#precisiontools

Text

Fabi Lok Measuring and Control Equipment LLC, a premier provider of cutting-edge measuring and control solutions has now joined TradersFind! They offer a range of top-notch products, including Wika Pressure Gauges, Calibration Services, Fluke Calibrator, and Biohall GlassWare. Their commitment to quality and precision ensures each product meets the highest industry standards, empowering businesses with the best-in-class instruments.

Click here to explore their superior-quality products and specialized services-

https://www.tradersfind.com/seller/fabi-lok-measuring-and-control-equipment-llc

#fabilokllc#measuringequipment#controlsolutions#industrialsupplies#qualityinstruments#precisiontools#wikapressuregauges#calibrationservices#flukecalibrator#biohallglassware#industrialautomation#processcontrol#engineeringtools#manufacturingsupplies#qualityassurance#precisionmeasuring#uaebusiness#uaemanufacturing#uaetrade#uaesuppliers#uaeindustry#uaebrands#tradersfind#b2bportal

1 note

·

View note

Text

With 45 years of experience, we specialize in manufacturing high-quality gear-cutting tools using the latest CNC Machines & Technology.

#GearCuttingTools#CNCManufacturing#QualityAssured#PrecisionTools#GearManufacturing#InnovativeTechnology#GearCutting#HighQualityTools#CNCMachines

0 notes

Text

Mastering Precision: A Guide to Gauges and Measuring Tools

Gauges and measuring tools are essential devices used to assess, compare, and measure various attributes such as length, depth, diameter, thickness, and angles. They are crucial for quality control, precision machining, calibration, and ensuring compliance with standards and specifications. By utilising these tools, professionals can maintain consistency, accuracy, and reliability in their work, thereby enhancing productivity and reducing errors and rework.

0 notes

Text

🌡️ Elevate your precision with the BRANNAN Gilt Dial Max Min Thermometer and Hygrometer! An instrument of accuracy and style. Explore the world of measurements at ANBI Solutions.

Shop Now : https://shorturl.at/ghuvC

#Thermometer#Hygrometer#BRANNAN#Instrumentation#PrecisionTools#TemperatureControl#WeatherMonitoring#ANBISolutions#OnlineShopping#HomeImprovement

1 note

·

View note

Text

Epe Foam Cutting Machine by AlliedTech Machine call @ 0091 9812994212 or whatapp

youtube

#FoamCutting#CircularCuttingMachine#PrecisionTools#FullyAutomatic#InnovationInManufacturing#EfficiencyUnleashed#Youtube

0 notes

Text

Micropipettes vs. Pipettes - Unveiling the Distinctions

In the ever-evolving realm of laboratory equipment, choosing the right tools is paramount for accurate scientific endeavors. Micropipettes and pipettes stand as indispensable instruments, but a profound understanding of their disparities is crucial. In this comprehensive comparison, we delve into the intricacies of these precision tools, unraveling the nuances that set them apart.

Micropipettes:…

View On WordPress

1 note

·

View note

Text

#MedicalSurgery#Otorhinolaryngology#ENTSpecialty#ENTInstruments#SurgicalTools#HealthcarePrecision#MedicalTechnology#PatientCare#ENTProcedures#SurgicalInstruments#NAZMEDSMS#ENTSuppliers#HealthcareQuality#ENTCare#SurgicalMedicalSupplies#PrecisionTools

0 notes

Text

Unleashing Precision and Efficiency: Exploring Electro Discharge Machining (EDM)

In the world of precision manufacturing, the quest for perfection never ceases. As industries demand ever more intricate and precise components, cutting-edge technologies step up to meet the challenge. One such technology that has revolutionized manufacturing is Electro Discharge Machining (EDM). Let’s delve into the captivating world of EDM, unraveling its principles, applications, and how it shapes the future of precision engineering.

1. Demystifying Electro Discharge Machining

Electro Discharge Machining, often abbreviated as EDM, is a non-traditional manufacturing process that relies on electrical discharges to shape and form materials. Unlike conventional machining methods that employ cutting tools, EDM uses a series of controlled electrical discharges to erode material from a workpiece.

