#ferro alloys producer in india

Text

Sarda Metals: Forging Excellence in the Indian Metal Industry

In the vast landscape of the Indian metal manufacturing industry, Sarda Metals stands as a stalwart, shaping the future of metal production with a blend of innovation, quality, and sustainability.

Introduction

India's prowess in metal manufacturing has been on a steady rise, and companies like Sarda Metals have played a pivotal role in this growth story. Established with a vision to redefine the standards of excellence in metal production, Sarda Metals has emerged as a distinguished player in the industry. The company's commitment to quality and innovation has solidified its position as a leading metal manufacturer in India. With a focus on technological advancements and sustainability, Sarda Metals continues to shape the landscape of the Indian metal manufacturing sector.

Sarda Metals: A Pioneer Metal Manufacturer In India

Company Background and History

Sarda Metals, with its roots deeply embedded in the Indian industrial landscape, boasts a rich history of contributing to the nation's economic growth. The company's journey is a testament to its resilience, adaptability, and commitment to excellence.

Core Values and Mission Statement

At the core of Sarda Metals' success are its unwavering values and a mission to be at the forefront of technological advancements in metal manufacturing. The company's commitment to integrity, customer satisfaction, and ethical practices sets it apart in a competitive market.

Product Portfolio

Sarda Metals takes pride in its diverse product portfolio, offering a comprehensive range of metal products catering to various industries. Specializing in the production of iron and steel products, the company ensures that each product meets the highest standards of quality and reliability.

Quality Assurance and Standards

The cornerstone of Sarda Metals' success lies in its uncompromising commitment to quality. The company adheres to stringent national and international standards, implementing robust quality assurance processes at every stage of production.

State-of-the-Art Manufacturing Facilities

Central to Sarda Metals' ability to deliver top-notch products is its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology and driven by a passion for innovation, these facilities enable the company to stay ahead in a dynamic market.

Sustainability Initiatives

In an era where environmental consciousness is paramount, Sarda Metals, as a leading metal manufacturer in India, takes proactive steps to minimize its ecological footprint. The company is dedicated to integrating sustainable practices into its manufacturing processes, ensuring a harmonious balance between industrial growth and environmental preservation. By prioritizing sustainability, Sarda Metals not only contributes to the well-being of the planet but also sets a noteworthy example for the broader Indian metal manufacturing industry.

Market Presence and Global Reach

Conclusion

In conclusion, Sarda Metals stands as a beacon of excellence in the Indian metal manufacturing industry. With a robust product portfolio, a commitment to quality, and a forward-looking approach, the company has not only weathered industry challenges but has also set new benchmarks for others to follow.

Frequently Asked Questions (FAQs)

Q: What makes Sarda Metals a leader in the metal manufacturing industry?

A: Sarda Metals' leadership stems from its unwavering commitment to quality, innovation, and sustainability.

Q: How does the company contribute to environmental sustainability?

A: Sarda Metals incorporates eco-friendly practices in its manufacturing processes to minimize its environmental impact.

Q: Can customers request customized metal products from Sarda Metals?

A: Yes, Sarda Metals prioritizes customer satisfaction and offers customization options for clients.

Q: What recognition has Sarda Metals received in the industry?

A: The company has received several awards for its contributions to the metal manufacturing sector.

Q: What are Sarda Metals' future plans and expansion strategies?

A: Sarda Metals has ambitious plans for the future, including expansion and diversification initiatives.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#ferro alloys producer in india#silico manganese#metals manufacturer in india#sarda metals and alloys ltd#ferro alloys suppliers in india#metal suppliers in india#sardametals#sarda#ferro manganese

1 note

·

View note

Text

Ferro Titanium Suppliers in India: Elevating Industries with High-Quality Alloys

In the realm of metallurgy and industrial manufacturing, Ferro Titanium has established itself as a crucial element for producing high-quality alloys. As one of the leading Ferro Titanium manufacturer in India, the country plays a significant role in meeting the global demand for this remarkable alloy. In this comprehensive article, we will delve into the importance of Ferro Titanium, the role of manufacturers in India, and how this alloy enhances various industries.

Introduction to Ferro Titanium

Ferro Titanium is an alloy composed of iron and titanium, with titanium content ranging from 20% to 75% depending on the grade. It is produced through the aluminothermic reduction of titanium tetrachloride or titanium dioxide using scrap iron or steel. This unique alloy possesses exceptional strength-to-weight ratio, corrosion resistance, and high melting point, making it highly desirable for numerous industrial applications.

