Text

0 notes

Text

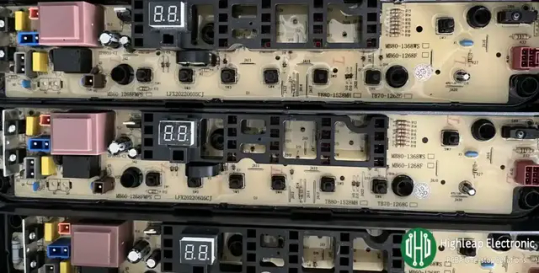

PCBA one-stop service

0 notes

Text

Unlock Superior Performance with Multilayer Aluminum PCBs!

🌟 Discover the ultimate guide to Multilayer Aluminum PCBs – essential components for modern electronics that demand efficient heat dissipation and robust performance. Learn about their structure, manufacturing processes, and key benefits that make them indispensable in various applications.

🔍 Highlights include:

Definition and structure of multilayer aluminum PCBs

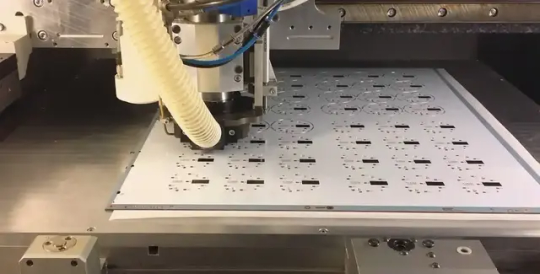

Detailed manufacturing process

Advantages like superior thermal management and enhanced electrical performance

Technical considerations in design and manufacturing

Applications in industries from LED lighting to aerospace

📈 Why choose Highleap Electronic?

Expertise and Advanced Technology: Leveraging cutting-edge manufacturing techniques and strict quality control.

Superior Thermal Management: Ideal for high-power applications.

Comprehensive Product Range: From FR4 to HDI PCBs, we cater to all your needs.

Exceptional Support: Competitive pricing, rapid delivery, and top-tier service.

Don't miss out on this essential read to elevate your next electronic project! 🚀

🔗 Read the full guide

Contact us today for more information!

#pcb#pcba#pcb assembly#smt#electronic#pcb design#PCB Projects#PCB manufacturing#PCB Encapsulation#flexible circuit board#flex pcb#pcb manufacturer

0 notes

Text

Enhance Your PCB Projects with Expert Encapsulation Solutions

Discover how PCB encapsulation and potting can protect your electronic components from environmental hazards, mechanical stress, and more. Dive into our comprehensive guide on selecting the best encapsulation materials, including EVA, PPS, PPO, PAI, Acrylics, and Polyesters, tailored for various applications and needs.

👉 Read the full guide to learn:

The importance of DFM checks in the PCB manufacturing process

Detailed benefits of different encapsulation materials

Practical advice on optimizing PCB design and manufacturing

Why Highleap Electronic?Our expert engineering team at Highleap Electronic ensures your PCB projects meet the highest standards of quality and efficiency. With extensive experience in complex PCB designs and specialized processes, we provide reliable solutions tailored to your specific industry requirements.

🔗 Read the full guide and take your PCB designs to the next level!

Contact us today for more information and a quote!

#pcb#pcba#pcb assembly#smt#electronic#pcb design#PCB Projects#PCB manufacturing#PCB Encapsulation#flexible circuit board#flex pcb#pcb manufacturer

0 notes

Text

🔧 Highleap Electronic: Your Partner in Premium PCB Assembly Services 🔧

Looking for top-tier PCB assembly solutions tailored to your precise specifications? Look no further than Highleap Electronic!

At Highleap, we pride ourselves on delivering exceptional quality and unparalleled expertise in PCB assembly. Our state-of-the-art facilities and cutting-edge technology ensure that your PCBs are assembled with precision and care, meeting the highest industry standards.

Why choose Highleap Electronic?

✅ Quality Assurance: Rigorous quality control measures at every stage of the assembly process guarantee flawless results, meeting your exact requirements.

✅ Customization: From prototype to production, we offer flexible assembly options to suit your project needs, ensuring optimal performance and reliability.

✅ Speed and Efficiency: With our streamlined processes and efficient workflow, we deliver fast turnaround times without compromising on quality.

✅ Technical Expertise: Our team of skilled engineers and technicians have years of experience in PCB assembly, providing expert guidance and support every step of the way.

✅ Cost-Effective Solutions: We offer competitive pricing and cost-effective solutions to help you maximize your budget without sacrificing quality.

Partner with Highleap Electronic for superior PCB assembly services that exceed your expectations. Contact us today to discuss your project needs and let us help you bring your vision to life!

Unlock the power of precision with Highleap Electronic. 🚀

#pcb#pcba#pcb assembly#smt#electronic#pcb design#robotics#automation#iot#drone#mechanical keyboard pcb

1 note

·

View note

Text

Learn more about the PCB manufacturing process

0 notes

Text

Mastering LED Polarity: A Guide to Ensuring Correct LED Installation

In electronic projects involving LEDs (Light Emitting Diodes), correct polarity identification is not just a good practice—it's essential. LEDs, unlike other electronic components, are directional and will only function if the current flows from the anode (positive side) to the cathode (negative side). Incorrectly connecting an LED can lead to it not functioning or being damaged. This guide outlines six reliable methods to determine LED polarity, ensuring your projects light up successfully every time.

