#predictive maintenance digital twin

Text

Exploring Advanced Solutions: Digital Twin Technology Unveiled

In today's data-driven world, industries are constantly seeking ways to optimize processes, improve efficiency, and predict potential issues. Enter digital twin technology, a revolutionary concept that creates virtual replicas of physical assets, processes, or systems.

These digital twins act as real-time mirrors, ingesting data from sensors, cameras, and other sources to provide a comprehensive view of the physical counterpart. This data can then be analyzed using powerful tools like solar data analytics platform or cloud solutions like Microsoft Azure Digital Twin, allowing for proactive decision-making and significant advancements in various fields.

Here's how digital twin technology is transforming industries:

Predictive Maintenance: Imagine being able to predict equipment failure before it happens! Digital twins continuously monitor the health of physical assets, analyzing sensor data for subtle changes that might indicate an impending problem. This enables predictive maintenance, allowing for timely intervention and preventing costly downtime.

Optimizing Performance: Digital twins provide valuable insights into the performance of physical systems. By analyzing data on factors like energy usage or production output, companies can identify areas for improvement and optimize processes for maximum efficiency.

Enhanced Product Development: Digital twins can be used to create virtual prototypes, allowing engineers to test and refine designs before physical production begins. This reduces development costs, streamlines the process, and leads to better-performing products.

The Rise of Solar Data Analytics Platforms and Digital Twins:

The renewable energy sector is a prime example of how digital twin technology is driving innovation. Solar data analytics platforms, combined with digital twins of solar farms, enable comprehensive monitoring and optimization of solar energy production. By analyzing data on factors like weather conditions, panel tilt, and shading, these platforms can identify underperforming areas and suggest adjustments for maximum energy output.

Unlocking the Potential with Celebal Technologies:

Celebal Technologies is at the forefront of digital twin development, offering cutting-edge solutions for various industries. Our team of experts can help you create a customized digital twin that meets your specific needs, empowering you to unlock the full potential of this transformative technology.

Ready to explore the possibilities of digital twin technology? Contact Celebal Technologies today and see how we can help you achieve operational excellence.

#digital twin technology#solar data analytics platform#azure digital twin solution#predictive maintenance digital twin

0 notes

Text

#artificial intelligence#manufacturing trends#smart home#internet of things#industry 50#extended reality#predictive maintenance#cobots#digital twin#generative ai

0 notes

Link

What is digital twin in predictive maintenance?

Wondering what digital twin in predictive maintenance is? Very well, because you will find the answer to this and other questions in our post. Briefly explaining the definition of the phrase, it is a digital copy of the physical world, specifically of a product, service or process. The two worlds are connected via a virtual and physical link and stored with components and sensors that are integrated into the physical element. Parameters such as simulations of different scenarios, conclusions from system monitoring and data analysis are implemented in the physical world. There are several types of digital twins. One can talk about data-driven, prototyped or domain knowledge-based ones.

Predictive maintenance

A digital twin in predictive maintenance is a strategy that goes hand in hand to improve the performance of machines and increase their uptime. Full control over resources will lead to reliability as well as long-term financial benefits. The combination offers the opportunity to simulate behaviour and test solutions for problems that have not previously occurred.

0 notes

Text

Digital Twin Market Size 2023-2030: ABB, AVEVA Group plc, Dassault Systemes

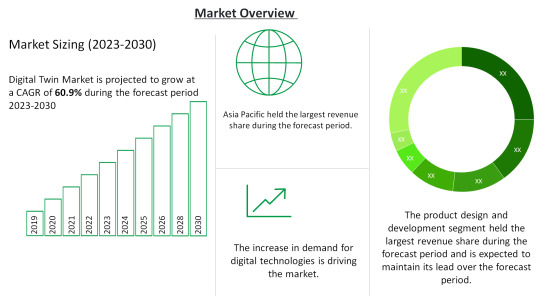

Digital Twin Market by Power Source (Battery-Powered, hardwired with battery backup, Hardwired without battery backup), Type (Photoelectric Smoke Detectors, Ionization Smoke Detectors), Service, Distribution Channel, and region (North America, Europe, Asia-Pacific, Middle East, and Africa and South America). The global Digital Twin Market size is 11.12 billion USD in 2022 and is projected to reach a CAGR of 60.9% from 2023-2030.

Click Here For a Free Sample + Related Graphs of the Report at: https://www.delvens.com/get-free-sample/digital-twin-market-trends-forecast-till-2030

Digital twin technology has allowed businesses in end-use industries to generate digital equivalents of objects and systems across the product lifecycle. The potential use cases of digital twin technology have expanded rapidly over the years, anchored in the increasing trend of integration with internet-of-things (IoT) sensors. Coupled with AI and analytics, the capabilities of digital twins are enabling engineers to carry out simulations before a physical product is developed. As a result, digital twins are being deployed by manufacturing companies to shorten time-to-market. Additionally, digital twin technology is also showing its potential in optimizing maintenance costs and timelines, thus has attracted colossal interest among manufacturing stalwarts, notably in discrete manufacturing.

The shift to interconnected environments across industries is driving the demand for digital twin solutions across the world. Massive adoption of IoT is being witnessed, with over 41 billion connected IoT devices expected to be in use by 2030. For the successful implementation and functioning of IoT, increasing the throughput for every part or “thing” is necessary, which is made possible by digital twin technology. Since the behavior and performance of a system over its lifetime depend on its components, the demand for digital twin technology is increasing across the world for system improvement. The emergence of digitalization in manufacturing is driving the global digital twin market. Manufacturing units across the globe are investing in digitalization strategies to increase their operational efficiency, productivity, and accuracy. These digitalization solutions including digital twin are contributing to an increase in manufacturer responsiveness and agility through changing customer demands and market conditions.

On the other hand, there has been a wide implementation of digital technologies like artificial intelligence, IoT, clog, and big data which is increasing across the business units. The market solutions help in the integration of IoT sensors and technologies that help in the virtualization of the physical twin. The connectivity is growing and so are the associated risks like security, data protection, and regulations, alongside compliance.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Delvens Industry Expert’s Standpoint

The use of solutions like digital twins is predicted to be fueled by the rapid uptake of 3D printing technology, rising demand for digital twins in the healthcare and pharmaceutical sectors, and the growing tendency for IoT solution adoption across multiple industries. With pre-analysis of the actual product, while it is still in the creation stage, digital twins technology helps to improve physical product design across the full product lifetime. Technology like digital twins can be of huge help to doctors and surgeons in the near future and hence, the market is expected to grow.

Market Portfolio

Key Findings

The enterprise segment is further segmented into Large Enterprises and Small & Medium Enterprises. Small & Medium Enterprises are expected to dominate the market during the forecast period. It is further expected to grow at the highest CAGR from 2023 to 2030.

The industry segment is further segmented into Automotive & Transportation, Energy & Utilities, Infrastructure, Healthcare, Aerospace, Oil & Gas, Telecommunications, Agriculture, Retail, and Other Industries. The automotive & transportation industry is expected to account for the largest share of the digital twin market during the forecast period. The growth can be attributed to the increasing usage of digital twins for designing, simulation, MRO (maintenance, repair, and overhaul), production, and after-service.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Regional Analysis

North America to Dominate the Market

North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

North America has an established ecosystem for digital twin practices and the presence of large automotive & transportation, aerospace, chemical, energy & utilities, and food & beverage companies in the US. These industries are replacing legacy systems with advanced solutions to improve performance efficiency and reduce overall operational costs, resulting in the growth of the digital twin technology market in this region.

