#stainless steel wire mesh

Text

Loop Tie Wire

Anping Dongming Wiremesh Co.,Ltd offers high-quality loop tie wire, a flexible way to secure and fasten things in crops and building applications. Our loop tie wire, which is made of strong components, provides consistent and strong connections. Loop tie wire is a perfect option for securing fencing or bundling rebars.

Phone No. +86-15131872040

Email: [email protected]

Address: Industrial Park, Anping, Hebei, China 053600

#Stainless Steel Wire Mesh#Perforated Metal Mesh#Mild Steel Wire Mesh#Rib Lath#Filter Disc#Hy Rib#Metal Coil Drapery#Stainless Steel Welded Mesh#Metal Fabric#Fan Guard#Stainless Steel Rope Mesh#Welded Razor Wire#Expanded Metal Mesh#Cut Straight Wire#Plaster Mesh#Loop Tie Wire

0 notes

Text

Introduction to Stainless Steel Welded Mesh:

Stainless steel welded mesh is a versatile material made from stainless steel wires that are welded together to form a grid pattern. It is known for its strength, durability, corrosion resistance, and aesthetic appeal. Stainless steel welded mesh finds applications in various industries, including construction, agriculture, architecture, and manufacturing.

Types of Stainless Steel Welded Mesh:

Material Grade: Stainless steel welded mesh is available in different grades of stainless steel, including 304, 316, and 316L, each offering varying levels of corrosion resistance and mechanical properties.

Wire Diameter and Mesh Size: Stainless steel welded mesh comes in a range of wire diameters and mesh sizes to suit different applications. Common wire diameters range from 1mm to 5mm, while mesh sizes vary from small openings suitable for filtration to larger openings for fencing and reinforcement.

Surface Finish: Stainless steel welded mesh can have different surface finishes, including plain (unfinished), galvanized, or powder-coated, providing additional protection against corrosion and enhancing aesthetics.

Applications of Stainless Steel Welded Mesh:

Security Fencing: Stainless steel welded mesh is commonly used for security fencing in residential, commercial, and industrial properties due to its strength, durability, and resistance to cutting and vandalism.

Animal Enclosures: Stainless steel welded mesh is ideal for constructing animal enclosures, such as aviaries, animal cages, and kennels, providing a secure and durable barrier while allowing for visibility and airflow.

Reinforcement: Stainless steel welded mesh is used as reinforcement in concrete structures, such as slabs, walls, and foundations, to improve tensile strength, prevent cracking, and enhance structural integrity.

Filtration and Screening: Stainless steel welded mesh with fine mesh sizes is used for filtration and screening applications, such as water filtration, air vents, sieving, and insect screens, due to its corrosion resistance and precise openings.

Decorative Applications: Stainless steel welded mesh is utilized in architectural and interior design for decorative purposes, including balustrades, partitions, wall cladding, and artistic installations, providing a modern and sleek aesthetic.

Installation and Maintenance:

Installation: Stainless steel welded mesh can be installed using various methods, including welding, bolting, or clamping, depending on the application and structural requirements. Proper installation techniques ensure stability, security, and longevity of the mesh.

Maintenance: Stainless steel welded mesh requires minimal maintenance due to its corrosion-resistant properties. Regular cleaning with mild detergent and water can help remove dirt, debris, and surface contaminants, preserving its appearance and performance over time.

Safety Considerations:

Handling: When handling stainless steel welded mesh, wear appropriate personal protective equipment, such as gloves and eye protection, to prevent injury from sharp wire edges.

Welding: If welding stainless steel welded mesh, follow proper welding procedures and ventilation measures to minimize exposure to fumes and ensure weld quality and integrity.

Sourcing Stainless Steel Welded Mesh:

Supplier Selection: Choose reputable suppliers or manufacturers of stainless steel welded mesh with a proven track record of quality products, reliable service, and adherence to industry standards and specifications.

Customization: Many suppliers offer customization options for stainless steel welded mesh, including custom sizes, configurations, and finishes, to meet specific project requirements and preferences.

