#ultrasonic testing of welds

Text

Service provider of NDT service, general safety training, inspections, safety audit, ultrasonic testing, pipeline inspection, hydro testing, crane inspection, third party inspection, shipment inspection and many more services.

#Inspections#safety audit#ultrasonic testing#ut testing#pipeline inspection#pipe inspection company#hydro testing#crane inspection#crane inspection near me#ultrasonic inspection#third party inspection#hydro static pressure testing#ultrasonic testing of welds#phased array ultrasonic testing#ut inspection#hydro testing near me#pipeline inspection services#overhead crane inspection#tank hydro testing near me#3rd party inspection#third party inspection companies#scuba tank hydro testing near me#hydrostatic testing scuba tanks#cylinder hydrostatic testing#pre shipment inspection#shipment inspection#tank hydro testing#fire extinguisher certification near me#online fire fighting course#fire safety class

1 note

·

View note

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#ultrasonic testing#ndt equipment in uae#uv light#visual & welding inspection equipment#general equipment#incor technical#uae

0 notes

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

Ultrasonic testing benefits excel at identifying corrosion problems, even in their early stages. Here is list of the benefits of ultrasonic testing. Read More!

#ndt#ndt methods#ndt technique#ndt techniques#non-destructive testing#ndt testing#ultrasonic inspection#ultrasonic welding#ultrasonic cleaner#ultrasonic testing#ultrasonic testing benefits

0 notes

Text

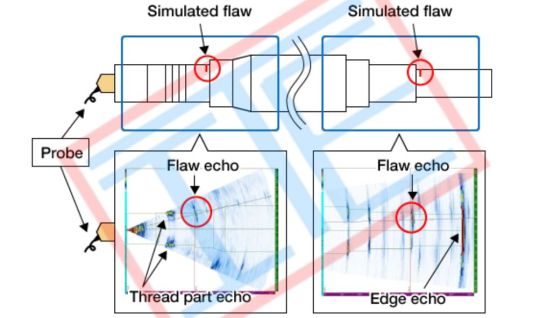

Phased Array Ultrasonic Testing services in India

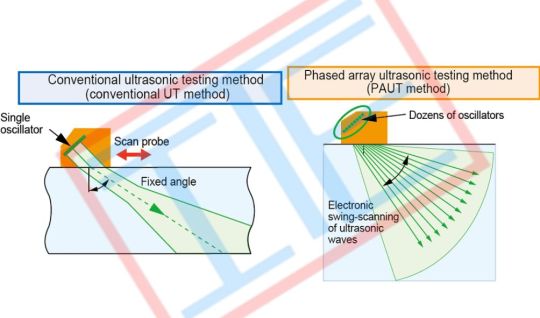

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

#nondestructivetesting#ndt#ndtinspection#inspection#ultrasonictesting#welding#ndttechnician#engineering#worldofndt#nondestructivetestingtechnician#asnt#ndtinspector#iso#oilandgas#testing#ultrasonic#mechanicalengineering#radiography#nondestructiveinspection#nde#pwht#ndtlife#nondestructivetestingcompany#weldinginspection#paut#ultrasound#ensayosnodestructivos#eddycurrent#piping#inspections

0 notes

Text

#Tower Crane Mast Section#1. The standard section is all processed by the overall sandblasting process. The surface is smoother and more beautiful. It is treated wit#with strong adhesion and longer durability.#2. All chord connections are gas-shielded and welded. All the products are tested by weld inspection#x-ray and UT ultrasonic inspection. It is more secure.