Key Components of Electro Discharge Machining:

Workpiece: The material being machined, which can range from metals to ceramics and conductive alloys.

Tool Electrode: Often made of graphite or copper, the tool electrode is used to create the desired shape on the workpiece.

Dielectric Fluid: A non-conductive fluid, typically deionized water, that acts as a medium for electrical discharges and flushes away eroded material.

Power Supply: The power supply generates the electrical discharges, controlling their intensity and duration.

2. How EDM Works

Setup: The workpiece and tool electrode are immersed in the dielectric fluid. The two are carefully positioned with a small gap between them.

Electrical Discharge: A series of short electrical pulses, typically in the range of microseconds, are discharged between the tool electrode and the workpiece.

Erosion: These electrical discharges create intense heat that melts and vaporizes a tiny portion of the workpiece, removing material from the surface.

Dielectric Flushing: The dielectric fluid serves a dual purpose, cooling the workpiece and flushing away the eroded material, ensuring a clean machining process.

Repeat Process: The entire process is repeated thousands or even millions of times, gradually shaping the workpiece to the desired form.

3. Types of Electro Discharge Machining

Wire EDM: Also known as Wire-Cut EDM, this method uses a thin wire electrode to cut through the workpiece. It’s ideal for intricate shapes and tight tolerances.

Sinker EDM: In Sinker EDM, a machined tool electrode creates a cavity in the workpiece. It’s commonly used for mold and die production.

Hole Drilling EDM: This type is designed for producing highly accurate holes in hard materials. It’s essential in industries like aerospace and medical device manufacturing.

Small Hole EDM: Similar to Hole Drilling EDM, this process creates small, deep holes, often for cooling and fluid passages in turbine components.

4. Applications of Electro Discharge Machining

EDM has found its way into numerous industries and applications due to its precision and versatility:

Aerospace: EDM is used to manufacture intricate components like turbine blades, fuel nozzles, and airfoils.

Medical Devices: The medical field relies on EDM for producing surgical instruments, dental tools, and implant components.

Automotive: EDM plays a pivotal role in crafting fuel injection components, gears, and transmission parts.

Electronics: EDM is crucial for manufacturing microelectronic components and fine-pitch connectors.

Tool and Die Making: EDM is the go-to method for producing complex molds and dies for plastic injection and metal stamping.

5. Advantages of Electro Discharge Machining

The adoption of EDM comes with a myriad of advantages that make it indispensable for precision manufacturing:

Precision: EDM can achieve intricate, micron-level details and tight tolerances that conventional machining processes struggle to match.

Material Versatility: It can be used on a wide range of materials, including those that are hard, brittle, or difficult to machine with conventional methods.

No Contact Cutting: Since there is no direct contact between the tool and the workpiece, there’s minimal risk of tool wear or deformation.

Complex Geometry: EDM excels in machining complex and three-dimensional shapes.

Minimal Heat-Affected Zone: The controlled erosion process generates minimal heat, making it suitable for materials that can’t withstand high temperatures.

6. Challenges and Considerations in EDM

Slow Material Removal: EDM is a slower process compared to conventional machining methods, making it less suitable for high-volume production.

Tool Wear: Despite minimal wear, tool electrodes in EDM do wear out over time and need periodic replacement.

Cost: EDM can be costlier than traditional machining, especially for simple or high-volume parts.

Post-Machining Processes: Some components may require additional finishing processes to achieve the desired surface finish.

7. The Future of Electro Discharge Machining

As technology continues to advance, so does EDM. Here are some trends that are shaping the future of EDM:

Automation: The integration of automation, robotics, and CNC technology is streamlining the EDM process.

3D Printing and EDM Hybridization: Combining 3D printing with EDM allows for rapid prototyping and complex part production.

Nanotechnology Applications: EDM is venturing into the world of nanotechnology, enabling the manufacturing of minuscule components.

Environmental Sustainability: Efforts are being made to reduce the environmental impact of EDM through eco-friendly dielectric fluids and waste management.

