#fiber gas cylinder

Text

अब राशन कार्ड धारकों की बल्ले बल्ले, इन लोगों को LPG Gas Cylinder मिलेगा बिल्कुल Free, यहां जाने कैसे मिलेगा

अब राशन कार्ड धारकों की बल्ले बल्ले, इन लोगों को LPG Gas Cylinder मिलेगा बिल्कुल Free, यहां जाने कैसे मिलेगा

LPG Gas Cylinder : देशभर में बढ़ती महंगाई के बीच आम जनता के लिए अच्छी खबर है। अब आपको एक साल में तीन गैस सिलेंडर मुफ्त मिल सकता है। दरअसल उत्तराखंड सरकार गरीबों की हर संभव मदद करने की कोशिश कर रही है। पहले सरकार द्वारा लोगों को मुफ्त राशन दिया गया, अब राशन कार्ड धारकों को मुफ्त गैस सिलेंडर दिया जा रहा है।

LPG Gas Cylinder

देशभर में बढ़ती महंगाई के बीच आम जनता के लिए अच्छी खबर है। अब आपको एक साल…

View On WordPress

#atm जैसा मिलेगा राशन कार्ड#cylinder#cylinder blast#cylinder price#cylinders#fiber gas cylinder#fiberglass cylinder#free gas cylinder#free lpg gas cylinder#gas cylinder#gas cylinder 2022#gas cylinder offer#gas cylinder price#gas cylinder price today#gas cylinder subsidy#gas cylinders#hp gas cylinder#lpg cylinder#lpg cylinder price#lpg cylinder price hike#lpg cylinder price today#lpg gas cylinder#lpg gas cylinder price#lpg gas cylinder price hike#अपात्र राशन कार्ड धारक#आधार कार्ड से राशन कैसे#न्यू रुल राशन कार्ड#बिहार राशन कार्ड लिस्ट#यूपी सरकार राशन कार्ड#रद्द हो जाएगा राशन कार्ड

0 notes

Text

#composite cylinders#composite lpg cylinder#composite lpg cylinder manufacturers#composite lpg gas cylinder#lpg composite cylinder#composite gas cylinders#composite cylinder manufacturers#plastic cylinder#composite cylinder#composite cylinders india#plastic gas cylinder#fiber cylinder#lpg cylinder manufacturer#lpg cylinders manufacturers

0 notes

Photo

TVR T440R (1 of 1)

A true homologation special, this TVR T440R is the only one of its kind ever produced. Made to homologate an endurance race car in 2003, the car was only recently recommissioned and is up for sale.The story of the TVR T440R starts with the T400R (aka the Typhon) race cars that were built to compete in endurance racing at Spa, Sebring, in British GT, and, of course, Le Mans. In order to obtain FIA homologation, TVR had to build four road cars.The British company chose to build three Typhons and this, the T440R. The Typhons were initially supposed to feature a supercharged 4.0-liter straight-six but were instead finished with a naturally aspirated 4.0-liter engine.

The T440R, meanwhile, was fitted with a naturally aspirated, 4.2-liter straight-six that incorporated a gas-flowed cylinder head, a steel crankshaft and conrods, as well as a carbon fiber airbox with six upper injectors and bespoke exhaust headers. For road use, the engine makes 440 hp (446 PS/328 kW), down from the supercharged race car’s 585 hp (593 PS/436 kW).

The underfloor is flat for better aerodynamics and is made of resin-sandwiched aluminum honeycomb. A separate carbon-fiber tub is bonded to the chassis and the carbon fiber bodywork is bonded to the tub and the floor.

Thanks to its power and lightweight construction, the car will hit 62 mph (100 km/h) in just four seconds and can go all the way up to 200 mph (320 km/h). Quite impressive numbers for 2003, and still more than respectable today.

Inside, the T440R has four seats and plenty of exposed carbon fiber, as well as Willans racing harnesses. The seats are trimmed in red and black leather and the Alcantara headliner is a surprisingly modern touch.

76 notes

·

View notes

Text

Marius's Mechanism, and speculation on its bioengineering

so, the elephant in the room. who built Marius's mechanism? how, exactly, does it keep him alive, if it isn't by Dr. Carmilla's masterwork?

today, i seek not to answer those questions. instead, easier ones! such as "what type of microelectrodes are used for somatosensory" and "where does osseointegration begin, and would there be wireless myoelectric leads?"

should this have probably waited until TDOBVR was released, so i could obtain potential new and updated details on the workings of Marius's brachial mechanism? no! 'cause i am not nearly that patient! anyway, 7.5k words and 3 distinct Sections under the cut!

(and for those of you who don't have the time to read 7.5k, there's a TLDR at the very very end!)

CW's for: avid descriptions of surgical procedures, medical injuries, generally invasive and fleshy experiments.

Sections-

How does it doggone move? an introduction to our dilemma - creating an external power source - alternative compliance designs in the fingers

How does it flippin' feel? peripheral nerve electrodes - reproducing bidirectional feedback - the epic highs and lows of highschool osseointegration

Why the shit does it do that? vestigial features - SKIN - closing statments and TLDR

but! before making like intrepid heros and striding into the treacherous heath of biomedical and neuroprosthetic jargon, it'd do well to get a refresher on what little lore there is to know Marius's mechanism so far, as like scavengers upon a tragedy, each scrap is sure to have its use. the checklist isn't long, but i'm enamoured with every bit of it-

Alongside Raphaella, (and potentially Tim), it wasn't created or implanted by Doc C. src: tumblr

Whereas the mechs normally 1) heal on command or instantly, 2) don't get hurt at all, or 3) may ignore a wound at leisure, Marius only "regenerates [his kneecaps] when he dies" src: Kofi's twitter

The casing of his fingers are occasionally "organic". src: Kofi's twitter (i still adore the insistence that the mechs aren't human. makes it lovingly impossible to humanize them!)

The surgical procedure, or perhaps the interface styling, that anchored Marius to his mechanism was "botched". src: Kofi's blog post about TDOBVR

Marius "always approached the concept of immortality with a little bit more skepticism than the rest of [The Mechanisms]". src: DTTM :(

way hey, look! i've got links this time!

so, How does it doggone move?! in this case, the TDOBVR post can half-help with that! (and count your lucky stars about it, too). directly quoted-

"Byron [Marius] is from a world that has devolved through an endless war of attrition. Once highly advanced, technology has regressed to circa 18th century fare..."

meaning, since we don't know where or who he got the arm from, its composition is either really advanced, or hilariously crude. but it would seem- or, i thought- if this is the same arm that's going to keep him alive for eons upon eons through supernatural powers, it's likely to be the same sort of technology which constitues those big mechas.

then, you know, i was all ready to explain to you lot about shape memory polymers, and heat wire electrodes, and the many plus sides of artifical muscle fibers, including but not limited to tolerance strain, industrial-like strength, and being the one of the most lightweight options when it comes to mass-producible robotics...

...and then i realized- i'm going too easy on him! what are the chances that Marius is receiving the "leading innovation"? nope! more likely, he's getting acquainted with pneumatic concepts from 1910's Germany that flunked! haHA!

oh, i mean that by the way. here it is-

[ID: A black and white conceptual schematic of a compressed gas-powered hand from 1919, showing a thumb-side and top-down sketch. Top down, there are four parallel cylinders in the palm, but complex gear systems only in the index and thumb. An airline, captioned "Luffzufuhr", comes up from the wrist. Thumb-side, the gear systems are clearer, as is a fifth cylinder for the thumb. /end ID]

this diagram, and that single annotation of "luffzufuhr", translating from German to "air supply", is literally all i can find about it. thankfully, there's at least one other research paper who has attempted to revive this general concept, which makes things much easier for me! both by way of not having to figure it out all by myself, and not having to choose between 300 different styles of motor systems. yippie!

to lay some basic groundwork- actuators, in the application of motorized prosthetics, operate as the replacement for muscles, providing power and resistance for an everyday range of motion- linear, rotary, oscillatory. accordingly, when looking at which actuation systems garner the most praise for prosthetic limbs, one of the first things you'll see is how sleek and precise they are, since jankiness is usually the biggest giveaway that a technology won't be human compatible.

and it's an important factor, but only half of the problem. or, well, the paradigm. it's one that's formed by no fault of our own, and bested even the most funded, functional, state-of-the-art arms. that is, dexterity vs. durability, where the more components a prosthetic requires, the more fragile it becomes. the tougher its materials are, the less agility is afforded.

