Text

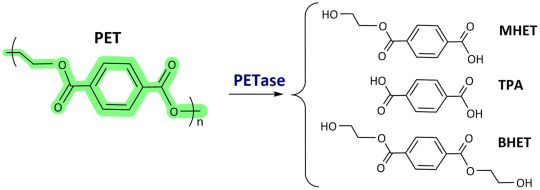

Enzymes will save us from microplastics.

A recent study replicates the molecular level enzymatic breakdown of PET.By interpreting spectroscopic data, they created a 3D molecular model of the process.

Why is this interesting? We know far too little about PETases. In fact, theories remain on how they function. Knowing more about the mechanisms that regulate degradation would help us build more specific and effective enzymes.

Thanks to this study we now know that they can "walk" on the PET chain and they do not need large amount of plastic to work, even 2 subunits are enough.

What to say, will enzymes really save us? I surely hope so.

Full article

Reference: Patricia Falkenstein et al, On the Binding Mode and Molecular Mechanism of Enzymatic Polyethylene Terephthalate Degradation, ACS Catalysis (2023). DOI: 10.1021/acscatal.3c00259

Image Reference: Carola Jerves et al , Reaction Mechanism of the PET Degrading Enzyme PETase Studied with DFT/MM Molecular Dynamics Simulations ACS Catalysis (2021) DOI: 10.1021/acscatal.1c03700

Journal information: ACS Catalysis

4 notes

·

View notes

Text

Disposable mask: a solution

Due to COVID-19, use of billions of disposable facemasks is raising environmental concerns especially when they are thoughtlessly discarded in public spaces, including - parks, open-air venues and beaches. Apart from the challenge of dealing with such huge volumes of essential personal healthcare items in a sustainable way, simply throwing the used masks away for disposal on landfill sites or in incineration plants represents a loss of valuable feedstock for new material.

- Fraunhofer Press Release 16 June 2021

P&G, Fraunhofer and Sabic joined forces to close the life cycle of masks.

Fraunhofer: the masks are first shredded and then converted to pyrolysis oil.

Sabic: the pyrolysis oil is used as feedstock for the production of new PP resin.

P&G: PP polymer is processed into non-woven fibers material to produce new masks.

This pilot project has helped us to assess if the close loop approach could work for hygienic and medical grade plastics.” says Hansjörg Reick, P&G Senior Director Open Innovation. “Of course, further work is needed but the results so far have been very encouraging”.

#COVID-19#facemask#masks#mask#polypropylene#P&G#Sabic#Fraunhofer#saveearth#earth#ecology#LCA#life cycle#environment

1 note

·

View note

Text

More paper bottles

Following the “success” of the paper bottle prototype from Paboco and CocaCola, Unilever launches the first ever paper-based laundry detergent bottle.

To tackle plastic waste, we need to completely rethink how we design and package products. Pulpex paper-based bottle technology is an exciting step in the right direction, and we are delighted to be working together to trial this innovation for our products.

“Innovating with alternative materials is a key part of our sustainable packaging strategy and will play an important role in our commitment to halve our use of virgin plastic materials by 2025.”

- Richard Slater, Unilever Chief R&D Officer

The main difference with Paboco’s solution stays on the inside which instead of being composed of a plastic layer is sprayed with a coating that repels water and should allow the bottle to be recyclable.

Unilever is transforming its approach to plastic packaging through a ‘Less plastic. Better plastic. No plastic.’ innovation framework.

'Less plastic' is about cutting down how much is used in the first place. For example, concentrated laundry detergent allows to ure less plastic.

‘Better plastic' is about making products recyclable, increasing recycled content, and eliminating problematic materials.

'No plastic' is about thinking differently – using alternative materials such as aluminium, glass, paper and board where possible and removing plastic where it is not necessary.

Creating recyclable, paper-based packaging without additional plastic layers is a huge challenge but Pulpex’s patented pulp packaging provides a promising solution.