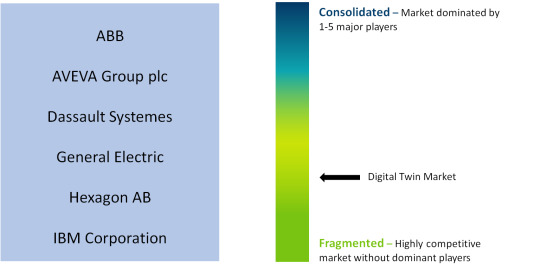

Competitive Landscape

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

Microsoft

Siemens

ANSYS

PTC

IBM

Recent Developments

In April 2022, GE Research (US) and GE Renewable Energy (France), subsidiaries of GE, collaborated and developed a cutting-edge artificial intelligence (AI)/machine learning (ML) technology that has the potential to save the worldwide wind industry billions of dollars in logistical expenses over the next decade. GE’s AI/ML tool uses a digital twin of the wind turbine logistics process to accurately predict and streamline logistics costs. Based on the current industry growth forecasts, AI/ML might enable a 10% decrease in logistics costs, representing a global cost saving to the wind sector of up to USD 2.6 billion annually by 2030.

In March 2022, Microsoft announced a strategic partnership with Newcrest. The mining business of Newcrest would adopt Azure as its preferred cloud provider globally, as well as work on digital twins and a sustainability data model. Both organizations are working together on projects, including the use of digital twins to improve operational performance and developing a high-impact sustainability data model.

Reasons to Acquire

Increase your understanding of the market for identifying the best and most suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends, and factors

Gain authentic and granular data access for Digital Twin Market so as to understand the trends and the factors involved in changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Direct Purchase of Digital Twin Market Research Report at: https://www.delvens.com/checkout/digital-twin-market-trends-forecast-till-2030

Report Scope

Report FeatureDescriptionsGrowth RateCAGR of 60.9% during the forecasting period, 2023-2030Historical Data2019-2021Forecast Years2023-2030Base Year2022Units ConsideredRevenue in USD million and CAGR from 2023 to 2030Report Segmentationenterprise, platform, application, and region.Report AttributeMarket Revenue Sizing (Global, Regional and Country Level) Company Share Analysis, Market Dynamics, Company ProfilingRegional Level ScopeNorth America, Europe, Asia-Pacific, South America, and Middle East, and AfricaCountry Level ScopeU.S., Japan, Germany, U.K., China, India, Brazil, UAE, and South Africa (50+ Countries Across the Globe)Companies ProfiledABB; AVEVA Group plc; Dassault Systems; General Electric; Hexagon AB; IBM Corp.; SAP.Available CustomizationIn addition to the market data for Digital Twin Market, Delvens offers client-centric reports and customized according to the company’s specific demand and requirement.

TABLE OF CONTENTS

Large Enterprises

Small & Medium Enterprises

Product Design & Development

Predictive Maintenance

Business Optimization

Performance Monitoring

Inventory Management

Other Applications

Automotive & Transportation

Energy & Utilities

Infrastructure

Healthcare

Aerospace

Oil & Gas

Telecommunications

Agriculture

Retail

Other Industries.

Asia Pacific

North America

Europe

South America

Middle East & Africa

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

[email protected]

WEBSITE: https://delvens.com/

#Digital Twin Market#Digital Twin#Digital Twin Market Size#Digital Twin Market Share#Semiconductors & Electronics

2 notes

·

View notes

Photo

Illustration Photo: Sugarcane is one of the most efficient producers of biomass of all plant species and can be used as a renewable fuel. The new variety Ho 06-9002 has a high fiber content, excellent regrowth ability over 4 to 5 years, is cold-tolerant, has a high stalk population, and produces excellent biomass yields. (credits: USDA Media by Lance Cheung / Public domain)

Repsol Entrepreneurs Fund for Startups in the Energy Transition

At the Repsol Foundation, we have been supporting entrepreneurship and entrepreneurs for more than 10 years through Fondo de Emprendedores, our accelerator for start-ups that provide technological solutions to meet the challenges of the Energy Transition. This is a perfect program for start-ups in the testing phase with real customers, or that will reach this phase in 1–2 years.

This program aims to accelerate startups working in any of the following:

SCOPE 1: LOW-CARBON ENERGY TECHNOLOGIES AND CIRCULAR ECONOMY

1. Recycling and treatment technologies: conversion of biomass, new processes for converting waste into chemical products

2. Biogas production, upgrading, transport and end use technologies

3. Low environmental impact H2 renewable solutions for production, blending, transport and storage

4. Advanced biofuel production and conversion technologies (liquefaction or de novo, gasification) and synthetic fuels for road, maritime and aviation transport

5. Processing of chemicals and other organic materials for circular economy

6. Low-carbon lubricants for industrial and automotive applications

7. CO2 Capture, Use and/or Storage Technologies. CO2 Direct Air Capture: new absorbent materials and efficient process design

8. COX, H2 conversion processes to Hydrocarbons

9. Low carbon technologies for Oil & Gas operations, including energy efficiency, GHG direct emissions (scopes 1 and 2), Methane emissions, CCS or Geothermal.

10. Other technologies related to this scope’s heading

SCOPE 2: BIOTECHNOLOGY AND NANOTECHNOLOGY FOR SUSTAINABLE SOLUTIONS

1. Bio conversion of organic material to chemicals. Biorefinery, biofactory

2. Protein engineering, development of biocatalysts and enzymes

3. Gene editing technologies and applications in energy and materials

4. Plastic biodegradation technologies

5. Biosensors design, production and end use.

6. Anti-corrosive, anti-bacterial, thermal nanocoating for pipelines and infrastructures

7. Organic and inorganic membrane technologies, including new materials

8. Improvement of the properties of fuels, lubricants and chemicals

9. Other technologies related to this scope’s heading

SCOPE 3: PRODUCTS AND SERVICES BASED ON ENERGY MANAGEMENT AND RENEWABLES

1. Intelligent energy management systems

2. New batteries and fuel cells technologies

3. Distributed energy solutions

4. Energy conversion and storage systems

5. Advanced mobility solutions

6. Renewable energy generation, maintenance and control and commercialization.

7. Other technologies related to this scope’s heading

SCOPE 4: DIGITAL TECHNOLOGIES FOR THE ENERGY SECTOR

1. Artificial intelligence applied to process optimization and energy efficiency.

2. Digital twins and intelligent interfaces for process control

3. Digital technologies for predictive and prescriptive maintenance

4. Smart trading for the energy marketplace

5. Computational chemistry tools for energy applications

6. Remote sensing, IoT and robotic solutions for industrial assets and environment

7. Quantum computing applications in energy sector

8. Other technologies related to this scope’s heading

SCOPE 5: NATURAL SOLUTIONS FOR CARBON FOOTPRINT REDUCTION

1. Reforestation and afforestation technologies for resilient CO2 absorption sinks

2. Advanced monitoring, reporting and verification technologies in CO2 absorption

3. Digital technologies applied to carbon markets value chain

4. Technologies for ESG (Environmental, Social and Governance) project certification

5. Other technologies related to this scope’s heading

Startups admitted to the Program will receive during the acceleration period a contribution of FIVE THOUSAND EUROS (€ 5,000) per month as ordinary funds.