The Versatility of Ferro Titanium in Industry

The remarkable properties of Ferro Titanium make it an invaluable addition to various industrial sectors. Its combination of high strength and lightweight characteristics make it an ideal choice for aerospace and aviation industries, where it is used in aircraft components and engine parts. Additionally, its resistance to corrosion makes it suitable for marine applications, such as shipbuilding and offshore structures.

The Role of Ferro Titanium in Steelmaking

In the steel manufacturing process, Ferro Titanium plays a crucial role as a deoxidizer and grain refiner. By removing unwanted oxygen and nitrogen from the molten steel, it enhances the material's quality and reduces brittleness. Furthermore, Ferro Titanium refines the grain structure of steel, improving its mechanical properties and ensuring its suitability for critical applications.

Ferro Titanium Suppliers in India: Meeting Global Demand

India has emerged as a major player in the global Ferro Titanium market. With a robust manufacturing infrastructure and access to abundant raw materials, the country's suppliers are capable of meeting the increasing demand from various industries. These suppliers adhere to stringent quality standards to ensure the delivery of high-quality Ferro Titanium to their customers worldwide.

Advantages of Choosing Indian Ferro Titanium Manufacturers

Opting for Ferro Titanium manufacturers in India offers several advantages to industries across the globe. Firstly, Indian suppliers provide a wide range of Ferro Titanium grades, allowing customers to select the most suitable alloy for their specific needs. Secondly, the competitive pricing offered by Indian manufacturers makes it an economically viable choice for businesses seeking high-quality Ferro Titanium.

Research and Development in Ferro Titanium Manufacturing

The Indian Ferro Titanium industry continues to invest in research and development to improve the quality and performance of their alloys. Ongoing efforts to refine manufacturing techniques, optimize alloy compositions, and explore new applications keep the industry at the forefront of technological advancements.

Future of Ferro Titanium

As industries continue to demand high-performance materials, the demand for Ferro Titanium is expected to grow steadily. With Indian suppliers leading the way in terms of quality and availability, they are poised to play a pivotal role in shaping the future of the Ferro Titanium market.

Conclusion

Ferro Titanium stands as a critical alloy that elevates industries with its exceptional properties. As one of the leading Ferro titanium producers in India, the country's suppliers play a vital role in meeting the global demand for this remarkable alloy. With its versatility, high-quality standards, and sustainable practices, the Indian Ferro Titanium industry is set to drive innovation and contribute significantly to various industrial sectors worldwide. Choosing Indian suppliers ensures access to top-notch Ferro Titanium, meeting the stringent requirements of modern industries and propelling progress in the metallurgical world.

For more details contact us –

Website: http://www.ferrotitanium.in/grades.html

Email: [email protected]

Phone: +91 9899738234

#ferro titanium manufacturer#ferro titanium#ferro alloys suppliers#ferro titanium producers#Ferro titanium manufacturer in India#Ferro titanium producers in India

0 notes

Text

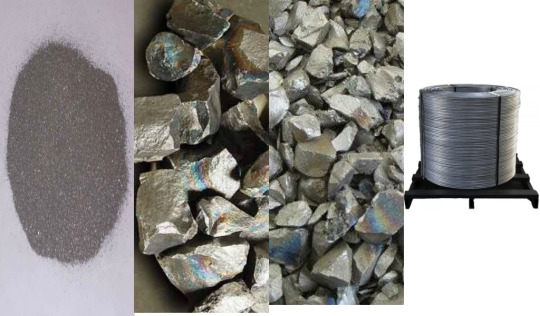

Ferro Titanium Manufacturer Powder {High Quality}

Where quality is the key, ferrotitanium is your partner. We are one of the leading manufacturers who specialize in manufacturing and marketing Ferro Titanium Powder. Ferrotitanium has been providing Ferro Titanium Powder for over 15+ years, and we are proud to say that our products are trusted by thousands of companies around the world! Official Website: http://www.ferrotitanium.in/