#Unilever#CocaCola#Pepsi#Diageo#Pilot Lite#Paboco#Pulpex#paper#paperbottle#plastic#plastic bottles#paper bottles#waste#environment#savetheplanet#saveearth#detergent#laundry#prototype

0 notes

Text

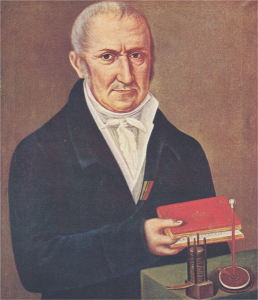

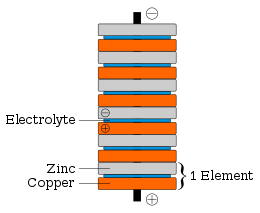

The 1st battery: Voltaic Pile

Alessandro Volta demonstrated that the contact of 2 metals soaked in Brine-solution (concentrated NaCl solution >5% up to 26%) produces electricity.

He used Copper and Zinc thus creating the famous Zn-Cu pile.

In practise series of disks was needed to achieve perceptible current flow. These were alterned with brine soaked cardboard.

The main parts of a battery are Cathode (➕), Anode (➖) and electrolite 🌊.

Therefore, in the voltaic pile the Cathode is Cu, the Anode is Zn and the electrolite is brine-solution.

How does it work?

The key factor is the standard reduction potential E°.

As the name says, the standard reduction potential indicates the tendency of a reduction reaction to happen in standard conditions. The higher the value, the higher the tendency.

You do not know what a reduction reaction is or how E° is measured? worry not! you will find deepening on the topic in other posts, I will link them as soon as I make them. For now accept that Elements can gain or lose electrons and that you can measure their tendency to do so! 😃

The “force” of a battery is the electromotive force ΔE that is expressed in Volts (named after Alessandro Volta).

A rough description of this force is the difference between the reduction potentials of the two metals separated by the electrolite.

Zn2++ 2 e−⇌Zn(s) E°= -0.7618

Cu2++ 2 e−⇌Cu(s) E°=+0.3370

E° of Cu is much higher than that of Zn therefore the reactions taking place are:

Zn(s) ⇌ Zn2++ 2 e− oxidation : loss of electrons

Cu2++ 2 e−⇌Cu(s) reduction : gain of electrons

Such exchange of electrons is called RedOx reaction, a combination of reduction and oxidation reactions. The standard electromotive force of this RedOx is:

ΔE°=E° Red - E° Ox = E° cathode - E° anode = E° Cu - E° Zn =

= 0.337 - (-0.7618) = 1.0988 V

In practise, copper is already solid (Cu(s)) thus there is no copper in solution ( Cu2+).

Therefore, copper acts in the cell as a noble, inert metal, conducting the eletrons from the circuit to the electrolite where the reduction takes place.

2 H+ + 2 e−⇌H2(g) E°=0

Then, the cell can be rapresented as:

Zn | Zn2+ || 2H+ | H2 | Cu

in which a vertical bar represents an interface. The double vertical bar represents the interfaces corresponding to the electrolyte impregnating the porous cardboard disk.

The corresponding electromotive force is ΔE°=0.76.

The Pile in the image above consists of 6 Cells for a total force of 4.56 V

#Alessandro Volta#volta#voltaic#voltaic pile#pile#Cu#Zn#copper#zinc#current#first#battery#electric#flow#electrolite#history#redox#reduction#oxidation

1 note

·

View note

Text

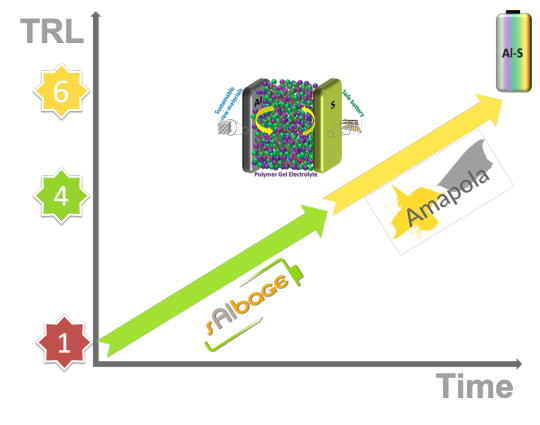

Organic Batteries

The research on polymer-gel electrolites for battery application continues as EU fund the successor of Salbage project: Amapola.