Additionally, admitted Startups may request up to a maximum of FORTY THOUSAND EUROS (€ 40,000) per year as extraordinary funds for strategic expenses to achieve the milestones of the Work Plan (as defined in section 4.4), mainly to complete the pilot test.

The disbursement of this additional contribution will be subject to the exclusive decision of Fundación Repsol.

Application Deadline: March 10, 2023

Check more https://adalidda.com/posts/c4qmPwNwToZAAbf2L/repsol-entrepreneurs-fund-for-startups-in-the-energy/call

2 notes

·

View notes

Text

Ports and Terminal Operations Market Outlook Report 2024-2031: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Ports and Terminal Operations Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Ports and Terminal Operations Market showcased a significant presence, boasting a valuation of US$ 4.5 trillion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-ports-and-terminal-operations-market/

Projected Growth: Projections suggest that the Ports and Terminal Operations Market will continue its upward trajectory, with a projected value of US$ 7.8 trillion by 2031. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 6.7%, reflecting a steady and robust growth rate for the Ports and Terminal Operations Market over the coming years.

Technology Adoption:

The ports and terminal operations market is experiencing significant technology adoption to enhance efficiency, security, and environmental sustainability. Technologies such as automated guided vehicles (AGVs), remote-controlled cranes, and real-time tracking systems are becoming standard. The implementation of blockchain technology for secure and transparent transactions, along with the integration of IoT devices for monitoring and maintenance, is also on the rise. Furthermore, advanced data analytics and artificial intelligence (AI) are being utilized to optimize logistics, predict maintenance needs, and improve overall operational efficiency.

Application Diversity:

Ports and terminal operations encompass a wide range of applications, including container handling, bulk cargo management, passenger services, and logistics coordination. These operations are vital for global trade, ensuring the smooth movement of goods across international borders. Specialized terminals, such as those for oil, gas, and liquefied natural gas (LNG), cater to specific industries, while multi-purpose terminals handle a variety of cargo types. Additionally, cruise terminals serve the tourism sector, highlighting the diverse applications within this market.

Consumer Preferences:

Stakeholders in the ports and terminal operations market, including shipping companies, logistics providers, and end-users, are increasingly demanding higher efficiency, reliability, and transparency. There is a growing preference for ports that offer advanced technological infrastructure to facilitate faster and more secure handling of goods. Environmental sustainability is also a key consideration, with consumers favoring operations that implement green practices and technologies to reduce carbon footprints. Additionally, enhanced safety measures and robust security protocols are becoming essential requirements.

Technological Advancements:

Technological advancements are revolutionizing ports and terminal operations. Automation is at the forefront, with the adoption of autonomous vehicles and automated stacking cranes reducing the need for human intervention and increasing operational speed. The use of AI and machine learning algorithms helps in predictive maintenance, minimizing downtime and enhancing productivity. Blockchain technology is being used to streamline documentation and increase transparency in the supply chain. Furthermore, digital twins—virtual replicas of physical assets—are being employed to simulate and optimize port operations in real time.

Market Competition:

The ports and terminal operations market is highly competitive, with major global players such as DP World, APM Terminals, and Hutchison Port Holdings competing for market share. Competitive factors include technological innovation, strategic geographical locations, service quality, and operational efficiency. Companies are investing heavily in upgrading their infrastructure and adopting cutting-edge technologies to stay ahead. Strategic alliances and partnerships with shipping lines and logistics companies are also common, as they enhance service offerings and expand market reach.

Environmental Considerations:

Environmental considerations are increasingly influencing the ports and terminal operations market. There is a strong focus on reducing greenhouse gas emissions through the adoption of cleaner energy sources, such as electrification of port equipment and the use of renewable energy. Ports are implementing green technologies, like shore power, which allows ships to plug into the electrical grid while docked, reducing the need to run auxiliary engines. Waste management practices are also being enhanced to minimize pollution, and efforts are being made to protect marine ecosystems. Compliance with international environmental standards and certifications is becoming a priority for port operators aiming to demonstrate their commitment to sustainability.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

APM Terminals,

DP World, Hutchison Ports,

PSA International,

China Merchants Port Holdings,

COSCO Shipping Ports,

MSC Mediterranean Shipping Company

The research report provides a comprehensive analysis of the Ports and Terminal Operations Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-ports-and-terminal-operations-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Innovative Technologies Enhancing Operational Safety in Process Safety Management

Introduction

The innovative technologies have revolutionized PSM practices, enhancing the effectiveness of methodologies such as Hazard and Operability Studies (HAZOP), Bowtie Analysis, Safety Cases, and Hazard Identification (HAZID). This essay explores how these advanced technologies are being applied to improve operational safety in PSM.

Innovative Technologies in PSM

Digital Twins

Digital twin technology creates a virtual replica of physical assets and processes. This dynamic model allows for real-time monitoring and simulation of process conditions, providing insights into potential hazards and operational efficiencies.

Enhancing PSM with Digital Twins:

HAZOP: Digital twins facilitate more detailed and accurate HAZOP studies by allowing teams to simulate process deviations and their impacts in a virtual environment.

Bowtie Analysis: They enable the continuous monitoring of the effectiveness of barriers identified in Bowtie Analysis, ensuring real-time risk management.

Safety Cases: Digital twins provide comprehensive, real-time data that can be incorporated into Safety Cases, enhancing their validity and relevance.

HAZID: They support proactive hazard identification by simulating different operational scenarios and identifying potential hazards before they materialize.

For example, a chemical plant using digital twins can simulate the effects of temperature variations in reactors, helping to predict and prevent hazardous situations.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies analyze vast amounts of data to identify patterns and predict potential failures, enhancing decision-making processes in PSM.

Enhancing PSM with AI and ML:

HAZOP: AI can process historical HAZOP data to identify recurring issues and suggest improvements, making HAZOP sessions more efficient and comprehensive.

Bowtie Analysis: ML algorithms can assess the effectiveness of preventive and mitigative barriers in Bowtie diagrams, providing insights into potential improvements.

Safety Cases: AI-driven analytics can enhance Safety Cases by providing predictive insights and risk assessments based on real-time and historical data.

HAZID: AI tools can assist in identifying hazards by analyzing large datasets from various sources, improving the thoroughness and accuracy of HAZID sessions.

For instance, AI can predict equipment failures by analyzing maintenance logs and operational data, allowing for timely interventions and reducing the risk of accidents.

Internet of Things (IoT) and Smart Sensors

IoT technology connects devices and systems, enabling real-time data collection and analysis through smart sensors. This connectivity enhances monitoring and control capabilities within PSM.

Enhancing PSM with IoT and Smart Sensors:

HAZOP: Smart sensors provide continuous data that can be used to validate and refine HAZOP findings, ensuring that identified risks are accurately monitored and managed.

Bowtie Analysis: IoT devices can monitor the condition of safety barriers in real-time, ensuring their effectiveness in preventing or mitigating hazards.

Safety Cases: Continuous data from IoT sensors can be integrated into Safety Cases, providing ongoing evidence of safe operation and compliance.

HAZID: Real-time data from IoT sensors helps identify new hazards and monitor existing ones, supporting proactive risk management.

For example, IoT-enabled gas detectors in a chemical plant can continuously monitor for leaks, alerting operators immediately to potential risks.

Enhancing PSM with AR and VR:

HAZOP: VR simulations can be used during HAZOP sessions to visualize process deviations and their consequences, improving hazard identification and understanding.