0 notes

Text

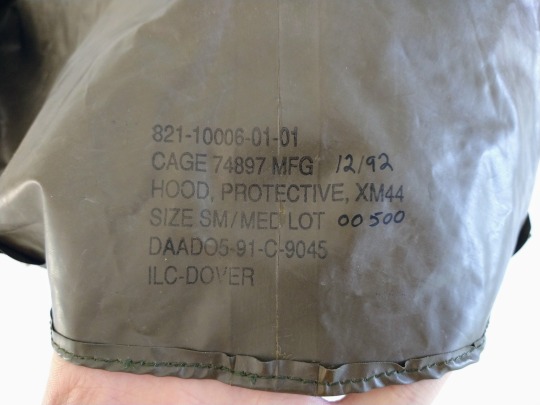

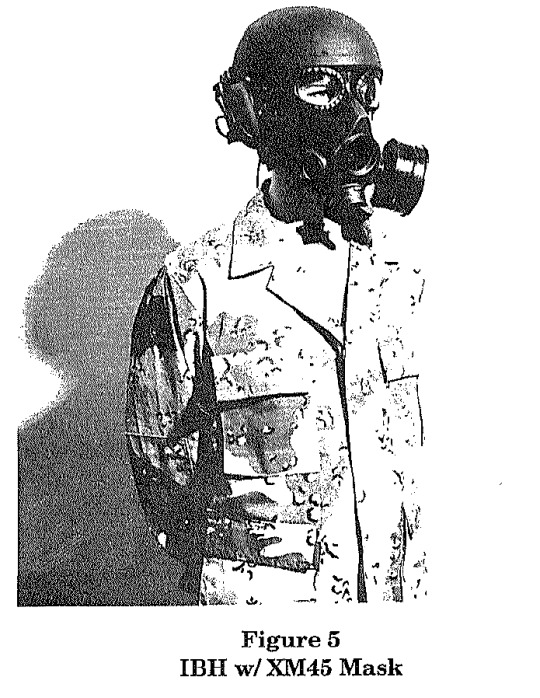

ILC Dover XM44 Experimental Protective Mask

Development beginning in the late 1980's, the XM44 Series Masks were originally intended to replace all the different gas masks in service at the time (M17A2, M40, MCU-2/P, ABC-M24, M25/M25A1, M43 Type II, etc.), but would ultimately be sidelined as an aircrew mask program (XM45).

The XM44/45 would ultimately be redesigned with ultrasonic welded plastic components between 1992-1995 and would be adopted as the Mask, Chemical-Biological, M45 in 1998.

There is also good evidence to believe Special Operations Forces had been testing the XM44 series since their introduction.

Far from complete and somewhat of a Frankenstein example, my specimen is sadly missing the nosecup valve and blanking plugs as well as being a size large while the hood is a small/medium.

If anyone is looking to trade a medium for a large facepiece or just has a medium facepiece to let go of, feel free to give me or @bureau-of-mines a shout.

6 notes

·

View notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information :

Visit our website : https://www.merakimetals.ae/

Contact us : +971-523973687, +971-48801107, +971-48240333

Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

How to Identify High-Quality ERW Pipes: Key Factors to Consider

When looking for a supplier of ERW (Electric Resistance Welded) pipes, it is crucial to pick high-quality items that may be customized to your needs. Because of its reliability, strength, and low price, ERW pipes have found widespread use in many different fields. This blog will help you choose which ERW pipes are of the highest quality by outlining the criteria you should use to make your selection. Tube Trading Co. is a great ERW Pipe Dealer in Gujarat, for those who are in search of a trustworthy ERW pipe dealer. We are a reliable ERW pipe provider, supplier, and distributor in Gujarat, and we stock a comprehensive inventory to meet your requirements.

· Manufacturing Standards:

Maintaining strict quality control during production is a vital part of making high-quality ERW pipes. Pipes should meet the standards set forth by the American Society for Testing and Materials (ASTM), the Indian Standards (IS), or any other applicable organizations. To put your mind at ease, Tube Trading Co. checks each batch of ERW pipes we produce to make sure it conforms to all applicable requirements.

· Material Quality:

The performance and durability of ERW pipes are profoundly affected by the quality of the raw materials used in their construction. The best ERW pipes are fabricated from high-quality steel that is both durable and resistant to corrosion. Tube Trading Co. only buys its raw materials from reliable vendors, so you know you're getting high-quality ERW pipes from the most distinguished ERW Pipe Provider in Gujarat.

· Welding Technique:

The welding method used to construct ERW pipes has a major impact on the durability of the finished product. Look for pipes that have been welded using precise processes to produce strong, uniform welds. Tube Trading Co. utilizes cutting-edge welding methods and meticulously supervises the welding process to produce durable ERW pipes suitable for a wide range of applications.

· Dimensional Accuracy:

For a trouble-free assembly and optimal fit with other parts, precise dimensions are required. The dimensions of high-quality ERW pipes, including their OD, ID, and wall thickness, are all precisely measured. The ERW pipes sold by Tube Trading Co. are guaranteed to have precise dimensions for a snug fit and superior performance in your machinery.

· Surface Finish:

Surface Finish High-quality ERW pipes always have a homogeneous and polished surface finish. A smooth, well-finished surface reduces the potential for corrosion, improves the visual appeal, and allows for more effective fluid or gas flow. The ERW pipes sold by Tube Trading Co. – a renowned ERW Pipe Supplier in Gujarat have excellent surface quality, guaranteeing their practicality and aesthetic appeal.