generally, people who want a "tool" are going to go for the stronger one, because if a prosthetic can't hold up to the stress and strain of the human condition, then its practicality is kind of worth jack and shit.

the pneumatic arm zeros in on this shortcoming of strength, since its simplistic components- a piston pushing against a spring within a hollow cylinder, bolstered by air- need only an increase in PSI to be faster, and are stronger against torque and backlash, giving it that advantage over electric motors.

they also don't draw current when retracting, since the spring elements naturally return to position, but their ability to pull all that power means they won't get shocked under a sudden or demanding influx. though, these plus sides are often achieved at the same cost of a heavy weight and excessive size, usually in response to supplying an appropriate power source. vapor is a bit harder to shuttle along than an electrical current, you know?

but unlike their electric counterparts, the fuel being a detached compromise makes this much more resolveable. and so, we're off on our merry way to make Marius far more steampunk than i initially planned! wahoo!

one of the factors necessitating a bulk-up is getting a servo-like control of the air valves, or servovalves, to fine tune motion and pressure more deliberately. it seems hard pressed to happen on a smaller scale at all, let alone while still packing a bigger punch than electric.

funnily, the way the paper phrases these drawbacks tends to raise the problem in the same paragraph that they solve it. "ah, unfortunately, there are so small-scale high peformace servovalves... fortunately, our team invented small-scale high performance servovalves." summarized, it's a rotary, four-way motor for the gas, compacted to roughly the size of a AA battery. now That's efficiency!

they seemed pretty proud of that, and i do think that Marius's arm would make use of something akin to those, though for us, the REAL focus is the fuel!

like i said, in terms of energy sourcing, gas cartridges have largely been regarded as a poor means. in those pioneer attempts of the early to mid 1900's, the CO2 they used was a limited resource, due to expense, and the quantity demands for a full day's power. add in the heavy bulk of steel canisters, and we don't have a very pretty picture for mobility.

but this obstacle is taken care of pretty smoothly, too, by switching to a liquid monopropellant as a gas generator. in this case, it's 70 percent hydrogen peroxide, which has a hissy fit when it has to buddy up with a catalyst, and spits out more energy than the liquid-to-gas phase change of liquid CO2. the catalyst, by the way, is iridium, typically known for its durability as a metal, but its decomposition under acid is used in the- get this- the Space Industry for propulsion.

yeah, that's right! Marius's arm is a low-grade ROCKET!

because of this drastic improvement, the tank for the hydrogen can stay at about 1 / 5th the size of what the CO2 would be, while manifesting the same power, keeping it nicely in a lightweight and anthropomorphic form. (said power, according to the paper, is comparable to skeletal muscle!)

then, with a setup of 200ml monopropellant cartridge, fuel lines, and a pack of catalyst pellets as the power behind the actuator's piston movement, and the servovalves as modulators to the incoming vapor flow, a choroid of surprisingly aesthetic stainless steel tubes is what carries that oxygen gas to the pneumatic cylinders. (Not a different thing than the actuators, as i learned the hard way).

they're also taking great care to assure us how NOT flammable the propellant is, despite being, you know, rocket-grade hydrogen peroxide. i'm sure this has no implications for Mr. Raum whatsoever!

the downsides to this way of powering his arm aren't many, but in the shadow of their silent, stable, battery-powered bretherin, the nitpicks include-

- exhaust products (ooh, dieselpunk...)

- audible exhaust noise (ooh, steampunk...)

- some unpredictable internal heat (ooh, hot...topic?)

and all of these, conveniently, could compile their inconveniences to explain away the arm cuff criss-cross laces by translating them in-universe as vent slats for exhaust outlets!

on that note, i genuinely enjoy postulating on what shortcomings the mech's -anisms could have. like, jonny's heart (~steel) weighs six pounds, nastya's blood is too dense and likely causes spPOTS (space POTS), ashes's lungs might be prone to clotting (damaged endothelial response), ivy's brain is. uh. well she already can't remember dog from shit of her past. brian's joints (metal-bound) could be fucky! oh, to be a new fan theorizing on all their faults again...!

ahem, anyway. when i was still considering artificial muscles for the articulation of Marius's extremeties, particlarly what those 4 bolts on the back of the costume's hand might signify, i first imagined linear actuators tugging a false tendon strung through his digits. this, as well, turned out to be the same "fully compliant" friction design of the gas-actuator prosthetic, just with electronic back-hand linears switched out for pneumatics in the wrist.

a.k.a, he'd have Marionette Fingies. and, truth be told, it's hard to find a hand that obeys these specifications i'm getting from two different directions- follow the pneumatics, but give Marius an arm that can at least maneuver a violin bow- without coming across strange trade-offs like "we're working on making the fingers move independently" or "if you lean on this arm it'll snap-crackle-pop fucking die"

but! this is where 2009 concepts that die ignoble deaths under the technological onslaught that was the 2010's come quite in handy! (get it?) under the work of the RoMeLa team at Virginia Tech, they led the innovation of a robotic hand roughly following the same principles of "air pressure controls grip", committing to a simplicity of lower pressure = lighter grip, and higher pressure = a tighter, "firm grip that could rip out a human's windpipe."

(editor's note: while the CNET author may be biased on that front, it is, indeed, applicable to the physical demands of Marius's job.)

but this time, in order to coordinate flexion and extension of the fingers, the compressed air fills up corrugated tube actuators (built like miniature accordions) spanning the length of the digit. however, it's pertinent to comment that the gas-actuated arm explicitly does not use compressed air, and i've decided the same holds true for whatever version of this build Marius would use. the four bolts, then, are likely some cylinders or servovalves to regulate the gas expenditure.

it's purportedly "strong" under this lack of linear actuators or motors to strain, and dextrous at the exclusion of "tendon" strings or gears, as is common for most prosthetic hands on the market. feedback sensors for grip and proprioreception work in tandem with the extent of pressure, which is already much more than the highly underactuated hand of the original monopropellant arm, and further awards a gentleness fit to handle raw eggs and lightbulbs.

hmm... with one catch. unlike the self-awarded praise of our essay's predecessor, this portion might be a bit weighty for Marius? its original creation saught to eventually appendage the hand to a separate ongoing robotics project of theirs, but the team deemed it "too heavy", and so it was subsided (cough, discarded, cough) into a separate project.

yet, this isn't exactly a downside, 'cause remember! Marius's tenuous grasp on reality (as per the TDOBVR blog post) doesn't come from nowhere! eons-long pain from an inordinately heavy prosthetic would drive anyone up the wall, i think! although, they theorized that a hardier material, such as carbon fiber, could do more favours toward ease of replacement and overall weight. not that we're too worried about that ;>

in general, by the way, i think the casing (cosmetic hard shell that covers all these inner components) of Marius's arm IS carbon fiber. most real-world casings are plastic, or aluminum, and it gets into a tricker area once you start trying to replicate skin. but for now, that material figures to be a pretty easy mention, since it's well known for being Strong As Steel But Lighter, the molding process is variable and easy, and comparably more forgiving to deformation from everyday wear.

anyway, i like the RoMeLa's hand especially because, on the sparse but official page for the hand, it even advertises a potential application in "Hazardous environment operation" and "Entertainment", which if i'm not mistaken, is Marius's middle name (hyphenated.)

oh, and guess what the protoype's acronym is! too late, i'm telling you- it's the "Robotic Air Powered Hand with Elastic Ligaments," or RAPHaEL. ah? ah, get it? like la Cogni- [i am dragged off-screen like a dead extra]

here's the beaut in action, too! what a charmer. i think Marius would love her. i may or may not be projecting.

it was very very interesting to touch on something that hasn't really been feasibly explored before, because in the event of making it work, we find ourselves in a beautiful gray area of "how!" and "why?", which i think is perfect for the technological stance of Marius's- sorry, Byron's era.

i'll do you the favour of linking the IEEE video that shows the gas-actuated fucker actually in motion too, because the beginning positively oozes 2008 "The Future Is Here" vibes

also, a quick credit to that crop of Ruth's art below the fingers tweet, whose depiction of Marius's arm with steel piping very much helped solidify the idea of throwing all that advanced technology into the garbage disposal!

but, How does it flippin' feel? first off, it feels weird to use flippin' instead of a swear, hold on- fuck! fuck! there we are. balance restored.

actually, let's take a closer look at that "botched" line.