Bowtie Analysis: AR can overlay critical safety information onto real-world views, helping operators understand and manage the barriers identified in Bowtie Analysis.

Safety Cases: VR-based training modules can be included in Safety Cases to demonstrate the competency and preparedness of the workforce.

HAZID: AR tools can assist in hazard identification by providing interactive visualizations of processes and potential hazards, enhancing the accuracy and effectiveness of HAZID sessions.

For instance, VR training modules can simulate emergency scenarios, allowing workers to practice responses in a safe, controlled environment.

Conclusion

These technologies improve the accuracy and efficiency of HAZOP, Bowtie Analysis, Safety Cases, and HAZID, leading to better hazard identification, risk assessment, and mitigation strategies. By leveraging these advanced tools, industries can create safer operational environments, protect their workforce, and ensure regulatory compliance.

0 notes

Text

The Future Of BIM Consulting: Emerging Trends And Technologies

Building Information Modeling (BIM) is transforming the way we approach architecture, engineering, and construction. The future of BIM consulting hinges on leveraging these advancements, focusing specifically on enhancing project execution and overall efficiency. This article looks into the transformative developments that are shaping the future of BIM consulting, offering insights into how these advancements will redefine the architecture, engineering, and construction (AEC) industries.

Enhanced Pre-Bid Estimation Accuracy

In the competitive realm of construction projects, the accuracy of pre-bid estimations can make or break the financial outcomes for firms. As projects grow in complexity, so does the need for precise cost forecasting. BIM technologies have evolved to meet this challenge, integrating data-rich models that offer a more comprehensive view of the project from its inception.

Key Considerations:

Detailing and Specification: Accurate BIM models include detailed representations of the components required, ensuring that every element, from material costs to labor estimates, is considered.

Scenario Analysis: Advanced BIM tools allow for multiple cost scenarios to be tested, providing a safety net for unexpected changes in project specifications or market conditions.

Integration with Historical Data: Leveraging data from previous projects helps refine the accuracy of cost estimations, making BIM not just a design tool but a financial forecasting asset.

Investing in high-quality BIM software enhances pre-bid accuracy and BIM architectural modeling services, thereby reducing the risk of cost overruns and ensuring project profitability. This precision is a critical asset for architects, engineers, and contractors aiming to align project bids with actual costs and timelines.

BIM Integration with Compliance and Standard

The landscape of BIM compliance is dotted with various international standards, with ISO 19650 at the forefront. This standard provides a framework for managing information over the built asset’s lifecycle, ensuring consistency and facilitating global project collaboration.

Dos and Don’ts:

Do: Ensure all project stakeholders are familiar with BIM compliance requirements as per ISO 19650.

Don’t: Overlook local regulations that might impose additional requirements or modifications to the standard practices.

Trends to watch:

Increasing Global Adoption: Countries like the UK, Norway, and Singapore are leading the way in mandating BIM for public sector projects, setting a precedent that others are likely to follow.

Collaborative Frameworks: As standards evolve, BIM is becoming more about collaborative practices, not just technical compliance.

Expert Tip: Stay proactive about compliance. Engaging a BIM consultant who specializes in international standards can mitigate the risks of non-compliance penalties and streamline project execution across borders.

The Rise of Digital Twins

Digital twins represent one of the most groundbreaking advancements in BIM technology. These dynamic, virtual replicas of physical buildings or infrastructure serve as a real-time simulation tool that mirrors the real-world environment.

Things to Consider:

Lifecycle Management: Digital twins are not just for the design phase but extend their utility across the lifecycle of the asset, aiding in operations, maintenance, and even decommissioning.

Data Integration: Successful digital twins integrate IoT, AI, and real-time data analytics to provide actionable insights that can dramatically improve operational efficiency and asset management.

Transformative Impacts:

Predictive Maintenance: By anticipating maintenance needs before they become critical, digital twins can save substantial costs and extend the lifespan of assets.

Enhanced Decision Making: With comprehensive analytics, stakeholders can make informed decisions that align with both immediate needs and long-term strategic goals.

Advanced Resource Management

Effective resource management is critical to the success of any construction project. BIM technology elevates this process by enabling more accurate tracking and utilization of materials, machinery, and manpower, reducing both waste and overhead costs.

Points to Ponder:

Material Usage: BIM helps in precise calculation of materials needed, which minimizes waste and ensures that purchasing is streamlined and cost-effective.

Workforce Allocation: By providing a clear overview of the project timeline and tasks, BIM allows for optimal scheduling of labor, ensuring that manpower is used efficiently across the project.

Current Trends:

Sustainability Practices: There’s a growing trend to integrate eco-friendly and sustainable practices through BIM by optimizing resource usage which not only supports environmental goals but also enhances project sustainability.

Real-Time Reassessment: As projects progress, BIM platforms can be used to reassess resource needs in real-time, allowing for adjustments that keep the project on track and within budget.

Pro Tip from SmartCADD: Always update your BIM model to reflect real-time changes and data. This practice helps maintain accuracy in resource management, ensuring that the project adapts to changes swiftly and efficiently.

BIM for Infrastructure Beyond Buildings

Traditionally associated with building construction, BIM is now making significant inroads into infrastructure projects such as highways, bridges, and tunnels. This expansion is enhancing the way these projects are planned, executed, and maintained.

Essential Considerations:

Complexity of Projects: Infrastructure projects involve complex integrations of various systems and a higher degree of coordination between diverse teams.

Regulatory Compliance: Infrastructure projects often face strict regulatory requirements, making the detailed documentation and revision capabilities of BIM crucial for compliance and reporting.

Transformative Outcomes:

Enhanced Bim Coordination Services: With BIM, the ability to manage and visualize every aspect of an infrastructure project improves, leading to better coordination among stakeholders.

Improved Risk Management: The predictive tools within BIM help identify potential issues before they become problems, reducing risks associated with infrastructure development.

SmartCADD’s Vision with BIM Consulting

At SmartCADD, we are committed to utilizing these emerging BIM trends to deliver superior BIM consulting services that not only meet but exceed our client expectations. By integrating these cutting-edge practices, we aim to lead in innovation and efficiency, providing solutions that embody precision and sustainability. As we look to the future, SmartCADD is dedicated to redefining industry standards and enhancing every project with the most advanced BIM technologies available.

Source URL:

0 notes

Text

Innovations Unveiled At Machine Shop Equipment Auctions

Machine shop equipment auctions have become hotspots for showcasing cutting-edge innovations, offering a glimpse into the future of manufacturing and machining. These auctions, traditionally venues for acquiring second-hand equipment, now also highlight the latest advancements in technology, materials, and processes.

Here are some of the key innovations unveiled at recent machine shop equipment auctions:

Advanced CNC Machines

CNC (Computer Numerical Control) machines are a staple in modern manufacturing, and recent auctions have displayed state-of-the-art models featuring significant enhancements:

Multi-axis Machining: Newer CNC machines with 5-axis or even 7-axis capabilities allow for more complex and precise manufacturing. These machines can produce intricate parts in a single setup, reducing the need for multiple machines and setups.

Integrated AI and Machine Learning: These systems optimize cutting paths and predict maintenance needs, reducing downtime and increasing efficiency. AI integration also improves quality control by continuously monitoring the production process.

3D Printing and Additive Manufacturing

The rise of 3D printing, particularly in metal additive manufacturing, is a significant innovation showcased at these auctions:

Hybrid Machines: Combining additive and subtractive processes, hybrid machines can print a part and then machine it to precise specifications within the same setup. This integration streamlines production and opens up new possibilities for complex geometries.

