Text

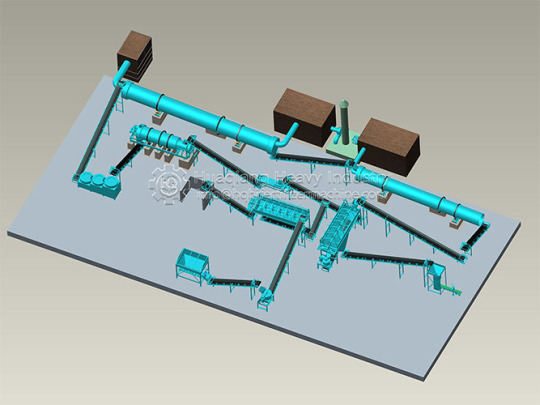

How much does it cost to invest in a small organic fertilizer production line?

What equipment does the small organic fertilizer production line include?

1. Fermentation turning and throwing machine: Fermentation turning (turning and throwing) the materials in the fermentation process;

2. Crusher: crushing and pulverizing high-humidity materials and other raw materials in the production process;

3. Granulator: granulate the mixed materials; it is convenient for sorting and packaging;

4. Organic fertilizer screening machine: screening and grading the finished fertilizer;

5. Automatic weighing and packaging machine: quantitatively bagging and packaging the finished products.

How much does it cost to invest in a small organic fertilizer production line?

The main purpose of the small-scale organic fertilizer production line is: for livestock and poultry manure organic fertilizer processing and production line projects. The small organic fertilizer production line is characterized by low overall investment price, low cost, and low technical requirements. It is suitable for large-scale planting and breeding enterprises and small fertilizer plants.

The organic fertilizer production machine has a significant effect on reducing pollution and reducing pollution from livestock manure. The processed organic fertilizer is widely used in the fruit, vegetable, tea, and grain industry. Due to the large-scale development of livestock and poultry breeding in recent years, a large amount of manure and sewage are concentrated.

These organic fertilizer equipment not only promote the harmless treatment and resource utilization of livestock and poultry manure, but also the formation of a commercial production chain to achieve the goals of industrialization, marketization and large-scale production, thereby effectively promoting green ecological agriculture and circular economy development of.

0 notes

Text

Things to pay attention to in organic fertilizer production line equipment

1: Fermentation part. The main function of the fermentation part of the organic fertilizer production line is to initially reduce the moisture content in the organic fertilizer raw materials. As we all know, the raw materials of organic fertilizer are mainly animal manure such as chicken manure, pig manure, cow manure and sheep manure. Cow dung and sheep dung are good, chicken dung and pig dung have too high humidity, especially chicken dung, the initial humidity is generally above, so the humidity is too high, it is impossible to directly treat it, and it must be fermented in a fermentation tank. Generally speaking, after about a week of fermentation, the humidity of the above fresh chicken manure can be reduced to below. In addition, Zhengzhou Huaqiang Machinery, a manufacturer of organic fertilizer equipment, tells you a little trick. During the fermentation of chicken manure, raw materials such as bran and wheat bran can be added. On the one hand, the fermentation time can be shortened, and on the other hand, the cost can be reduced.

2: The crushed part. Fermented animal feces will agglomerate, and a large amount of material is not easy to dry directly. Therefore, it is recommended to grind it with a small grinder before proceeding to the next step. In organic fertilizer production machine, the crushing part is often indispensable

3: Dry part. Seeing this, some friends may want to ask, there is no fermentation link in the front, and how can I dry it? In fact, fermentation can only control the surrounding humidity. To truly granulate the organic fertilizer, the moisture must be below, so the drying process is also essential of.

4: Granulation part. The organic fertilizer granulator is the core link of the entire organic fertilizer production line. Generally speaking, we recommend using a combination of a pelletizer and a pelletizer to achieve the pelletizing function, rather than a traditional disc pelletizer. Its advantages are high granulation rate and good compactness

5: Cooling and packaging. For users with small output, the cooling and packaging links can be ignored. Users with low output can directly inflate and airbag manually. Only the entire organic fertilizer production line with large output needs an automatic packaging machine.

0 notes

Photo

Production advantages of organic fertilizer granulator

Granulation is an important part of organic fertilizer production and processing. Granulation equipment occupies the main market in organic fertilizer machine. For different raw materials and production processes, we have designed and manufactured different types of fertilizer granulation equipment, roller press granulator, rotary drum granulator, organic fertilizer granulator, flat die pelleting machine, etc. Among them, organic fertilizer granulator is more popular and has certain production advantages.