"One of the first things I decided when creating Marius is that the effects of his (probably botched) mechanisation and his advancing years have left him with a somewhat tenuous grasp on reality..."

that doesn't give us much detail, does it? commendably so, seeing as it's a spoiler-free rundown, but that dissonance between whether it was the surgical manner or the internal mechanics that render "botched" an apt descriptor kind of worried me. i mean, how would i narrow down which configuartion worked best for him, when even the lore doesn't have his best interests at heart?

and, you know what? the question kind of answered itself! what we're capable of in the real world, right now, is genuinely pretty cool, but remains unusually limited.

i think our best example of this is the microelectrode array! the way we're using them, microelectrodes, in short, (get it?), are a rather direct interface with the peripheral nervous system on the cellular level, communicating bidirectionally (translating and sending) sensory, motor, and electrical signals with the axons they're implanted in or around.

there's different types, whose physical attributes determine their strengths and weakness per application. the one that we're looking at today is an "intraneural", meaning its needles physically pierce the nerve sheath.

did i say pierce? i meant stabs it clean through the middle.

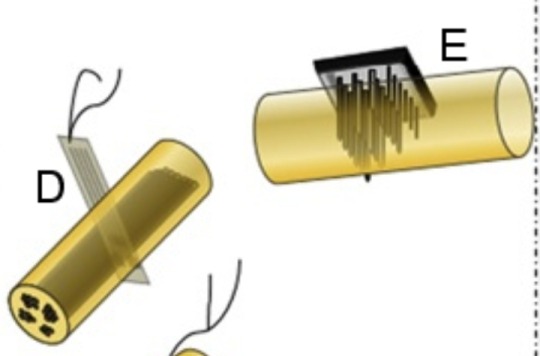

[ID: A zoomed-in screenshot on a simplistic diagram of two intraneural electrode styles. The nerves are cylindrical, yellow, and transparent. To the left, labelled "D", a flat gray electrode cuts the nerve perpendicular. To the right, labelled "E", something akin so a slanted bed of nails is embedded up to the square base. /end ID.]

(the one to the left is our guy, transverse intrafascicular multichannel electrode! the cutie right beside him is the USEA, Utah Slanted Electrode Array, which i personally headcanon Nastya as having. talk about metal!)

i'd make a running joke where we call this microelectrode TRANS, but unfortunately, pride month is over, therefore its actual acronym is TIME. you're free to imagine that i've made an awesome pun on "bidirectional", however.

the more broadly discerning that these electrodes are, the more invasive their design is- for example, bed-of-nails USEA has some 100 channels, while a C-FINE (imagine a tiny clasp, gently squeezing the nerve) may have only 8 or 16. while TIME doesn't fair much better with 10 electrodes, and its cross-section style implantation may look a tad horrific (which is exactly why i chose it), its wider spatial range of fascicles allows it to get more picky during recruitment.

it also seems to be pioneered specifically with prostheses interfacing in mind, where most TIME studies (as per a May 2018 report) have been to test its design of "selectively [activating] subsets of axons". or, sending signals from the sensors to very particular parts of the nerves- and that's perfect when our goal is to restore a sense of "touch".

the most complete long-term configuration between human and machine of indwelling electrodes sending two-way signals that i've been able to find is the 2019 in-person trial of the DEKA "LUKE" arm, which unlike their commercially available FDA-approved version, used chronically implanted USEA's to "evoke tactile perceptions on the phantom hand". and, thankfully, this is the production that most articles i've found latch onto like a lamprey.

sorry, that's misinfo. lampreys don't latch onto their prey. that's leeches!

basically, the way this can happen is by finding a method to taper and dilute those bursts of electrical signals coming into the nerve. for this team, the key in registering actual textures, pressure, joint tension, etcetera was by recording the neural responses from primate's fintertips when touched, and alongside some vaguely referenced "calculations", coding this into a procedural model for the arm.

and like i said, the LUKE system is actually bidirectional! ...as usual, with some caveats. my sources may be outdated, taking from early to mid 2010 experiment papers as i often am, but when papers say "bidirectional", they tend to mean "microelectrodes for sensation, sEMG for decoding motor command."

the "sEMG" being a superficial electrode, stuck on the skin to sense and interpret voluntary contraction on the muscles of the residual limb. y'know, the weird stickers? it's the most common, intuitive, and non-invasive way for prostheses users to "control it with their mind!!1!1!", but when the backlog of complaints ranges from socket pressure sores, sweating interference, superficial recording and loss of contact during limb repositioning, i'm not so sure that our mischevious violinist can affort that sort of setup.

but the DEKA model, at least the non-portable USEA prototype, solves this nicely. making dual-use of implantable EMGs to train a Kalmann filter on recognizing the muscular commands, the user mimics "pre-programmed movements", whose recorded values are whittled down to a select number of "features", or what i'm guessing is potential kinematic positions. i think, in laymans terms, that entails some Physical Therapy for Marius!

since when have i been here just to praise things, though, huh? ...okay, roughly the entire time, but i ain't no liar about downsides! 'cause, when referring to "touch", we're not yet at a vis-a-vis recreation of our somatosensory. more often than not, haptic interfaces are missing ways to convey accurate temperature and pain, if any.

even though i found at least a handful of articles saying that LUKE's USEA can "help sense pain and temperature" (sometimes in a copy-paste phrasing), after turning to the official NSF pdf, the only two claims they'd made on that front was, "the LUKE does not include pain and temperature sensors", and "any evoked pain or temperature sensations are uncommon". so, man, i just dunno who to believe!

but a bigger, and more perplexing issue to circumvent, is the electrodes themselves. technically, their placement is a chronic injury to our tissues, and while it might seem like the resultant scarring is ideal for securing its positon on the nerve trunk, the fibrosis can sometimes grow bad enough to insulate it and completely cut off the signals. or other times, completely push the electrode out of the nerve. (which is just our bodies reacting how they should to foreign objects. the same thing would happen if you got a splinter)

at minimum, you're looking at a good chance for nerve damage and signal disruption. and- awe, while researching for the downsides of microelectrodes, i've just stumbled across my first ever bookmarked science paper for that essay i did on Nastya's cybernetics <3 talk about ouroboric deeds! and talk about upgrades- that thing was from 2003, jeez!

ack, distractions! moreover, unless your electrodes are wireless, their channel leads will have to trail a considerable ways through the muscles, and won't be sitting pretty when forming scar tissue can pull them taut. then, if the system can't sustain itself solely indwelling, external hardware will need a way to get ahold of the nerve signals, so a percuntaneous incision will often bring the leads to outside connector pads, opening opportunities for infection and tissue decay.

why am i saying "yours"? you don't own incredibly expensive, defense agency-funded materials. right? at least, i don't. all my tupperware is already used up.

but what i Do have is some inconveniences for Marius, fabricated purely by a nature of my own design! yeah, that's right! I'M creating issues out of thin air!!

since i made the executive decision for Marius to operate under microelectrodes exclusively, and the DEKA system i mentioned used iEMG's for motor decoding, (a.k.a muscular action potential over electrical neuron firings) there's a significant likelyhood of crosstalk and interference between commands coming and going on that shared peripheral channel.

meaning, he might get some rogue signals that are twitchy, painful, or just plain uncooperative. not a complete ravage to his range as a violinist, but certainly some obstacles to overcome. (or angst about, do how you do.) told ya that i liked downsides, didn't i?

the peripheral nervous system, by the way, is just what translates sensory information to the brain. the somatic (somatosensory) is a more voluntary divison of it, and registers the stimulation of mechanoreceptors by pressure, temperature, proprioception, etcetera, for input when considering to the appropriate actions to take. when i say "peripheral", i basically mean both.

and, hey, so long as we're taking about fudging up phrases and bodies alike, how about a little admission time? because, see, here's the thing. roughly half of the robotics that i've talked about today aren't actually... wearable? frequently being "proof of concept"s created by distinctly non-amputee college teams, they would be controlled by an external computer, or someone wearing a "master exoskeleton" glove that mirrors the motions commands into the prototype.

that, or they can be removed at will, after the connecting pads for microeletrodes are merely detached. and at risk of squandering a potential hilarity, but for the sake of preserving the "ahhh irrevocable immortality!" faustian, i stringently don't believe that Marius can separate his whole mechanism from his flesh body. at most, his fingers, maybe his hand as well. (you'll see why later on ;> and that's a threat ;D)

so, let's get a rundown of osseointegration, or OI, which is probably the most Not Portable a prosthetic socket can get. for Marius, i've decided that his amputation is NOT up to the shoulder. instead, he is a transhumeral amputee, the same as every "bionic upper limb OI" subject i've seen news of, because the status of the residual limb is of course the deciding factor in candidacy for this type of surgery.