New Materials: Advances in materials science have led to the development of new metal powders and composites that offer superior strength, heat resistance, and durability, expanding the applications of 3D printing in industries like aerospace and medical devices.

Robotics and Automation

Automation continues to transform machine shops, and the latest robotic systems were prominently featured:

Collaborative Robots (Cobots): Designed to work alongside human operators, cobots enhance productivity without requiring extensive safety measures. They are used for tasks such as loading/unloading machines, assembly, and quality inspection.

Automated Guided Vehicles (AGVs): These autonomous vehicles transport materials and parts around the shop floor, optimizing workflow and reducing manual handling. Integration with shop floor management software ensures precise and efficient material movement.

Smart Tooling and Sensors

Smart tooling and sensor technologies are pivotal in enhancing machine efficiency and product quality:

Tool Condition Monitoring: Sensors embedded in cutting tools and machines monitor tool wear and performance in real time. This data helps in predicting tool life and scheduling timely maintenance, thereby avoiding unexpected downtime.

Vibration and Thermal Sensors: These sensors track machine conditions and detect anomalies that could indicate mechanical issues, allowing for proactive maintenance and reducing the risk of breakdowns.

IoT and Digital Twin Technology

The Internet of Things (IoT) and digital twin technology are revolutionizing how machine shops operate:

IoT-Enabled Machines: These machines can communicate with each other and with central management systems, providing real-time data on performance, energy consumption, and production metrics. This connectivity enhances decision-making and operational efficiency.

Digital Twins: Creating a digital replica of physical equipment allows for simulation and analysis of performance under various conditions. This technology aids in optimizing processes, planning maintenance, and improving overall productivity.

Energy Efficiency and Sustainability

Innovations aimed at reducing the environmental footprint of machine shops were also highlighted:

Energy-Efficient Machines: Newer machines are designed to consume less power while maintaining high performance. Technologies such as regenerative drives and energy-efficient motors are becoming standard.

Recycling and Waste Management: Advanced systems for recycling metal shavings and waste materials were showcased, highlighting efforts to create more sustainable manufacturing processes.

In conclusion, machine shop equipment auctions are now pivotal in introducing and disseminating innovative technologies that shape the future of manufacturing. These advancements not only enhance productivity and precision but also pave the way for more sustainable and efficient production practices.

0 notes

Text

Brazil Industry 4.0 Market - Forecast(2024 - 2030)

Brazil Industry 4.0 Market Overview

Brazil Industry 4.0 Market size is forecasted to reach $6230.29 million by 2027, growing at a CAGR of 10.91% during the forecast period from 2022-2027. Industry 4. has become vital for all organizations owing to paradigm shift towards real time or near real-time process monitoring in the industrial sector. The growing emphasis towards high-speed machine-to-machine (M2M) communication on the factory floor coupled with the increasing investment in plant digitalization is set to drive the Brazil Industry 4.0 Market growth during the forecast period. In addition to this, adoption of various advanced technologies including augmented reality, cloud computing, enterprise resource planning, internet of things, robotics and others; across industry verticals such as oil and gas, transportation, energy, mining, utilities and so on, is set to drive system integration service market growth. Increasing penetration of industry 4.0 across the globe combining artificial intelligence, big data and analytics, 4G, 5G with operational technology as a part of addressing worker safety, optimizing field operations, and boosting maintenance productivity along with process efficiency in industrial environments is considered vital in driving the growth of Brazil industry 4.0 industry.

Report Coverage

The report: “Brazil Industry 4.0 Market Report– Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Brazil Industry 4.0 Market.

By Offerings: Hardware, Software and Services (System Integration Services, Testing & Certification, Maintenance and Operational Services, Consulting and Others).

By Technology: Artificial Intelligence, Machine-to-Machine, Big Data and Analytics, Augmented Reality & Virtual Reality, Autonomous Robots, SCADA, Simulation, Horizontal and vertical System Integration, Cloud Computing, Cyber Security, Internet of Things (IoT), Digital Twin, Advanced human-machine interfaces (HMI), Additive Manufacturing (3D Printing) and Others.

By End-User: General Manufacturing, Transportations & Logistics, Medical & Pharmaceutical, Metal & Mining, Oil & Gas (Upstream, Midstream and Downstream), Automotive & Tire, Aerospace & Defence, Food & Beverage, Electronics & Semiconductors, Power (Power Generation, Power Distribution and Power Transmission), Construction, Agriculture (Seeding and Weeding, Monitoring, Fertilizer Application, Harvesting, Pruning, and Others), Water & Wastewater Treatment, Paper & Pulp, Chemical and Others.

Request Sample

Key Takeaways

Big Data & Analytics held a significant market share in 2021 and is estimated to be the fastest segment during 2022-2027, owing to the shift of Brazil towards Industry 4.0, with industries such as oil, gas, minerals, and agriculture through the adoption of big data & analytics.

The market of Brazil Industry 4.0 is estimated to witness a significant upsurge during the forecast period, owing to the increasing adoption of advanced technologies such as predictive maintenance, data analytics, digital twins, artificial intelligence and others in the Oil & Gas sector.

This industry is consolidated with top market players including Iastech Automação De Sistemas Ltda, Simatec Tecnologia em Automacao Ltda, Techplus Automacao, Automind Automação, Greylogix Brasil among others.

Brazil Industry 4.0 Market Segment Analysis - by Offerings

Brazil's Industry 4.0 market is segmented into Hardware, Software and Services, based on offerings. According to the Brazil Industry 4.0 Market report of IndustyrARC, the Hardware segment held the major market share in 2021 of $1659.71 million and is estimated to reach $2978.08 million in 2027, with a CAGR of around 10.19% during the forecast period 2022-2027. The growth of this segment is mainly driven by the increasing adoption of industry 4.0 across industries and a growing inclination toward digitalization along with increasing investment. Furthermore, Industry standards that achieve higher levels of security to enable connected solutions in the factory are driving the need for hardware security. This is expected to boost market growth. The increasing popularity and high penetration rate among the end-user industries play a major role in offering incentives to the market players to take various strategic steps. For instance, in February 2021, ABB introduced the SWIFTI cobot, which combines a payload of 4 kg and a reach of up to 580 mm with the advantages of safe collaborative operation and convenience of use. This will offer up new opportunities for increased efficiency in a variety of sectors ranging from manufacturing to logistics and beyond, allowing more organizations to embrace automation. Such developments fuel the growth rate Brazil Industry 4.0 Market in the forecast period 2022-2027.

Inquiry Before Buying

Brazil Industry 4.0 Market Segment Analysis - by Technology

By Technology, the Brazil Industry 4.0 Market is segmented into Artificial Intelligence, Machine-to-Machine, Big Data and Analytics, Augmented Reality & Virtual Reality, Autonomous Robots, SCADA, Simulation, Horizontal and vertical System Integration, Cloud Computing, Cyber Security, Internet of Things (IoT), Digital Twin, Advanced human-machine interfaces (HMI), Additive Manufacturing (3D Printing) and Others. Big Data and Analytics segment held the major market share in 2021 of $474.28 million and is estimated to reach $834.86 million in 2027, with a CAGR of around 9.84% during the forecast period. Brazil is gradually moving toward Industry 4.0, with industries such as oil, gas, minerals, and agriculture expected to be early adopters of Big Data services. According to Software.org, 21 to 24 percent of Brazilian small and medium-sized businesses believe digitization will aid in the development of more personalized products and services. Such high penetration of advanced technologies and inclination towards digitalization will give incentives to the market players to take various steps to expand their business. Hence, the above-mentioned factors will drive the growth of this market during 2022-2027.