By following this guide, you can gain a comprehensive understanding of stainless steel welded mesh sheets and rolls, including their types, applications, installation, maintenance, safety considerations, and sourcing options, enabling you to make informed decisions for your projects or applications.

#wire mesh#oman business#sharjah#galvanized#stainless steel wire mesh#welded wire mesh#stainless steel mesh#stainless steel woven mesh#almiqathardware shadenetting netting birdnet

0 notes

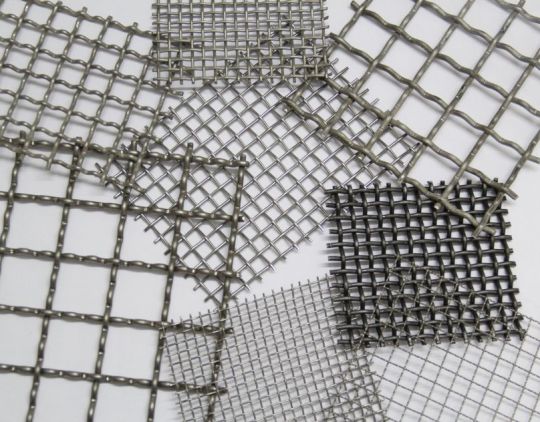

Photo

316L SS Wire Net

316L SS Wire Net boasts high corrosion resistance.

Its low carbon content enhances weldability and durability.

1: Material Composition

(1) 316L SS wire construction.

(2) Low carbon content for enhanced corrosion resistance.

(3) High-grade stainless steel alloy.

(4) Non-reactive to various chemicals.

(5) Ideal for demanding industrial applications.

(6) Superior durability and longevity.

(7) Anti-rust properties for extended use.

(8) Excellent resistance to pitting and crevice corrosion.

(9) Maintains integrity under extreme temperatures.

(10) Premium quality for critical environments.

(11) Conforms to international quality standards.

(12) Precision-engineered for optimal performance.

2: Mesh Design

(1) Intricate mesh pattern for versatility.

(2) Uniform and consistent openings.

(3) Precision-woven for strength.

(4) Ensures effective filtration.

(5) Customizable mesh sizes available.

(6) Facilitates efficient airflow and visibility.

(7) Suitable for various sieving applications.

(8) Mesh integrity for particle retention.

(9) Enhances structural stability.

(10) Ideal for sieving and filtering operations.

(11) Resistant to wear and tear.

(12) Easy to handle and install.

3: Applications

(1) This Wire Net is widely used in chemical processing.

(2) Essential for oil and gas filtration.

(3) Ideal for marine and coastal applications.

(4) Suitable for pharmaceutical manufacturing.

(5) As Security screen mesh, it is critical in aerospace engineering.

(6) Facilitates food and beverage processing.

(7) Used in architectural and design projects.

(8) Crucial in automotive manufacturing.

(9) Essential for water treatment plants.

(10) Indispensable in electronic component production.

(11) Meets strict hygienic standards in the medical industry.

(12) Ensures reliability in power generation.

4: Advantages

(1) Minimal maintenance requirements.

(2) Long-lasting service life.

(3) Cost-effective solution.

(4) Versatile in various applications.

(5) Easy to clean and sterilize.

(6) Resistant to abrasion and impact.

(7) Non-magnetic properties.

(8) Low risk of contamination.

(9) High tensile strength.

(10) Minimal environmental impact.

(11) Contributes to sustainable practices.

(12) 316L SS Wire Net complies with industry regulations.

The product 316L SS Wire Net appeared first on Alex Wire Mesh.

#316L SS Wire Mesh#316L SS Wire Net#316L SS Wire Screen#316L SS Woven Wire Mesh#316L Stainless Steel Wire Mesh#SS Wire Mesh#SS Wire Net#Stainless Mesh#Stainless Steel Mesh#Stainless Steel Wire Cloth#Stainless Steel Wire Mesh#Stainless Wire Cloth

0 notes

Text

#stainless steel wire mesh#ss wire cloth#stainless steel woven wire mesh#steel woven mesh#wire mesh woven stainless steel

0 notes

Text

Stainless Steel Wire Mesh: What Is It? What Are The Applications?