(that's why the gas-actuated arm is conveniently also transhumeral- they crafted it with eventual OI implementation in mind)

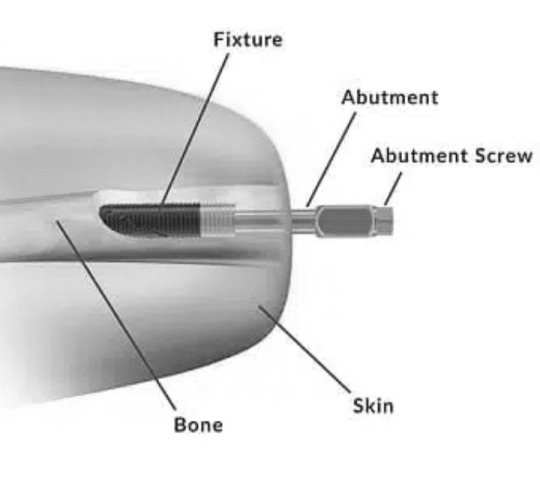

in summary, they (the Scientists) implant a metal rod fixture, typically titanium, into the remaining skeleton. an abutement section of it protrudes out of the skin in a stoma opening, where the prosthetic is attached as an extension. (Marius, i think, does not get that differential luxury. ergo, his "arm"'s titanium bone IS the fixture itself.) obviously, there's alternative types and methods, but this is what we're giving our dear Baron.

for a basic depiction of that setup, from the OPR A Implant System site, and edited so that tungle doesn't kill me dead-

[ID: A grayscale diagram of a rounded residual limb, transparent to show a sturdy bone. Within the bone is a dark threaded metallic rod, labelled "fixture". Outside of the limb, the continuing rod smoothens, now labelled "abutement," and the thicker, bolt-like end is "abutement screw". /end ID]

i run a risky game here, folks.

the humerus is one of the 5 bones eligible for osseointegration, which does not include the shoulder, and it's reportedly ideal for the socket troubles that would come to a residual limb that's "short, wide, scarred, or painful", promptly speedrunning the checklist for "botched".

to hit those point by point- well, in opposite order- for a limb with nerve pain, the necessary compression of a socket may be a deal breaker in everyday use. energy transfer (that is, the inertial strength when performing actions) from the muscles can be put more effectively, and without much misalignment, into the prosthetic.

there's markedly less fatigue than having to work for sEMG devices to proceed with movement via over contraction of unrelated muscles, and a robustness fit for physically demanding jobs, i.e. a truck driver, a builder, a murderer. then, a stable precision for finer tasks, i.e. brushing teeth, handling eggs, setting up security cameras outside the Penelope vault.

as an added bonus, linking the prosthetic directly with the bone reopens an avenue for natural sensation, "osseoperception", where the mechanical vibration from contact (touching or stepping) can be felt through the skeleton. apparently, we can even hear the frequencies?! in our ears?! then, since this eliminates the factor of a cup socket, a suspension rig, and ideally sEMGs, a microelectrode interface is nearly a given for this system to work.

(a lot of OI is paired with Targeted Muscle Reinnervation to control the prosthesis, though. i haven't looked too far into this method myself, but it seems more helpful for transhumeral or shoulder amputees without much of a residual limb.)

(because, while TMR surgically transfers the residual nerves to defunct muscles in a gambit to boost their own signal, then communes those re-assigned nerves to the prosthetic, the TIME would talk directly to whatever remains of the upper arm's somatic. it would definitely require lots more rehabilitation than peripheral interfacing.)

so, viola! overall, a pretty marvelous way of melding a prosthetic to the body, as well as giving Marius's environmental perception and navigation a solid 2x modifier, if he can handle the months-to-years long physical therapy and rehabilitation protocol!

ah, although, the point of a lot of these surgeries is to be rather clean? like, hiding the leads via intramedullary canals, using wireless myoelectrodes. personally, if Marius's arm popped away from his limb, i'd be imagining more wires and connectors and sensors running out of him than King Cole to his machines.

which, you know who else runs the risk of infection besides percutaneous leads? a stoma! which is exactly what this exposed implant is! especially when the infection rate is "well accepted" as 100 percent! ...okay, maybe that's a bit fearmongering. mostly, these infections are "superficial", only causing inflammation or drainage at the skin around the stoma from bacteria making it past the daily hygiene.

a skilled surgeon minimizing the amount of soft tissue that can shear, or crafting an epithelial seal around the abutement can lower this risk. but when it happens, it must be intervened with strong antibiotics, and fast, 'cause any infection close to underlying bone runs the risk of becoming a "deep infection". beyond that, the pain of just that "minor" infection can purportedly keep people bedridden.

alongside the whole predictable subset of issues that can arise when melding Human and Machine, i.e. bone deterioration (aseptic) or fracturing because of the implant, when loadbearing demands on the prosthetic are excessive- machine's fault- and the implant loosening or requiring explantation because of the bone, when natural remodeling fails to fill in the gaps between metal and residuum, or after osteomyelitis (septic) failure. simplisticly, human's fault.

accidents, high-impact events such as falls and sports, patient overuse, or improper rehabilitation (cough, cough, doubling over with my coughing) MARIUS (cough.) can cause both and all of those issues, exacerbated under the event that the components were already shitty. ...do i need to start coughing again, or are we in agreement?

despite their infrequency, managing infections and monitoring the integration's efficacy is a life-long maintenance. now, you've probably seen the catch here- how for Marius, and the mechanisms at large, as immortals whose whole shtick includes (as per a tumblr ask) never getting sick and shrugging off bullet wounds like burrs, he probably wouldn't be bothered by roughly any of this...

...but, during his initial implantation, with regards to the notion that Dr. Carmilla wasn't present? as well as for reasons that i'll touch later on...? suffice to say, hooo boy! eeks! yowzers! uh-oh!

but, hell, nothing says "botched" like pioneer procedures, am i right!

Why The Shit Does It Do That?

and kicking off the final section is my favourite subsegment, titled on the fly "What The Fuck Is That"! the fuck in question-

[ID: A zoomed-in screenshot of Marius's arm, showcasing a strange brass circle on the "upper" outer forearm, where two thin side-by-side wires, colored white and red, trail up and disappear into the laced corset arm cuff. /end ID]

in my initial brainstorming post, for those who saw it, you might recall that i mentioned the similarity of the white and red wires on the back of Marius's arm and MOSFET wires, whose electric nature implied a potential utilization of that weird brass thing on the back as a Solar Cell.

wellll, if you haven't already guessed, i changed my mind. no motors here, no sir! the wires, i'm afraid i can't explain, but with regards to the gas cartridges often being treated as a separate entity from the anthropomorphic prosthetic, from even the actuators that it powers, it could be an extraneous seal for when the arm is not connected to a canister source. so, not quite an insignificant residuum.

or, imagining Marius's arm as slightly more advanced, as a stopper cap to an internal basin that stores the hydrogen peroxide. by its appearance and function, not too dissimilar from a fuel cap in automotives :>

to quote myself from a reply i made in the comments of my interest check, i do believe that Marius's mechanism is Voidily, Outer-Godily powered in terms of immortality, so i think a benign generator like this would either be vestigial of its intended applications (a.k.a., Used By Normal People), or what makes it physically operate.

as for what electrically powers the servovalves and sensors... i dunno. brother, he can just die. (/ref)

operating under that paradigm, when the monopropellant has run out, it might be limp and nonresponsive, but far from dead. kind of like a limb out of socket! the arm falling inert might also harbinger a potential return of Phantom Limb pain! i'll actually link this one, since the normal article has since become paywalled, but in 2015, one Igor Spectic who took part in DARPA'S Haptix trials, described the phantom pain from his amputated hand as "a vice grip all around."

following the experiment's development of generating communicable sensation in a prosthetic hand, where the manually varied electrical signals from pressure sensors on the hand's surface were sent to C-FINE electrodes around his remaining ulnar, radial, and median nerve trunks, the pain was reported to have decreased immensely, if not entirely disappear!

this is good news for Marius, if his arm is active. and this is bad news for Marius, if his arm isn't active. ah, aporia my beloved!

okay, self-plagiarism over. onto the most lovingly terrible section! Skiiin!

for some prelude- remember those Artificial Muscles that i kind of left in the dust? the shape-memory polymers who could hold 5000 times their own weight without permanently deforming at all? well, honesty corner, one of the features i somewhat lament losing in tandem with that whole charade is... the lead professor, Zhenan Bao.