#Ferro Titanium Powder#Ferro Titanium#Ferro alloys suppliers#Ferro titanium alloys#Ferro Titanium Lumps 65%#Ferro Titanium Lumps#Ferro Titanium Lumps 70%#Ferro Titanium Cored Wire#Titanium Cored Wire#Ferro titanium manufacturer#Ferro Titanium Manufacturer India#Ferro Titanium Suppliers India#Ferro titanium manufacturers in India#Ferro titanium suppliers India#Ferro titanium manufacturer in India#Ferro titanium producers in India#Ferro titanium India#Ferro titanium producers#Ferro titanium scrap

0 notes

Text

Quality Control in Ferro Alloy Manufacturing

Quality control and assurance are like the guardians of excellence in the world of ferro alloy manufacturing. We want our alloys to be top-notch, meeting high standards and leaving our customers satisfied. This blog is all about understanding the importance of quality control and assurance in ferro alloy manufacturing and how they play a vital role in maintaining standards for customer satisfaction.

In the fast-paced world of manufacturing, quality control is the glue that holds everything together. It's like making sure all the pieces of a puzzle fit just right. From testing procedures at every step to following strict guidelines by Bulk Ferro Alloy Exporters in India and other countries, quality control ensures that every alloy they produce meets the mark. So, let's dive into the world of ferro alloy manufacturing and uncover the secrets behind maintaining excellence in quality control and assurance.

The Importance of Quality Control

Quality control ensures that every alloy produced by renowned manufacturers like Mortex meets the highest standards, ensuring customer satisfaction and industry credibility. Here's why it's crucial:

Customer Satisfaction: High-quality alloys delight customers, fostering loyalty and repeat business.

Industry Reputation: Consistently delivering top-notch alloys enhances the company's reputation and builds trust among stakeholders.

Safety: Rigorous quality control measures guarantee that the alloys are safe for use, prioritizing the well-being of customers and workers alike.

Processes and Techniques

Maintaining quality involves implementing robust processes and techniques throughout the manufacturing cycle:

Testing: Alloys undergo thorough testing at various stages to ensure they meet specified standards and performance criteria.

Adherence to Standards: Strict adherence to industry standards and regulations ensures consistency and reliability in the quality of alloys produced.

Continuous Improvement: Embracing a culture of continuous improvement enables the refinement of processes and the adoption of innovative techniques to enhance quality and efficiency.

Ensuring Customer Satisfaction and Feedback

Customer satisfaction is at the core of quality control and assurance efforts:

Listening to Customers: Actively listening to customer feedback helps identify areas for improvement and ensures that their needs are met.

Addressing Issues Promptly: Any issues or concerns raised by customers are addressed promptly and effectively to maintain their trust and satisfaction.

Building Long-Term Relationships: Consistently delivering high-quality alloys builds trust and fosters long-term relationships with customers, positioning the company as a reliable partner in their success.

Quality control and assurance are fundamental aspects of ferro alloy manufacturing. Organizations like ferro manganese or Ferro Chrome Manufacturers in India and abroad diligently monitor processes to deliver alloys of unparalleled quality. By maintaining high standards and prioritizing customer satisfaction, they not only uphold our reputation but also contribute to the growth and success of the industry as a whole.

Maintaining quality standards is not just about meeting industry benchmarks – it's about fostering trust, building relationships, and ultimately, ensuring customer satisfaction. By upholding the integrity of products and listening to the needs of customers, exporters pave the way for continued growth, innovation, and excellence in the world of ferro alloy manufacturing.

0 notes

Text

Unveiling the Powerhouses: Ferro Alloy Manufacturers in India

Ferro alloys play a vital role in the metallurgical industry, serving as essential additives in the production of steel and other alloys. These alloys, comprising iron and one or more other elements such as manganese, silicon, chromium, or nickel, impart specific properties to the final product, enhancing its strength, durability, and corrosion resistance. With India's burgeoning steel and alloy manufacturing sector, the demand for high-quality ferro alloys has surged, leading to the emergence of several prominent manufacturers in the country. In this article, we delve into the landscape of ferro alloy manufacturing in India and shed light on the key players driving the industry forward.

Rising Demand in the Steel Sector

India's steel industry is one of the fastest-growing in the world, fueled by infrastructural development, urbanization, and the booming construction sector. Ferro alloys are indispensable in steelmaking, as they facilitate the removal of impurities and enhance the properties of steel, making it suitable for various applications. The growing demand for steel, both domestically and internationally, has spurred the need for high-quality ferro alloys, propelling the expansion of manufacturing facilities across the country.