Working principle of organic fertilizer granulator:

https://m.hqhifertilizermachine.com/products/fertilizer-granulator-machine-series/new-type-organic-fertilizer-granulator.html

The belt pulley and belt are driven by the main motor, and the small gear is driven by the reducer. The small gear and the big gear fixed at the bottom of the plate are open to each other and work in opposite directions. The big gear is installed on the spindle fixed on the adjusting disc of the machine through a special and reasonable design to support the work of the whole granulation plate (the machine is used in the spray machine). After the material enters the granulation tray, the continuous rotation and spray device of the granulation disc makes the material stick together to form spherical pellets, and an automatic cleaning device is designed at the upper and middle parts of the machine's granulating disc. As a result, the service life of the granulator for cow manure organic fertilizer is greatly increased. With the continuous rotation of the motor and the continuous entry of materials, mass production can be realized, which has met the needs of users.

0 notes

Text

Methods of applying organic fertilizer machine processed commercial fertilizer

1. After the commercial fertilizer is processed by the organic fertilizer machine, the nutrients of the fertilizer are more comprehensive and the durability is better. However, the long-acting properties of organic fertilizers cannot replace the quick-acting properties of chemical fertilizers. It must be applied according to different crops and soils, combined with urea, formula fertilizers, etc., to increase and renew soil organic matter, improve soil physical and chemical properties and biological activity, in order to achieve the best effect.

2. The roller press granulator can make organic fertilizer into granules, which is easy to use. Commercial organic fertilizer is generally used as base fertilizer and seed fertilizer. Before planting, the fertilizer should be evenly spread, ploughed into the soil or mixed with chemical fertilizer before sowing. Attention should be paid to prevent centralized application of fertilizer and burning of seedlings.

3. When commercial organic fertilizer is used as topdressing, sufficient water must be poured in time.

4. When commercial organic fertilizer is used on dry land crops in high temperature season, it is necessary to reduce the amount of application properly to prevent seedling burning.

5. The pH value of commercial organic fertilizer should be paid attention to, and its adaptability and application amount should be paid attention to in different soil environment.

0 notes

Photo

How to deal with air leakage of dryer in organic fertilizer production line

In the organic fertilizer machine processing process, https://m.hqhifertilizermachine.com/products/ if the drying equipment air leakage? This is not a small problem. Once the drying equipment leaks, the whole fertilizer production line will have operation problems. A small problem will lead to a big problem, the air leakage of dryer should be given high attention.

If the air leakage of the dryer is mainly manifested in the contact surface between the equipment and the engine hood, the contact position between the product door and the cover, tail and smoke chamber is the surface air leakage, but the impact of different positions is different, but the efforts of the fan will be wasted and the power consumption will increase. When the air leakage of dryer changes, the balance between calciner and machine air will change.

Air leakage on the top of the equipment will affect the secondary air intake, thereby reducing air temperature and increasing heat consumption. Air leakage at the end of the equipment will affect the amount of air used during the combustion of the equipment, resulting in insufficient combustion, increased coal usage, and increased carbon monoxide emissions from the equipment, leading to flue rise and smoke condensation.

Although air leakage is not a big problem, it is a common problem. However, if this problem is not solved, it may lead to major problems, which is also a special mechanical failure. Therefore, we should pay attention to any failure of organic fertilizer machine. Whether it is small equipment such as roller press granulator, pulverizer and mixer, or large equipment such as dryer, cooler and NPK and organic fertilizer granulator, maintenance should be done well.

0 notes

Text

Organic fertilizer can promote microbial reproduction in soil

The high-quality fertilizer processed by the organic fertilizer machine can reproduce the microorganisms in the soil, especially many beneficial microorganisms, such as nitrogen-fixing bacteria, ammonifying bacteria, and cellulose decomposing bacteria. These beneficial microorganisms can decompose the organic matter in the soil, increase the soil aggregate structure, and improve the soil composition.

Microbes grow quickly in the soil. They're like an invisible web. They're complex. After the death of microbial cells, many small pipes will be left in the soil, which not only increases the permeability of the soil, but also makes the soil soft and soft, and the nutrients and water are not easy to lose, which increases the water storage and fertilizer storage capacity of the soil, and avoids and eliminates the soil hardening.

The beneficial microorganisms in organic fertilizer can also inhibit the reproduction of harmful bacteria, so less chemicals can be used. If it is applied continuously for many years, it can effectively inhibit soil harmful organisms and save manpower, financial resources and pollution.