The aim is to develop an Al-S cell that achieves very high energy density values (660 Wh/l or 400 Wh/kg) , [...] further investigate the materials proposed in the Salbage project and develop advanced cathode formulations.

- Electrive 31/05/2021

All rights reserved to Amapola project

So, Amapola aims to reach the “industrial pilot” Technology Readiness Level (TRL) by 30 September 2022.

Why organic?

Polymers are organic compounds, meaning they are mainly composed of Carbon. Inorganic batteries such as Lead-acid use liquid inorganic electrolites.

#Amapola#Salbage#Europe#EU#Research#fund#batteries#Aluminum#sulfur#cell#project#cathode#polymer#electrolites

0 notes

Text

The man who cristalized plastic

Giulio Natta, first and only Italian scientist to win a Nobel prize for Chemistry.

Natta was curious of the fact that ethylene polyaddition took place in the presence of organometallic compounds showed in Ziegler’s conference in 1952.

This new catalyst allowed to obtain polymerization at lower pressure and temperature than the typical processes involved at the time.

Moreover:

<<In the first months of 1954, using Ziegler's catalysts, Natta obtained the first partly crystalline polypropylene and on 11 March noted in his diary, "Made polypropylene". He at once recognized that the crystallinity of the polymer thus obtained was due to a particular type of steric regularity, which he defined as "isotactic". >>

- Giulio Natta Archive Part I

Natta was the first to obtain an organized structure of a polymer. The discovery was impressive and rapidly most university and industry research laboratories involved in macromolecular chemistry ended up focusing on stereospecific polymerization.

#Polymer#polypropylene#Natta#Giulio Natta#Chemistry#Histroy#nobel#nobel prize#organometallic#conference#catalys#1952#1953#1954#1955

0 notes

Text

Nine of the top 10 worldwide producers place their trust in LyondellBasell licensed PP technologies.

With more than 150 licensed lines around the globe and 40 years of continuous innovation, LyondellBasell is a leading pioneer in the development of polypropylene.

A leading advantage of the Spheripol process, in combination with Avant catalysts (5th generation Ziegler-Natta Catalyst), is its unique ability to produce polymer spheres directly in the reactor. Spherical polypropylene provides superior process reliability and best in class operability, in contrast to the processability of small, irregularly shaped, granular polymer particles produced by other technologies.

“In South Korea, a new 400,000 tons per year polypropylene plant has been put into operation. [...]

Managed by Ulsan PP, the new unit uses the fifth generation of LyondellBasell's Spheripol PP process technology.”

- Polimerica 11 Giugno 2021

0 notes

Video

so I realised @racinglesbian had beaten me to it, but welp, I made my own vine comp, because fuck my responsibilities