Technological Advancements and Innovation

Manufacturers of ferro alloys in India are leveraging advanced technologies and innovative processes to enhance production efficiency and product quality. State-of-the-art smelting furnaces, modern beneficiation techniques, and stringent quality control measures are being implemented to ensure the consistency and purity of ferro alloys. Furthermore, continuous research and development efforts are focused on developing new alloy compositions and optimizing production processes to meet the evolving requirements of end-users in industries such as automotive, construction, and infrastructure.

Diverse Product Portfolio

Ferro alloy manufacturers in India offer a diverse range of products tailored to meet the specific requirements of different industries. From ferro manganese and ferro silicon to ferro chrome and ferro vanadium, the product portfolio encompasses a wide spectrum of alloys catering to various steelmaking and alloying applications. These manufacturers have the flexibility to produce standard grades as well as customized alloys based on customer specifications, thereby ensuring compatibility with specific manufacturing processes and end-product requirements.

Commitment to Sustainability

In alignment with global sustainability initiatives, ferro alloy manufacturers in India are increasingly adopting eco-friendly practices and sustainable production processes. Efforts are being made to minimize environmental impact by optimizing energy consumption, reducing emissions, and implementing waste recycling and management systems. Additionally, manufacturers are investing in technologies that enable the utilization of renewable energy sources and the reduction of carbon footprint throughout the production lifecycle. By embracing sustainable practices, ferro alloy manufacturers are not only fulfilling their corporate social responsibility but also contributing to the overall sustainability goals of the metallurgical industry.

Global Reach and Market Competitiveness

Indian manufacturers of ferro alloys are not only catering to the domestic market but also expanding their footprint in the global arena. With a focus on quality, reliability, and competitive pricing, these manufacturers are exporting their products to various countries across the globe. Strategic alliances, partnerships, and collaborations with international players are further enhancing market penetration and facilitating technology transfer and knowledge exchange. Moreover, compliance with international quality standards and certifications is bolstering the reputation of Indian ferro alloys in the global marketplace, positioning them as preferred suppliers for discerning customers worldwide.

Conclusion

In conclusion, the manufacturers of ferro alloys in India are playing a pivotal role in driving the growth and competitiveness of the metallurgical industry. With a strong focus on technological innovation, product diversification, sustainability, and global expansion, these manufacturers are poised to capitalize on the burgeoning demand for ferro alloys both domestically and internationally. As India continues its journey towards becoming a global manufacturing hub, the ferro alloy sector is set to remain a key contributor to the country's industrial development and economic prosperity.

0 notes

Text

Shyam Metalics: The Foundation of Future

A leading integrated metal producing company based in India with a focus on Long Steel Products and Ferro Alloys; We operate three manufacturing plants, one in Odisha and two in West Bengal. To know more visit here: https://www.seltigertmt.com/

0 notes

Text

Petonic Infotech is leading EcoMins Mineral Waste Management in Madhya Pradesh

EcoMins, a dynamic force in the mining industry, has taken the lead in revolutionizing manganese ore extraction and refining in Madhya Pradesh. In collaboration with SR FERRO ALLOYS, the largest manganese producer in Madhya Pradesh and one of the top-five producers in India, Ecomins’ dedicated efforts are currently focused on the Kajali Dungari mines in the Jhabua district, showcasing a commitment to innovation, efficiency, and sustainability.

EcoMins contains the capacity of 300 Metric Tons of Manganese ORE’s beneficiation per day, the collaboration positions it as a driving force in the Mineral Waste Management. EcoMins with unwavering dedication to research and development, results in the creation of state-of-the-art processes that significantly enhance efficiency, reduce costs, and elevate sustainability in Mineral Waste Management.

“At EcoMins, our vision is to revolutionize the mining industry by introducing cutting-edge technologies. The Kajali Dungari mines project is a showcase of our commitment to sustainable mining practices, minimizing environmental impact, and ensuring the long-term viability of our operations. We are poised to become a driving force for positive change in the manganese ore mining sector, contributing to a more sustainable and prosperous future. EcoMins aspires to become the preferred and most trusted supplier of manganese ore in the industry,” said Mr. Sawariya Saraf, Director, EcoMins.

