#Boron Nitride

Text

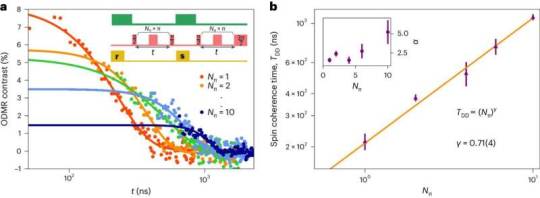

Scientists discover single atom defect in 2D material can hold quantum information at room temperature

Scientists have discovered that a "single atomic defect" in a layered 2D material can hold onto quantum information for microseconds at room temperature, underscoring the potential of 2D materials in advancing quantum technologies.

The defect, found by researchers from the Universities of Manchester and Cambridge using a thin material called hexagonal boron nitride (hBN), demonstrates spin coherence—a property where an electronic spin can retain quantum information—under ambient conditions. They also found that these spins can be controlled with light.

Up until now, only a few solid-state materials have been able to do this, marking a significant step forward in quantum technologies.

The findings, published in Nature Materials, further confirm that the accessible spin coherence at room temperature is longer than the researchers initially imagined it could be.

Read more.

#Materials Science#Science#Defects#Quantum mechanics#2D materials#Layered materials#Boron nitride#Boron#Nitrides#Spintronics#University of Manchester

21 notes

·

View notes

Text

Boron Nitride Electroless Nickel || Advanced Surface Technologies

Our Boron Nitride Electroless Nickel (BNEN) plating service provides a composite deposition of Electroless Nickel and Boron Nitride particles. This advanced composite plating operation is ideal for parts that require both hardness and lubricity. The benefits of this deposit include the exceptionally low coefficient of friction, superior release, and excellent wear resistance. BNEN can be coated to thicknesses ranging from .00005-.002 inches. Unlike EN-PTFE, EN Boron Nitride deposits can be heat-treated to attain maximum hardness for severe wear applications. Our team at Advanced Surface Technologies can deposit the Electroless Nickel with Boron Nitride on various materials, including Aluminum, Copper, Brass, Magnesium, Stainless Steel, and Steel.

Contact Us today for the best nickel boron coating service. We are the only expert in plating in the USA

1 note

·

View note

Text

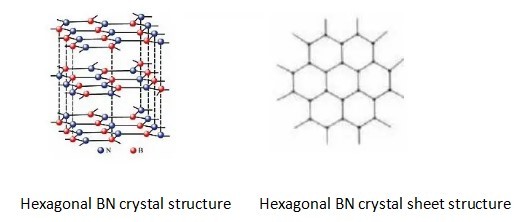

Properties and synthesis of hexagonal boron nitride

Hexagonal boron nitride is a kind of synthetic inorganic material with many excellent properties, which is more and more widely used in a variety of new technologies and products, improving the technical level of modern industry and promoting the development of new material industry to deeper and wider fields.

Properties of hexagonal boron nitride

(1) High heat resistance. Hexagonal boron nitride (h-BN) in 0.1Mpa nitrogen heated to more than 3000 ℃ will sublimate, at 1800 ℃ when the strength of the room temperature for twice, so has excellent thermal shock resistance, in 1500 ℃ air-cooled to room temperature dozens of times will not rupture.

(2) High thermal conductivity. The thermal conductivity of hexagonal boron nitride products is about 34W/m-k, which is similar to that of stainless steel, and the thermal conductivity is larger.

(3) Low expansion coefficient. The expansion coefficient of hexagonal boron nitride is (2.0~6.5)*10-6/℃, second only to quartz glass, coupled with its high coefficient of thermal conductivity, so have excellent thermal shock resistance.

(4) Excellent electrical insulation. Hexagonal boron nitride has good high-temperature insulation, high purity hexagonal boron nitride maximum volume resistivity up to 1016 ~ 1018Ω-m, even at 1000 ℃ high temperature, there is still 104 ~ 106Ω-m.

