#ndt inspection services

Text

Exploring NDT Inspection Services Through Imagery

Curious about NDT Inspection Services and their impact? Delve into the world of non-destructive testing with Overhaul Accessory, Inc. Witness how cutting-edge technology ensures safety and reliability through every inspection. Explore the intricate details and precision through vivid imagery, unraveling the essence of our services. Ready to experience excellence? Contact us at (305) 558-4540 to schedule your consultation today.

0 notes

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Quality Inspection Services#Factory Acceptance Test#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Hydrostatic & Performance Tests#Welding Inspection Services#expediting services

0 notes

Text

CMM Inspection Services For Precision and Quality Assurance

Nel PreTech specializes in providing comprehensive CMM inspection services for precision and quality assurance. Leveraging cutting-edge technology, our team ensures meticulous dimensional measuring to prevent errors and uphold the highest standards of quality. From first article inspection to part validation, gage R&R, and capability studies, we assist manufacturers in various industries, including automotive, aerospace, and medical devices. Trust Nel PreTech for accurate measurements, efficient inspections, and cost-effective solutions to enhance your product quality and reduce manufacturing costs. Contact us at 708-429-4887 to learn more about our services.

#cmm inspection services#3d scanning chicago#industrial ct scan#dimensional inspection#ndt x-ray#3d scanning

0 notes

Text

Eddy Current Training Courses | NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS

Enter Eddy Current Testing (ECT), a cutting-edge non-destructive testing (NDT) technique revered for its ability to detect flaws and anomalies with remarkable precision. Amidst this backdrop, the necessity for proficient Eddy Current Training Courses has never been more vital. Join us as we delve into the realm of the invisible and uncover five compelling reasons to invest in Eddy Current Training.

Know More: NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS

#titanium alloys#eddy current training courses#NDT STANDARD REFERENCE BLOCKS /NDT FLAW SPECIMENS#third party inspection services

0 notes

Text

#ndt#assetintegritymanagement#thirdpartyinspection#storagetank#heattreatment#inspection#ndt services

0 notes

Link

0 notes

Text

Forge Ahead with Virat’s H13!

The Pinnacle of Durability and Performance in Every Extrusion!

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Molds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬[email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#h13toolsteels#DieSteelH13#Aluminium Extrusion#Extrusion Die Steel#AluminumProfiles#MetalShaping

2 notes

·

View notes

Text

AceForge: Spearheading Innovation in Automobile Spare Parts Manufacturing

In the intricate network of the automotive industry, spare parts manufacturing companies serve as the backbone, ensuring the reliability, performance, and longevity of vehicles on the road. Among these essential entities, AceForge emerges as a trailblazer, redefining the standards of excellence in automobile spare parts manufacturing. With a relentless pursuit of innovation, commitment to quality, and customer-centric approach, AceForge has solidified its position as a leader in the field. Let's delve into the distinctive qualities and contributions of AceForge in this critical sector.

A Legacy of Precision Engineering

At the core of AceForge's success lies its rich heritage of precision engineering and craftsmanship. Established with a vision to deliver superior quality spare parts, the company has amassed decades of experience in honing its manufacturing processes and techniques.

Through a combination of advanced technologies and skilled craftsmanship, AceForge produces spare parts that meet and exceed the stringent standards set by the automotive industry. From engine components to braking systems, every product undergoes rigorous testing and quality control measures to ensure optimal performance and reliability.

Innovation at the Forefront

Innovation is the driving force behind AceForge's operations, propelling the company to new heights of excellence. Recognizing the ever-evolving demands of the automotive market, AceForge invests heavily in research and development to stay ahead of the curve.

Advanced technologies such as computer-aided design (CAD), additive manufacturing, and robotics are seamlessly integrated into AceForge's production processes, enabling the company to produce spare parts with unparalleled precision and efficiency. Moreover, AceForge continually explores new materials and production techniques to enhance the performance, durability, and sustainability of its products.