With a specific emphasis on the beneficiation of manganese ore, EcoMins is pioneering approaches that go beyond conventional methods, promising a transformative era for the mining industries. The company’s commitment to pushing the boundaries of what’s achievable in manganese mining is driving a paradigm shift in the sector.

“Our collaboration with EcoMins is not just about being the largest producer; it is about leading the industry in innovation and sustainability. We are amazed and proud to be a partner with EcoMins, as their dedication to harnessing the untapped potential of manganese ore, coupled with their commitment to cutting-edge technologies and pioneering approaches, is going to bring a positive change in the industry,” expressed Dr. Sudhir Sharma, Director at SR FERRO ALLOYS.

As the industry undergoes this transformative phase, EcoMins stands at the forefront, promising a future where innovation, efficiency, and sustainability are seamlessly integrated into the fabric of mining operations.

READ FULL ARTICLE HERE:-

https://indiaeducationdiary.in/ecomins-leads-mineral-waste-management-revolution-in-madhya-pradesh/

#PetonicGlobal #BusinessConsulting #RiskandCompliance #TechnologyConsulting #LegalConsulting #FinancialServices #ITConsulting #HealthcareConsulting #RiskAdvisory #ManagementandStrategyConsulting #SupplyChain #AuditFirm #RealEstateAdvisory #MarketingConsulting #BusinessAdvisory #DigitalConsulting #CyberSecurity #GovernanceRiskandControlsAdvisory #InsuranceConsulting #AssetManagement

1 note

·

View note

Text

Ferro Manganese Manufacturers in India

Ferro manganese alloys are a type of alloy composed of iron (Fe) and manganese (Mn). They are primarily used in steel production as an additive or alloying element to enhance the properties of steel.

Ferro manganese alloys are produced by combining iron and manganese in a smelting process. Typically, high-grade manganese ores and iron ores are mixed together along with coke or coal as a reducing agent. The mixture is then heated in a blast furnace or an electric arc furnace at high temperatures, usually above 1,200 degrees Celsius (2,200 degrees Fahrenheit). The reduction process takes place, resulting in the formation of molten ferro manganese alloy.

The composition of ferro manganese alloys can vary, but they generally contain a significant amount of manganese, typically ranging from 30% to 80%. The manganese content determines the properties of the alloy, including its strength, hardness, and resistance to corrosion.

Ferro manganese alloys have several important functions in steel production. They act as a deoxidizer, removing oxygen and other impurities from the molten steel. This helps improve the quality and cleanliness of the steel. Additionally, ferro manganese alloys increase the hardenability and tensile strength of steel, making it more suitable for various applications, such as construction, automotive manufacturing, and machinery production.

Furthermore, ferro manganese alloys can improve the steel's resistance to abrasion, wear, and impact, making it suitable for applications that require high durability, such as railway tracks, mining equipment, and industrial machinery parts.

Visit : Ferro Manganese Manufacturers in India to knowmore !

1 note

·

View note

Text

Ferro alloy powder manufacturer in india - Jayesh Group

Jayesh Group is a leading ferro alloy powder manufacturer in India, producing a wide range of ferro alloys including ferro silicon, ferro manganese, and ferro chrome. With a state-of-the-art manufacturing facility and a team of experienced professionals, they provide high-quality products to meet the needs of diverse industries. Their commitment to innovation, quality, and customer satisfaction has made them a trusted supplier for clients across the globe. Visit their website to learn more about their products and services.

0 notes

Text

Exploring the Legacy of Sarda Metals: India's Premier Metal Manufacturer in India

Introduction

In the heart of India's industrial landscape, Sarda Metals and Alloys Ltd. (SMAL) stands as a beacon of sustainability and innovation. As a leading metal manufacturer in India, their commitment to becoming the largest and most preferred manganese alloy producer is coupled with a dedication to minimizing their carbon footprint. This article delves into Sarda's ethos, their core values, and their relentless pursuit of a sustainable future.

Core Values: Quality, Technology, and Sustainability

At the nucleus of Sarda's strategy lies an unwavering commitment to quality, technology, and sustainability. Since its inception, Sarda has aimed to build a Ferro manganese business that not only meets global standards but surpasses them. This commitment extends beyond production, seeping into their practices in Environment, health, and safety. Sarda is resolute in its pursuit of being a company with the least carbon footprint and a record of zero incidents and accidents.