chemical engineering is her field of expertise, and her team also pioneered a thin plastic "skin-like sensor" that could distinguish between pressures and accordingly interface with a neuron cell! and i was gonna do a little callback, start a bioengineering cinematic universe, all that fun stuff.

but, taking a step back, it becomes apparent that Zhenan's approach is So novel, that it literally can't interface with Marius in any of the ways that i've described. or that's in any way natural. what they did, see, was translate the electrical pulses into light pulses, and had those sensed by line of CNS neurons that were optogentically modified. a.k.a., they're specifically bioengineered to be influenced or activated by light frequencies.

it worked, but, not quite what we're looking for, you know? and, considering how we've already devoted lots of space to integrating Marius with the TIME microelectrodes and RAPHaEL proprioception feedback, i think we can just skip right to the part where we make this thing out of living tissue. Kofi said Marius's fingers were occasionally "organic", remember?

on that note, time to overhaul one of my cornerstone ideas on Marius's arm for, oh, say, the third time? we're getting to "she's not the same Aurora" levels, at this point! (just be glad i didn't have to turn to the fleshy phone case for research, hm?)

you know, i've noticed that a lot of these articles are just playing synonym hopscotch with each other? they don't quite care to reveal more information than the last one, the last one- just rephrase it a bit, getting more and more scant on as it goes down.

well! time to enthusiastically propogate the issue!

the broader goal by this particular team, from the University of Tokyo, is to trounce the uncanney valley by cultivating a sense of familiarity with The Artificial, under a predilection that robots would eventually be an integral staple in caretaker jobs. thankfully, i care roughly zero percent about that, so let's dig into the sciencey bits.

colloquially deemed a "biohybrid robot", the product of the experiment is cool, but not nearly so outlandish. it's actually marvelously simple! in fact, i'll keep the outline i had for "questions to answer" as a guide for us, since this subsegment runs on a big longer than my others.

How can it cover the metal?

we've already got the "covering robotic fingers" bit down on lock from the getgo, because this skin was specificially made to grow around a finger-mimicking structure! (this time, electrically driven.) it only faces strain at those typical three joints, but seems to "stretch and contract" rather forgivingly when it does!

since it's a different cadence from "grafting" on lab grown skin-sheets, adhered to each other and wrapped snug on the surface by stiches, which runs the parallel risk of the living skin incurring injury in the surgical-esque procedure, this recreation would prove a bit more complex. and fleshier.

How is it grown, exactly?

using a solution of "commercially available human cells", of course! which sounds like it should be appendaged by a * on the black market. but, hey, i know this song! from the meat berry video! we've all been haunted by Meat Berry in our recommendations, right? ...right?

okay, look, it's not as creepy as it sounds. it's actually comprised of the similar sort of ingredients in implants and hydrogels for severe burns- collagen, in that case, but the culture media also had dermal fibroblasts, both of whom are two big players in the building of connective tissue.

so with the robotic scaffold bathing calmly in that mixture, the cells, as they grew over the course of 3 days, naturally compacted and conformed to the surface's contour, as is the tendancy of collagen's elasticity and fibroblasts's traction. the team then moved it to an ablution of epidermal cells, keratinocytes, and let it develop that sealing outer layer for two weeks.

the whole sleeve ended up at about 1.5 millimeters thick, similar to an average human dermis! the scentists also lauded it for its "natural wrinkles", so... a win for Marius?

by the way, culture media- as per the meat berry video- is a solution primed with the nutrients, antibiotics, and hormones for the specific type of cell it intends to grow. it's usually a pinkish benadryl color, not naturally, but colored that way, and its hue shifts with the health of its condition, indicating to the cultivators whether it's gone bad or not.

just imagine Marius going "Raph I want organic fingers for our next performance :(" and she says, "okay, but remove them from your arm. they'll have to soak in the Science Fluids for about two weeks... beforehand."

ah, get it? get it? beforeha- [i am killed, veritably]

Does it need bloodflow?

NOPE. It pointedly doesn't have a circulatory system or sweat glands- basically only collagen and a layer to un-gooify it, right now, and it dries up (dies) when left out of the solution too long. that also means no nerves, but, eh, Marius could probably just sliiide some sensors under that bad boy.

that was actually a big selling point of one of the previous iterations of "artificial skin" i delved into researching, before i noticed that it technically duped the criteria what Kofi had originally stated as "organic". but, most incriminatingly, the prototype wasn't even skin! just some circle little sensors that "could be" placed under cosmetic silicone.

his version of the culture would also need some melanocytes, since the prototype flesh doesn't have even a bit of melanin, making it look either like a pepto bismol finger, when in the culture, or a ballistic gel dummy outside of it.

How realistic is it?

"Water repellant, self-healing, and with a texture that looks and feels like ours," as every article will happily tell you, one in particular repeated themselves 3 different ways in the same paragraph! in short- thank you epidermal, thank you fibroblasts, thank you collagen.

it's not yet up to par, however. apparently the cells weren't very mature, so although it could tolerate being pinched and stretched by the robotic joints, it was rather weaker than human skin should be. but, the epidermal could at least be picked up by tweazers! which hurts like a motherfucker, if you've ever done it.

and when these articles say "heal" they mean placing a "collagen bandage" over the clean, surgical slice, and letting the cells assimilate it into the wound. not to undercut (get it?) the achievement, though, because importantly this means the cells are living- the skin is alive! how about THAT for organic, Kofi!

Finally, what melange of mean things have articles called this scientific beauty?

icky-looking, sweaty, gooey, stinky, "westworld", "terminator", creepy, revulsive, ersatz, "out of a horror movie", and that it "looks like a, um". (you get three guesses, and none of them count. that's also why i'm giving no links this time, friends! sorry!)

also, y'all? hey y'all? this news came out, as of the time writing this (July 12th), almost Exactly a month ago. this is right now! we're LIVING in it! the future is HERE! and that just goes to show, folks- procrastination DOES pay off! because i, like, kicked this idea around for months... and months...

any! way! arriving at last to our closing statements, it is my firm bias that we would both benefit from making only as many wrap-up claims as further questions they raise. do i honestly expect any of them to be answered in TDOBVR? not a lick of hope! will i propose them anyway? absolutely!

most of these quandaries, i will admit, are conjucture stemming from one jokeful tweet. but when you add upon the more canonical layers, i.e., his mechanism lacking Dr. Carmilla's certified seal of approval, himself harboring a strangely outlier mistrust in the likelihood of true immorality, and in general, hailing from a planet that has regressed badly enough to go back to muskets, it would not surprise me if these conundrums came to pass at one point or another.

and on that peroration of resounding confidence, here goes nothing!

TLDR:

Marius's mechanism is styled, in general concept, after illustrations within a German "limb substitution" book from 1919 that ideates an externally gas-powered hand prostheses. revitalized under our "modern" technology, it is fuelled by catalyzing monopropellant hydrogen peroxide with iridium pellets in an internal reservoir.

a steel tubing network and small scale servovalves shuttle along the gas, providing the pneumatic cylinders with ample power for linear actuation, while the vapor leaves as an exhaust product through a crosshatch grille spanning the length of his inner forearm.

Plus sides are- stronger than most electromechanical prostheses, steel is very quite aesthetic

Downsides are- lacks an offhanded dexerity, constant need for fuel

as our counterpoint, let's indulge on some fun curiosities about Marius's healing factor- canonically the "device's self-regulation", as per Drive The Cold Winter Away. incipiently, if his patellas don't regenerate until he "dies," must his brain be clinically dead before he can start to heal? or does he just not share that preternatural haste of repair, where the assumption would be that he often meets death's clammy grasp quicker than any healing may have its finishing touches?

Marius's pneumatic hand is materially influenced by Virginia Tech's robotic RAPHaEL prototype, though altering RoMeLa's design to preserve the fuelant approach in its coordination. rocket-powered air fills up corrugated tubing within each finger for an enticingly individualized articulation, and an oscillatory grip strength is commanded by lowering and raising the air pressure at hand. the cosmetic shell of his entire arm, including the hand, is made of carbon fiber.

Plus sides are- fine tuned manipulation of objects, a sense of independence

Downsides are- no steampunk gears, a bit too heavy

seeing to it that his regeneration fails to be as thorough as his companions, and a stabilized form doesn't come back until death, would he still be able to recover minimally over the intervening weeks and months, like a normal person? gaping wounds to fibrous scars, deep infections to chronic sicknesses, whose remnants only get cleared away when he's fully dead, like one big reset button?