Quality Assurance and Reliability

In an industry where safety and reliability are paramount, AceForge maintains uncompromising standards of quality assurance. From the selection of raw materials to the final inspection of finished products, every step of the manufacturing process is meticulously monitored and evaluated.

AceForge employs advanced testing methodologies, including non-destructive testing (NDT) and computerized quality control systems, to ensure that each spare part meets the highest standards of excellence. By adhering to stringent quality assurance protocols, AceForge instills confidence in its customers and establishes itself as a trusted provider of automotive spare parts.

Customer-Centric Approach

AceForge places a strong emphasis on understanding and addressing the unique needs of its customers. By fostering close partnerships and open communication, the company collaborates with clients to develop customized solutions that meet their specific requirements.

Whether it's a large automotive manufacturer or a local repair shop, AceForge remains committed to delivering exceptional service and support. The company's responsive approach to customer service ensures that clients receive prompt assistance and personalized attention at every stage of their interaction with AceForge.

Sustainability and Environmental Responsibility

In today's environmentally conscious world, sustainability is a key consideration for automotive spare parts manufacturers. AceForge is committed to minimizing its environmental footprint and promoting eco-friendly manufacturing practices.

Through initiatives such as waste reduction, energy efficiency improvements, and recycling programs, AceForge strives to minimize its impact on the environment while maximizing resource efficiency. By embracing sustainability as a core value, the company not only contributes to environmental conservation but also enhances its reputation as a responsible corporate citizen.

Embracing Digital Transformation

As the automotive industry embraces digital transformation, AceForge is at the forefront of this technological revolution. By harnessing the power of digital technologies such as artificial intelligence, Internet of Things (IoT), and big data analytics, the company is transforming the way spare parts are designed, manufactured, and distributed.

Real-time monitoring and predictive maintenance systems enable AceForge to optimize production processes and minimize downtime, while digital twins facilitate virtual simulations and prototyping, accelerating time-to-market for new products. By embracing digital transformation, AceForge enhances its agility, efficiency, and innovation capabilities, positioning itself for long-term success in the rapidly evolving automotive industry.

Looking Ahead

As the automotive industry continues to evolve, so too do the challenges and opportunities facing spare parts manufacturing companies. However, with its unwavering commitment to innovation, quality, and customer satisfaction, AceForge is well-positioned to thrive in this dynamic environment.

By staying true to its core values and embracing emerging technologies, AceForge will continue to push the boundaries of what is possible in automobile spare parts manufacturing. Whether it's pioneering new materials, optimizing production processes, or reimagining the future of mobility, AceForge remains dedicated to driving positive change and shaping the industry for generations to come.

0 notes

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development,Total quality management.Vendor pre evaluation, Inspection and Expediting Services,Pre-Shipment Inspection,NDT inspection and testing like Radiography and many more.

For more details, please visit our website- https://avengineersefp.com/service/third-party-inspection-ndt-services/