Are you looking for quality-made, efficient and economical stainless steel wire mesh? Wondering about the applications and uses of SS (Stainless Steel wire mesh? Make sure you read this blog to discover everything you need to know about SS wire mesh. So without wasting a fraction of second, let’s consider!

What Is Stainless Steel Wire Mesh?

Wire mesh made of stainless steel is manufactured through a weaving method that is perfectly suited to the material. Carefully choosing the material for your stainless steel mesh is important since it significantly impacts the manufacturing process.

Stainless steel alloys are generally good for high-temperature operations, for instance, marine applications. Meshes made from stainless steel often rely on the robustness and sturdiness of stainless steel, an excellent high-temperature corrosion-resistant alloy known for its exceptional mechanical properties.

If you are looking for quality-made, high performance and best-in-class stainless steel wire mesh for your diverse industrial applications, can trust the years of manufacturing excellence, expertise and dedication of Jeetmull Jaichandlall (P) Ltd. India one of the top Stainless steel wire mesh manufacturers, supplier and exporter in India that offers best-in-class, economical and quality-made wire mesh personalised to your industrial applications and needs. Whether you are looking for a preeminent Carbon Steel Wire Mesh manufacturer, Copper Wire Mesh Manufacturers or any range of wire mesh manufacturing companies in India, we have got you covered.

Stainless steel mesh products are available on the market today in a wide variety. The Stainless Steel wire mesh can be annealed or cold-rolled, passed out a drawing plate, cut into pieces by equipment or machine, and woven into a design with either a diamond or square shape depending on what the pattern is.

Stainless steel wire mesh offers excellent corrosion resistance and robustness owing to its high chromium content. On the other hand, you can use carbon steel wire mesh if you are looking for something robust, stronger and durable for your diverse industrial applications.

Top Benefits Of Stainless Steel Wire Mesh

❖ Robustness: Stainless steel is popular for its robustness and durability. Their robustness and sturdiness offer resistance to mechanical and chemical damage.

❖ Cost-effective: Unlike other alloys, stainless steel wire mesh is considered to be cost-efficient making it an economical option for a wide range of industries and applications.

❖ Corrosion Resistance: Stainless steel offers corrosion resistance making it suitable for use in harsh climatic environments.

❖ Low maintenance cost: The wire mesh made from stainless steel is durable and long-lasting. This consequently lowers the need for maintenance or replacements and henceforth offers no or minimum cost.

What Are The Uses And Applications Of SS Wire Mesh?

SS (Stainless Steel) wire mesh is commonly used across a wide range of industries and applications. Their robustness, versatility and durability make them ideal for plenty of applications in industries.

From manufacturing to construction to food processing, stainless steel wire mesh is commonly used in a wide range of sectors such as commercial & residential settings for fencing purposes, Industrial buildings, manufacturing facilities, the construction industry, the automotive industry, security & safety applications and so on.

Quality-Made Stainless Steel Wire Mesh Directly From The Manufacturer

Jeetmull Jaichandlall (P) Ltd. is a professional manufacturer and exporter of all types of wire mesh. We at Jeetmull Jaichandlall build a comprehensive range of wire mesh from GI (Galvanised Iron) wire mesh to carbon steel wire mesh to copper wire mesh to stainless steel wire mesh, we have got you covered. If you are looking for a long-lasting, economical and fully custom-made stainless steel wire mesh manufacturer for your specific industrial applications, we are the preeminent wire mesh manufacturing company to trust.

Conclusion

To wrap it up, here is everything you need to know about SS (Stainless Steel) wire mesh. It is one of the most versatile and durable security solutions for any commercial & residential setting. Not just that, stainless steel wire mesh is used across a comprehensive range of industries and applications such as manufacturing processes, medical, pharmaceuticals, food processing, construction and so on. No matter the industry or application, we at Jeetmull Jaichandlall (P) Ltd. can meet your all industrial needs. To discover more about our wide range of wire mesh, feel free to get in touch with one of our manufacturing specialists by dropping us a message or calling us directly.