(5) Good corrosion resistance. Hexagonal boron nitride has good chemical stability and is not wetted by most molten metals, glass, and salt, so it has strong resistance to acid, alkali, molten metal, and glass erosion, and good chemical inertia.

(6) Low coefficient of friction. Hexagonal boron nitride has excellent lubricating properties, the coefficient of friction is 0.16, which does not increase at high temperatures and is more resistant to high temperatures and oxidation than molybdenum disulfide and graphite.

(7) Machinability. Hexagonal boron nitride is very easy to use conventional metal cutting technology for product finishing, with a turning accuracy of up to 0.05mm, so the hexagonal boron nitride blanks can be processed to get the complex shape of the product.

Synthesis of hexagonal boron nitride

There are various methods to prepare hexagonal boron nitride, such as the elemental boron method, boric acid method, borate method, boron halide method, and so on. The basic principle is that boron compounds (such as boric acid, elemental boron, boron halide, and other borates) and nitrogen-containing compounds (such as ammonia, urea, ammonia chloride, melamine, etc.) together with the heating reaction can be obtained after chemical treatment of hexagonal boron nitride of different purities.

0 notes

Text

Electrons become fractions of themselves in graphene, study finds

New Post has been published on https://thedigitalinsider.com/electrons-become-fractions-of-themselves-in-graphene-study-finds/

Electrons become fractions of themselves in graphene, study finds

The electron is the basic unit of electricity, as it carries a single negative charge. This is what we’re taught in high school physics, and it is overwhelmingly the case in most materials in nature.

But in very special states of matter, electrons can splinter into fractions of their whole. This phenomenon, known as “fractional charge,” is exceedingly rare, and if it can be corralled and controlled, the exotic electronic state could help to build resilient, fault-tolerant quantum computers.

To date, this effect, known to physicists as the “fractional quantum Hall effect,” has been observed a handful of times, and mostly under very high, carefully maintained magnetic fields. Only recently have scientists seen the effect in a material that did not require such powerful magnetic manipulation.

Now, MIT physicists have observed the elusive fractional charge effect, this time in a simpler material: five layers of graphene — an atom-thin layer of carbon that stems from graphite and common pencil lead. They report their results today in Nature.

They found that when five sheets of graphene are stacked like steps on a staircase, the resulting structure inherently provides just the right conditions for electrons to pass through as fractions of their total charge, with no need for any external magnetic field.

The results are the first evidence of the “fractional quantum anomalous Hall effect” (the term “anomalous” refers to the absence of a magnetic field) in crystalline graphene, a material that physicists did not expect to exhibit this effect.

“This five-layer graphene is a material system where many good surprises happen,” says study author Long Ju, assistant professor of physics at MIT. “Fractional charge is just so exotic, and now we can realize this effect with a much simpler system and without a magnetic field. That in itself is important for fundamental physics. And it could enable the possibility for a type of quantum computing that is more robust against perturbation.”

Ju’s MIT co-authors are lead author Zhengguang Lu, Tonghang Han, Yuxuan Yao, Aidan Reddy, Jixiang Yang, Junseok Seo, and Liang Fu, along with Kenji Watanabe and Takashi Taniguchi at the National Institute for Materials Science in Japan.

A bizarre state

The fractional quantum Hall effect is an example of the weird phenomena that can arise when particles shift from behaving as individual units to acting together as a whole. This collective “correlated” behavior emerges in special states, for instance when electrons are slowed from their normally frenetic pace to a crawl that enables the particles to sense each other and interact. These interactions can produce rare electronic states, such as the seemingly unorthodox splitting of an electron’s charge.

In 1982, scientists discovered the fractional quantum Hall effect in heterostructures of gallium arsenide, where a gas of electrons confined in a two-dimensional plane is placed under high magnetic fields. The discovery later won the group a Nobel Prize in Physics.