· Testing and Certification:

Look for pipes that have been put through a battery of tests, such as hydrostatic, ultrasonic, and eddy currents. The ERW pipes' quality and dependability have also been verified by third-party certificates. Tube Trading Co. has certifications proving the quality of their ERW pipes and conducts rigorous testing to ensure this.

Advantages of using ERW Pipes:

ERW (Electrical Resistance Welded) pipes are widely used because of their many benefits, including;

● Cost-Effective: When compared to other pipe options, such as seamless pipes, the price of ERW pipes is far lower. ERW pipes have lower production costs because of their simpler and more efficient manufacturing method.

● High Strength: The strength and durability of ERW pipes are well-known. The welding procedure employed during production fortifies the connection between the pipes, making them resistant to stress and pressure.

● Versatility: The wide range of sizes, shapes, and wall thicknesses available for ERW pipes makes them an extremely flexible material.

● Easy Installation: Due to their uniform dimensions and tight tolerances, ERW pipes are a breeze to set up. Their exact OD, ID, and wall thickness assure a snug fit and the ability to work with a wide variety of other parts.

● Corrosion Resistance: Longevity Improvement & Environmental Protection Coatings/Materials that resist corrosion can be used during the production of ERW pipes.

● Environmentally Friendly: Due to its efficient production method, ERW pipes are regarded as environmentally benign. When compared to conventional pipe production methods, they result in less waste and fewer carbon emissions.

Final Thoughts:

Taking into account the aforementioned criteria when shopping for ERW pipes will help you choose products of the highest quality that are suited to your demands. The ERW pipes sold by Tube Trading Co., an excellent ERW Pipe Distributor in Gujarat, are of the highest quality, manufactured to exacting standards, and boasting exceptional material quality, precise dimensions, superb surface finish, and thorough testing. When you work with Tube Trading Co., you can rest assured that your ERW pipe solutions will last for years to come.

#ERW Pipe Dealer in Gujarat#ERW Pipe Provider in Gujarat#ERW Pipe Supplier in Gujarat#ERW Pipe Distributor in Gujarat#distributor#Jindal pipes#steel industry#steel companies#industrial#plumbing industry#construction structure#construction sites

6 notes

·

View notes

Text

“You put that in wrong and melted all the wires.”

“Hey, asshole! You’re the one here with a masters, so why don’t you do it!”

Toadette put her hands on her hips as she stared down Luigi. He looked up from his nintendo switch.

“Hmm… Nah. It’s funnier watching you screw it up.”

“Well, I never!” She dramatically folded her arms and turned her head, trying to avoid giggling. Sure, it was a bit annoying to have him only watch, but he wasn’t here for company only. If he got involved in the work, she’d have to split the pay with him. Which wasn’t a problem for her, but for him, it was. Weirdly enough.

“Can you at least give me a hint?”

She returned her hands to her hips, stepping back to give her coworker a better look at what she was working on- an old Steam Gardener chassis that she had found beaten up and left in a forest. Luigi leaned forward from his chair, tilting his head and squinting slightly, before leaning back and returning to his game.

“Try connecting the power supply to the interior with the sonotrode instead of the torch welder. The heat makes the metal expand and warps the parts. That’s why you keep having to replace the copper wires, the insides are melting.”

He pointed a finger at a device set on the table.

“Right. The sonotrode.”

“You know what a sonotrode does. Right?”

“It welds.”

“How does it weld?”

That was about as much as she knew. She’d seen Luigi use the sonotrode before, but it was a recent addition to their arsenal. Idly scratching her chin, she connected the dots in her head to form a guess at the use of a sonotrode and how it welds. She knew only Luigi really used it, and he always used electrical devices- never propane or butane- So the sonotrode had to be electric. Not to mention that squealing it made.

“It’s ultrasonic, right? I don’t know what ultrasonic welding actually does. I just know it’s really noisy and high-pitched.”

“It jiggles so fast it melts whatever it touches. Nice guess.”

She took the sonotrode and the power box off of the countertop and plugged it into the generator.

“Be sure to press it in hard when you use the Sonotrode or the weld won’t take.”

Gently stripping out the old, ruined copper wires and replacing them with new ones, she carefully sautered them into place in the power supply, and then welded the power supply into the back of the chassis with the sonotrode. Giving it a light tug to ensure it was welded firmly, she set down the sonotrode and removed power from it, plugging in the chassis of the old steam gardener to ensure the power supply was properly supplying power.

