#epp recycling

Text

ed è stato un metodo promosso da INTCO RECYCLING-GREENMAX per oltre una decade

Il materiale compresso della schiuma, un sottoprodotto del riciclaggio della schiuma, può essere trasformato in un prodotto di valore attraverso la corretta tecnologia di trattamento e le giuste vie di mercato. Il riciclaggio della schiuma non solo consente di risparmiare risorse, ma porta anche a dei guadagni, ed è stato un metodo promosso da INTCO RECYCLING-GREENMAX per oltre una decade.

La compressione della schiuma è comunemente eseguita utilizzando apparecchiature specializzate note come macchine per la compressione della schiuma. Queste macchine si dividono principalmente in due tipi: le macchine a fusione termica e quelle a compressione a freddo.

Le prime utilizzano il calore per fondere il materiale della schiuma e comprimerlo in blocchi compatti, mentre le seconde applicano pressione senza riscaldamento per formare blocchi compressi di schiuma. Entrambi i tipi di macchine possono produrre blocchi compressi di schiuma che possono essere venduti come prodotti di valore.

0 notes

Text

Rozszerzona pianka polipropylenowa (EPP) to rodzaj pianki z tworzywa sztucznego, która jest stosowana w wielu różnych branżach ze względu na swoje unikalne właściwości. Powszechnie występuje w materiałach opakowaniowych, częściach samochodowych i sprzęcie sportowym. Pianka EPP jest preferowana ze względu na jej zdolność do pochłaniania energii uderzenia, dzięki czemu idealnie nadaje się do opakowań ochronnych i zastosowań związanych z bezpieczeństwem.

0 notes

Video

youtube

EPP Foam Melting Machine/EPP Melter/Polypropylene Foam Melting Machine/E...

#youtube#epp melting machine#epe melting machine#eps melting machine#eps recycling machine#styrofoam recycling machine#eps melter#eps densifier#styrofoam densifier

0 notes

Text

EPP Recycling Make Waste EPP Return the Market

Hyundai Motorsport Ltd uses expanded polypropylene foam to create side impact protection for race cars in the World Rally Championship (WRC) to provide optimal driver protection. Nowadays, many companies are pursuing sustainable development, and EPP recycling has also become a hot topic.

EPP recycling is to transform discarded EPP foam products into renewable resources, put them into the production of other plastic products, and return them to the market in another form. From a business perspective, EPP recycling is an investment project with high returns. Investing in foam recycling equipment to process EPP is far more cost-effective than spending money to landfill it.

Foam densifier can compress waste EPP foam into dense ingots, which can be sold to downstream recyclers for subsequent recycling and process. As a leader in plastic recycling, INTCO Recycling has not only developed an integrated EPP recycling system, but also developed GREENMAX Zeus Series foam densifier. This foam densifier is specially designed for EPP recycling, with high automation and easy operation.

0 notes

Text

To encourage resource reuse and environmental protection, recycle EPP and EPE foam using a foam compactor.

Although the extensive use of plastic products in today's society has greatly increased convenience, it has also resulted in significant environmental issues. Among these, common plastic foam materials that are utilized for product packaging, transportation, and protection are EPP (polypropylene foam) and EPE (polyethylene foam). But these foam materials are typically thrown away after being used as disposable packaging, which puts a tremendous strain on the environment. It has become especially crucial to use foam compactors for the recycling of EPP and EPE foam in order to overcome this issue.

An apparatus made especially to process and compress foam waste is called a foam compactor. It can reduce the volume of foam material and make it easier to transport and store by compressing huge amounts of foam material into high-density blocks. EPP and EPE foam waste can be efficiently collected, treated, and reused with the use of a foam compactor, which lowers resource consumption and lessens environmental impact.

Using mechanical extrusion, the Foam Compactor first compresses leftover EPP and EPE foam ingredients into solid blocks. Because no additional chemical additives are needed for this compression process, the recycled material is guaranteed to be pure and reusable. Specifically, the introduction of the GREENMAX foam compactor Zeus series has made it possible to recycle not just EPS but also EPE and EPP foam. Because the special hot-melt ring construction of the GREENMAX foam compactor guarantees tight compaction.

Recycling EPP and EPE foam with a foam compactor is a financially and environmentally responsible idea. It contributes to environmental protection by lowering plastic waste emissions. It also has a good impact on social peace and stability as well as sustained economic development.