Brazil Industry 4.0 Market Segment Analysis – by End-user

Based on end-user, the market is segmented into General Manufacturing, Transportations & Logistics, Medical & Pharmaceutical, Metal & Mining, Oil & Gas, Automotive & Tire, Aerospace & Defence, Food & Beverage, Electronics & Semiconductors, Power, Construction, Agriculture, Water & Wastewater Treatment, Paper & Pulp, Chemical and Others. The metal and Mining segment held the major Brazil Industry 4.0 Market share in 2021 of $434.20 million and is estimated to reach $831.47 million in 2027, with a CAGR of around 11.40% during the forecast period. The value of digital technology in the mining industry is growing as companies look for ways to reduce geological uncertainty, market volatility, and operational hazards. Big data analytics and the internet of things (IoT) offer a unique opportunity to rethink existing processes and create new value. The metal and mining industry is now involved in connecting previously unconnected operational technology (OT), devices and systems, and information technology (IT) for data exchange and operational efficiency via IT/OT convergence, integrated sales and operational planning, agile supply chain, digital EHS monitoring, and performance parameters. According to the Ibram association, the mining industry in Brazil will invest $40.4 billion by 2026. This will help to improve the mining business in Brazil and, eventually, the Industry 4.0 market in Brazil. Such factors will drive the growth of this market.

Schedule a Call

Brazil Industry 4.0 Market Drivers

Increasing proliferation of technologies like predictive maintenance, data analytics, digital twins, artificial intelligence and others in Oil & Gas sector fuels the growth:

Over the last few years, the oil & gas sector is undergoing a transition as leading players in this industry are adopting advanced technology to reshape their operating landscape and reap the benefits of improved productivity, higher efficiency, and increased cost savings. In order to decarbonize and optimize operations, the Brazilian O&G industry has started to take advantage of advanced technologies including cloud services, digital twins Internet of things (IoT) and Artificial Intelligence (AI), among other digital services. Apart from that, the adoption of video surveillance complemented by advanced analytics and machine learning to improve operational efficiency as well as health and safety in the O&G sector can be considered vital in driving the Brazil Industry 4.0 Market growth forward. For instance, in November 2021, Brazil’s Petrobras, the leading oil, natural gas and derivatives exploration, production and distribution company, announced the plan of investing $68 Bn from 2022-2026 to boost oil production in the subsea pre-salt area by leveraging the advanced technologies to fulfill the demand of the customers. Such steps create a positive impact on the growth of this market.

The burgeoning demand for establishing a digital infrastructure in the mining sector is accelerating the growth of this market:

The Brazilian mining industry is opting for technological innovation to remain competitive while driving safety and transparency standards. Mining is of major importance to the Brazilian economy, having more than 3,000 mines spread across the national territory. The Brazilian mining industry is facing significant challenges due to plummeting commodity prices, lessening global demand and increasing safety and security risks. To reduce the effect of such challenges, miners need to improve safety, scale operations, improve operational processes, and enhance production, thereby driving the need for new business models and operating models. Leading mining companies in Brazil are harnessing the high computing power of digital technologies, including cloud-enabled mobility, big data-powered analytics and the industrial Internet of Things (IoT). This in turn drives the growth of this market. Furthermore, the increasing usage of robotics and penetration of automation with assisted and remote-control equipment and autonomous drilling and related process in the mining industry, to deliver safer and more effective mining performance, is fueling the growth of this market. In June 2021, Japan’s ITOCHU Corporation announced signing an MoU with the Brazilian CSN Group with the aim of promoting decarbonization and digital transformation (DX) for Casa de Pedra iron ore mines in Brazil. Such events trigger the growth of this market.

Buy Now

Brazil Industry 4.0 Market Challenge

The lack of investments in digital infrastructure in Brazil is creating hurdles for the market growth

Even though the Brazil Industry 4.0 Market is growing rapidly, but the lack of investment for developing digital infrastructure in Brazil creates challenges for the growth of this market. The implementation of Industry 4.0 in Brazil is still a challenge owing to the lack of investment in IT infrastructure in the country. IT readiness and appropriate telecommunications infrastructure are necessary for Industry 4.0 to thrive across Brazil. The research conducted by CNI shows that the alarming point is that only 33% of companies in Brazil claim that no new investment is needed. Another survey report of CNI states that innovation benefits the production chain and the country, demonstrating impacting results for the companies involved and for the country's economy, but the reality in Brazil is approximately half of the companies are still considered industry 2.0. To shift it from industry 2.0 to industry 4.0, a huge amount of investment is required. Hence, the lack of investment creates challenges for this market.

Brazil Industry 4.0 Industry Outlook

Technology launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Brazil Industry 4.0 Market. In 2021, the market of Brazil Industry 4.0 industry outlook has been fragmented by several companies. The top 10 companies in the Brazil Industry 4.0 include

Iastech Automacao De Sistemas Ltda

Simatec Tecnologia em Automacao Ltda

Techplus Automacao

Automind Automacao

Greylogix Brasil

Icone Tecnologia e Automacao

Automaton Automacao

Company 8

Company 9

Company 10

Recent Developments

In June 2021, Schneider Electric, a global leader in digital transformation and energy management and automation, inaugurated a new industrial automation laboratory in Brooklyn, south of São Paulo which was made in partnership with Westcon Instrumentation Industrial to simulate the industrial internet of things (IIoT) and industry 4.0 applications with augmented reality demonstrations.

In May 2020, Siemens announced its partnership with GreyLogix to produce respirators in-house for use in healthcare facilities in Brazil to help fight the coronavirus. The equipment featured Siemens solutions, with emphasis on the controllers and HMIs of the SIMATIC line and the power supplies of the SITOP line, and at the same time, GreyLogix ensured that the equipment produced followed the necessary medical requirements.

In March 2020, Schneider Electric announced to invest in the Titled High-Performance Machine journey based on Industry 4.0, by providing a series of training and workshops to support machine manufacturers and end users who want to improve performance and productivity and reduce costs in production processes in Brazil.

#Brazil Industry 4.0 Market#Brazil Industry 4.0 Market Share#Brazil Industry 4.0 Market Size#Brazil Industry 4.0 Market Forecast#Brazil Industry 4.0 Market Report#Brazil Industry 4.0 Market Growth

0 notes

Text

Examining the Potential of Digital Twin Technology

Digital twin technology is one breakthrough that stands out in the world of digital innovation because of its capacity for change. Building virtual replicas of real-world objects, procedures, or systems is the basis of this innovative idea. Then, by monitoring, analyzing, and simulating data, these digital twins may be used to provide hitherto unthinkable insights.

Solar data analytics is one exciting use of digital twin technology. Businesses may gain a better understanding of their performance and identify areas for improvement by creating digital twins of solar panels and other equipment. This may result in increased dependability, cost savings, and energy efficiency.

Businesses may leverage digital twin technologies thanks to the stable foundation provided by the Azure Digital Twin Solution. With a comprehensive toolkit for creating, managing, and assessing digital twins, it's now simpler than ever to take advantage of this technology's revolutionary potential.