Conclusion

Electro Discharge Machining is the unsung hero in precision manufacturing, enabling the creation of intricate and challenging components across a multitude of industries. Whether it’s crafting aerospace components, medical devices, or intricate molds, EDM excels in delivering unparalleled precision. As technology continues to advance, EDM will only become more versatile and sustainable, opening up new possibilities in manufacturing and reshaping the future of precision engineering. It’s a testament to human innovation and our unceasing quest for perfection in the world of manufacturing.

Also Read: Revolutionizing Business Success: Unveiling the Benefits of Vending Machines

0 notes

Text

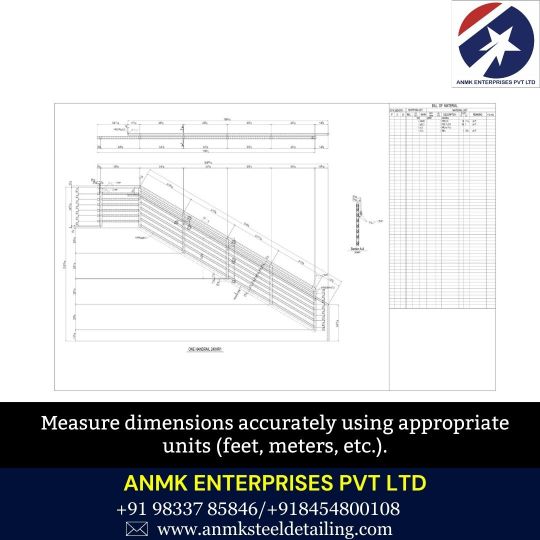

"At ANMK Enterprise PVT. LTD., we don't just measure dimensions; we engineer precision with the perfect units!"

@anmksteeldetailing

@cpwworld

Tumblr

Twitter

instagram

Instagram

LinkedIn

#ANMKEnterprise#DimensionMeasurement#AccuracyMatters#UnitsOfMeasurement#PrecisionTools#QualityControl#industrialmeasurement#Instagram

0 notes

Text

0 notes

Text

Aviation Drilling Tools: Precision and Safety in the Skies

One of the primary considerations in aviation drilling tools is precision. The aerospace industry demands extremely tight tolerances to ensure structural integrity and aerodynamic efficiency. Every hole drilled must be precise, both in terms of its location and dimensions. Any deviation from the required specifications can have significant consequences, affecting the aircraft’s performance and safety. These drilling tools are engineered to deliver high precision, minimising any margin of error.

0 notes

Text

Horizontal Foam Cutting Machine ||Horizontal Foam Cutting Machine Mastery +91- 9812994212

youtube

#FoamCutting#PrecisionTools#Craftsmanship#Upholstery#Packaging#Innovation#Efficiency#CreativeProcess#CuttingEdgeTechnology#Youtube

0 notes

Text

Crafting Fine Woodwork: The Art of Using Precision Tools

Introduction

Crafting fine woodwork is a skilled artform that requires patience, precision, and an innate understanding of the beauty of wood. As a woodworker myself, I have always been fascinated by the intricate craftsmanship and attention to detail that goes into creating a stunning piece of furniture or a delicate wooden sculpture. In this article, I will delve into the world of precision woodworking tools and explore their crucial role in bringing these masterpieces to life.

The beauty of crafting fine woodwork

Wood, with its natural grains and warm tones, has an undeniable allure that draws us in. When carefully shaped and polished, it can transform into something truly extraordinary. Precision tools play a vital role in enhancing this natural beauty, allowing woodworkers to carve intricate patterns, create smooth finishes, and bring out the stunning visual appeal of the material.

Exploring the artistry behind precision woodworking

Precision woodworking is not merely about cutting and shaping wood; it is an artform that requires a deep understanding of the material and an eye for aesthetics. Working with precision tools allows woodworkers like myself to push the boundaries of creativity, experimenting with different techniques and designs to produce unique and extraordinary pieces.

Importance of using precision tools

The use of precision tools cannot be overstated in the world of fine woodwork. These tools enable us to achieve the highest level of accuracy and detail in our craft. Whether it is a chisel for intricate carvings, a plane for smoothing surfaces, or a miter saw for precise angles, each tool has its specific role in ensuring the final masterpiece meets our exacting standards.