0 notes

Text

304 Stainless Steel Wire Mesh Suppliers, Stuckist in Mumbai, India

Trusted suppliers of 304 stainless steel wire in Mumbai, India. Ready stock available of 304 SS Wire Mesh Size Chart. Visit our website to know more. Stainless Steel 304 Wire Mesh is made from the highest quality Steel that stands out strong from other alloys. All stainless steel mesh wires are perfectly good to work in an aqueous solution

0 notes

Text

Stainless Steel Wire Mesh Manufacturer in India - Bhansali Wire Mesh

Bhansali Wire Mesh is one of the leading Stainless Steel Wire Mesh Manufacturers in India. SS Wire Mesh Manufacturers in India have established themselves as key players in the global wire industry. We are commonly considered as industry experts and consistently meet the needs and requests of our clients for all types of wire mesh.

Because of its corrosion resistance and strength, stainless steel wire mesh is a popular choice for many industrial and commercial applications. Stainless Steel Wire Mesh Suppliers in India work with various manufacturers to ensure that they have a vast inventory of wires available for immediate delivery to their customers.

Bhansali Wire Mesh is one of the leading SS Wire Mesh Manufacturers in Saudi Arabia. In order to help our clients' work be simpler and more effective, we provide the highest quality goods at a fair price. It is also among the top exporters of steel wire mesh, concentrating on top-notch goods.

We are also a SS Wire Mesh in such countries:

SS Wire Mesh Manufacturers in Oman

SS Wire Mesh Manufacturers in Kuwait

SS Wire Mesh Manufacturers in Iran

SS Wire Mesh Manufacturers in Qatar

SS Wire Mesh Manufacturers in Uae

For More Detail

Website: bhansaliwiremesh.com

Product: Stainless Steel Wire Mesh Manufacturer in India

Other Product: Double Crimped Wire Mesh Manufacturer in India

#Stainless Steel Wire Mesh Manufacturer in India#Stainless Steel Wire Mesh Manufacturer#Stainless Steel Wire Mesh

0 notes

Text

How Is Stainless Steel Mesh Made?

A versatile product with many uses is stainless steel wire mesh. It has an astonishing ability to get attracted into wires. Steel wires are particularly practical due to this, as well as their flexibility and tensile strength. Due to its many uses and exceptional rust resistance, stainless steel is a great option.

One of the earliest and most straightforward things made from steel is wire mesh. They have been in use in one form or another for many centuries and are constructed of stainless steel. Steel wire mesh has various inventive applications in the world's social economy, including barricading, running machine safety covers, grills, shelves, sifters, cages, etc.

Nonetheless, wire mesh serves an important purpose by serving as a form of reinforcement for concrete. All steel wire mesh producers weave or weld the steel to create the mesh.

Weaved Wire Mesh

Single wires are aligned vertically and horizontally, at a 90-degree angle to one another, to produce woven-type wire mesh using a spinning technique. Depending on the pattern you want to create, you can use a single or two strands of stainless steel mesh wire per weave. Automated machines that are programmed to follow instructions are used for this type of spin weaving to produce quick weaves. Every steel wire mesh that is knitted features flexibility as its main quality.

Welded Wire Mesh

Stainless steel is used to create welded wire mesh using a precision, semi-automatic welding process. These devices have a chamber that can give precise welds at calculated junctions, which are formed by the intersection of steel wires that are vertically and horizontally aligned.

Read More on About How Is Stainless Steel Mesh Made?

#stainless steel wire mesh#wire mesh sheets#stainless wire mesh#wire mesh stainless steel#stainless steel fencing#stainless steel wire fence#stainless steel mesh sheet#steel wire mesh panels#woven steel mesh sheets#wire mesh woven#wire woven mesh

0 notes

Photo

"Stainless Steel Wires."