Another area where digital twin technology is making a significant impact is predictive maintenance. Businesses that build digital twins of their machinery and equipment are able to predict when maintenance is needed before issues arise. This can save a lot of money by extending the life of the equipment and preventing expensive downtime.

In summary, new insights and efficiency possibilities brought about by digital twin technologies are revolutionizing whole sectors. Digital twins are unquestionably powerful, whether used for predictive maintenance, solar data analytics, or other purposes. We ought to anticipate seeing even more inventive solutions surface in the future as businesses investigate the potential of this technology. For more details, contact Digital Twin Technology for Solar Data Analytics Platform (celebaltech.com)

#digital twin technology#solar data analytics platform#azure digital twin solution#predictive maintenance digital twin

0 notes

Text

How Digital Twins Can Optimize Industrial RO Operations?

Industries around the world are turning to membrane-based reverse osmosis (RO) technology to reuse wastewater streams and desalinate non-traditional water sources as water scarcity becomes more acute. However, running RO plants at peak performance while reducing costs and environmental impact can be a challenging task. Issues such as process fluctuations, membrane fouling and scaling, unplanned downtime, and excessive use of chemicals can all affect operational efficiency.

Visit the link for more information: https://www.netsolwater.com/how-digital-twins-can-optimize-industrial-ro-operations.php?blog=6308

#netsolwater#commercial ro plant#industrial ro plant manufacturers#sewage treatment plant manufacturer#industrial ro plant#effluent treatment plant#sewage treatment plant#watertreatment plant#effluent treatment plant manufacturer

0 notes

Text

Challenges and Alternatives in High-Pressure Piping Methods

Piping executive is really a important control within the broader field of executive, enjoying a vital role in a variety of industries, including fat and gasoline, substance handling, energy generation, and water treatment. The principal target of piping engineering is the design, evaluation, installment, and maintenance of piping programs that transfer fluids and gases.

Foundations of Piping Executive

At its key, piping design requires understanding liquid makeup, material research, and mechanical principles. Piping designers must make sure that methods are designed to handle the supposed fluids below various functioning problems, including temperature, force, and flow rate. Critical factors contain:

Product Variety: Deciding on the best products is vital for ensuring the toughness and integrity of piping systems. Components should withstand corrosion, resist force and temperature extremes, and conform to market standards.

Style and Structure: Efficient design minimizes force falls and guarantees smooth liquid flow. Proper structure also assists in lowering installment and preservation prices while sticking with protection regulations.

Stress Analysis: Technicians must analyze worries caused by thermal growth, vibration, and different facets to prevent failures.

Inventions in Piping Design

New improvements in technology have somewhat impacted the subject of piping engineering. Some of the significant innovations contain:

Advanced Resources: The development of new materials such as for instance composite pipes and corrosion-resistant alloys has improved the efficiency and life of piping systems.

3D Modeling and Simulation: The usage of 3D CAD software and computational fluid makeup (CFD) enables engineers to produce step-by-step models and imitate fluid flow, identifying possible problems before physical implementation. piping engineer

Automation and Wise Piping Techniques: The integration of receptors and IoT (Internet of Things) technology helps real-time checking and control of piping methods, improving effectiveness and reducing the likelihood of failures.

Problems and Answers

Piping designers experience a few challenges, particularly when coping with high-pressure and high-temperature systems. Some typically common problems and their solutions include:

Rust: Corrosion is really a significant problem, particularly in severe environments. Alternatives contain using corrosion-resistant materials, applying protective coatings, and employing cathodic protection techniques.

Leak Detection: Ensuring the reliability of piping techniques is essential to avoid leaks, which could trigger environmental injury and economic loss. Advanced flow recognition systems, such as for instance audio detectors and infra-red cameras, are significantly applied to spot escapes early.

Complicated Regulations: Piping programs must adhere to stringent safety and environmental regulations. Technicians should stay updated with the most recent requirements and ensure that styles match all required specifications.

Potential Styles in Piping Engineering

The future of piping executive is positioned to be shaped by a few emerging trends and technologies:

Sustainable Techniques: As industries shift towards sustainability, there's an increasing focus on planning eco-friendly piping programs that decrease environmental impact. This includes applying recyclable materials and optimizing energy use.

Digital Twins: Producing electronic replicas of bodily piping techniques can assist in predictive preservation and efficiency optimization. Digital twins allow engineers to reproduce numerous cases and produce data-driven decisions.

Modular Construction: Modular piping programs, where parts are pre-fabricated and built on-site, are becoming more popular. This method reduces structure time and fees while enhancing quality control.

Conclusion

Piping design can be an ever-evolving area that's important for the working of numerous professional processes. With developments in resources, style tools, and checking systems, piping engineers are greater prepared than actually to design successful, reliable, and sustainable systems. As industries continue to cultivate and innovate, the position of piping designers may remain crucial in ensuring the safe and effective transport of liquids and gases.

0 notes

Text

Revolutionizing Automobile Parts Manufacturing: The AceForge Approach

In the ever-evolving landscape of the automotive industry, manufacturing companies play a pivotal role in supplying the necessary components that drive innovation and efficiency. Among these, AceForge stands out as a beacon of excellence, pioneering new standards in automobile parts manufacturing. With a commitment to quality, innovation, and sustainability, AceForge has cemented its position as a leader in the field. Let's delve into what sets AceForge apart and how it is reshaping the future of automobile parts manufacturing.

The Foundation of Excellence

Founded on the principles of precision engineering and relentless pursuit of excellence, AceForge has established itself as a trusted name in the automotive parts manufacturing sector. From its inception, the company has been driven by a singular mission: to deliver superior quality products that exceed customer expectations.

At the heart of AceForge's success lies its unwavering commitment to innovation. By investing heavily in research and development, the company continually pushes the boundaries of what is possible in automobile parts manufacturing. Advanced technologies such as computer-aided design (CAD), additive manufacturing, and robotics are seamlessly integrated into AceForge's production processes, allowing for greater precision, efficiency, and customization.

Unparalleled Quality Control

In an industry where precision and reliability are non-negotiable, quality control is paramount. AceForge employs rigorous quality control measures at every stage of the manufacturing process to ensure that each component meets the highest standards of excellence.

From raw material sourcing to final inspection, every aspect of production is meticulously monitored and evaluated. Advanced testing methodologies, including non-destructive testing (NDT) and computerized quality assurance systems, are utilized to detect even the slightest deviations from specifications. This relentless focus on quality has earned AceForge the trust of leading automobile manufacturers worldwide.

Sustainable Manufacturing Practices

Recognizing this, AceForge has made significant strides towards reducing its environmental footprint and promoting eco-friendly manufacturing practices.

Through initiatives such as waste minimization, energy efficiency improvements, and recycling programs, AceForge is leading the charge towards a greener future for automobile parts manufacturing. By embracing sustainability as a core value, the company not only reduces its environmental impact but also enhances its reputation as a responsible corporate citizen.

Customer-Centric Approach

At AceForge, customer satisfaction is more than just a goal—it's a driving force behind everything the company does. By fostering close partnerships with customers and understanding their unique needs and challenges, AceForge is able to deliver tailored solutions that address specific requirements.

From initial concept development to final delivery, AceForge works hand-in-hand with customers to ensure that every aspect of the manufacturing process is optimized for their success. This customer-centric approach has earned AceForge a reputation for reliability, responsiveness, and unparalleled service.