“[The discovery] was a very big deal, because these unit charges interacting in a way to give something like fractional charge was very, very bizarre,” Ju says. “At the time, there were no theory predictions, and the experiments surprised everyone.”

Those researchers achieved their groundbreaking results using magnetic fields to slow down the material’s electrons enough for them to interact. The fields they worked with were about 10 times stronger than what typically powers an MRI machine.

In August 2023, scientists at the University of Washington reported the first evidence of fractional charge without a magnetic field. They observed this “anomalous” version of the effect, in a twisted semiconductor called molybdenum ditelluride. The group prepared the material in a specific configuration, which theorists predicted would give the material an inherent magnetic field, enough to encourage electrons to fractionalize without any external magnetic control.

The “no magnets” result opened a promising route to topological quantum computing — a more secure form of quantum computing, in which the added ingredient of topology (a property that remains unchanged in the face of weak deformation or disturbance) gives a qubit added protection when carrying out a computation. This computation scheme is based on a combination of fractional quantum Hall effect and a superconductor. It used to be almost impossible to realize: One needs a strong magnetic field to get fractional charge, while the same magnetic field will usually kill the superconductor. In this case the fractional charges would serve as a qubit (the basic unit of a quantum computer).

Making steps

That same month, Ju and his team happened to also observe signs of anomalous fractional charge in graphene — a material for which there had been no predictions for exhibiting such an effect.

Ju’s group has been exploring electronic behavior in graphene, which by itself has exhibited exceptional properties. Most recently, Ju’s group has looked into pentalayer graphene — a structure of five graphene sheets, each stacked slightly off from the other, like steps on a staircase. Such pentalayer graphene structure is embedded in graphite and can be obtained by exfoliation using Scotch tape. When placed in a refrigerator at ultracold temperatures, the structure’s electrons slow to a crawl and interact in ways they normally wouldn’t when whizzing around at higher temperatures.

In their new work, the researchers did some calculations and found that electrons might interact with each other even more strongly if the pentalayer structure were aligned with hexagonal boron nitride (hBN) — a material that has a similar atomic structure to that of graphene, but with slightly different dimensions. In combination, the two materials should produce a moiré superlattice — an intricate, scaffold-like atomic structure that could slow electrons down in ways that mimic a magnetic field.

“We did these calculations, then thought, let’s go for it,” says Ju, who happened to install a new dilution refrigerator in his MIT lab last summer, which the team planned to use to cool materials down to ultralow temperatures, to study exotic electronic behavior.

The researchers fabricated two samples of the hybrid graphene structure by first exfoliating graphene layers from a block of graphite, then using optical tools to identify five-layered flakes in the steplike configuration. They then stamped the graphene flake onto an hBN flake and placed a second hBN flake over the graphene structure. Finally, they attached electrodes to the structure and placed it in the refrigerator, set to near absolute zero.

As they applied a current to the material and measured the voltage output, they started to see signatures of fractional charge, where the voltage equals the current multiplied by a fractional number and some fundamental physics constants.

“The day we saw it, we didn’t recognize it at first,” says first author Lu. “Then we started to shout as we realized, this was really big. It was a completely surprising moment.”

“This was probably the first serious samples we put in the new fridge,” adds co-first author Han. “Once we calmed down, we looked in detail to make sure that what we were seeing was real.”

With further analysis, the team confirmed that the graphene structure indeed exhibited the fractional quantum anomalous Hall effect. It is the first time the effect has been seen in graphene.

“Graphene can also be a superconductor,” Ju says. “So, you could have two totally different effects in the same material, right next to each other. If you use graphene to talk to graphene, it avoids a lot of unwanted effects when bridging graphene with other materials.”

For now, the group is continuing to explore multilayer graphene for other rare electronic states.

“We are diving in to explore many fundamental physics ideas and applications,” he says. “We know there will be more to come.”