Marius has transverse intrafascicular multichannel electrodes interfacing with his peripheral nervous system to stimulate sensory feedback on the ulnar, radial, and median nerve trunks of his residual limb.

Plus sides are- increased somatosensory and kinematic precision, seeming metal as hell

Downsides are- neural scarring, and long-term glitches from signal crosstalk

on that note, during those rare occasions he survives the crew's raucous lifestyle for a continuous length of time, will his immune system begin responding appropriately untoward the traumatic, invasive, foreign implantation that is, in essence, his mechanism?

are there infections to ensue, and inflammation, and eventual scarring whose nature is inclined to cut off both his sense of touch and motor skills? by proxy, making him uncharacteristically ill and in considerable pain? (this line of thought, patently, is why i kicked up such a fuss about "wuauggh, his scar tissue! infections! stoma! blargh!")

Marius underwent a major implantation surgery to osseointegrate a threaded titanium stem, screw-fixation type, into his transhumeral. most likely, he did not have the resources at hand to abide by the prolonged rehabilitation protocol. there are no intramedullary leads going solely through his abutement, and the exoskeleton of his arm is inseparable from the indwelling fixture.

Plus sides are- remarkable stability, and rejuvinated osseoperception

Downsides are- acute infection, innate incompatibilities between skeleton and metal.

with the established hypothetical that he doesn't return to a generic save-state in an automatic fashion, we have to wonder- does he age? how slow, if altered at all? more pressingly, can his mechanism get worn down alongside it?

especially when taking into account how, while several pros-and-cons lists have praised the pneumatic actuator's simplicity under an impression of less oversight, that's once again treating the baby separate from the bathwater. maintenance of the several components, fuel lines and tight seals and valve fittings, required for reliable gas generation basically creates an inverse sunk cost.

whether he knows this or not, if the mechanism starts to act archaic and clunky after he's gone a bit too long without kicking the bucket, would he perhaps settle for a tune-up in lieu of literally biting the bullet? is he scared? is that why?

does walking head-first into certain doom become a reflex at the first sign of mechanical failure? is that why?

Marius, at a whim, may adorn his mechanism's fingers with living skin cultivated from commercially available human cells. ideally, his organics would be buffed by self sustaining perfusion channels, and melanocytes.

Plus sides- flesh, hell yeah!

Downsides- will be fingerless for a number of weeks, as the digits soak in the culture media petri dish

most of all, why doesn't he believe in immortality?

i've, well, got half an answer to that. 'cause when the contraption that's supposed to keep you alive already started out so messy, and makes no promises to keep you in top shape through your millennia of mangling and make-do, it's probably a bit hard to place the trust of eternity in its air-actuated hand, huh?

#the mechanisms#marius von raum#tdobvr#marius#oz.txt#this thing took two whole weeks to write y'all it is a Monster#oz.essay

114 notes

·

View notes

Text

arguably the first "car", the benz-patent motorwagen, kinda fucks honestly. this is cool. maybe everyone gave the steampunk people too much flack. also i like this weirdly technical section from the wikipedia page:

Although its open crankcase and drip oiling system would be alien to a modern mechanic, its use of a pushrod-operated poppet valve for exhaust would be quite familiar. A large horizontal flywheel stabilized the single-cylinder engine's power output. An evaporative carburettor was controlled by a sleeve valve to regulate power and engine speed. The first model of the Motorwagen had not been built with a carburettor, rather a basin of fuel soaked fibers that supplied fuel to the cylinder by evaporation.

also... there's modern working replicas

isnt that cool!

i was reading about this because i was trying to figure out if you could have a totally electric-free car, and i figured the first cars would be less likely to be electric. anyway this has an early electric ignition but there were steam cars, which i think dont require electricity? also, early internal combustion engines could be started with a hand crank (there are also modern non-electric starting systems), altho im not sure what they used to replace spark plugs. oh, maybe theyd didnt:

In 1860 Étienne Lenoir (credit is also given to Edmond Berger, who invented but never patented the spark plug on February 2, 1839) used an electric spark plug in his gas engine, the first internal combustion piston engine

oh! diesel doesnt use spark plugs! cuz diesel ignites from compression alone. requires initial heating though. bet you could design a zero-electricity diesel engine. also, there are experimental gas spark-less engines (apparently its more efficient?)

23 notes

·

View notes

Text

CNG cylinder

Type 1 CNG CYLINDERS

Type 1 CNG Cylinders for LIGHT-DUTY VEHICLES, MEDIUM AND HEAVY-DUTY VEHICLES

Type 1 CNG cylinders are made of steel.

Available Capacity (L), 30, 35, 40, 50, 60, 70, 80, 90.

DSW CNG cylinders are manufactured conforming to specific country national standards or International standards like ISO: 11439, ECER 110, GB17258, ISO: 11120

Compressed Natural Gas cylinders (CNG cylinders) are a popular alternative with truck, transit, and refuse fleets.

Category: cng cylinders for vehicleTags: CNG Gas Cylinder, Compressed Gas Cylinder

Description

ISO11439 Type 1 CNG CYLINDERS

Type 1 CNG cylinders are used regularly in science and engineering buildings, machine shops, and retail and campus dining.

Researchers, staff, and contractors store and use various compressed gases for different reasons.

Compressed natural gas (CNG) is a fuel gas mainly composed of methane (CH4), compressed to less than 1% of the volume it occupies at standard atmospheric pressure.

CNG TANK SIZES

what is a Type 1 gas cylinder?

Type 1 CNG gas cylinders:

Type 1 cylinders feature an all-steel shell construction, featuring no composite materials in their design.

Type 1 CNG Cylinder, which can store natural gas under pressure 20MPa or 25MPa made of 4130X

seamless steel tube with ISO9809-1/ISO9809-3/EN/DOT approval.

which are explosive pressure vessels containing flammable and explosive gases.

The storage pressure for automotive cylinders is 20MPa.

Suitable applications include:

Scuba

Modified atmosphere packaging (MAP)

Laboratory

Onsite industrial/manufacturing

There are four categories available in CNG gas cylinders.

The first category is seamless alloy steel cylinders (CNG-1).

CNG-2 is a composite gas cylinder with steel or aluminum lining and a barrel reinforced

with long fibers impregnated with “hoop winding” resin.

The third category is composite gas cylinders with aluminum liner plus carbon fiber fully

wound and glass fiber ring wound reinforcement (CNG-3).

The fourth category is the composite gas cylinder with plastic liner plus carbon fiber

full winding and glass fiber ring winding reinforcement (CNG-4).

Each of these Compressed Gas cylinders has its advantages and disadvantages, and it depends.

The main cylinders used worldwide are steel cylinders, generally made from high-quality

chromium-molybdenum steel, and the ISO 11439 and ECE R110 standards can meet

the requirements of most countries.

A complete automotive CNG cylinder has a cap, a valve, and a safety relief device.

The cap protects the valve, and the safety relief device on the valve should be of

the rupture disc-fusible plug combination type.

0 notes

Text

Segment Ball Valve: Applications and Advantages in Fluid and Gas Control Industries

Segment Ball Valve: Applications and Advantages in Fluid and Gas Control Industries

In industries where fluids or gases need to be controlled, valves are essential components. A segment ball valve is one such valve that is widely used in various industries. In this article, we will discuss what a segment ball valve is, its applications, how it works, and its advantages and disadvantages.

What is a Segment Ball Valve?

A segment ball valve is a type of single-seated trunnion-mounted ball valve that has an adjustable ratio of 100:1. Its flow characteristics are equal, and the valve has a shearing effect between the V-shaped cut in the seat and the metal valve seat. It is ideal for fluids containing fibers or slurries.

Applications of Segment Ball Valves Segment ball valves are widely used in various industries, including paper and pulp industries, petroleum refineries, petrochemical services, water treatment, food products, pharmaceuticals, and gas. These valves are known for their high reliability and durability, and they can be used to control the flow of various materials.

How Does a Segment Ball Valve Work?

Segment ball valves have a V-shaped portion that houses its internal components. These components are made from rigid and hard materials, and they are also made with thermoplastic-lined metallic materials. They also have seats, which provide sealing between the segmented ball and the body, and are useful in industries where harsh conditions can damage other types of valves.