304 wires is the most widely used stainless steel, and like 302, it has good mechanical properties and corrosion resistance. This alloy can withstand attack in a range of corrosive media, and its durability makes it easy to sanitise, meaning it is ideal for kitchen and food applications. SS 309/309L Wires , which is associated in nursing solid solution heat resistant alloy with wonderful resistance to oxidation underneath gently cyclic conditions through 2000 Degree F. Stainless Steel 309/309L Wires is quickly fancied by commonplace industrial procedures compared to steel, unsullied steels are harder and have a tendency to figure harden speedily. Bhansali Enterprise is a well-known distributor and stockiest of Stainless Steel 316 Wires , which is essentially a standard carbon 316 type with titanium stabilization. It is similar in principle to the titanium stabilization of the 304. Grade 316 Wires is a titanium-stabilized version of Type 316 molybdenum-bearing austenitic stainless steel. This Stainless Steel 321 Wires must be absolutely clean and free from all oil, paint, grease, and shop soil when charged into the furnace. The furnace atmosphere for forging or open annealing in our Stainless Steel 321 Wire should be slightly reducing, containing at least 2 % of carbon monoxide.

#stainless steel wire#stainless steel wire mesh#stainless steel wire manufacturers in india#stainless steel 304#wire manufacturers#stainless steel 201 cu wire manufactures in mumbai#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#stainless steel mesh wire

0 notes

Text

Find a Trusted Wire Mesh Manufacturer for the Benefit of Your Business Growth

For the majority of us, conducting business internationally is unthinkable. However, some people will always start making purchases from Plaster Mesh manufacturers since they wish to have a chance to become wealthy. There you will also find high-quality Welded Razor Wire, and other materials.

Phone No. +86-15131872040

Email: [email protected]

Address: Industrial Park, Anping, Hebei, China 053600

#Stainless Steel Wire Mesh#Perforated Metal Mesh#Mild Steel Wire Mesh#Rib Lath#Filter Disc#Hy Rib#Metal Coil Drapery#Stainless Steel Welded Mesh#Metal Fabric#Fan Guard#Stainless Steel Rope Mesh#Welded Razor Wire#Expanded Metal Mesh#Cut Straight Wire#Plaster Mesh#Loop Tie Wire

0 notes

Text

Stainless steel mesh offers numerous benefits across various applications due to its unique combination of properties. Here are some key advantages of using stainless steel mesh:

Corrosion Resistance: Stainless steel is highly resistant to corrosion, rust, and staining, making it suitable for use in environments with exposure to moisture, chemicals, or harsh weather conditions.

Durable and Strong: Stainless steel mesh has high tensile strength and durability, ensuring it can withstand mechanical stress, impacts, and external forces without losing its structural integrity.

Longevity: The corrosion resistance and durability of stainless steel contribute to its long lifespan, reducing the need for frequent replacements and maintenance. This makes it a cost-effective choice over time.

Temperature Resistance: Stainless steel maintains its mechanical properties at both high and low temperatures, making it suitable for applications that involve extreme temperature variations.

Hygienic Properties: Stainless steel is easy to clean and maintain, and it does not harbor bacteria or other pathogens. This makes it an excellent material for applications in food processing, healthcare, and other industries where hygiene is critical.

Aesthetic Appeal: Stainless steel has a sleek and modern appearance that adds aesthetic value to various applications. It is often chosen for architectural and decorative purposes, such as in mesh screens, facades, or interior design elements.

Chemical Resistance: Stainless steel is resistant to a wide range of chemicals, acids, and alkalis, making it suitable for use in industries where exposure to corrosive substances is a concern.

Versatility: Stainless steel mesh is versatile and can be customized for various applications, including filtration, screening, fencing, architectural elements, and industrial processes.

High Strength-to-Weight Ratio: Stainless steel mesh offers a high strength-to-weight ratio, providing strength and stability without excessive weight. This is advantageous in applications where weight is a consideration.

Recyclability: Stainless steel is a recyclable material, contributing to sustainability and reduced environmental impact. The ability to recycle and reuse stainless steel makes it an eco-friendly choice.