Crafting fine woodwork requires more than just skill; it requires the right tools. Precision tools are the backbone of this artform, allowing woodworkers to transform a simple piece of wood into a work of art. In the following sections, we will explore some of the essential precision tools used in this craft and understand how they contribute to the creation of exceptional woodwork.

Crafting Fine Woodwork: The Art of Using Precision Tools

Choosing the Right Precision Woodworking Tools

When it comes to crafting fine woodwork, selecting the right precision tools is crucial. These tools can make a significant difference in the quality of your finished project. It is essential to understand the different types of precision woodworking tools available in the market. From hand planes to chisels, each tool serves a specific purpose and contributes to the overall precision of your work.

Understanding the different types of precision woodworking tools

One of the primary tools you will need is a hand plane. This tool allows you to shape and smooth the surface of the wood accurately. Additionally, chisels are essential for creating intricate details and making precise cuts. A good set of chisels with various sizes and cutting edges will give you the versatility needed for intricate woodworking projects.

Factors to consider when selecting precision tools

When choosing precision tools, several factors should be taken into consideration. Firstly, consider the material of the tool. High-quality tools made from durable materials will provide better performance and longevity. Secondly, evaluate the tool’s functionality and features. Look for tools with adjustable settings and comfortable grips to enhance your precision and control during usage.

The role of ergonomics in tool selection

Ergonomics play a vital role in woodworking tool selection. The comfort and ease of use are essential for long hours of woodworking. Look for tools with ergonomic designs, such as contoured handles and balanced weight distribution. These features will reduce fatigue and strain on your hands, allowing you to focus on your craftsmanship.

selecting the right precision woodworking tools is essential for crafting fine woodwork. Understanding the different types of tools available, considering their material and functionality, and prioritizing ergonomics will help you achieve the precision and quality you desire in your woodworking projects. Happy woodworking!

Essential Precision Tools for Fine Woodwork

Crafting fine woodwork requires a mastery of precision tools that enable artisans to create intricate details and flawless finishes. In this article, I will delve into the world of precision woodworking tools, exploring their significance and highlighting their versatility.

Detailed look at hand planes and their purpose

Hand planes are essential tools in achieving smooth and level surfaces. With their sharp blades and adjustable mouths, these tools allow me to shave off thin layers of wood, resulting in a polished and refined finish. From removing rough edges to smoothing out imperfections, hand planes are indispensable in creating a flawless foundation for any woodworking project.

The significance of chisels in creating intricate details

Chisels are my go-to tools for adding intricate details to my woodwork. Whether it’s carving ornate designs or creating crisp edges, these precision tools allow for utmost control and accuracy. With various sizes and shapes available, chisels enable me to bring my artistic vision to life, elevating my projects from ordinary to extraordinary.

Exploring the versatility of routers in precision woodworking

Routers are power tools that play a crucial role in precision woodworking. They allow me to hollow out spaces, create decorative edges, and carve intricate patterns. With the capability to work on both edges and surfaces, routers provide endless possibilities for customization, making them an invaluable addition to any woodworker’s toolbox.

The role of marking and measuring tools

Precision is paramount in woodworking, and marking and measuring tools ensure accuracy in every step of the process. From marking dimensions on wood to determining angles and levels, these tools act as guides, ensuring that each cut and joint is precise and secure. Without them, achieving impeccable craftsmanship would be a daunting task.

precision tools are the backbone of fine woodwork. Hand planes, chisels, routers, and marking and measuring tools are essential in achieving smooth finishes, intricate detailing, and precise cuts. By mastering the art of using these precision tools, woodworkers can unlock endless possibilities in creating stunning and flawless works of art.

Precision Tool Maintenance and Care

Crafting fine woodwork requires the skillful use of precision woodworking tools. These tools are designed to provide accurate and consistent results, allowing woodworkers to create exquisite pieces. However, to ensure their optimal performance, proper maintenance and care are crucial.

Why proper maintenance is crucial for precision tools

Precision tools, such as chisels, planes, and saws, are delicate instruments that rely on meticulous craftsmanship. Any mishandling or neglect could lead to decreased performance or even damage. Regular maintenance ensures that these tools remain in top condition, allowing woodworkers to achieve the desired precision in their work.