Innovative Solutions

With a rich history spanning decades, Sarda Metals has left an indelible mark on India's metallurgical industry. Their innovative solutions have positioned them as a trusted Ferro Alloys producer. Sarda's ability to adapt and evolve with changing times has allowed them to maintain a robust reputation in the market.

Specialization in Manganese Ferro Alloys

Sarda Metals takes pride in being India's leader in manganese ferro alloys. Their specialization lies in the production of high-quality Silico Manganese, tailored to diverse industrial needs. The company operates with a passion for excellence and a commitment to synergizing energy.

Sustainability Goals

Striving for sustainability through technology and innovation is the driving force behind all Sarda's endeavors. The ambition to become the largest and most preferred manganese alloy producer in India is coupled with a conscious effort to reduce their carbon footprint continually. Sarda Metals embraces change, challenging the status quo daily in their quest to become a better version of themselves.

Community Impact

Sarda Metals understands the importance of community development. Actively involved in creating a positive impact on the socio-economic fabric, they extend their commitment to sustainability to the communities around them. With a vision for a carbon-neutral footprint, Sarda Metals is not just a business; it's a force for positive change.

Conclusion

In conclusion, Sarda Metals and Alloys Ltd. exemplify how a company can marry industrial success with environmental responsibility. As a leading metal manufacturer in India, their journey towards sustainability is not just a corporate goal but a commitment to future generations. Sarda's emphasis on quality, technology, and sustainability positions them as leaders in the industry, setting a benchmark for others to follow.

FAQs

What makes Sarda Metals and Alloys Ltd. a leading metal manufacturer in India?

Sarda's commitment to quality, technology, and sustainability makes them a leader in the metallurgical industry in India.

How does Sarda Metals contribute to community development?

Actively involved in community initiatives, Sarda Metals strives to create a positive impact on the socio-economic fabric.

What is Sarda Metals' primary focus in its sustainability goals?

Sarda aims to become the largest and most preferred manganese alloy producer in India with the least carbon footprint.

#metals manufacturer in india#silico manganese#ferro alloys producer in india#sardametals#ferro alloys suppliers in india#metal suppliers in india#ferro manganese#sarda metals and alloys ltd

1 note

·

View note

Text

Leading Ferro Titanium Manufacturer in India - Ferrotitanium

Discover high-quality ferro titanium products manufactured by the leading producer in India - Ferrotitanium.in. With a commitment to excellence and reliability, we offer a range of ferro titanium alloys that meet the stringent requirements of various industries.

Ferro Titanium Manufacturer in India: Setting Industry Standards

As a prominent ferro titanium manufacturer in India, Ferrotitanium.in is dedicated to setting industry standards through innovation and superior quality. Our state-of-the-art manufacturing facilities and stringent quality control measures ensure that our products meet the highest standards of purity and performance.

Ferro Titanium Producers in India: Trusted by Industries Worldwide

With years of experience and expertise, Ferrotitanium.in has earned the trust of industries worldwide as one of the leading ferro titanium producers in India. Our commitment to customer satisfaction and consistent product quality has made us the preferred choice for businesses seeking reliable ferro titanium suppliers.

Ferro Titanium India: Unmatched Quality and Performance

Experience unmatched quality and performance with Ferrotitanium.in's range of ferro titanium products. Whether you require ferro titanium for steelmaking, foundry applications, or any other industrial use, our alloys are engineered to deliver exceptional performance and reliability in every application.

Ferrotitanium.in: Your Partner in Success

At Ferrotitanium.in, we understand the importance of reliable supply and consistent quality for your business success. With our comprehensive range of ferro titanium products and unwavering commitment to customer satisfaction, we strive to be your trusted partner in achieving your goals. Explore our website today to learn more about our products and services.

Conclusion: Trust Ferrotitanium.in for Premium Ferro Titanium Products

When it comes to ferro titanium, trust the expertise and reliability of Ferrotitanium.in. As a leading manufacturer and producer in India, we are committed to delivering premium-quality products that meet the diverse needs of industries worldwide. Partner with us and experience the difference in quality and service that sets us apart from the rest. Visit www.ferrotitanium.in now to discover our range of ferro titanium alloys and solutions.