“You know, usually you test that before you weld it in.”

“I mean. It works, doesn’t it?”

“Yeah, but if it didn’t, you’d have to rewire it while it’s welded in.”

“Right.”

“You always gotta prepare for things to go wrong. Something is always gonna go wrong and it’s better to expect it than to be surprised.”

It was kind of a pessimistic way of putting it, but he was right.

“What, did you write your thesis on how a cynical attitude is beneficial?”

“No, I wrote it on the use of magical energy to power electronics and houses over fossil fuels.”

“Is that why you don’t use the butane welder?”

“No, I don’t use it because I burn my fingers whenever I do and I don’t like putting on a welding mask. Also, my thunderhand can power any electronics I use. It’s convenient.”

“Oh yeah. Thunderhand. Isn’t it also why your phone and switch batteries never die?”

He simply gave a short hum in response. He was more focussed on whatever game he was playing on his switch. That was fine by her. She plugged in her laptop to the power supply, affixed the moving parts inside to the wires that ran through the power supply, and ran some test parameters to ensure the parts all moved correctly. He looked back up and watched as they all moved.

“You know they have a T rex there?”

“Where?”

“The wooded kingdom. With the steam gardeners.”

“Huh.” She pulled the laptop’s cord out of the power supply. “Wonder how a T rex got there?”

“Not sure. But it has a hat on. Mario said it chased him down when he crossed in front of it.”

“Oh yeah, Mario went to the wooded kingdom. Do you think he’d be able to know if we’re fixing this steam gardener right?”

“Probably, but he couldn’t give technical advice on it. Also, I went to the wooded kingdom, too. Didn’t see the T rex, but i did see a lot of uproots”

“I didn’t know you’d been to the wooded kingdom.”

“It wasn’t like a big deal. We just visited.”

“I mean. Your concept of a big deal is weird, dude. You didn’t tell anybody about your degrees from the Hooniversity for years. Mario only found out because I was teaching him how to fold laundry while your wrists were all janked up and sore and we found them tucked away in a drawer.”

“It’s not like you brag about a highschool diploma.”

“A degree and a diploma are super different!”

“It’s just a paper that says you know something.”

That was technically true. Everything with Luigi was about technicality. He said he liked certainty and not having to guess what something ‘really meant’. It made sense, but it was also a struggle when she used hyperbolic language and he didn’t quite understand.

“I think it’s a big deal since it’s a specialized course you take. Also It’s expensive and very difficult. It’s like the educational version of running a marathon.”

“Are marathons a big deal?”

“Oh yeah. Like a huge deal.”

“Humans used to be persistence hunters. They’re supposed to run slowly over a long distance.”

“Yeah, but do humans still hunt?”

“Sometimes.”

“I don’t think eating a live lizard for a dare is ‘hunting’.”

“What? No, I was thinking about. ‘Hunting for a deal’ or whatever. That requires persistence.”

“Metro kingdom is weird.”

She attached the final pieces to the interior of the steam gardener, bolting them into place, and giving the interior a final dusting. One last test to make sure everything was connected properly, and then she closed the front panel.

“It looks like a cleaner version of the ones in the wooded kingdom.”

“I mean, I wasn’t gonna leave it all dented and chipped.”

“It’s weird to see one that’s so clean and shiny.”

“I think in a few weeks it’ll be grimy once we get it in an actual garden.”

“Anybody gets grimy when they're in a garden for a few weeks.”

“Yeah, true. You certainly get grimy when you garden for a few weeks.”

“I’m the grime man. I come bearing carrots and peas.” He wiggled the fingers of one hand idly, like he was casting a spell. She snickered at his nonchalant tone and weird words.

“Oh great grime man, what is thine wisdom?”

“For gardening or for the robot.”

“Both.”

“Grow more potatoes. Also, you have one of the arms upside down.”

#luigi#toadette#dont tag as ship for the love of god they're just besties#writing#also i was bored today so

12 notes

·

View notes

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#penetrant testing#uv light#visual & welding inspection equipment#general equipment#ultrasonic testing#incor technical

0 notes

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

Enhancing Safety with Radiography Testing at Integrated NDE

Radiography testing is a vital technology in the field of non-destructive testing (NDT), providing unique insight into the internal structures of materials and welds without causing damage. At Integrated NDE, we specialise in offering high-quality radiography testing as part of our comprehensive NDT inspection services, assisting industries in maintaining high safety and quality requirements.