At the same time, organic fertilizer contains a variety of active enzymes secreted by animal digestive tract and various enzymes produced by microorganisms. After these substances are applied into the soil, the soil enzyme activity can be greatly improved. Long term continuous use of organic fertilizer can improve soil quality. If the soil quality is fundamentally improved, there is no need to worry that high-quality fruits will not be able to grow. After the fertilizer is processed by roller press granulator, disc granulator and other fertilizer granulator equipment, the fertilizer effect time is improved.

0 notes

Photo

Use roller press granulator to make manure into organic fertilizer

With the continuous popularization of organic fertilizer, more and more people begin to use organic fertilizer for production and planting. There are many raw materials for producing organic fertilizer, but many of them use roller press granulator to produce organic fertilizer from manure. Why? Next, let's explore why.

Organic fertilizer machine promotes green, ecological economy and sustainable development. It not only ensures food safety, but also solves the environmental pollution caused by feces. The water content of organic fertilizer fermentation should be controlled at 65%. So how do you determine the moisture content? Hold on to a handful of material with your hand, and you can see the watermark on your finger, but it won't drip, it will fall to the ground and scatter. High moisture content can lead to poor ventilation, slow temperature rise and bad smell. Adding straw, sawdust and mushroom residue can obtain regulated moisture. When the water content is too low, the fermentation is slow. When the water content is too low, the manure or water separated by the solid-liquid separator can be used to ensure the water content. Finally, the fermented compost is granulated by roller press granulator, and the whole treatment is completed by other fertilizer machines.

0 notes

Video

Precautions for using roller press granulator to produce fertilizer

Usually, when we use the double roller press granulator to produce fertilizer, we need to pay attention to the following: the application conditions of the roller press granulator are not so harsh, the main thing is the requirements for the production of particles, irregular particles are OK, and there is also the problem of particle hardness. They should not be too soft. If they are too soft, they cannot be transported over long distances.

In the production of fertilizer, it is necessary to carry out production according to the crushing and moisture content of the materials. If the materials can not meet the production requirements, the production can not be carried out, because this will lead to the decrease of the pelletizing rate of the particles and the screening can not be carried out.

However, as an industrial organic fertilizer machine, the sanitation requirements are low. When the roller press granulator is used to produce medicine or food for people to eat, the production requirements of roller granulator are high. The external part of the equipment can be the original material, but from the feeding to discharging, including the internal part of the machine, stainless steel materials are required to be used wherever the materials are contacted, so as to ensure the quality and hygiene of the products produced by the granulator. Grasp the above several main application conditions, you can skillfully use the equipment.

0 notes

Text

Which aspects should be paid attention to in extruding granulation?

Matters needing attention in granulation of double roller extrusion granulatorMatters needing attention in granulation of double roller extrusion granulator

1. Regularly check and clean the lubricating oil system of the roller press granulator, measure the main motor bearing with vibration meter and infrared thermometer, and form a trend chart. If the trend value is exceeded, determine whether the idle rotation current value or power value of the main motor exceeds the specified value, and judge whether the bearing should be replaced.2. Regularly check the alignment between the output shaft of the main motor and the input shaft of the gearbox, and check the alignment after testing or replacing the bearing for three months.3. Carry out electrical test and inspection on the roller press granulator to determine the cause of rotor unbalance; test the vibration speed of clutch; if it exceeds the specified value, adjust the dynamic balance again.

4. Regularly check the heating and cooling system of the cylinder to ensure that the material is heated evenly and completely melted.

5. When the roller press granulator is started, if the power curve and melt pressure curve of the main motor increase instantaneously, it indicates that the feed rate of the feeding system is too large, and the feed rate should be reduced.

6. Start the organic fertilizer machine from slow to fast, check whether the operation is normal, and observe the working state of the instrument.

7. Turn on the heater to heat the head and body. When the temperature of each part reaches the set value, keep the temperature for about 40 minutes to make the temperature inside and outside the machine consistent.

8. Sometimes it is necessary to replace the perforated plate and filter screen of the roller granulator and add enough lubricating oil. The pelletizing mould must be cleaned after use before it can be used again.

0 notes

Text

Organic fertilizer equipment promotes ecological development

With the rapid development of livestock and poultry industry, a large number of feces and sewage have been produced. The harmful elements in these wastes exceed the standard seriously, which is difficult to be treated by the traditional method. In view of this situation, people have developed an organic fertilizer production line composed of high-efficiency fermentation tipper, mixer, granulator (roller press granulator, drum granulator, flat die pellet mill), dryer, cooler and other fertilizer production equipment.

