cooperation. E mail: [email protected] Whatsapp: 008613812016908 www.immy.cn https://lnkd.in/gnYbSr_9

#flourmachine #flourmillmachine #grainmachine #flourmill #wheatflourmillmachine #maizeflourmachine #semolina #Addamaidamachine #nshimamachine #wheatwashingmachine #recycleaspiration #aspirationselector #rollermill #rollerbody #brandischarger #branfinisher #wheatscourer #wheatwasher #wheatcleaner #branbrush #colorsorter #flowbalance #vitaminfeeder #highplansifter #purifier #airlocker #pressurefan #flourconveyor #bucketelevator #steelsilo #degerminator #maizeembryo #destoner #dampener #aspirator #moisturecontroller #PLCsystem #EPCflourmillproject #turnkeyflourmillline #integratedflourmillline #largeflourmillline #dryerwheatflour #dryerwheatban #dryerwheatgerms #productioncapacity #wheatflourmillingmachines #processingplant #flourmillmachine #automaticflour #flourmillplant #millingmachine #flourmillmachine #wheatflourmillmachine #packingmachine #quantitativepacker #spoutpacker #wheatspoutpacker #maizeflourspoutpacker #wheatflourspoutpacker

0 notes

Text

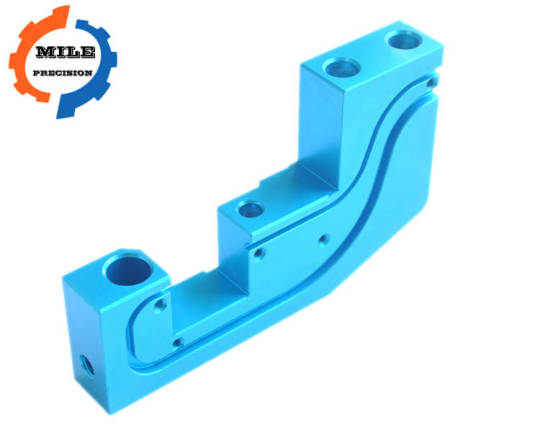

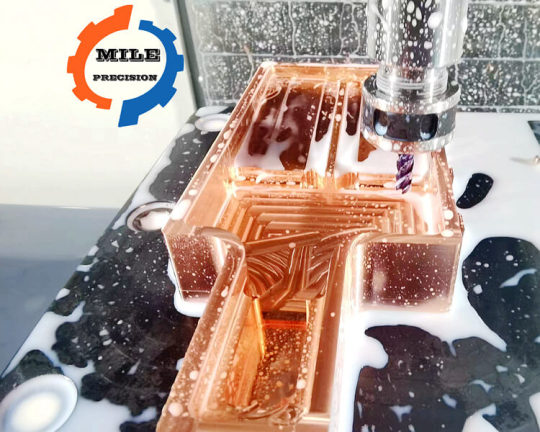

We are an experienced Custom precision machining services supplier, manufacturer in China

Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling.

Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

Battery Cover, a precision-engineered accessory designed to protect and secure your device's power source. Crafted from high-quality, durable materials, this sleek and stylish cover ensures a snug fit, while providing easy access for battery replacement. Enhance your gadget's longevity and performance with this reliable safeguard.

Functions and Importance of Battery Terminal Covers in Vehicles

Protection: Battery caps are designed to protect the battery from external elements such as dust, dirt, moisture, and road debris. They shield the battery from physical damage and prevent contaminants from entering the battery compartment. This protection is crucial for maintaining the battery's integrity and preventing potential malfunctions or short circuits.

Thermal Management: Batteries generate heat during operation, especially during charging and discharging cycles. Battery covers often have built-in insulation and ventilation features to manage the battery's temperature. They help dissipate heat and maintain optimal operating conditions for the battery, enhancing its performance and extending its lifespan.

Safety: Battery covers play a significant role in ensuring the safety of both the vehicle and its occupants. They help contain any potential acid leaks or spills from the battery, preventing them from coming into contact with other components or causing harm. Battery covers also act as a barrier between the battery terminals and any conductive material, reducing the risk of electrical shorts or accidental contact.

Noise Reduction: In electric vehicles (EVs) and hybrid vehicles, battery covers can contribute to reducing noise levels. They act as sound barriers, minimizing the transmission of noise and vibrations generated by the battery, thereby enhancing the overall driving experience for passengers.

Aesthetics and Integration: Battery covers are designed to integrate seamlessly with the vehicle's overall design and aesthetics. They provide a neat and finished appearance to the battery compartment, contributing to the overall visual appeal of the vehicle.

Specification of Battery Terminal Cap

Material

Iron, stainless steel, brass, copper, galvanized steel, titanium, Aluminium, etc.