#ferro titanium#ferro titanium manufacturer#ferro titanium producers#ferrotitanium#ferro alloys suppliers

0 notes

Text

Ferro Titanium Manufacturer | Titanium Powder for Sale Buy Ferrotitanium

Ferro Titanium Powder Buy Ferrotitanium.in online is the best and safe way to get Ferro Titanium powder is a new generation of titanium material which can improve the performance of many industrial applications. Ferro Titanium Powder is a white, odourless and tasteless powder which can be easily mixed with other materials. For more information, please visit our website: http://www.ferrotitanium.in/

#Ferro Titanium powder#Ferro titanium manufacturer#Ferro Titanium Manufacturer India#Ferro Titanium Suppliers India#Ferro titanium suppliers India#Ferro titanium manufacturer in India#Ferro titanium producers in India#Ferro titanium India#Ferro titanium producers#Ferro titanium scrap#Ferro Titanium#Ferro alloys suppliers#Ferro Titanium Lumps 65%#Ferro Titanium Lumps#Ferro Titanium Lumps 70%#Ferro Titanium Cored Wire#Titanium Cored Wire

0 notes

Text

Innovations in Ferro Alloy Production to Drive Sustainability

Ferro alloys play a vital role in various industries, providing essential properties such as strength, heat resistance, and corrosion resistance. However, traditional methods of ferro alloy production often come with environmental and sustainability challenges. As a result, the industry is undergoing a shift towards more sustainable production practices.

One of the key innovations in ferro alloy production is the adoption of greener technologies and processes. Advancements in technology are enabling Bulk Ferro Alloy Exporters in India and abroad to transition towards cleaner and more sustainable alternatives. For example, the use of electric arc furnaces powered by renewable energy sources can significantly reduce carbon footprint.

Sustainable Practices with Green Technologies

The pursuit of sustainability has spurred the development of green technologies in ferro alloy production. These innovations focus on reducing energy consumption, minimizing emissions, and optimizing resource utilization throughout the production process. The advancements include:

Adoption of energy-efficient furnaces and reactors that utilize advanced heating and cooling systems to reduce energy wastage and improve process efficiency.

Integration of renewable energy sources, such as solar and wind power, into production facilities further reduces carbon footprint and reliance on fossil fuels.

Advancements in process optimization and waste management techniques enable manufacturers to minimize waste generation and maximize resource recovery, contributing to a more sustainable and environmentally friendly ferro alloy industry.

Digitalization and Automation for Efficiency

Digitalization and automation technologies are revolutionizing ferro alloy production, driving improvements in efficiency, quality, and safety. The integration of sensors, data analytics, and artificial intelligence (AI) into production processes enables real-time monitoring and control, optimizing process parameters and reducing variability.

Predictive maintenance algorithms predict equipment failures before they occur, minimizing downtime and maximizing uptime. Furthermore, automated material handling systems and robotics streamline material flow and logistics, reducing manual labor requirements and improving overall productivity.

By harnessing the power of digitalization and automation, manufacturers can achieve higher levels of efficiency and performance while reducing operational costs and environmental impact.

Alloy Design and Product Development to Meet Market Demands

Innovations in alloy design and product development are shaping the future of ferro alloy production, enabling manufacturers to meet the evolving demands of end-users and industries. Advanced alloy formulations and refining techniques allow for the customization of ferro alloys with specific chemical compositions and properties tailored to meet the requirements of various applications.

Additionally, advancements in alloy processing technologies, such as powder metallurgy and additive manufacturing, offer new possibilities for producing complex shapes and components with enhanced performance characteristics. By continually innovating in alloy design and product development, manufacturers can stay ahead of market trends and deliver solutions that meet the needs of their customers.

Innovations in ferro alloy production are driving significant advancements in sustainability and performance, paving the way for a more efficient, environmentally friendly, and economically viable industry. Ferro alloy companies such as Ferro Manganese Manufacturers in India and abroad are adopting green technology to produce ferro alloys in bulk quantities while keeping a check on sustainability.

From green technologies and digitalization to alloy design and product development, these innovations are revolutionizing the way ferro alloys are manufactured, enabling manufacturers to meet the demands of a rapidly evolving market while minimizing their environmental footprint and maximizing their competitiveness. As the industry continues to embrace innovation, the future of ferro alloy production looks brighter than ever.

0 notes

Text

Ferro Silicon Magnesium Alloy Manufacturers & Exporter India

Ferrosiliconmagnesium alloy is used to produce all types of ductile iron castings. It is added to molten iron for producing a structure containing graphite in Nodularisers or spheroidal form.