Radiography testing uses X-rays or gamma rays to produce detailed photographs of a material's internal structure. This non-destructive inspection method is crucial for detecting hidden faults such as cracks, cavities, and inclusions, which could jeopardise the material's integrity. The ability to detect these flaws early is vital for avoiding potential breakdowns and extending the life of critical components.

Unlike destructive testing, which requires cutting, breaking, or otherwise harming the material to analyse its qualities, radiographic testing provides for a thorough analysis while preserving the part's usability. This makes it very useful in non-destructive weld testing, where the structural integrity of the weld is critical. Radiography testing can detect minute flaws that other methods may overlook, ensuring that welds satisfy high safety and quality standards.

Integrated NDE's radiography testing services are supplemented by other sophisticated NDT techniques, such as ultrasonic testing NDT. Ultrasonic testing detects defects and measures material thickness, offering a complete picture of the material's state when combined with radiography testing. This multifaceted approach guarantees that all potential concerns are detected and solved, providing you with confidence in your components' safety and reliability.

Our highly skilled and certified specialists offer vast experience to each project, delivering precise and accurate outcomes. We use cutting-edge equipment and follow stringent industry standards to provide NDT inspection services of the highest quality and reliability. Whether you work in aircraft, construction, energy, or manufacturing, we can tailor our radiography testing services to your exact requirements.

Integrated NDE is dedicated to excellence in non-destructive testing. By selecting our radiography testing services, you will benefit from our commitment to accuracy, dependability, and client satisfaction. Our goal is to assist you in maintaining the safety and integrity of your projects by ensuring that your materials and welds are free of faults that could lead to costly failures or accidents.

Trust Integrated NDE for all of your non-destructive testing requirements. Our radiography testing services provide crucial insights into the durability and safety of your materials and structures, allowing you to achieve peace of mind and operational success.

#destructive testing#non destructive testing#non destructive weld testing#non destructive radiography testing

0 notes

Text

Unlocking Insights: The Importance and Techniques of Non-Destructive Examination (NDE)

Non-destructive examination (NDE) plays a crucial role in various industries, including manufacturing, aerospace, automotive, and infrastructure, by providing valuable insights into the integrity, quality, and reliability of materials and components without causing damage. In this comprehensive guide, we’ll explore the significance of NDE, discuss common techniques used in non-destructive examination, and highlight its applications across different sectors for ensuring safety, efficiency, and compliance.

Understanding Non-Destructive Examination (NDE)

Non-destructive examination (NDE), also known as non-destructive testing (NDT), is a collection of techniques used to evaluate the properties, integrity, and condition of materials, components, and structures without causing damage or altering their physical properties. NDE methods are essential for detecting defects, discontinuities, and anomalies that could compromise the performance or safety of critical assets.

Importance of Non-Destructive Examination

1. Safety Assurance:

NDE techniques help identify defects, flaws, or weaknesses in materials and structures, ensuring they meet safety standards and regulatory requirements to prevent catastrophic failures or accidents.

2. Quality Control:

NDE plays a vital role in quality assurance and quality control processes by detecting manufacturing defects, surface irregularities, or material inconsistencies early in the production or fabrication process, reducing rework and scrap.

3. Asset Integrity:

By monitoring the condition and integrity of assets such as pipelines, bridges, aircraft, and machinery, NDE helps extend their operational life, optimize maintenance strategies, and minimize downtime.

4. Cost Savings:

Early detection of defects or damage through NDE techniques can prevent costly repairs, replacements, or unplanned downtime, resulting in significant cost savings over the lifecycle of assets.

Common Techniques in Non-Destructive Examination

1. Visual Inspection (VI):

Visual inspection is the simplest form of NDE, involving direct visual examination of surfaces, welds, or components for visible defects, cracks, corrosion, or surface irregularities.

2. Radiographic Testing (RT):

Radiographic testing uses X-rays or gamma rays to penetrate materials and create images that reveal internal defects, voids, or discontinuities, making it suitable for inspecting thick-walled components or complex geometries.

3. Ultrasonic Testing (UT):

Ultrasonic testing utilizes high-frequency sound waves to detect internal flaws, cracks, or material thickness variations by analyzing the time it takes for ultrasonic waves to travel through a material and reflect back to a receiver.

4. Magnetic Particle Testing (MT):

Magnetic particle testing involves magnetizing ferromagnetic materials and applying magnetic particles or liquid suspensions to detect surface and near-surface defects, cracks, or discontinuities by visual or magnetic field indicators.