Surface treatment

Zinc/Nickel/Tin/Ag-Plated/Au-Plated, etc.

Type

High-Precision nonstandard parts

(OEM Service)

Process

Stamping/Punching/Pressing, CNC machining/Turning/Milling, Deep Drawing and other process.

Certificate

IATF16949 2016;I SO9001 2015; ISO14001:2015;RoHS&REACH, etc.

Usage

Automotive/ Car Thermostat, Switch, Electric Heating, Aerospace, New energy, etc.

Factors to Consider in Choosing the Right Battery Cover for Your Vehicle

When choosing the right battery cover for your vehicle, there are several factors to consider. These factors can help ensure that the battery cover is compatible with your vehicle's specifications and provides the necessary protection and functionality. Here are some key factors to consider:

Vehicle Make and Model

Material and Construction of Battery covers

The ventilation and thermal management features of the battery cover

The level of protection and safety features provided by the battery cover

Ensure that the battery cover is easy to install and remove

Manufacturer Reputation and Warranty

Budget.

0 notes

Text

youtube

CNC Tool Setter China Manufacturer and Supplier | Silvercnc

Are you in need of high-quality CNC tool setters? Look no further! We are the leading CNC tool setter manufacturer and supplier in China, offering top-notch products that are sure to meet your requirements. With our advanced technology and state-of-the-art manufacturing facilities, we produce precision tool setters that are reliable, accurate, and built to last.

Our CNC tool setters are designed to increase productivity, reduce setup time, and improve overall machining performance. Whether you need tool setters for milling, turning, or grinding applications, we have a wide range of options to choose from. From standard tool setters to custom solutions, we can cater to your specific needs.

Choose us as your CNC tool setter manufacturer and supplier, and experience the difference in performance and reliability. Contact us today to discuss your requirements and get a quote tailored to your needs.

For more information about CNC tool setter, visit here: https://www.silvercnc.com/tool-setter/

Welcome to contact and communicate with us

Email: [email protected]

whatsapp: +8618098920890 (Liu)

1 note

·

View note

Text

CNC Machining vs. Traditional Machining: Which is Better?

CNC Machining vs. Traditional Machining: Which is Better?

In the world of manufacturing, precision and efficiency are paramount. As industries continue to evolve, the methods of producing

intricate parts and components have also advanced significantly. Two key players in this evolution are CNC machining and traditional

machining. But the question that lingers is: CNC Machining service vs. Traditional Machining service: Which is Better? Let's embark on

a journey to explore the nuances of these two techniques and uncover the answer.

CNC Machining: The Modern Marvel

Imagine a world where machines operate with unparalleled accuracy, tirelessly executing complex tasks with minimal human intervention.

This is the realm of Computer Numerical Control (CNC) machining. Utilizing cutting-edge technology, CNC machines follow pre-programmed

instructions to perform various tasks such as cutting, drilling, milling, and shaping materials with exquisite precision. This method eliminates

the variability introduced by human error and ensures consistent results every time.

Traditional Machining: A Glimpse into the Past

In contrast, traditional machining methods rely heavily on human operators to guide tools through the manufacturing process. These

methods have served industries faithfully for centuries, involving techniques like manual milling, turning, grinding, and shaping. Skilled

machinists use their expertise to control the process, adjusting parameters based on experience and visual cues. However, this human

touch can lead to slight variations in the final product.

So, Which is Better?

As with most questions in the world of manufacturing, the answer depends on various factors. CNC machining undoubtedly shines when

it comes to precision, repeatability, and complex geometries. The ability to program intricate designs into the machine's software ensures

that each part produced is a mirror image of the last, down to the tiniest detail. Moreover, CNC machining allows for automation, reducing

the need for constant monitoring and potentially increasing production speed.

On the other hand, traditional machining methods offer a level of adaptability that CNC machines struggle to match. Skilled machinists can

make real-time adjustments and corrections based on their intuition and experience, which can be crucial when dealing with unconventional

materials or unique situations. Additionally, traditional methods might be more cost-effective for simpler projects or low-volume production runs.

Finding Common Ground

The manufacturing landscape isn't simply black and white; it's a spectrum of techniques that can be combined for optimal results. In fact,

many manufacturing processes today employ a hybrid approach that combines the strengths of both CNC and traditional machining. For

instance, a CNC machine could be used to create a precise base structure, while a skilled machinist adds intricate details by hand.

Unveiling the Bigger Picture

As CNC machining and traditional machining continue to evolve, they coexist in a harmonious dance that caters to the diverse needs of

various industries. From aerospace to automotive, medical to electronics, these methods provide the tools necessary to craft the world

around us. It's worth noting that small businesses and individuals also benefit from these advancements, utilizing CNC machines for

prototypes, custom parts, and personal projects. The accessibility and affordability of CNC machines have democratized the world of

manufacturing, allowing creativity to flourish.