Almost all steel and iron plants employ this Ferro silicon magnesium alloy as an oxidizer element for iron and steel. The combined properties of Silicon and Magnesium increase the strength, ductility, rigidity, and high resistance of the steel.

Manganese and iron are the main components of Ferro manganese. It is utilized in steel products where low levels of silicon content must be controlled and have a high manganese concentration. It is primarily employed in the production of flat steel, steel with a high manganese content, and stainless steel products.

We are the manufacturers, exporters, and distributors of Ferro silicon magnesium alloy, Magnesium 6-8, Nodularisers, Ductile Iron, and all type of Ferro silicon magnesium products.

If you have any queries then contact us :

☎️ : +91 7610125164 | 📧 : [email protected]

🌐 : https://www.ferrosiliconmagnesium.com/products.php

#ferrosIliconmagnesium#ferrosiliconmagnesiumcoredwire#ferrosiliconmagnesiummanufacturersinindia#nodularisers#ductileiron#magnesium6-8#ductileirontreatment#FeSimgcoredwires#FeSiMG8-10#FeSiMg6-8#desulphurisationofiron#magnesiumcoredwire#magnesiumcoredwirefeeder#SGirontreatment#highnodularity

0 notes

Text

Ferro Silicon Magnesium (FeSiMg): Leading Manufacturers in India

In the dynamic landscape of metal alloy production, Ferro Silicon Magnesium (FeSiMg) has emerged as a crucial component with diverse applications. India, a key player in the global metallurgical industry, boasts prominent manufacturers specializing in FeSiMg alloys. This article delves into the significance of these alloys, exploring the offerings of leading manufacturers and their contributions to the industry.

Ferrosilicon Magnesium (FeSiMg): It is an important alloy in metallurgy.FeSiMg is a spheroidizing agent widely used in the production of spherical ductile iron castings. Magnesium silicate is known for its ability to improve the sphericity and mechanical strength of steel and is used in many industries such as automotive, construction and engineering.Ferrosilicon Magnesium (FeSiMg): It is an important alloy in metallurgy.

FeSiMg is a spheroidizing agent widely used in the production of spherical ductile iron castings. Magnesium silicate is known for its ability to improve the sphericity and mechanical strength of steel and is used in many industries such as automotive, construction and engineering.

Leading Ferro Silicon Magnesium manufacturers in India

Quality Standards with FeSiMG 8-10:

FeSiMG is India's leading company, specialized in FeSiMG alloy as well as FeSiMG 8-10 variant. This metal contains 8-10% magnesium and is known for its quality and consistency. It plays an important role in making the magnetic material with the best material.

Precision in Alloy Composition with FeSiMg 6-8:

Another notable product from these manufacturers is the FeSiMg 6-8 alloy. With a magnesium content ranging from 6-8%, this alloy offers precision in composition, catering to specific requirements in metallurgical processes. Its application contributes to the production of cast iron with improved nodularity and thermal stability.

Industry Impact and Applications

The influence of these manufacturers extends beyond national borders, with their FeSiMg alloys making a significant impact on the global metallurgical landscape. Industries reliant on high-quality ductile iron, such as automotive manufacturing, benefit from the consistent and reliable performance of these alloys.

Commitment to Quality and Innovation

The manufacturers highlighted here prioritize quality control and innovation in their production processes. Rigorous testing procedures ensure that their FeSiMg alloys meet international standards, guaranteeing optimal performance in various metallurgical applications.

Conclusion: Nurturing Growth in Metallurgy

In the realm of Ferro Silicon Magnesium production, Indian manufacturers stand out for their commitment to quality and innovation. The FeSiMG 8-10 and FeSiMg 6-8 alloys produced by these manufacturers play a crucial role in enhancing the properties of ductile iron, contributing to the growth and advancement of metallurgical processes globally.

As the demand for exciting products continues, the role of companies specializing in ferrosilicon becomes important. Their commitment to precision, consistency and innovation make them significant contributors to the ever-evolving field of metallurgy.

Discover the products of Indian silicon-metal magnesium producers and witness the evolution of metal-silicon magnesium alloys in global use in metallurgy.

For more details visit us- www.ferrosiliconmagnesium.com

0 notes