it’s cringy, but aren’t we all

388 notes

·

View notes

Text

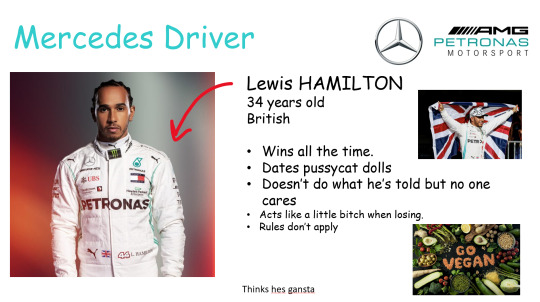

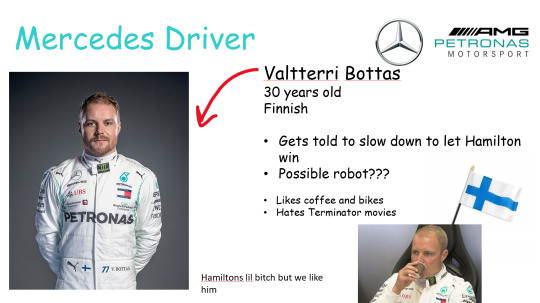

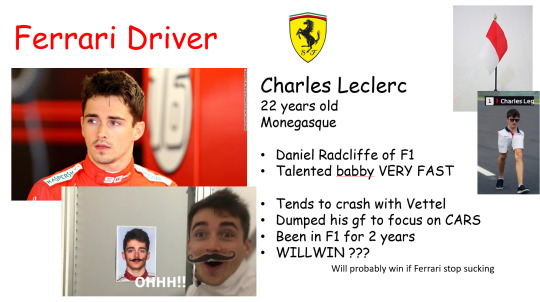

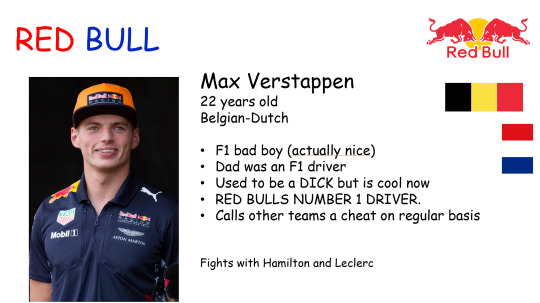

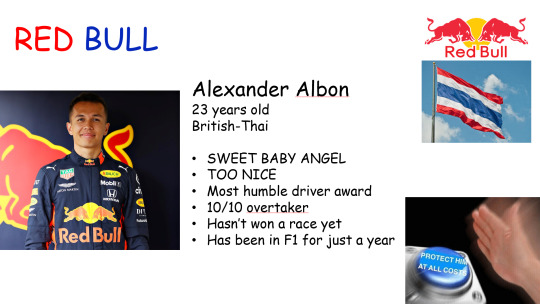

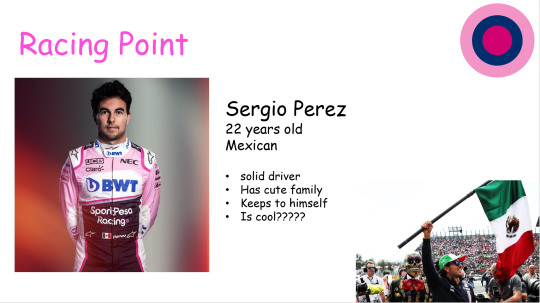

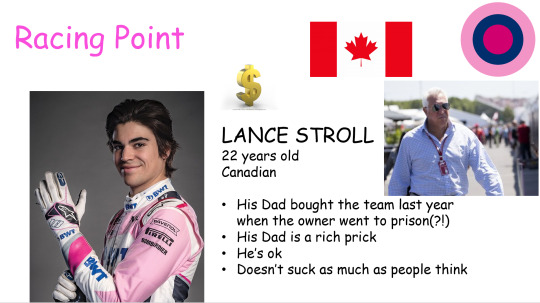

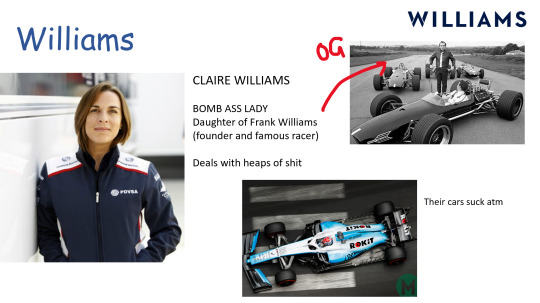

2020 F1 GUIDE FOR NOOBS

#f1#formula1#formula one#f1memes#formula1memes#redbull#ferrari#mercedes#sebastian vettel#max verstappen#daniel ricciardo#valtteri bottas#engineering

3K notes

·

View notes

Photo

Check out @whiskeythrottlerallyteam for some amazing builds, this is one of my favorites by them!

179 notes

·

View notes