Embracing Industry 4.0

As the automotive industry enters the era of Industry 4.0, AceForge is at the forefront of this digital revolution. By embracing cutting-edge technologies such as artificial intelligence, Internet of Things (IoT), and big data analytics, the company is transforming the way automobile parts are designed, manufactured, and distributed.

Real-time monitoring and predictive maintenance systems ensure optimal performance and minimize downtime, while digital twins enable virtual simulations and prototyping, accelerating time-to-market for new products. By harnessing the power of Industry 4.0, AceForge is driving efficiency, agility, and innovation across the entire value chain.

Looking Towards the Future

As the automotive industry continues to evolve, so too will the challenges and opportunities facing automobile parts manufacturers. However, with its unwavering commitment to excellence, innovation, and sustainability, AceForge is well-positioned to thrive in this dynamic environment.

By staying ahead of the curve and embracing emerging technologies, AceForge will continue to push the boundaries of what is possible in automobile parts manufacturing. Whether it's pioneering new materials, optimizing production processes, or reimagining the future of mobility, AceForge remains steadfast in its pursuit of excellence.

In conclusion, AceForge stands as a shining example of what can be achieved through a relentless commitment to quality, innovation, and customer satisfaction. As the automotive industry marches forward into the future, AceForge will be there every step of the way, shaping the landscape of automobile parts manufacturing for generations to come.

0 notes

Text

Plant Asset Management (PAM) Market Forecast 2024-2033

Overview and Scope

Plant asset management refers to the process of managing and maintaining physical assets within a plant or industrial facility. This includes managing the lifecycle of assets, from acquisition to disposal, as well as optimizing asset performance, reliability, and maintenance processes. The goal of plant asset management is to ensure that assets are operating efficiently, effectively, and safely to support the organization's goals and objectives.

Sizing and Forecast

The plant asset management (PAM) market size has grown rapidly in recent years. It will grow from $8.09 billion in 2023 to $9.14 billion in 2024 at a compound annual growth rate (CAGR) of 13.1%. The growth in the historic period can be attributed to advancements in technology, industry 4.0 initiatives, integration with enterprise systems, shift towards cloud-based solutions, aging infrastructure.

The plant asset management (PAM) market size is expected to see rapid growth in the next few years. It will grow to $14.11 billion in 2028 at a compound annual growth rate (CAGR) of 11.5%. The growth in the forecast period can be attributed to adoption of predictive analytics, focus on remote monitoring, integration with digital twins, advancements in sensor technologies, focus on cybersecurity. Major trends in the forecast period include artificial intelligence integration, digitalization trend, advancement in technology, asset integrity management priority.

To access more details regarding this report, visit the link:

Segmentation & Regional Insights

The plant asset management (PAM) market covered in this report is segmented –

1) By Offering: Software, Services

2) By Deployment: On-Premise, Cloud

3) By Asset Type: Production Assets, Automation Assets

4) By End-User: Energy And Power, Oil And Gas, Petrochemical, Mining And Metal, Aerospace And Defense, Automotive, Other End-Users

North America was the largest region in the plant asset management market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the plant asset management (PAM) market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Major Driver Impacting Market Growth

The adoption of automation technologies is expected to propel the growth of the plant asset management market going forward. Automation technologies include a wide range of methods, processes, and systems that use diverse technologies to do tasks with minimal human participation. Plant asset management (PAM) helps automation technologies by providing a comprehensive approach to managing and maintaining physical assets in industrial settings. For instance, in October 2022, according to the International Federation of Robotics, a Germany-based non-profit organization, in 2021, factories worldwide installed 517,385 new industrial robots, representing a 31% annual growth rate. This figure also marked a 22% increase compared to the previous two years' pre-pandemic record for robot installations. Therefore, the adoption of automation technologies is driving the growth of the plant asset management market.

Key Industry Players

Major companies operating in the plant asset management (PAM) market are Google LLC, Microsoft Corporation, Hitachi Ltd., Siemens AG, General Electric Co., International Business Machines Corporation, Oracle Corporation, Schneider Electric SA, Honeywell International Inc., SAP SE, BAE Systems plc, Emerson Electric Company, CGI Group Inc., AB SKF, Rockwell Automation Inc., Dassault Systemes, Yokogawa Electric Corporation, KUKA AG, Endress+Hauser Management AG, Bentley Systems, Maxwell Technologies Inc., Aspen Technology Inc., Ramco Systems Ltd.

The plant asset management (pam) market report table of contents includes:

1. Executive Summary

2. Plant Asset Management (PAM) Market Characteristics

3. Plant Asset Management (PAM) Market Trends And Strategies

4. Plant Asset Management (PAM) Market - Macro Economic Scenario

5. Global Plant Asset Management (PAM) Market Size and Growth

.

.

.

32. Global Plant Asset Management (PAM) Market Competitive Benchmarking

33. Global Plant Asset Management (PAM) Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Plant Asset Management (PAM) Market

35. Plant Asset Management (PAM) Market Future Outlook and Potential Analysis

36. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

data management services

Navigating the Future of Project and Site Management: Innovative Solutions for Modern Challenges

In an era where efficiency and precision are paramount, the landscape of project and site management is undergoing transformational change. The integration of cutting-edge technologies and innovative strategies is redefining how projects are planned, executed and managed. This development is not just a trend but a necessity, driven by the complexities and demands of modern construction and development projects. Let's explore some of the unique solutions that are shaping the future of project and site management.

embracing digital twins

Digital twin technology is revolutionizing project management by creating exact virtual replicas of physical assets. These digital models provide real-time data and analytics, allowing managers to simulate scenarios, predict outcomes, and optimize processes before implementing them on site. This not only reduces risk but also increases the accuracy of decision making.

For example, in large-scale construction projects, digital twins can be used to monitor the structural integrity of buildings, manage energy consumption, and even predict maintenance needs. By having a comprehensive digital overview, managers can ensure projects stay on track and within budget.

Leveraging AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are powerful tools in project management. AI can analyze large amounts of data to identify patterns and predict potential issues before they arise. This proactive approach helps reduce risks and improve efficiency.

Machine learning algorithms can optimize resource allocation, ensuring that materials and labor are used effectively. For example, in site management, ML can predict the best time to use equipment to avoid downtime and reduce operating costs. This level of precision ensures that projects are not only completed rapidly but also within the allotted budget.

Enhancing Collaboration with Cloud-Based Platforms

Cloud-based project management platforms are enhancing collaboration by providing a centralized hub for all project-related activities. These platforms provide real-time updates, document sharing, and communication tools that keep all stakeholders on the same page.

Platforms like Procore and Autodesk BIM 360 enable seamless collaboration between teams, regardless of their location. This is especially beneficial for large projects with multiple contractors and subcontractors. With everyone having access to the same information, the risk of miscommunication is significantly reduced, leading to more harmonious project execution.

(IoT) Implementation of Internet of Things

The Internet of Things (IoT) is playing an important role in site management by connecting various devices and systems to form an integrated network. IoT devices can monitor environmental conditions, track equipment usage, and ensure employee safety in real time.

For example, smart sensors can detect temperature changes, humidity levels, and air quality at a construction site. This information is important to maintain optimal working conditions and prevent potential hazards. Additionally, IoT-enabled equipment tracking ensures that all equipment and machinery is accounted for, reducing losses and improving productivity.

adopting modular construction

Modular construction is gaining popularity as a solution to efficient project management. By manufacturing building components off-site and then assembling them on-site, this method significantly reduces construction time and waste.