1. Pin Length Observation

One of the simplest and most common methods to identify LED polarity is by observing the lengths of the pins:

Longer Pin: Typically the anode (+).

Shorter Pin: Generally the cathode (-).

This method is most effective when the LED is new and the pins have not been altered or trimmed.

2. The Flat Side Indicator

Most LEDs are encased in a clear or colored plastic shell that often has one side flattened:

Flat Side: This side of the plastic casing is almost always next to the cathode. Identifying this flat side quickly tells you which pin is negative.

This physical trait is particularly helpful for quick visual identification without requiring any tools.

3. Internal Structure Method

For clear-bodied LEDs, the internal structure itself provides clues:

Larger Electrode: The side with the larger metal piece inside the LED is the cathode.

Smaller Electrode: The smaller metal piece is connected to the anode.

This method might require a magnifying glass but offers a direct look at the internal polarity markers.

4. Using a Multimeter

A more technical approach involves using a multimeter set to the diode mode:

Connect the Red Probe: Attach it to one of the LED pins.

Connect the Black Probe: Attach it to the other pin.

Observation: If the LED lights up, the pin connected to the red probe is the anode; if it does not, switch the probes and try again.

This method not only confirms polarity but also helps verify that the LED is functioning correctly.

5. Battery Test Technique

When no multimeter is available, a simple battery can be used to test polarity:

Battery Setup: Use a battery with a voltage that matches or is slightly lower than the LED’s rating.

Connection: Touch the battery’s positive end to one pin and the negative to the other.

LED Illumination: If the LED lights up, the pin connected to the battery’s positive end is the anode. If not, reverse the pins.

Ensure the battery's voltage is appropriate to prevent damaging the LED.

6. Circuit Integration Test

In a controlled setup, integrate the LED into a simple circuit to test connectivity:

Set Up a Simple Circuit: Include a power source, a resistor, and connections for an LED.

Insert the LED: Place the LED in one direction.

Power the Circuit: If the LED lights up, note the direction; if not, reverse the LED.

This method also helps in understanding how the LED behaves within a circuit, providing practical learning in addition to polarity checking.

Conclusion

Identifying the correct polarity of an LED is crucial for any project involving these versatile components. Whether you are a hobbyist or a professional, knowing these six methods to check LED polarity will help you ensure that your electronic projects are successful and durable. Each method offers a way to confirm the directionality of an LED, enhancing your overall understanding and proficiency in electronics assembly.

PCB manufacturer from China:https://hilelectronic.com/about/

0 notes

Text

Chinese hobbyists modify drones,To learn more about interesting drones and making drone PCB, please contact us.

0 notes

Text

The Rise of Drone PCB Technology in China: An Aerial Revolution

Over the last decade, China's drone industry has seen explosive growth, emerging as a global leader. At the heart of drone technology lies its intricate electronic systems, with Printed Circuit Boards (PCB) playing an indispensable role. China's advancements in drone PCB technology not only enhance the operational capabilities of drones but also position the country at the forefront of the aerial technology sector.

Key Developments in China's Drone PCB Technology

Drone PCBs in China have evolved significantly, driven by both demand and technological innovation. These circuit boards are designed to be lightweight yet robust, capable of withstanding various environmental challenges while maintaining functionality. The integration of high-density interconnect (HDI) technology is a notable advancement. HDI PCBs allow for finer lines and spaces, smaller vias, and higher connection pad densities, which are crucial for the miniaturization of drones and enhancement of their functionality.

Another significant advancement is the use of flexible PCBs. These are particularly beneficial for drones as they conform to the contours of uniquely shaped devices, reducing weight and improving reliability. Flex PCBs are integral in drones, facilitating complex connections between different sections of the drone without sacrificing performance.

Impact on Commercial and Military Applications

China's drone technology is not limited to consumer applications but extends to significant military and commercial uses. In commercial sectors, drones equipped with advanced PCBs are used for agricultural monitoring, aerial photography, and logistics. These drones require highly reliable PCBs to perform tasks such as real-time data processing, navigation, and autonomous operation.

Military drones, on the other hand, demand even more from their PCBs. They must operate under extreme conditions and often carry additional payloads such as communication hardware, sensors, and sometimes weaponry. The reliability of these PCBs is critical, as they must ensure the drone's performance in critical missions.

Challenges and Innovations

Despite these advancements, the drone PCB manufacturing sector in China faces several challenges. One of the primary concerns is the need for continual innovation to keep up with the rapidly evolving drone technologies. This requires constant research and development efforts to devise more efficient, durable, and smaller PCBs that fit the new generations of drones.

Another challenge is environmental sustainability. The PCB manufacturing process can be resource-intensive and environmentally taxing. Addressing these concerns, many Chinese PCB manufacturers are increasingly turning towards more sustainable manufacturing processes and materials, which not only reduce the environmental impact but also cater to the global demand for greener electronics.