A segment ball valve is a quarter-turn valve that works like an eccentric plug valve. The driving shaft connects to one side of the ball, and the follower shaft connects to the other side. When the shaft rotates, the ball rotates and starts the flow along the V-notch. As the handle is moved in the opposite direction, the ball rotates again to stop the flow.

Advantages of Segment Ball Valves

Segment ball valves have several advantages over other types of valves. They are lightweight and easy to install, making them ideal for high-pressure applications. They are also highly resistant to slurries and have a long lifespan. The shearing effect between the V-shaped cut in the seat and the metal valve seat helps to prevent clogging.

Disadvantages of Segment Ball Valves

Despite their many advantages, segment ball valves also have some disadvantages. They can be expensive compared to other types of valves, and their design may not be suitable for all applications. In some cases, they may also require frequent maintenance.

Conclusion Segment ball valves are essential components in various industries where fluids or gases need to be controlled. Their unique design and adjustable ratio make them ideal for applications that require precise control over the flow of materials. While they may have some disadvantages, their advantages make them a popular choice for many industries.

MAN 7S35MC-MK7 Cylinder Liner

from Decho Marine Services

Decho Marine Services (China)

Tingting

+86 159-6706-1188

[email protected]

from Decho Marine Services

Decho Marine Services (China)

Tingting

+86 159-6706-1188

[email protected]

0 notes

Text

Propene

The Propene Molecule

Propene is an extremely important molecule relating to petroleum and natural gas. It is also commonly used as a precursor to polyethylene and polypropylene plastics, fibers, and films.

Propene is made up entirely of carbon (C) and hydrogen (H).

Per valence bond theory, atoms want eight electrons in their outer shell to fill it up. Hydrogen is an exception to this rule because it's so small; hydrogen is at capacity with two electrons.

Each carbon atom has four electrons to put towards bonding (red) and each hydrogen atom has one electron to put towards bonding (black). Propene stabilizes by forming a double bond between two carbons. This fulfills the requirement for each carbon to have eight electrons in its shell.

Colorless

Propene is a colorless molecule.

Chemicals are colorful when their electrons absorb energy in the form of photons (light particles) and become excited. This higher-energy amount corresponds directly to a light wavelength, and each wavelength in the visible spectrum corresponds to a color. When electrons absorb energy of a certain wavelength, the complementary color of the absorbed wavelength is what we see.

Propene absorbs wavelengths that don't fall in the visible spectrum, and don't have a visible complement.

Liquid Under Pressure

When propene is stored for industrial purposes, it is put under pressure. The pressure forces more propene molecules to come together under intermolecular forces, which turns propene from its natural state of gas at room temperature into a liquid. Liquids allow for greater amounts of propene to be stored.

Gas in Approved Containers

Propene can also be stored as a gas. Outside of a storage container, propene would be a gas at room temperature. The pressurization to turn it into a liquid increases the severity of a potential explosion. Like hairspray, Febreze, and propane tanks, liquids under pressure can explode when exposed to heat.

Propene as a gas is still flammable. But the pressure added could be disastrous.

Propene can be stored as a gas in approved containers. These cylinders usually have an expiration date.

------------------------------------------------------------------------------

Propene,

Colorless? You're telling me nothing in your life has ever colored you?

You've never wrote a shitty poem about being purple?

Your purpose is defined and clear. I wish I could relate. It's probably problematic that you're so involved in petrochemical bullshit, but we all uphold the system in someways. You can't be blamed.

It's cool that you can exist as both a liquid and a gas. That people go out of their way to accommodate you.

If I was chlorine, I'd want to borrow from you too. To take some of that clarity and knowing, the confidence in structure and stability.

I imagine you'd be fun to hang out with. I can picture us hanging out in some trendy bar that didn't play any sports and talking for hours. You'd give me advice and help me calm down and I think I'd really look up to you.

0 notes

Text

Inside The Koenigsegg Gemera, A Correct Four-seat Hybrid Hypercar

Yup, the Gemera has a posh powertrain with the Koenigsegg Gemera engine alone comprising of a 2-liter 3-cylinder dry-sumped twin-turbo freevalve engine together with no much less than three electric motors. Nicknamed the ‘Tiny Friendly Giant’ (TFG), the Gemera’s three-cylinder is type of a feat of engineering. The twin-turbocharged 2.0-litre combustion engine alone produces a whopping 600bhp, 443 lb ft of torque, and it’s part of a hybrid drivetrain that’s supplemented by three electric motors. Two electrical koenigsegg gemera price motors power each rear wheel, producing 500bhp and 737 lb ft of torque, while a 400bhp electric motor can also supply 369 lb ft of torque to the crankshaft. The technically that makes this possible is fairly remarkable with the “Tiny Friendly Giant” combustion engine that’s a 2.0litre 3cyl turbo unit making 600hp, with an additional electrical motor, all of which sends 1,000hp to the front wheels.

The firm has been liable for numerous technological advances including a camless piston engine. Up until 2020, Koenigsegg was targeted on 2-seater hypercars with little to no room for anything gemera koenigsegg but its driver and passenger. That changed when its new camless engine was introduced within the 2020 Koenigsegg Gemera. The inside is as lavish as we have come to anticipate from a Koenigsegg.

He went on, saying that, whereas Freevalve ought to enable for sooner opening and closing rates at lower engine speeds than cam-driven valve, he doesn’t suppose this a huge benefit over standard systems. At high RPM, sooner closing valves could provide extra of a benefit, but “you’re still limited by the valve spring stiffness, valve mass, and seating rates to keep away from bodily damaging elements,” he informed me through e-mail. Turning off one of the consumption valves for increased swirl is also a well-known idea that has been implemented in production as properly. There are numerous benefits to altering when valves open within the combustion cycle, how far they open, and the way lengthy they remain open. The primary ones revolve round growing volumetric efficiency for higher gas economy, energy, and emissions, in addition to drivability (i.e. broadening the torque band across the rev range). When the major target is totally on the exterior aspect of static fashions the wheels at all times must perform well, GT Spirit once once more delivers.

This offers the Gemera torque-vectoring all-wheel drive, which is something of a necessity for a automobile which, when fueled on pure ethanol, generates 1,seven-hundred horsepower and 2,581 pound-feet of torque. "Ultimate efficiency has belonged to the world of two-seaters with very limited luggage house -- till now," Koenigsegg CEO Christian von Koenigsegg stated koenigsegg gemera in a statement. "Each individual valve has whole freedom. How much to open, when to open, how long to remain open." At low loads, solely one of many two consumption valves per cylinder opens, distributing atomized fuel more evenly.

To be trustworthy, static models usually don’t excel in the total package, but the Gemera proves robust. Like different Koenigseggs, the Gemera's chassis consists of a carbon-fiber tub and aluminum sub-structures. The center-lock carbon-fiber wheels are wrapped in Michelin Pilot Sport 4S tires, 21 inches in entrance and 22 inches in the rear. This could possibly be the last word household automotive or simply the most irrational thing Koenigsegg has ever made, and that's saying something.

They appear significantly worthy of the Gemera name, which mixes the Swedish words for "give" and "extra". Those who had been able to listen to the digital stream of the release would first have seen the outstanding levels of space Koenigsegg has packed into this automotive. The automotive is capable of swallowing, with ease, four carry gemera on suitcases for its 4 passengers. Koenigsegg chose to stay in Geneva to deal with their newest releases, despite the precise fact that the Geneva Motor Show 2020 was not as a result of open. The company presented a revolutionary new four-seater in the shape of the Koenigsegg Gemera. The Gemera is limited to an version of 300 cars so hurry and get your order in now.

As a outcome, the automotive doesn’t sound exactly like you might anticipate, and as it’s nonetheless within the development stage it has a raw and raspy edge. This prototype model can be presently limited to around 4,500rpm, so it’s but to be heard at its full, wild potential. Unlike a fully-electric hypercar, the 4-seater Koenigsegg has three electrical motors that work alongside a three-cylinder engine so it could possibly still roar through the exhaust. The TFG is a expertise showcase, an alternate vision for the automotive future. Koenigsegg posits that with some left-field thinking, the internal-combustion engine can still have a spot in the electrified automotive world. The interior of this Gemera continues to be unfinished and many wires are visible.