Electrically Conductive: Some stainless steel mesh types exhibit good electrical conductivity. This property is valuable in applications where electrical conductivity is required, such as in electromagnetic shielding or grounding.

Security and Safety: Stainless steel mesh can be used for security purposes, providing a strong and secure barrier. It is often employed in fencing, screens, and partitions to enhance safety and deter unauthorized access.

Non-Magnetic Options Available: For applications where magnetic properties are undesirable, non-magnetic grades of stainless steel mesh are available, providing flexibility in material selection.

Resistance to Wear and Abrasion: Stainless steel mesh is resistant to wear and abrasion, making it suitable for applications where the material is subjected to friction or rubbing.

#wire mesh#galvanized#business#oman business#chicken wire mesh#galvanized wire mesh#stainless steel wire mesh#wire mesh in oman#welded wire mesh#fencing#sharjah business

0 notes

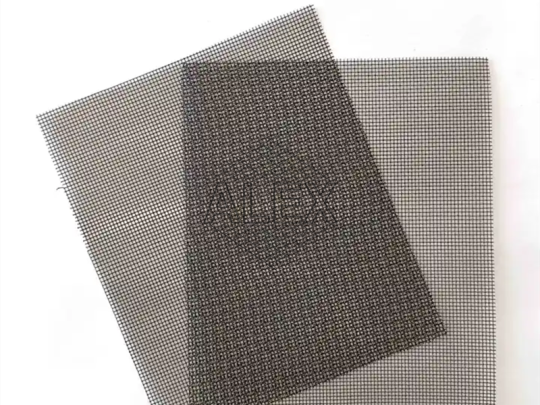

Photo

304 Wire Netting

304 Wire Netting ensure precision in particle separation processes.

The wire netting is essential in crafting reliable filters for various industries.

Features:

(1) Crafted from high-quality 304 stainless steel for durability.

(2) Resistant to corrosion, making it suitable for outdoor use.

(3) Uniform mesh structure ensures consistent performance.

(4) Easy to handle due to its lightweight yet sturdy design.

(5) Smooth surface finish enhances aesthetic appeal.

(6) Excellent heat resistance for various industrial applications.

(7) Low maintenance, reducing long-term operational costs.

(8) Versatile and customizable for specific project needs.

(9) Quick and straightforward installation process.

(10) Eco-friendly choice, as it is fully recyclable.

(11) Offers exceptional longevity even in harsh environments.

(12) Meets industry standards for quality and performance.

Advantages:

(1) Long-lasting solution for diverse industrial needs.

(2) Enhances safety with reliable fencing and enclosures.

(3) Provides cost-effective solutions for various projects.

(4) Versatile applications due to its customizable nature.

(5) Low environmental impact with recyclable materials.

(6) Improves aesthetics while maintaining functionality.

(7) This screen mesh is suitable for both indoor and outdoor applications.

(8) Withstands harsh weather conditions for durability.

(9) Reduces the risk of rust and degradation over time.

(10) Enhances security with strong and resilient barriers.

(11) Requires minimal maintenance for prolonged use.

(12) Complies with international standards for quality.

Specifications:

(1) Mesh size options catering to different requirements.

(2) This safety screen is available in various thicknesses for increased strength.

(3) Customizable dimensions to fit specific project needs.

(4) Standard roll lengths for convenient handling.

(5) Options for different surface finishes based on preference.

(6) Packaging options ensuring safe and efficient delivery.

(7) Detailed product documentation for easy understanding.

(8) Clear labeling for quick identification of specifications.

(9) Options for bulk orders to meet large-scale demands.

(10) Comprehensive warranty for customer satisfaction.

(11) Compliant with industry standards for consistency.

(12) Continuous testing to ensure quality and performance.

Installation Tips:

(1) Ensure a level and stable foundation for accurate installation.

(2) Use appropriate tools for cutting and shaping as needed.

(3) Secure edges tightly to prevent sagging or deformation.

(4) Follow recommended spacing guidelines for optimal results.

(5) Check and tighten connections periodically for stability.

(6) Choose compatible accessories for a seamless installation.

