#ultrasonic inspection

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

Total Focusing Method (TFM) represents an Advanced Ultrasonic Testing (UT) Technique that revolutionizes flaw detection in materials. Read More!

#Total Focusing Method (TFM)#non-destructive testing#ndt technique#ultrasonic testing#ndt techniques#ndt methods#ndt#ultrasonic inspection#ut#ndt testing

1 note

·

View note

Text

Service provider of NDT service, general safety training, inspections, safety audit, ultrasonic testing, pipeline inspection, hydro testing, crane inspection, third party inspection, shipment inspection and many more services.

#Inspections#safety audit#ultrasonic testing#ut testing#pipeline inspection#pipe inspection company#hydro testing#crane inspection#crane inspection near me#ultrasonic inspection#third party inspection#hydro static pressure testing#ultrasonic testing of welds#phased array ultrasonic testing#ut inspection#hydro testing near me#pipeline inspection services#overhead crane inspection#tank hydro testing near me#3rd party inspection#third party inspection companies#scuba tank hydro testing near me#hydrostatic testing scuba tanks#cylinder hydrostatic testing#pre shipment inspection#shipment inspection#tank hydro testing#fire extinguisher certification near me#online fire fighting course#fire safety class

1 note

·

View note

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#ultrasonic testing#ndt equipment in uae#uv light#visual & welding inspection equipment#general equipment#incor technical#uae

0 notes

Text

Dolphitech's advanced NDT testing solutions revolutionize defense and aviation safety with precise ultrasonic inspection technology, ensuring mission-critical assets meet stringent standards

#ndt testing#NDT Inspection#Non Destructive Evaluation#Non Destructive Testing#Non Destructive Inspection#ndt ultrasonic testing

0 notes

Text

Phased Array Ultrasonic Testing services in India

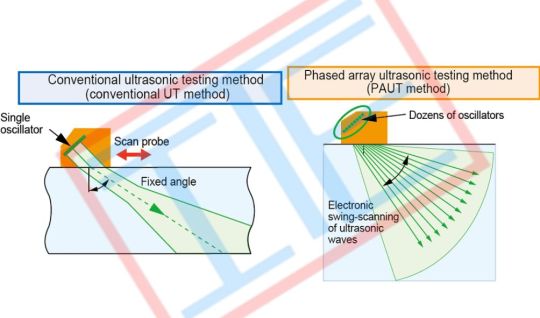

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

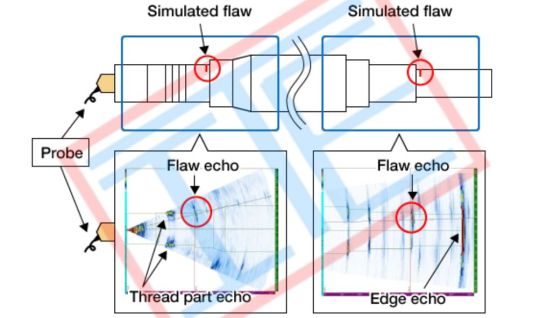

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

Ultrasonic Testing by Volaralta

Ultrasonic Testing by Volaralta is a non-destructive testing technique used to inspect the integrity and quality of materials and structures. It involves the use of high-frequency sound waves that are transmitted through the object being tested. These sound waves travel through the material and are reflected back when they encounter any flaws, such as cracks, voids, or inhomogeneities.

0 notes

Text

#nondestructivetesting#ndt#ndtinspection#inspection#ultrasonictesting#welding#ndttechnician#engineering#worldofndt#nondestructivetestingtechnician#asnt#ndtinspector#iso#oilandgas#testing#ultrasonic#mechanicalengineering#radiography#nondestructiveinspection#nde#pwht#ndtlife#nondestructivetestingcompany#weldinginspection#paut#ultrasound#ensayosnodestructivos#eddycurrent#piping#inspections

0 notes

Text

Get Advanced NDE Inspection Solutions Here!

At Insight NDE, we offer a full range of conventional NDE services in both field and in-house lab settings, utilizing fully trained, certified technicians. Our many years of experience across multiple industry sectors allow us to safely, accurately, and efficiently provide a wide variety of NDT methods and techniques to meet our client's unique requirements. Contact us today!

0 notes

Text

#ultrasonic testing#nondestructiveinspection#non destructive testing#nondestructive#ndt inspection#ndttechnician#ndt inspector#ndt jobs#ndtexamination

0 notes

Text

#Tower Crane Mast Section#1. The standard section is all processed by the overall sandblasting process. The surface is smoother and more beautiful. It is treated wit#with strong adhesion and longer durability.#2. All chord connections are gas-shielded and welded. All the products are tested by weld inspection#x-ray and UT ultrasonic inspection. It is more secure.

0 notes

Text

How is welding engineering inspection a proactive approach to prevent risks in any industry?

In industries where welding is a fundamental process, ensuring safety and quality is paramount. Welded components are ubiquitous in various sectors, from construction to manufacturing, and any compromise in their integrity can lead to significant risks. This is where engineering and inspection services step in as a proactive approach to prevent potential hazards before they escalate. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection

0 notes

Text

Visual Inspection is a method in Non-destructive Testing, that relies on the human eye to assess the surface conditions of materials, and structures. Read More!

#ndt methods#ndt techniques#nde#ultrasonic inspection#ndt technique#Visual Inspection#Visual Inspection Method#Visual Inspection Types

0 notes

Text

Forge Ahead with Virat’s H13!

The Pinnacle of Durability and Performance in Every Extrusion!

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Molds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬[email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#h13toolsteels#DieSteelH13#Aluminium Extrusion#Extrusion Die Steel#AluminumProfiles#MetalShaping

2 notes

·

View notes

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#penetrant testing#uv light#visual & welding inspection equipment#general equipment#ultrasonic testing#incor technical

0 notes

Text

Discover DIAB: Dolphitech's compact powerhouse, revolutionizing non destructive evaluation with its portable Matrix Array Ultrasonic Technology, setting new standards for industrial inspection efficiency.

#Non Destructive Evaluation#Non Destructive Testing#NDT companies#ndt ultrasonic testing#NDT Inspection

0 notes