0 notes

Text

Reusable EPP Food Boxes: Redefining Sustainability in Food Packaging

In today's society, where environmental consciousness is on the rise, the demand for sustainable solutions extends to every aspect of our lives, including food packaging. Enter Reusable Expanded Polypropylene (EPP) food boxes – a game-changer in the quest for eco-friendly packaging. Pairing this innovative material with PP + PET felt, a sustainable solution for modern design, offers a compelling combination of functionality, durability, and environmental responsibility.

Introducing Reusable EPP Food Boxes

Reusable EPP food boxes represent a significant departure from traditional single-use packaging materials. Crafted from Expanded Polypropylene (EPP), these containers offer exceptional durability and insulation properties, making them ideal for storing and transporting food items. Unlike disposable alternatives, EPP food boxes can be reused countless times, significantly reducing waste and environmental impact.

Sustainability at Its Core

At the heart of Reusable EPP food boxes lies a commitment to sustainability. By opting for a reusable solution, consumers can dramatically decrease their reliance on single-use plastics and other disposable materials. Furthermore, EPP is a fully recyclable material, ensuring that at the end of its lifecycle, it can be repurposed into new products, further minimizing waste generation.

The Role of PP + PET Felt in Modern Design

In tandem with Reusable EPP food boxes, PP + PET felt emerges as a sustainable solution for modern design. This composite material, comprised of recycled polypropylene and polyester fibers, offers a myriad of benefits, including durability, versatility, and eco-friendliness. By incorporating PP + PET felt into the design of food box exteriors or accessories, designers can enhance both the functionality and aesthetic appeal of reusable packaging solutions.

Advantages of Reusable EPP Food Boxes with PP + PET Felt

Durability: Reusable EPP food boxes are built to last, withstanding repeated use and rigorous handling. When paired with PP + PET felt, these containers gain an additional layer of protection, ensuring long-lasting performance and visual appeal.

Insulation: EPP's inherent thermal properties make it an excellent choice for food storage containers, maintaining the temperature of hot or cold items for extended periods. The addition of PP + PET felt further enhances insulation, preserving food freshness while reducing the need for single-use packaging materials.

Customization: With PP + PET felt, designers have the freedom to customize the appearance of Reusable EPP food boxes to suit specific branding or design preferences. Whether adding a splash of color or incorporating texture and pattern, PP + PET felt allows for endless design possibilities.

Conclusion

Reusable EPP food boxes, coupled with PP + PET felt, represent a sustainable solution that meets the evolving needs of consumers and designers alike. By prioritizing durability, functionality, and environmental responsibility, these innovative packaging solutions offer a viable alternative to disposable options, contributing to a greener, more sustainable future. As awareness of the environmental impact of single-use plastics continues to grow, Reusable EPP food boxes with PP + PET felt stand poised to revolutionize the way we package and consume food, one reusable container at a time.

#light weight insulation#pp + pet felt#non woven battery gaunlets#plastic extrusion profile#compressor felt

0 notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Text

Automotive Expanded Polypropylene (EPP) Foam Market Analysis Demand, Statistics, Top Manufacturers, Revenue by Reports and Insights 2030

The latest market report published by Credence Research, Inc. “Global Automotive Expanded Polypropylene (EPP) Foam Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global automotive expanded polypropylene (EPP) foam market has witnessed steady growth in recent years and is expected to continue growing at a CAGR of 6.80% between 2023 and 2030. The market was valued at USD 0.45 billion in 2022 and is expected to reach USD 0.71 billion in 2030.

The global automotive expanded polypropylene (EPP) foam market is driven by several factors, including the low cost, high mechanical qualities, and adaptability of EPP foam, making it a commonly utilized material in the automobile sector. The foam is known for its energy absorption, impact resistance, thermal insulation, chemical resistance, and recyclability. Its applications range from packaging and consumer goods to building and construction, making it a versatile material in various industries.

One of the key drivers of the market is the increasing demand for passenger safety and the need for noise, vibration, and harshness (NVH) reduction in automobiles. Expanded polypropylene foam is widely used in automotive components such as bumpers, door panels, and seats due to its lightweight design and enhanced functionality. The foam's ability to absorb energy and improve passenger safety is contributing to its growing adoption in the automotive industry.