1 note

·

View note

Text

BASALT FIBER REINFORCED POLYMER (BFRP) USES

Basalt fiber reinforced polymer (BFRP), is an advanced material with a lower density, higher strength, and excellent damage resistance especially when they are used in harsh environments or under high loading conditions, compared with conventional fiber-reinforced composites, all these properties make it has several uses in the modern industry, including the following :

BFRP USES IN CONSTRUCTION ENGINEERING

Basalt fiber reinforced polymer (BFRP) is a structural material used for several uses such as contour beams, columns, and diaphragms in construction. It has high strength, high modulus of elasticity, high stiffness, and good corrosion resistance. BFRP has different uses including but not limited to reinforcement bars, beams, and plates as well as thin sheets, in civil structures, bridges, tunnels, railways sleepers and road construction.

BFRP USES IN AUTOMOTIVE INDUSTRY

At present, the automotive industry is focusing its efforts on the reduction of energy consumption and the protection of the environment, therefore Basalt fiber reinforced polymer (BFRP) uses in automobile industry has an important role, because It provides a stronger, lighter, more durable, and corrosion resistant material than steel, while also absorbing and storing heat more effectively.

BFRP USES IN PETROCHEMICAL INDUSTRY

Basalt fiber reinforced polymer (BFRP) has unrivaled combination of high temperature performance and high strength, this ideal for demanding uses in the petrochemical industry, the best example of basalt fiber reinforced polymer uses in petrochemical industry is the separation process of natural gas which uses a polymer membrane with fine fibers to separate the gas molecules based on their size and hence their permeability.

Basalt fiber reinforced polymer (BFRP) has another important use in petrochemical industry which is represented by pipes and gas cylinders industry to decrease the weight of the material and thus it is suited for pipeline transportation of crude oil, natural gas, and other fluids, these pipes are used for longer service duration life 60 – 80 years which is 2 -3 times longer than conventional metallic pipe.

BFRP USES IN THE ELECTRICAL SECTOR

As a result of Basalt fiber reinforced polymer (BFRP) unique properties, this makes it suited to a wide range of electrical uses such as insulators, transformers, and capacitors.

One of the most important uses of BFRP in the electrical sector is wind turbine blades, because BFRP has excellent mechanical properties, high-temperature resistance, and acid and alkali corrosion resistance, and it can operate in harsh environments, such as the sea for long periods.

Moreover, BFRP has the advantages of a low cost, high designability, good performance, and easy processing, which can meet the requirements of wind turbine blades.

Arab Basalt Fiber Company

building material supplier

قضبان التسليح البازلتية

0 notes

Text

Composite LPG Cylinders Industry Current Trends and Challenges Analysis by 2023-2030

The composite LPG (liquefied petroleum gas) cylinder market is a rapidly growing industry, driven by increasing demand for lightweight and durable gas storage solutions for a variety of applications. Composite LPG cylinders are made from high-strength, lightweight materials such as carbon fiber and fiberglass, which offer numerous advantages over traditional metal cylinders, including increased safety, corrosion resistance, and longer service life.

The market for composite LPG cylinders is being driven by a range of factors, including growing demand for cleaner and more efficient energy sources, increasing adoption of LPG as a cooking fuel in emerging economies, and growing awareness of the benefits of lightweight, portable gas storage solutions in industrial and commercial settings.

For Download Free Sample Link Here:-https://www.marketinforeports.com/Market-Reports/Request-Sample/430511

The global composite LPG cylinder market is highly competitive, with a number of leading manufacturers competing for market share. Some of the key players in the market include Hexagon Ragasco, Time Technoplast, Santek, and Rubis Caribbean.

The market is expected to continue to grow in the coming years, driven by increasing adoption of LPG as a clean and efficient cooking fuel, rising demand for portable and lightweight gas storage solutions, and ongoing innovation in the design and manufacture of composite LPG cylinders.

#composite LPG (liquefied petroleum gas) cylinder market#composite LPG (liquefied petroleum gas) cylinder

0 notes

Text

Composite Cylinder Market Research Report 2032

The composite cylinder market has seen significant growth in recent years, and is projected to continue growing in the coming years. Composite cylinders are made from a combination of high-strength fibers, such as carbon or glass, and a resin matrix. This combination of materials creates a strong and lightweight cylinder that is highly resistant to corrosion and impact.

One of the main drivers of growth in the composite cylinder market is the increasing demand for compressed natural gas (CNG) and liquefied petroleum gas (LPG) as alternative fuels. Composite cylinders are ideal for storing these gases because of their lightweight design and high durability. In addition, composite cylinders offer better safety features than traditional metal cylinders, as they are less prone to explosions or ruptures.

Request Sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-5111

The transportation sector is one of the biggest users of composite cylinders, as CNG and LPG are increasingly being used as alternative fuels for vehicles. Composite cylinders are also used in other applications such as medical oxygen cylinders, firefighting equipment, and breathing apparatus.

One of the biggest challenges facing the composite cylinder market is the high cost of production. The raw materials used in the production of composite cylinders are expensive, which results in a higher cost for the finished product. However, the benefits of composite cylinders, such as their lightweight design and durability, make them a cost-effective option in the long run.

Another challenge facing the composite cylinder market is the lack of standardization in regulations across different countries. This can result in different safety standards and testing requirements, which can make it difficult for companies to sell their products in different markets.

Despite these challenges, the composite cylinder market is expected to continue growing in the coming years. The increasing demand for alternative fuels, as well as the growing need for lightweight and durable cylinders in various industries, will continue to drive growth in the market. In addition, the development of new manufacturing techniques and materials is expected to further reduce the cost of production, making composite cylinders more affordable and accessible to a wider range of customers.

Overall, the composite cylinder market is a dynamic and growing industry that offers numerous opportunities for companies that are able to innovate and adapt to changing market conditions. As the demand for alternative fuels and lightweight and durable cylinders continues to increase, the composite cylinder market is poised for continued growth in the coming years.

Composite Cylinder market - Key Players:

Some major players of the composite cylinder market are Quantum Technologies, Worthington Cylinders, Hexagon Composites, LiteSafe Cylinder, Santek Equipments Pvt Ltd, Luxfer Gas Cylinders, Beijing Tianhai Industry Co., Aburi Composites, ALAMAN Gas Cylinders Manufacturing LLC, Time Technoplast, Faber Industries S.p.A., Shijiazhuang Yunhong Trade Co., Ltd. and Shanghai Qiaoyu Industrial Co., Ltd.

View Full Report @ https://www.futuremarketinsights.com/reports/composite-cylinder-market

0 notes

Text

How to Prevent Costly Car Repairs

Keeping your car in good condition is important to its safety and performance.

Getting regular maintenance is the best way to prevent costly repairs in the future.

Many repairs can be performed by do-it-yourselfers, but others require professional skills and equipment. This is why it's wise to leave these more complex jobs to a mechanic.

Check Engine Light

When a check engine light comes on, it can signal a wide range of issues that need to be addressed. Some of them are simple and quick to fix, but others require a professional mechanic.

While not all of the Car repairs problems that trigger a check engine light are serious, ignoring them can lead to more expensive repairs down the road. Additionally, if a problem is severe, it can damage important parts or cause an emissions system to fail.

Insufficient EGR Flow: This is a problem with your engine’s ability to recirculate exhaust gas back into the combustion chamber to help it achieve optimal temperatures. This can occur when there is a valve or sensor failure.

The best way to find out what is causing the check engine light is to purchase an OBD-II code reader. These devices are available at most auto repair shops and can read a vehicle’s logged trouble codes to pinpoint the issue.

Brake Light

The brake light is a safety feature that lights up to tell you when your car’s braking system has an issue. It can also indicate that you should change your brake pads.

The braking process involves hydraulic pressure being converted by the master cylinder into force that is pushed through the brake lines and actuates various braking mechanisms in your vehicle. This includes brake calipers that clamp the brake pads onto rotors (disc brakes) or wheel cylinders that push brake shoes on brake drums (drum brakes).

It’s important to note that this braking process can be affected by moisture and frequent driving. That’s why it’s always a good idea to check your brake fluid levels regularly.

If the Brake Light comes on, pull over safely and turn off your engine. Then, top off the brake fluid if necessary.

Oil Change

Oil changes are an essential service for maintaining the health of your vehicle. This simple and inexpensive process keeps your engine well-lubricated, preventing friction and wear on metal parts that can lead to costly repairs.

It also protects the engine from heat by keeping it cool and removing carbon from the combustion chamber, which prevents overheating.

Generally, car service should get an oil change every 3,000 miles or three months. However, this can vary depending on how often you drive and what your driving habits are.

A good way to know when your oil needs to be changed is to check the dipstick. If the oil looks cloudy or frothy, or if you can see glittery chunks of metal, that's usually an indication that your engine is starting to suffer from damage.

Tires