#pcba

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

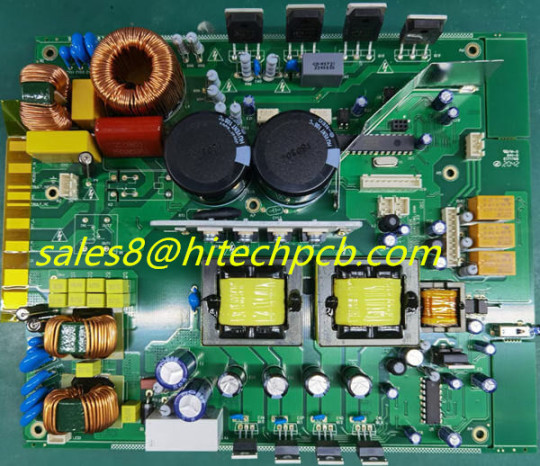

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

6 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

PCBA assembly manufacturing services provides by Hitech provides, from PCBA sample to medium or mass production volume. Our professional SMT factory has advanced equipments help us to offer rich experience in various PCBA manufacturing. Contact susie [email protected]

3 notes

·

View notes

Text

Hitech express prototype PCB assembly manufacturing is a specialized service that enables us to take complicated PCB fabrication, components souring and prepare them for assembly and testing. As the top PCB manufacturer in the China, Hitech Group can fulfill your prototype and production needs. We understand that bringing a product to market in a timely and cost effective manner can mean everything in business. Our quality, experience, service and pricing combine to become your efficient and reliable electronic supplier. We use the latest equipment to assembly complex PCBs as promptly as possible – often with 24 hours. We are setup specifically for deal with fast turn electronics assembly and all the issues that go hand in hand with the process, giving us an upper hand over most manufacturers, our team is capable of manufacturing prototype printed wiring board assembly volumes of 1-50 pieces.

Our knowledgeable and experienced staff have the know-how and equipment to be able to deal with any project you care to send our way – no job is too demanding. We can guarantee we will deliver exactly what you need with both speed and quality, so you can rest easy knowing you're in good hands.

Email us: [email protected]

Tel: +86 181 2652 1250

4 notes

·

View notes

Text

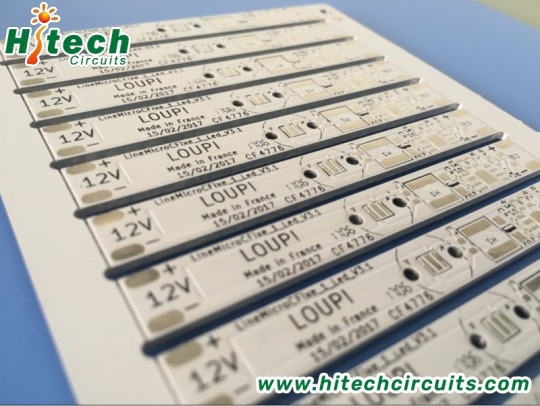

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

Quality Control: Rigorous quality control measures are implemented throughout the SMT assembly process to ensure that the final product meets the specified quality standards.

#aluminum pcb#pcb#pcb design#pcb fabrication#pcb factory#pcb manufacturer#pcba#pcbassembly#pcb board#pcb prototype

2 notes

·

View notes

Text

Provide solutions to pcb and pcba problems

2 notes

·

View notes

Text

📢 Elecrow #PartnerSeller Program Product #Newarrival 🔥

🔱 Introducing the #EncoderCounter, meticulously designed by Y2Kb! This advanced device accurately displays and outputs the count of incremental output encoder pulses. 😻 #ElecrowPCB

🚀 #PCBA, selling, and shipping services provided by #Elecrow. For more info 👇

https://www.elecrow.com/encoder-counter.html?utm_source=tumblr&utm_term=idd=2

2 notes

·

View notes

Text

What Are Mechanical Keyboard PCBs?

Mechanical keyboards have gained immense popularity due to their tactile feedback and durability. However, behind their satisfying keypresses lies a crucial component - the Printed Circuit Board (PCB). In this guide, we delve into the inner workings of mechanical keyboard PCBs, exploring their functions, features, and the key role they play in keyboard layouts.

The Role of a Mechanical Keyboard PCB

At its core, a mechanical keyboard PCB acts as the central nervous system of the keyboard, facilitating communication between the keys and the computer. Each key is linked to a specific switch on the PCB, and when a key is pressed, the switch sends an electrical signal to the PCB, which then translates it into a digital signal that the computer understands. This seamless interaction is what allows you to type, game, or perform any other function on your computer using your keyboard.