Browse 170 pages report Global Automotive Expanded Polypropylene (EPP) Foam Market By Product Type (Synthetic Polypropylene , Bio-Based Polypropylene, Other Product Types)By Product Form (Fabricated EPP, Molded EPP) -Growth, Future Prospects & Competitive Analysis, 2016 – 2030)- https://www.credenceresearch.com/report/automotive-expanded-polypropylene-epp-foam-market

The Asia Pacific region leads the global market, accounting for over one-third of the market share in 2022. This growth can be attributed to the rapid industrialization, accessibility to raw resources, and availability of labor in countries like China, India, and Japan. North America and Europe collectively account for just under 50% of the market share in 2022, with Europe holding over 22% share in the same year.

The automotive industry has witnessed a surge in the demand for lightweight materials that offer exceptional strength and durability. This is where Automotive Expanded Polypropylene (EPP) Foam comes into play as one of the key market drivers. EPP foam, known for its remarkable energy absorption capabilities and excellent cushioning properties, has found extensive usage in various automotive applications such as bumpers, seating systems, instrument panels, door trims, and headrests. The growing emphasis on passenger safety combined with stringent regulations regarding vehicle crashworthiness have fueled the adoption of EPP foam in automobiles.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Automotive Expanded Polypropylene (EPP) Foam Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Automotive Expanded Polypropylene (EPP) Foam Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/automotive-expanded-polypropylene-epp-foam-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/u-bolt-clamps-market

Related Report: https://www.credenceresearch.com/report/automotive-testing-and-inspection-market

Browse Our Blog: https://www.linkedin.com/pulse/automotive-expanded-polypropylene-epp-foam-market-rising-singh

Browse Our Blog: https://tealfeed.com/automotive-expanded-polypropylene-epp-foam-market-doun3

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

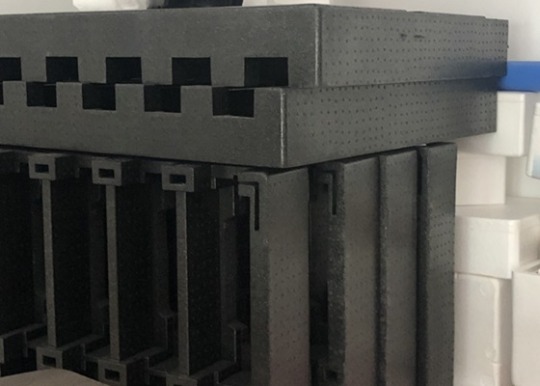

Photo

We used EPP (Expanded Polypropylene) when we designed these custom trays for a client in the automotive industry. EPP is a highly versatile closed-cell bead foam that provides a unique range of properties, including outstanding energy absorption, multiple impact resistance, thermal insulation, buoyancy, water and chemical resistance, exceptionally high strength to weight ratio and 100% recyclability. For more information about our foam packaging services call (480) 966-6889 or click the link below:https://foampackspec.com/foam-packaging/

0 notes

Text

Requisiti di spazio specifici sono richiesti poiché il processo di fusione termica può generare odori

Macchina di fusione termica per schiuma EPE:

Si consiglia l'uso dei dispositivi M-C100, M-C200, M-C300.

Riscalda i rifiuti di schiuma per farli fondere, quindi li spreme attraverso una vite senza fine, trasformandoli in un materiale fuso a schiuma con una densità più bassa. Richiede il caricamento manuale dei materiali, ma ha una velocità di scarico rapida. Requisiti di spazio specifici sono richiesti poiché il processo di fusione termica può generare odori, ma questo può essere risolto con l'uso di una pompa di aspirazione.

Macchina per la compressione a freddo/pressa idraulica per schiuma EPE:

Si consiglia l'uso dei dispositivi Z-C100, Z-C200, H-C300.

Si tratta di un processo di fusione superficiale che risolve il problema della dispersione dei materiali a causa della loro elasticità. Durante tutto il processo, viene riscaldata solo la superficie del materiale compresso, il che significa che la temperatura rimane bassa. Il processo di scarico può essere automatizzato e può essere aggiunta un'opzione di taglio automatico.