Collaboration and Global Influence

China's drone PCB industry is not operating in isolation but is part of a larger global ecosystem. There is extensive collaboration between Chinese PCB manufacturers and global technology firms, enhancing the overall quality and capabilities of drone technologies. These collaborations help set international standards for drone PCBs, which, in turn, influence global market trends.

China's influence in the drone sector also extends to its role in setting global regulatory standards. As a leading market player, the policies and standards set in China have a cascading effect, influencing how drones are manufactured and used worldwide.

The Future of Drone PCBs in China

Looking forward, the future of drone PCBs in China is tied to the broader trends in technology such as AI and IoT. Integration of AI allows drones to perform more complex tasks autonomously, such as predictive maintenance and threat assessment in military applications. IoT integration, on the other hand, enables better connectivity and control, essential for managing fleets of drones used in logistics or agricultural monitoring.

Moreover, as 5G technology becomes more widespread, the capabilities of drones are expected to expand further. The ultra-low latency and high-speed connectivity offered by 5G will enhance the real-time data transmission abilities of drones, opening up new possibilities for their application.

Conclusion

China’s rapid advancements in drone PCB technology showcase its capacity to lead in high-tech industries. As the country continues to innovate and push the boundaries of what drones can achieve, the global impact of its developments will undoubtedly continue to grow. The integration of cutting-edge technologies into drone PCBs not only transforms the landscape of the drone industry but also sets the stage for the next era of aerial innovation.

0 notes

Text

Flex PCB Design Mastery: A Comprehensive Guide for Procurement Professionals

Introduction

Welcome, esteemed procurement professionals, to a journey through the intricate world of Flexible Printed Circuit Board (PCB) design. In the realm of modern electronics, where innovation knows no bounds, understanding the nuances of flexible PCBs is paramount. Join us as we unravel the complexities, explore the design fundamentals, and equip you with the knowledge to make informed decisions in your procurement endeavors.

Unveiling the Concept

Flexible PCBs, often dubbed as flexible circuits, epitomize the fusion of technology and flexibility. Picture a circuit that bends and folds seamlessly, adapting to the contours of its environment. This is the essence of flexible PCBs. They comprise a myriad of materials intricately woven together:

Conductive Copper Foil: The lifeblood of electrical conductivity in the circuit, available in fully annealed or low-temperature annealed forms for enhanced flexibility.

Insulator: A plethora of materials such as polyimide, PET, PEN, PTFE, and aramid, meticulously chosen for their flexibility.

Cover Layer: Serving as the circuit's armor, safeguarding it against external elements while flexing along with the circuit.

Adhesive: The invisible glue that binds the layers into a cohesive unit post lamination.

Adhesive-less: A boon for projects requiring utmost flexibility, mitigating issues like high-temperature cracks and moisture absorption.

The Design Odyssey Begins

Embark on the design journey armed with insights into the core principles of flexible PCB design:

Project Understanding: Delve deep into project requirements encompassing current specifications, voltage thresholds, impedance, and the intricacies of signal propagation.

Schematic Creation: Craft a blueprint detailing the circuit's anatomy, mapping out the intricate web of electronic components.

Circuit Layout: Navigate the labyrinth of component placement, meticulously calibrating distances and traces to accommodate the circuit's dynamic nature.

Design Validation: Employ simulation tools or build prototypes to scrutinize the design's integrity and functionality.

Manufacturing Blueprint: Generate manufacturing files, including Gerber files, ensuring seamless translation of design into reality.

Collaborative Endeavors: Foster synergy with additive manufacturing and mechanical engineering teams to ensure seamless integration of flexible PCBs into the final product.

Navigating the Design Terrain

As you traverse the design landscape, keep these invaluable tips close at hand:

Circuit Typology: Understand the nuances between static and dynamic flexible PCBs, tailoring your design approach accordingly.

Routing Rigor: Navigate the labyrinth of impedance control, leveraging ground layers as reference planes to enhance signal integrity.

Component Choreography: Mitigate the risk of pad lifting through strategic placement and reinforcement techniques, ensuring resilience against bending stresses.

Manufacturing Maestro: Partner with seasoned manufacturers like Highleap Electronic, well-versed in the intricacies of flexible PCB fabrication, and armed with intelligent data formats like IPC-2581 for seamless file transfer.

Tool Selection: Empower your design prowess with cutting-edge tools like OrCAD PCB Designer by Cadence, equipped with tailor-made features for flex design guidelines.

Epilogue

As we draw the curtains on this immersive journey through flexible PCB design, remember, knowledge is power, and your expertise is the beacon guiding the procurement landscape. Let your curiosity fuel your quest for innovation, and let Highleap Electronic be your trusted ally in transforming ideas into reality. Take the leap, explore the realm of flexible PCBs, and together, let's redefine possibilities.

Your feedback is invaluable, your experiences are enriching—share them with us, for in collaboration lies the true essence of innovation. Explore the realm of possibilities with Highleap Electronic's turnkey PCBA service. Let's embark on a journey of innovation together—click here for a flexible PCB quote and witness your ideas come to life!

2 notes

·

View notes