Cleaning and lubrication techniques for longer tool life

Regular cleaning of precision woodworking tools is essential to remove dirt, sawdust, and other debris that can accumulate over time. This can be done using a soft cloth or brush. Lubrication is equally important to prevent rust and corrosion. Applying a thin coat of oil or wax to the metal parts of the tools helps maintain their smooth operation and prolongs their lifespan.

Sharpening and honing methods for consistent performance

To achieve consistent results, precision tools must be sharp and properly honed. Regular sharpening ensures that chisels, planes, and saws maintain their keen edge for clean and precise cuts. Honing, on the other hand, removes any burrs or imperfections, further enhancing the tools’ performance. Diamond stones, sharpening guides, or honing jigs can be used for these tasks, depending on personal preference.

By diligently practicing proper maintenance and care techniques, woodworkers can extend the lifespan and optimize the performance of their precision tools, allowing them to create beautiful and intricate woodwork with unmatched precision and craftsmanship.

Techniques for Precision Woodworking

Crafting fine woodwork requires the delicate touch and expertise of a true artist. As a woodworker, I have been honing my craft for many years, working diligently to perfect the art of using precision tools. In this post, I will share some of the essential techniques that I have learned along the way.

Mastering the art of accurate measuring and marking

One of the fundamental skills in woodworking is the ability to measure and mark with precision. From the initial planning stages to the final assembly, accurate measurements are crucial for creating flawless pieces. I always ensure that my measuring tools are of the highest quality, regularly calibrated, and kept in pristine condition. Additionally, using marking gauges and scribing tools allows me to make precise lines and reference points, ensuring that each cut and joint is perfectly aligned.

Proper sawing techniques for precise cuts

A crucial aspect of woodworking is making accurate cuts. Whether it’s a straight or curved line, using the right saw and employing proper technique is key. I meticulously select the appropriate saw for the specific cut I need to make, ensuring that the blade is sharp and properly tensioned. With a steady hand and controlled motions, I am able to achieve clean cuts each time.

Achieving smooth finishes with sanding and planing

To create a seamless finish, sanding and planing are essential steps in the woodworking process. I start with coarse sandpaper or a hand plane to remove any uneven surfaces or imperfections. Gradually, I move to finer grits of sandpaper or adjust the blade of the hand plane for a smoother finish. This attention to detail ensures that each surface is flawlessly smooth and ready for the finishing touches.

Joinery methods for strong and seamless connections

One of the hallmarks of fine woodwork is strong and seamless joinery. Whether it’s a dovetail, mortise and tenon, or finger joint, precision and accuracy are paramount. I take great care in selecting the correct joinery method for each project, ensuring that the joints fit snugly and securely. By using proper techniques and employing precision tools, I am able to create long-lasting and visually appealing connections.

precision woodworking is an art form that requires a mastery of techniques and the use of high-quality tools. By employing accurate measuring and marking, proper sawing techniques, achieving smooth finishes, and employing strong joinery methods, I am able to create fine woodwork that is both aesthetically pleasing and structurally sound. With every project, I continue to refine my skills and learn new techniques that push the boundaries of this ancient craft.

youtube

Safety Measures for Precision Woodworking

Woodworking is a rewarding and creative craft that allows us to transform raw materials into beautiful pieces of art. However, working with precision tools requires a responsible approach to ensure both the quality of our work and our personal safety. In this section, I will discuss the various safety measures that should be taken when using these tools.

Understanding the potential risks and hazards in woodworking

Woodworking involves using sharp tools and powerful machinery, which can pose risks if not handled properly. It is important to be aware of potential hazards such as cutting, nicking, or injuring oneself. Additionally, wood dust can be harmful if inhaled, so proper ventilation is crucial to maintain a healthy work environment.

Personal protective equipment (PPE) for safe woodworking practices

To minimize the risks associated with precision woodworking, it is essential to wear appropriate personal protective equipment (PPE). This includes safety goggles to protect our eyes from flying debris, a dust mask to avoid inhaling harmful particles, and gloves to protect our hands while handling tools.