The organic fertilizer production line of livestock and poultry manure is conducive to promoting the harmless treatment of livestock and poultry manure. The organic fertilizer machine is conducive to the formation of industrial chain of resource utilization and commercial operation, achieving the goal of industrialization, marketization and large-scale production, and effectively promoting the development of ecological agriculture and circular economy.

The products produced by organic fertilizer machine take chicken and pig manure as raw materials and do not contain any chemical components. The digestion capacity of chicken and pig is poor, and only 25% of the nutrients can be consumed, while the other 75% of the nutrients in the feed are discharged with the feces, so that the dry product contains nitrogen, phosphorus, potassium, organic matter, amino acid, protein and other components. Chicken manure dryer not only creates economic benefits for enterprises, but also makes great contribution to environmental protection project of human beings.

0 notes

Photo

5000t /a small organic fertilizer production machine exported to Nigeria

Recently, the Huaqiang factory exported a complete set of small organic fertilizer production lines to Nigeria. This set of organic fertilizer machine can reach an annual production capacity of 5,000 tons.

Complete set of organic fertilizer production process

1.Chicken manure, pig manure, sludge and other raw materials are fermented with strains, and the fermented product is processed by a turning machine2.Computer-controlled belt scale automatically batches according to the formula ratio3.The disc granulator performs granulation. Different raw materials use different granulation equipment. Such as flat die granulator, drum granulator, roller press granulator.4.Drum dryer for drying, drum cooler for cooling.5.Large particles and small particles meet industry requirements, the particles are automatically polished, and the products are separated by a screening machine6.The finished product is automatically filled with a 50kg bag or a 25kg bag with an automatic quantitative packaging scale, and the finished product is sealed, put into storage or directly loaded into the car.According to the scale of fertilizer plant and ground conditions, it will be more scientific and reasonable to use small equipment, build more fermentation tanks, and combine infrastructure construction with equipment.

0 notes

Text

What are the main factors affecting the production efficiency of roller granulator

Double roller press granulator is used in fertilizer, pharmaceutical, food, chemical industry and other industries. It can make the mixed materials into the required granules, especially for the materials with high viscosity. At present, due to the process arrangement and operation technology problems of granulator in many fertilizer production plants, the output can not meet the expected design requirements, and the particle surface is not smooth, the hardness is low, easy to break, and the powder content is high.

In the granulation process of the organic fertilizer machine, there are many main reasons that affect the production efficiency of the roller granulator, one of which is the influence of the raw material. The raw material factors directly affect the effect of granulation. Materials with higher starch content are easy to be gelatinized by steam. These raw materials have a certain viscosity after tempering, which is beneficial to the formation of granules.

From the point of view of granulation, the raw material is crushed finely and the granulation strength is high, but the steam is added more, so it is easy to block the machine if you don't pay attention to it. And the raw material is crushed too fine, resulting in the crushing power consumption is too high. It is difficult for granulation, especially for the ring die with small diameter, which leads to poor gelatinization effect of materials, resulting in high material consumption, low output and high powder content of particles.

0 notes

Photo

What combination of components does the roller press granulator have?

The main engine of the roller type press granulator is mainly divided into two parts: granulation and crushing. The fully mixed material is continuously fed into a pair of rolls of two types from the bin opening. The gap between the two rollers can be adjusted properly. At the same time, in order to ensure that the cavities on the two rollers can be fully aligned, one of the rollers can be adjusted properly to the left and right. The granulation part is mainly composed of motor, belt transmission device, special reducer for hard tooth surface, coupling, drive wheel, bearing seat, bearing, drum, hopper, etc.

Part of the materials of the roller press granulator are dispersed into blocks, which are mainly composed of motor, transmission device, gear, bearing seat, bearing, dispersion teeth, etc. The drum of the equipment is made of alloy steel, the scattering teeth are made of stainless steel, the base plate and bearing seat of the main engine are castings of other materials with corrosion resistance and stability considered, and the hopper and discharge are made of stainless steel.

Characteristics of double roller press granulator

The machine has the characteristics of mature technology, reasonable design, compact structure, novel and practical, low energy consumption. It can be used in combination with organic fertilizer machine and production line.

0 notes

Text

Points for attention in roller extrusion granulation

Roller press granulator uses physical method to granulation. The whole process has no pollution and no waste. It is a very environment-friendly organic fertilizer machine. The following will lead you to understand the use of double roller extrusion granulator precautions.