(7) Seek professional advice for complex or large-scale projects.

(8) Consider environmental factors when determining placement.

(9) Utilize corrosion-resistant fasteners for lasting results.

(10) Inspect regularly and address any signs of wear promptly.

(11) Provide proper support for vertical installations.

(12) Follow safety guidelines to prevent injuries during installation.

The product 304 Wire Netting appeared first on Alex Wire Mesh.

#304 Wire Net#304 Wire Netting#304 Wire Screen#SS 304 Wire Mesh#SS 304 Wire Netting#SS304 Wire Netting#Stainless Mesh#Stainless Steel Mesh#Stainless Steel Wire Mesh#Stainless Steel Wire Net

0 notes

Text

Stainless Steel Wire Mesh Manufacturers In India

Ladhani Metal Corporation is one of the Stainless Steel Wire Mesh Manufacturers in India, as well as the largest ss mesh supplier. The steel wiremesh is used in the construction industry to create barriers between different sections of a building.

Stainless Steel Wire Mesh Manufacturers transport these ss wire mesh all across the country.

Our goods are in high demand in the market, and we are among the best stainless steel clamp manufacturers and supplier.

Ladhani Metal Corporation is most well-known for manufacturing, supplying and providing high-quality Titanium Tank and Vessels and titanium ball valve for a wide range of industrial applications.

Astm F67 titanium sheet is a standard specification available here.

For More Details Contact us:

Source: Stainless Steel Wire Mesh Manufacturers

Website: ladhanimetals.com/

Mail us: [email protected]

Contact us:+91 22661 51913

#stainless steel wire mesh#ss mesh#steel wiremesh#ss wire mesh#stainless steel mesh#steel window mesh#stainless steel welded mesh

1 note

·

View note

Text

The global steel wire market size was USD 93.2 billion in 2020 and is expected to reach USD 124.7 billion by 2025, projecting a CAGR of 6.0% between 2020 and 2025. Steel wires are increasingly used in the construction, automotive, energy, industrial, agriculture, and other end-use industries. The increasing demand of construction end-use industry drives the demand for steel wire. However, the outbreak of COVID-19 has created ripples across various application industries leading to reduced demand for steel wire. Due to the lockdown scenario in Europe and North America, the demand for steel wire from construction, automotive, industrial and other industries have declined sharply in the first half of 2020.

The construction is the largest end-use industry of steel wire in terms of value. The steel wires offer increased strength to concrete, increase life span, increased crack resistance, reduces construction time in construction industry. These factors drive the demand of steel wires in variety of applications in construction end-use industry.

The China is the largest market for steel wire in the world, in terms of both value and volume. The trend is expected to be the same during the forecast period. The country is home to some of the major steel wire manufacturers. The growing construction industry, automotive industry and industrial activities in the region are propelling the market for steel wire in the China. With Germany, the US, Spain, India being the most affected countries, the entire supply chain in the steel wire industry is disrupted globally. The lockdown of international borders has reduced the demand for steel wire in Europe and North America.

Steel wires are segmented based on form in to non-rope form and rope form. The non-rope form of steel wire accounted for a largest share in the steel wire market. The construction and automotive industries are two major consumers of steel wires due to high usages in applications such as concreter reinforcement, masonry reinforcement, roads & bridges, tire cord, and among others. The demand for non-rope form of steel wire is expected to see a decline in 2020 due to the pandemic.

#Steel Wire Demand#steel wire rod market#mig welding stainless steel#stainless steel cables#wire mesh sheets#wire rod market#steel cord market#Carbon Steel Wire#Alloy Steel Wire#Stainless Steel Wire#stainless steel wire mesh#steel wire mesh#Steel Wire Market Analysis#Steel Wire Market Growth#Steel Wire Market 2022#Steel Wire Market#Steel Wire Market Industry#Steel Wire Market Size#Steel Wire Market Share#Steel Wire Market Trends#Steel Wire Market Research#Steel Wire Market Revenue#Covid 19 Impact on Steel Wire Market#Covid 19 Impact on Steel Wire

0 notes