Features Supported by Mechanical Keyboard PCBs

Beyond basic key input, modern mechanical keyboard PCBs offer a range of advanced features that enhance the user experience. These include:

Stabilizers: Some PCBs support screw-in or clip-in stabilizers for larger keys like the spacebar and enter key. These stabilizers provide a more uniform and stable keypress.

Hot-swap Sockets: Certain PCBs come with hot-swap sockets, allowing you to easily replace switches without the need for soldering. This feature is particularly useful for users who enjoy customizing their keyboard's feel and sound.

RGB Lighting: Many mechanical keyboard PCBs support RGB lighting, allowing for customizable backlighting effects. This feature adds a vibrant and aesthetic element to your keyboard setup.

Mounting Options for Mechanical Keyboard PCBs

Mechanical keyboard PCBs can be mounted in several ways, each affecting the typing experience:

Top Mount: In this configuration, the PCB is secured to the top of the keyboard case, providing a sturdy typing platform.

Tray Mount: Tray-mounted PCBs are secured to the bottom of the keyboard case. While this mounting style is common, it can lead to uneven typing due to tension from the screws.

Gasket Mount: This mounting method involves using foam pieces between the PCB and plate. It provides a cushioned typing experience, reducing typing fatigue.

Keyboard Layout Support

One of the most appealing aspects of mechanical keyboard PCBs is their flexibility in supporting various layouts. Common layouts include:

60%

65%

75%

TKL (Tenkeyless)

100%

These layouts vary in size and key configuration, catering to different user preferences. Moreover, enthusiasts can design and create their own PCBs using online PCB makers, allowing for limitless customization possibilities.

Conclusion

In conclusion, mechanical keyboard PCBs are the backbone of any keyboard build, dictating its functionality and layout. Understanding the role and features of a PCB is crucial for anyone looking to build or customize their mechanical keyboard. By familiarizing yourself with the intricacies of mechanical keyboard PCBs, you can create a personalized typing experience that suits your preferences and style.

3 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

We are a 20 years PCB&PCBA factory.

4 notes

·

View notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Advantages of Full Turnkey PCB Assembly Services

• Shorter Lead Time

As a fundamental form of electronic assembly, PCB assembly primarily contains three phases: PCB fabrication, components procurement and PCB assembly. Traditionally, you should quote and confirm design files with sales and engineers working for your PCB manufacturer, then components distributors and finally PCB assemblers. Such series of quotations and confirmations just need your time spent in contacting with different partners. If those partners are from different countries, you have to overcome some problems such as time zone, communication habits etc. Full-turnkey PCB assembly, however, is a highly-efficient form of electronic assembly. As soon as full-turnkey PCB assembly is determined, an overall assembly quotation and indispensible issues prohibiting smooth manufacturing will be raised so that three times of communication have been cut to one time with electronic assembly efficiency dramatically improved in Hitech Circuits Co., Limited.

• Lower Cost

Another advantage of full-turnkey PCB assembly service is overall cost reduction. Pack-up service is usually cheaper than separate ones as far as electronic assembly is concerned. At least, freight fee will be saved because you don’t need to get manufactured PCB boards and electronic components delivered to assembly workshop. Moreover, components procurement may get easy and customer-friendly because experienced electronic assemblers are usually able to provide reliable components with relatively low cost based on their long-term cooperation with parts manufacturers or distributors.

• Transparent Monitoring

When it comes to electronic assembly process, it’s significant yet difficult to monitor your products’ manufacturing stage as it is totally related with your products’ performance and time to market. Full-turnkey PCB assembly allows engineers at each stage to be aware of what they’ve accomplished and to better understand their status for better performance of final products.

Who Can Benefit Most From Our Turnkey PCB Assembly Services?

Now that full turnkey PCB assembly allows PCB designers to make better use of their time to focus more on PCB design, it works perfectly on companies striving for frequent upgrading and refreshing of products. They need to dig into deeper market by providing multiple creative electronic products and they strongly call for a steady and smooth electronic assembly process.

Turnkey printed circuit board assembly is also an ideal electronic assembly solution for small businesses or startup companies that want to bring smaller quantities of assembled PCBs to market without having to invest in or carry an extensive inventory. It also offers a more cost-effective, efficient means of assembling and testing PCB prototypes for new products. In addition, quick-turn PCB assembly service makes sense for any company that needs to receive their circuit boards with the shortest possible lead time.

4 notes

·

View notes