INTCO RECYCLING-GREENMAX ritiene che le attrezzature per il riciclaggio dei rifiuti di schiuma EPE siano fondamentali per affrontare l'inquinamento e lo spreco di risorse derivanti dalla schiuma EPE. Con la comprensione dei principi di funzionamento delle attrezzature, la selezione delle attrezzature appropriate e l'applicazione delle procedure operative corrette, insieme a una serie di altre misure, possiamo migliorare l'utilizzo delle risorse, proteggere l'ambiente e raggiungere gli obiettivi di sviluppo sostenibile.

#eps riciclaggio#compattatore per polistirolo#recupero di polistirolo#riciclaggio del pet#epp recycling

0 notes

Text

Jako producent zajmujący się recykling pianki polietylenowej i produkcją sprężarek pianek

Jako producent zajmujący się recykling pianki polietylenowej i produkcją sprężarek pianek, Intco Recycling zapewnia klientom na całym świecie wielokategoryjne rozwiązania w zakresie recyklingu odpadów piankowych. Oprócz typowych odpadów z pianki EPS, istnieją również odpady z bawełny perłowej EPE, EPP, pianki XPS itp. Dzisiaj omówimy z Państwem trudności i przyszłe trendy w recyklingu pianki z perłowej bawełny EPE, mając nadzieję, że pomożemy rozwiać Państwa wątpliwości.

1. Analiza trudności w recyklingu pianki EPE

Trudności w obróbce materiału: pianka z bawełny perłowej EPE jest trudna do recyklingu ze względu na jej lekką i porowatą charakterystykę. Zwłaszcza podczas obróbki kompresyjnej pianka EPE ma pewien stopień sprężystości, dlatego ma również wyższe wymagania dotyczące obróbki kompresyjnej.

Słabe kanały recyklingu: Kanały recyklingu pianki z bawełny perłowej EPE są stosunkowo ubogie, a wielu konsumentów nie wie, jak prawidłowo utylizować te materiały. Jednocześnie, ponieważ pianka zajmuje dużą przestrzeń i wiąże się z wysokimi kosztami transportu, ekonomika recyklingu staje pod znakiem zapytania.

Technologia ponownego wykorzystania niedojrzałych zasobów: chociaż pianka z bawełny perłowej EPE sama w sobie jest materiałem nadającym się do recyklingu, technologia skutecznego wykorzystania tych pianek pochodzących z recyklingu do ponownego przetwarzania i ponownego użycia nie jest wystarczająco dojrzała i wymaga większych inwestycji w badania i rozwój oraz innowacji technologicznych.

0 notes

Text

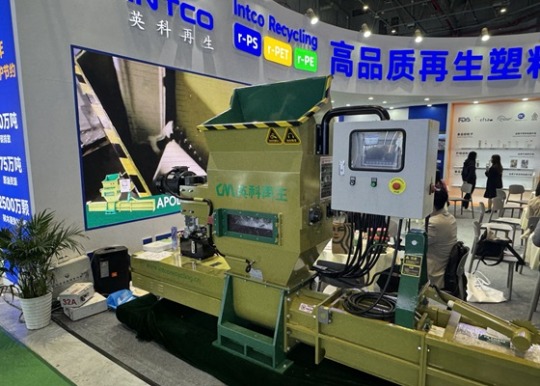

The 2024 Chinaplas International Rubber and Plastics Exhibition is underway!

INTCO Recycling displays the professional foam compactor A-C100, which is used to compress loose waste foam at the ratio of 50:1. This machine is mainly used to compact EPS, EPP, and PE foam, and can also handle foam with higher water content, such as fish boxes.

In addition, INTCO Recycling also provides sales solutions for compacted foam, and we offer buy-back services at favorable prices.

0 notes

Text

The public is well aware of the environmental preservation project that recycles EPP foam using an EPP compactor

Plastic pollution has emerged as one of the main issues affecting the environment worldwide in today's society. Expandable polypropylene (EPP) foam is a lightweight, high-strength, impact-resistant plastic material that finds extensive use in transportation, packaging, and other areas. But as more and more EPP foam products are used, wasted EPP foam is starting to rank among the major causes of pollution in the environment. The recycling of EPP foam using EPP briquetting machines has become a crucial environmental protection measure in the fight against this issue.