0 notes

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Photo

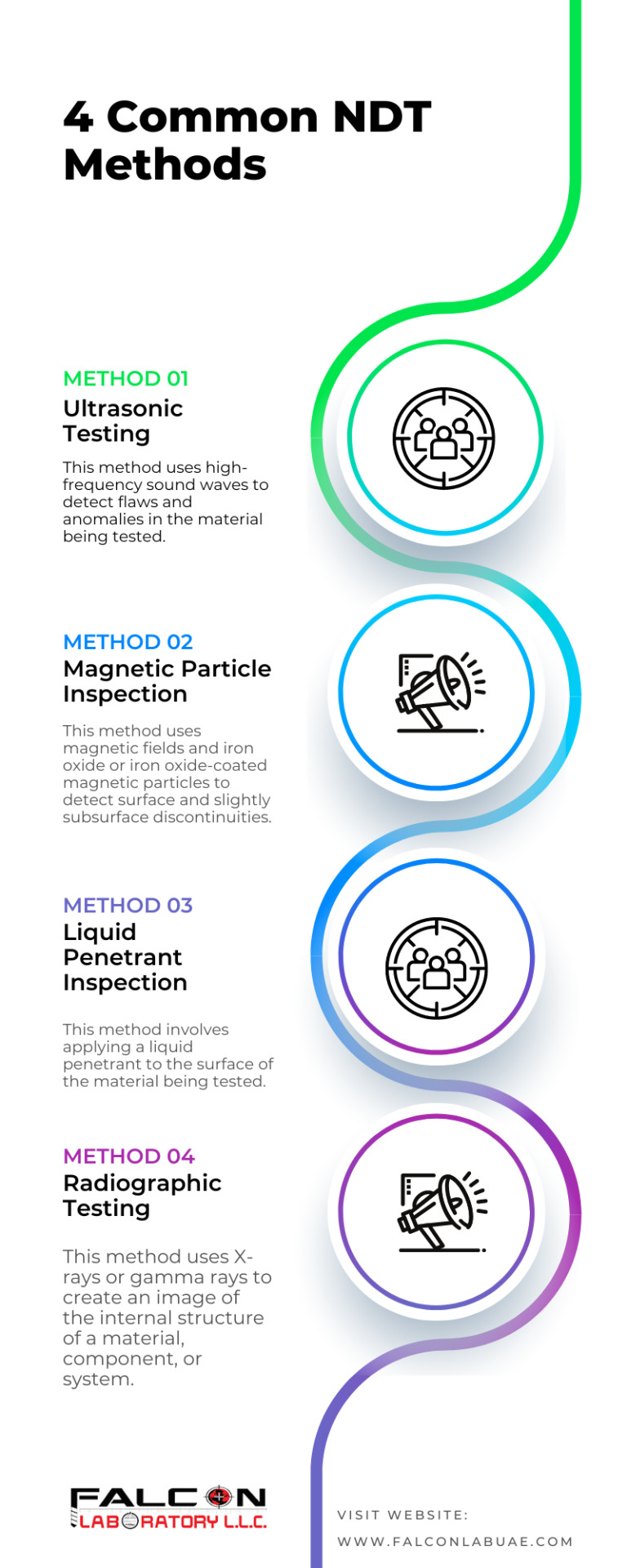

4 Common NDT Methods

There are several different types of NDT inspection services that can be used to evaluate the properties of materials, components, and systems.

Please Visit: https://www.falconlabuae.com/ndt-services/

0 notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Factory Acceptance Test#Quality Inspection Services#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Welding Inspection Services#Third Party Industrial Inspection Services#Witness Inspection Services#Positive Material identification Services#IT Inspection Services#Cyber Security Assessment Services#Vulnerability management services#Audit and Assessments Services

0 notes

Text

3D Scanning Services in Chicago

Experience the full range of possibilities unlocked by the cutting-edge technology 3D scanning in Chicago, enabling you to achieve unparalleled levels of accuracy and precision. Immerse yourself in the innovative and advanced solutions we provide for creating detailed digital replicas and models with unmatched intricacy, precision, and fidelity, setting new standards in the industry.

#cmm inspection services#3d scanning chicago#3d scanning companies#dimensional inspection#industrial ct scan#ndt x-ray#metrology services

0 notes

Text

Titanium Alloys

RVS Quality Certifications Pvt. Ltd. is a leading company specializing in Titanium Alloys. Renowned for its commitment to excellence, It is at the forefront of providing high-quality titanium alloy solutions for diverse industries. With a focus on precision engineering and advanced metallurgy, the company ensures superior strength, corrosion resistance, and lightweight properties in its alloys. They dedicated to meeting stringent quality standards, offering innovative solutions, and fostering client satisfaction. As a trusted name in the industry, RVS Quality Certifications Pvt. Ltd. continues to be a reliable partner for those seeking top-notch titanium alloy products for various applications.

#Titanium Alloys#Third-Party Inspection Services#Eddy Current Training Courses#Rebound Hammer Testing Services#Non Destructive Testing Services#NDT Equipment Supply Services#Forging Consultants

1 note

·

View note