Delving Deeper: The Client Perspective

Let's take a closer look at the clientele who benefit from CNC machining and traditional machining. Individuals like Mark Sheng, a

discerning executive in a Canadian company, prioritize quality over price and prefer products made in China. They seek personalized

service and trusted suppliers who understand their unique requirements. CNC machining, with its ability to deliver consistent quality

and customization, aligns perfectly with such preferences.

Navigating Challenges and Solutions

The manufacturing industry is not without its challenges. Suppliers often struggle with issues such as low efficiency, delayed deliveries,

and fraudulent certifications. These pain points can hinder the manufacturing process and jeopardize client relationships. As a reliable

supplier in the field, REGO addresses these challenges head-on by prioritizing quality control, certifications, logistics, and payment methods.

Conclusion: A Symphony of Innovation

In the grand debate of CNC Machining vs. Traditional Machining, it's not about one technique being superior to the other. Rather, it's

about understanding their strengths and weaknesses and harnessing them to create a symphony of innovation. CNC machining delivers

precision and consistency, while traditional methods offer adaptability and craftsmanship. The wise manufacturer knows when to let each

technique take the lead and when to blend them harmoniously to achieve the perfect result.

So, whether you're crafting components for a space shuttle or bringing your personal project to life, remember that both CNC and traditional

machining have their place in shaping the world we live in. The journey of manufacturing is an ever-evolving one, and by embracing the

best of both worlds, we ensure that innovation and creativity continue to thrive.

0 notes

Text

0 notes

Text

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

1. Resistance to dissolution.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Motors For Negative Pressure Air Fan suppliers

Motors For Negative Pressure Air Fan suppliers Our History 1972: State owned Wenling Micromotor Factory Co., Ltd. 2008: Wenling Nosch Motor Co., Ltd. 2018: Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. 2019: Establish Shandong Branch 2020: Establish Foreign Trade Department Our Factory Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. is a high-tech enterprise focusing on motor R&D, manufacturing and sales. It is one of the core enterprises in the manufacturing sector of China's top 500 private enterprises under the Fangyuan Group. The company's main products include iron-shell single three-phase asynchronous motor series, aluminum-shell single three-phase asynchronous motor series, fan special motor series, frequency conversion motor series, permanent magnet DC motor series, etc. Mainly used in water pump power, fan power, machine equipment power, agricultural machinery power, new energy vehicle power, marine equipment power and other fields. The company is located at No. 2479, Haifeng Road, Taizhou Bay New District, Zhejiang (3 kilometers from the east exit of Jiaojiang Coastal Expressway, 10 kilometers from Taizhou Airport, and 20 kilometers from Taizhou High-speed Railway Station).Covering an area of 43 acres, it has a standardized workshop of 35,000 square meters, equipped with more than 50 sets of automatic CNC lathes, CNC grinders, CNC milling machines, machining centers, high-speed punching machines and other metal processing equipment, and equipped with advanced equipment such as automatic wire embedding lines, spraying lines, and automatic assembly lines. There are domestic leading wind tunnel laboratories, test centers, and motor type laboratories. The company has a technical management team with strong professional skills and excellent management capabilities. So far, it has obtained dozens of patent certificates (including 5 invention patents), participated in the formulation of 4 industry standards, and obtained 3C certification, CE Certification, ISO9001 management system certification, ISO45001 occupational health and safety management system certification, ISO14001 environmental management system certification, etc. It has also launched long-term technical cooperation with universities such as China Jiliang University and Zhejiang University of Technology to enhance core power in terms of innovation, stability, high efficiency, and energy saving. Our Product 鈼?IE3 Premium Motor 鈼?IE4 Super Premium Motor 鈼?Single Phase Motor 鈼?FRP Fan Motor 鈼?Negative Pressure Fan Motor 鈼?Cooling Fan Motor 鈼?Exhaust Fan Motor for Cowshed 鈼?Portable Cooler Motor 鈼?Vertical Pump Motor 鈼?Acid and Alkali Resistant Chemical Pump Motor 鈼?Washer Motor 鈼?Special Motor for Woodworking Product Application FRP Fan, Negative Pressure Fan, Cooling Fan, Exhaust Fan, Portable Cooler, Vertical Pump, Acid and Alkali Resistant Chemical Pump, Washer, Woodworking Our Certificate CE, Reach, RoHS, CCC (China Compulsory Certification), IPMS, China Energy Label Production Equipment Automatic wire embedding machine: 10 CNC lathe: 12 CNC grinder : 4 Dynamic balance machine: 4 CNC milling machine: 3 Plastic spraying line: 1 Production line: 9 Paint dipping machine: 2 Multi hole drilling machine: 2 Production Market Annual Output Value: US$20- US$50Million Domestic Market: 55% Eastern Europe: 10% Southeast Asia: 10% Middle East: 5% Africa: 5% South America: 3% Western Europe: 3% Other Areas: 9% Our Service The company takes the spirit of innovation as the guideline, takes high-quality products as the foundation, and takes full-staff entrepreneurship as the core driving force, strongly promotes R&D and innovation, accelerates the adjustment of product structure, optimizes technical processes, improves operational efficiency, and strengthens the spirit of chemical craftsmanship, and uses this as a driving force to build Outstanding enterprise, creating market opportunities, and striding forward to the vanguard of industry segmentation.Motors For Negative Pressure Air Fan suppliers website:http://www.sivomotor.com/