Safe usage guidelines for precision tools

When using precision woodworking tools, it is vital to follow safe usage guidelines. This includes keeping the work area clean and clutter-free, ensuring the tools are properly sharpened and maintained, and using them only for their intended purposes. Additionally, it is crucial to maintain good posture and use proper body mechanics to avoid strain or injury.

By understanding the potential risks, wearing the appropriate PPE, and following safe usage guidelines, we can ensure a safe and enjoyable experience while crafting fine woodwork. Remember, safety should always be a top priority to protect both yourself and the quality of your work.

Advanced Techniques in Precision Woodworking

When it comes to crafting fine woodwork, mastering the use of precision tools is just the beginning. To truly elevate your skills and create exquisite pieces, it is essential to explore advanced techniques that push the boundaries of traditional woodworking. In this post, I will guide you through three areas where precision woodworking techniques can be taken to the next level: advanced joinery techniques, incorporating intricate inlays and marquetry, and working with curved and sculptural designs.

Exploring Advanced Joinery Techniques

Joinery is the foundation of woodworking, and by mastering advanced techniques, you can elevate the strength, beauty, and longevity of your creations. From dovetail and mortise-and-tenon joints to tongue-and-groove and box joints, there are countless variations to explore. By combining different joint techniques, you can create intricate and unique connections that add both structural integrity and artistic flair to your woodworking projects.

Incorporating Intricate Inlays and Marquetry

Inlays and marquetry are techniques that allow you to add intricate designs and patterns to your wooden surfaces. By carefully cutting and fitting contrasting pieces of wood, metal, or other materials into the surface of your work, you can create stunning visual effects and add refined details. Whether it’s a delicate floral motif, an elaborate geometric pattern, or a custom design, the possibilities for inlays and marquetry are limited only by your imagination.

Working with Curved and Sculptural Designs

Moving beyond traditional straight lines and angles, working with curved and sculptural designs can truly test your precision woodworking skills. From bent laminations and steam bending to carving and shaping, exploring the world of curves unlocks a whole new realm of creativity. Whether it’s crafting a sinuous chair back or sculpting intricate details on a decorative box, mastering the art of working with curves will take your woodworking skills to the next level.

by delving into advanced joinery techniques, incorporating intricate inlays and marquetry, and exploring curved and sculptural designs, you can evolve your precision woodworking skills to create truly remarkable pieces. So, grab your precision tools, unleash your creativity, and embark on a journey of craftsmanship that will leave a lasting impression.

Conclusion

Crafting fine woodwork requires a unique combination of skill and precision. Throughout this article, I have explored the art of using precision tools and how they contribute to the legacy of craftsmanship in woodworking. From appreciating the skill and precision involved in fine woodwork to embracing the artistry of using precision tools, there is much to be learned and admired in this age-old craft.

Appreciating the skill and precision in fine woodwork

Fine woodworking is not just about making functional pieces; it is about creating pieces that are works of art in their own right. Whether it is a beautifully carved chair or an intricately designed dresser, every detail reflects the skill and precision of the woodworker. The use of precision tools enables them to achieve the intricate cuts, seamless joints, and flawless finishes that define fine woodwork.

Continuing the legacy of craftsmanship in woodworking

Woodworking has a rich history that dates back centuries, and today’s woodworkers strive to continue this legacy of craftsmanship. By honing their skills and mastering the use of precision tools, they pay homage to the techniques passed down through generations. Each carefully crafted piece becomes a testament to the dedication and passion of the woodworker.

Embracing the artistry of using precision tools

Precision tools are not only functional instruments but also artistic tools. Woodworkers develop a deep understanding of their tools and the ways they can manipulate wood to create desired shapes and forms. By embracing the artistry of using precision tools, woodworkers elevate their craftsmanship to new levels, pushing the boundaries of what is possible in fine woodwork.

In conclusion, crafting fine woodwork is both a skill and an art, requiring precision and a deep appreciation for the craft. By mastering the use of precision tools and continuing the legacy of craftsmanship, woodworkers create pieces that stand the test of time and inspire awe in anyone who appreciates their beauty.

The article Crafting Fine Woodwork: The Art of Using Precision Tools first appeared on https://www.66thlondon.org.

https://pinkribbonmail.com/crafting-fine-woodwork-the-art-of-using-precision-tools/

0 notes