An apparatus designed specifically for recycling spent EPP foam is the EPP compactor. Waste EPP foam can be compacted into small blocks for easier transportation, storage, and reuse by using the GREENMAX EPP compactor. This apparatus has a compression ratio of 50:1. By using this compressed EPP material to make new plastic products, a closed-loop cycle of waste resource utilization can be achieved.

Utilizing an EPP compactor to recycle EPP foam has several benefits. It is important to note that using the GREENMAX EPP compactor is easy and doesn't require any specific training. Additionally, when used properly, this equipment can efficiently assure worker safety and is quite safe.

Apart from the aforementioned benefits, recycling EPP foam with an EPP compactor also lessens adverse environmental effects. Products made of EPP foam take up a lot of room in landfills, take a long time to break down, and waste land resources.

0 notes

Text

Revolutionizing Food Storage: The Rise of Reusable EPP Food Boxes

In a world where sustainability is increasingly becoming a priority, innovations in food storage are taking center stage. Enter reusable Expanded Polypropylene (EPP) food boxes – a game-changer in the quest for eco-friendly and practical solutions for storing and transporting food. In this blog, we explore the benefits of EPP food boxes and how Park Nonwoven is leading the charge in providing quality products in this space.

Embracing Sustainability with Reusable EPP Food Boxes

The shift towards sustainability has sparked a growing demand for alternatives to single-use plastic containers. Reusable EPP food boxes offer a viable solution by providing a durable and environmentally friendly option for storing and transporting food. Made from Expanded Polypropylene, a lightweight yet robust material known for its excellent insulation properties, these food boxes offer several advantages:

Durability: EPP is highly durable and resistant to damage, making it ideal for reusable food containers that need to withstand frequent use and handling. Unlike single-use plastic containers that degrade over time, EPP food boxes can last for years with proper care.

Insulation: EPP has excellent insulation properties, which help to maintain the temperature of hot or cold foods for extended periods. This makes EPP food boxes suitable for storing a wide range of items, from hot soups to chilled salads, without compromising freshness.

Lightweight: Despite its durability, EPP is remarkably lightweight, making it easy to carry and transport food without added bulk or weight. This makes EPP food boxes ideal for on-the-go lifestyles, whether for picnics, outdoor events, or everyday meal prep.

Reusable and Recyclable: One of the key benefits of EPP food boxes is their reusability. By opting for reusable containers instead of single-use plastics, consumers can significantly reduce their environmental impact and contribute to waste reduction efforts. Additionally, EPP is recyclable at the end of its life, further minimizing its environmental footprint.

Park Nonwoven: Setting the Standard for Quality EPP Food Boxes

When it comes to quality and reliability, Park Nonwoven is a name you can trust. As a leading manufacturer of EPP food boxes, Park Nonwoven is committed to delivering products that meet the highest standards of performance and sustainability.

Here's why Park Nonwoven stands out in the industry:

Advanced Manufacturing Processes: Park Nonwoven utilizes state-of-the-art manufacturing processes to produce EPP food boxes of exceptional quality. From material selection to molding techniques, every aspect of the production process is optimized for durability and performance.

Stringent Quality Control: Park Nonwoven maintains rigorous quality control measures to ensure that every EPP food box meets or exceeds industry standards. From initial design to final inspection, each product undergoes thorough testing to ensure its reliability and durability.

Customization Options: Recognizing that every customer has unique needs, Park Nonwoven offers customization options for EPP food boxes. Whether it's size, shape, or color, Park Nonwoven works closely with customers to develop tailored solutions that meet their specific requirements.

Sustainability Commitment: Park Nonwoven is dedicated to sustainability and environmental responsibility. By prioritizing eco-friendly materials and production processes, the company strives to minimize its carbon footprint and promote a more sustainable future.

Conclusion

Reusable EPP food boxes offer a sustainable and practical solution for storing and transporting food in today's eco-conscious world. With their durability, insulation properties, and environmental benefits, EPP food boxes are poised to revolutionize the way we think about food storage.

When it comes to quality and reliability, Park Nonwoven leads the pack with its commitment to excellence and sustainability. By choosing Park Nonwoven EPP food boxes, consumers can enjoy peace of mind knowing that they are investing in a product that delivers both performance and sustainability.

#pp + pet felt#plastic extrusion profile#non woven battery gaunlets#pet acoustic panel#breather fabric#lint free wipes

0 notes