Working principle of double roller press granulator

When the roller extrusion pelletizer is working, it is forced to roll the material into shape by two opposite moving roller skins of the granulation machine. Semi circular spherical cavities are regularly distributed on the two cylindrical roller skins. When the roller skin rotates against each other, the two semicircular cavities just form a complete spherical mold, and the materials inside are forced to be extruded into spherical particles. Due to the continuity of extrusion production, the particles and particles are connected together when they are just extruded, forming a cloth full of particles, which needs to be broken up by the crushing roller and divided into small round particles, and then screened from the screen to select the qualified particles.

The use of roller press granulator

When the double roller extrusion pelletizer is producing granular fertilizers, it should be noted that the ball sockets on the two roller skins should be properly positioned. If they are not adjusted in place, they will be misaligned during granulation and cannot produce qualified products. Granular fertilizer. In addition, after the particles are formed, they are released from the ball socket of the roller skin in time, so that uninterrupted production can be realized. If the formed particles are not released in time, complete particles will not be formed, which will affect the normal production.

0 notes

Video

Fertilizer machine manufacturer introduces reasons for purchasing roller granulator

As a professional organic fertilizer machine factory, our double roller press granulator has the following advantages:

1. Circulation operation, realize continuous production, high output of finished products;2. The material is compressed by mechanical pressure, without any additives, and the purity of the product is guaranteed.3. The particle strength can be adjusted, and the finished product strength can be controlled by adjusting the roller pressure;4. The extrusion granulator is suitable for a wide range of raw materials, and the particle strength can be adjusted freely according to different materials.5. Compact structure, convenient maintenance, simple operation, short process flow, low energy consumption, high efficiency and low failure rate.The double roller extrusion pelletizer consists of the following main components: hinged press frame, easy to replace roller components, floating and fixed rollers, main transmission device with reduction gear, feeding equipment, hydraulic pressure boosting system, automatic grease. Enclosed machine housing to minimize the spread of dust.

Technical parameters of roller press granulator

https://m.hqhifertilizermachine.com/products/fertilizer-granulator-machine-series/roller-press-granulator.html

The whole Huaqiang brand of this machine is divided into DZJ Ⅰ series and Ⅱ series, the power includes 15Kw, 18.5Kw, 22Kw. The output is 1-3 (t/h), and the moisture content of the raw materials is generally controlled at 2%-8%. The roller pelletizer is a newly developed high-efficiency and energy-saving product in our factory. It has the characteristics of reasonable structure, safety and reliability, convenient use, and output power. This model is equipped with a refueling system, which greatly improves the life of the machine.

0 notes

Text

How does the roller press granulator achieve green reuse of resources

How to achieve the green reuse of resources, is the issue of concern. The roller type extrusion granulator is a kind of machine product designed and produced under such a big premise. The following organic fertilizer machine manufacturers for you to introduce in detail:

First of all, the roller press pelletizer is widely used to granulate some abandoned materials, such as pulverized coal, carbon powder, coke powder, carbon black, mineral powder, dust removal ash, lime powder and other metal mineral powders, industrial recycled dust materials, cast iron mill dust, lead, zinc, aluminum dust, converter dust, filter dust, grinding dust, etc.

The roller press granulator can realize the recycling of resources and protect the environment greatly at the same time. In terms of environmental protection, the equipment adopts the process of no drying and normal temperature production, with high particle strength and higher bulk specific gravity than other granulation methods, which is especially suitable for increasing the bulk specific gravity of products.

What's more important is that the mechanical transmission system of the roller type granulator is completely sealed in the body. As the powder material completes the granulation process in the wet state, there is no three wastes discharged from the operation of the prilling and its follow-up process, which truly achieves green production. The roller press granulator has achieved the green reuse of resources, and its market potential is huge.

0 notes

Text

Factors to be controlled and paid attention to in dry roll granulation technology

Compared with wet granulation, dry granulation of roller press granulator is a simpler and continuous method, which is often used as granulation equipment in organic fertilizer machine. In wet granulation, the granules are prepared by mixing, granulating and drying. In dry granulation, the process of fertilizer production is relatively short, because there is no need to combine and dry the prepared materials with water. The steps of granulation are mixing, rolling and grinding, which requires less fertilizer machine, time and energy.

Roller pressing is a simple dry granulation method, but the control and optimization factors in the production of roller press granulator must be considered. For example, rolling, roll speed and feed rate of raw materials determine the product properties and final particle shape. They affect the quality of the product, such as the density, fluidity, compressibility and pressure capacity of the particles, as well as the tensile strength of the particles.

It is important to control these factors to obtain the required quality products, and it is also necessary to fully understand the chemical and physical properties of raw materials and process parameters. In order to improve the rolling compaction, good modeling based on the type of machine used and the characteristics of the raw materials will be very helpful to predict, control and optimize the process and improve the product quality.

0 notes