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

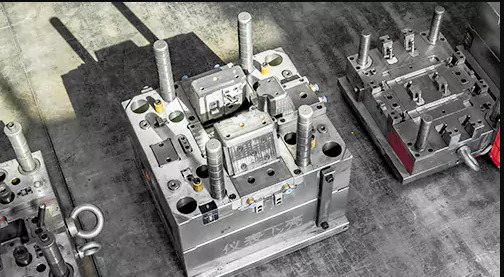

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Video

youtube

HIGH PLANSIFTER Is one of the main equipment in flour mill industry, utilized to classify intermediate products in accordance with their particle size at all milling stages and to separate out different flour types per quality required. www.immy.cn

WUXI HASEN IMPORT AND EXPORT CO.,LTD is a general solution service provider and project system integration service provider with grain and oil equipment technology research and development, engineering design, manufacturing, installation,training and commissioning, project contracting as business main structure.

Products including energy saving roller mill,high plansifter, purifier,wheat scourer,wheat peeler,wheat washer,branbrush,bran finish,maize embryo remmoval,degerminator,flow balance,micro feeder(weight in loss feeder,diffrential micro feeder),rotary sifter,vibro sifter,packing machine,double shaft paddle mixer,quantitative weighing scale, paper bag packing machine,impact detacher,hammer mill(water drop pulverizer).suction duct,aspiration separator,moisture controller,single(double)bin control(inspection)sifter,CNC grooving machine,fluting machine,auto stack robot machine,vibro discharger, bran outlet discharger,color sorter,LAB mill,scraper conveyorbucket elevator,air locker,cyclone pipe,PLC control system.dampener, flour dryer.flour refeeder,conveyor feeder.pre cleaning sifter,pulse dust collector,quantitative flow scale,heavy duty combined sifter XMTS,gate, gravity grading destoner(stone removal),rotary screen. ETC flour mill equipment&machine.

We are leading Integrated wheat maize flour mill engineering equipment manufacture EPC turnkey project services provider from 100 to 3000TPD in China,

Inquiry us if you need high standard Full Auto Flour Mill Line from 100-5000 tons per a day.

Hope to be your valued supplier for life time cooperation.

E mail: [email protected]

Whatsapp: 008613812016908

www.immy.cn

https://lnkd.in/gnYbSr_9

#flourmachine #flourmillmachine #grainmachine #flourmill #wheatflourmillmachine #maizeflourmachine #semolina #Addamaidamachine #nshimamachine #wheatwashingmachine #recycleaspiration #aspirationselector #rollermill #rollerbody #brandischarger #branfinisher #wheatscourer #wheatwasher #wheatcleaner #branbrush #colorsorter #flowbalance #vitaminfeeder #highplansifter #purifier #airlocker #pressurefan #flourconveyor #bucketelevator #steelsilo #degerminator #maizeembryo #destoner #dampener #aspirator #moisturecontroller #PLCsystem #EPCflourmillproject #turnkeyflourmillline #integratedflourmillline #largeflourmillline #dryerwheatflour #dryerwheatban #dryerwheatgerms #productioncapacity #wheatflourmillingmachines #processingplant #flourmillmachine #automaticflour #flourmillplant #millingmachine #flourmillmachine #wheatflourmillmachine #packingmachine #quantitativepacker #spoutpacker #wheatspoutpacker #maizeflourspoutpacker #wheatflourspoutpacker

0 notes

Text

China Machining Parts

Chinese CNC machining services supplier offers high precision CNC milling service and custom CNC machined parts cheaply in China.China machining service? Here today, we will share you top 10 cnc machining service provider from China who offer good machining service. I hope this information will be helpful to you!

https://www.sagemetalparts.com/blog/top-10-china-cnc-machining-service-provider/

0 notes