5. Liquid Penetrant Testing (PT):

Liquid penetrant testing involves applying a liquid dye or fluorescent penetrant to the surface of a component, allowing it to seep into surface cracks or defects before being removed and inspected under UV light.

6. Eddy Current Testing (ET):

Eddy current testing induces electrical currents in conductive materials and detects changes in impedance caused by defects, cracks, or material variations, making it suitable for detecting surface and near-surface flaws.

Applications of Non-Destructive Examination

1. Aerospace and Defense:

NDE techniques are widely used in aerospace and defense industries to inspect aircraft components, engine parts, and structural assemblies for defects, fatigue cracks, or corrosion.

2. Manufacturing and Fabrication:

NDE plays a critical role in manufacturing processes, including casting, forging, welding, and machining, to ensure the quality, integrity, and dimensional accuracy of components and structures.

3. Oil and Gas:

In the oil and gas industry, NDE techniques are employed to inspect pipelines, storage tanks, pressure vessels, and offshore platforms for corrosion, weld defects, and material degradation to prevent leaks or failures.

4. Automotive and Transportation:

NDE is used in automotive manufacturing to inspect critical components such as engine blocks, chassis, and safety systems for defects, weld quality, and material integrity to ensure vehicle safety and reliability.

5. Infrastructure and Construction:

NDE techniques are applied in infrastructure projects, including bridges, buildings, dams, and railways, to assess structural integrity, detect defects, and monitor aging infrastructure for maintenance and repair.

Conclusion

Non-destructive examination (NDE) plays a critical role in ensuring the safety, quality, and reliability of materials, components, and structures across various industries. By employing a range of NDE techniques such as visual inspection, radiographic testing, ultrasonic testing, and magnetic particle testing, organizations can detect defects, flaws, or anomalies early in the lifecycle of assets, minimizing risks, optimizing maintenance strategies, and enhancing operational efficiency. As industries continue to prioritize safety, quality, and compliance, the importance of non-destructive inspection as a valuable tool for asset integrity management and risk mitigation will only continue to grow.

Also Read: Embracing Innovation: The Evolution of Manufacturing Technology

0 notes

Text

Carbon Steel ASTM A694 Flanges Exporters in India

Introduction to Carbon Steel ASTM A694 Flanges Exporters in India:

Exporters of Carbon Steel ASTM A694 Flanges in India play a crucial role in the global distribution of piping components. They serve as intermediaries between manufacturers and international customers, facilitating the export of high-quality flanges to various countries around the world. Indian exporters leverage the country's manufacturing capabilities and expertise to meet the demands of global markets for piping components.

Specifications:

Material: Carbon Steel ASTM A694

Standard: ASTM A694

Types: Weld Neck, Slip-On, Blind, Socket Weld, Threaded

Pressure Ratings: ANSI Class 150, 300, 600, 900, 1500, 2500

Sizes: 1/2" to 48" (DN 15 to DN 1200)

Temperature Range: -20°F to 1000°F (-29°C to 538°C)

Testing: Hydrostatic Testing, Ultrasonic Testing, Radiographic Testing, etc.

Product Overview:

Exporters in India maintain a comprehensive inventory of Carbon Steel ASTM A694 Flanges sourced from reputable manufacturers across the country. They offer a wide range of flanges in different sizes, types, and pressure ratings to cater to the diverse needs of customers worldwide. These flanges undergo thorough quality checks to ensure compliance with ASTM A694 standards and regulations before being exported.

Benefits:

Global Reach: Exporters in India enable the distribution of Carbon Steel ASTM A694 Flanges to customers worldwide, leveraging the country's strategic location and logistical infrastructure for efficient international shipping.

Quality Assurance: Indian exporters ensure that the flanges meet international standards and regulatory requirements, providing customers with assurance regarding product quality, reliability, and compliance.

Competitive Pricing: With competitive pricing and cost-effective manufacturing processes, exporters in India offer competitive pricing for Carbon Steel ASTM A694 Flanges, making them accessible to customers in global markets.

Conclusion:

Exporters of Carbon Steel ASTM A694 Flanges in India play a vital role in the global supply chain of piping components, facilitating the export of high-quality flanges to customers worldwide. By leveraging India's manufacturing capabilities, expertise, and logistical infrastructure, they contribute to the efficiency, reliability, and accessibility of piping components in various industries and regions. With their focus on quality assurance, competitive pricing, and efficient logistics, Indian exporters serve as reliable partners for customers seeking dependable solutions for their piping needs on a global scale.

0 notes