This research is supported in part by the Sloan Foundation, and the National Science Foundation.

#2023#Analysis#applications#atom#atomic#Behavior#boron nitride#carbon#Collective#computation#computer#computers#computing#crystalline#deal#dimensions#diving#effects#electricity#electrodes#electron#electronic#electrons#form#Forms#Foundation#Fundamental#Gallium#gas#graphene

1 note

·

View note

Text

Scientists have solved a decades-long puzzle and unveiled a near unbreakable substance that could rival diamond as the hardest material on Earth.

Researchers found that when carbon and nitrogen precursors were subjected to extreme heat and pressure, the resulting materials—known as carbon nitrides—were tougher than cubic boron nitride, the second hardest material after diamond.

0 notes

Text

Oasis Collection – Rose Dune Eyeshadow Palette - Farmasi USA

https://farmasius.com/ua000007/product/detail/oasis-collection-rose-dune-eyeshadow-palette?pid=1001546

Oasis Collection – Rose Dune Eyeshadow Palette

Inspired by nature, brought to life by FARMASI.

Dusty rose and mystical mauves in bedazzling shimmers and silky mattesAn eyeshadow palette that reinvents pink and mauve tones with 9 highly pigmented shades.

A versatile eyeshadow palette for easy…

View On WordPress

#Acrylates Copolymer#Aluminum#Aluminum Hydroxide# Octyldodecanol#Boron nitride#Diisostearyl Malate#Dimethicone#Dimethicone Crosspolymer#Ethylhexylglycerin.#Ethylhexy| Palmitate#Fragrance#Hydrogenated Polyisobutene#Hydrogenated Vegetable Oil#Hydroxystearic acid#Iriethoxycaprylylsilane#lsononyl Isononanoate#Magnesium Stearate#Mica#Microcrystalline Wax#Mineral Oil#Octyldodecyl Stearoyl Stearate#Phenoxyethanol#Polyethylene#Polyethylene Terephthalate#Polyisobutene#Silica#Synthetic estan eer fae Aluminum Borosilicate#Synthetic Wax#Talc#Tridecyl Trimellitate

0 notes

Text

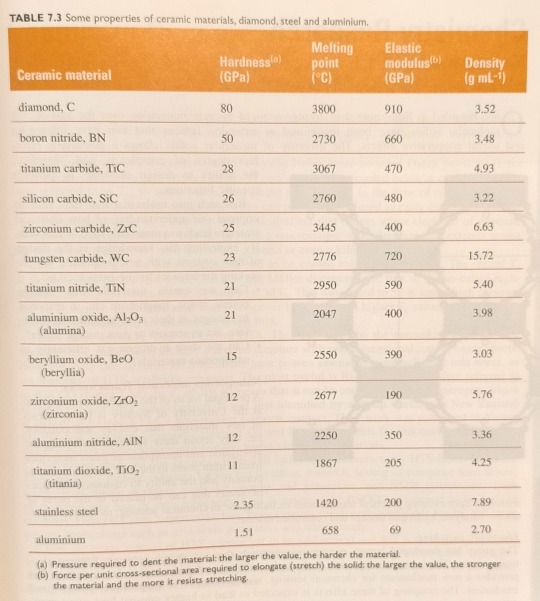

Table 7.3 contains a list of some advanced ceramic materials and they're properties, along with the properties of some metals in common use. (...) Table 7.3 shows that ceramics generally contain metals in relatively high positive oxidation states, combined with small nonmetals (e.g. O, N and C) with high negative oxidation states. (...) Actually, the ceramic compounds listed in table 7.3 possess substantial covalent bonding between the atoms.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ceramics#carbon#oxygen#nitrogen#diamond#boron nitride#titanium carbide#silicon carbide#zirconium carbide#tungsten carbide#titanium nitride#alumina#aluminum oxide#beryllia#beryllium oxide#zirconia#zirconium oxide#aluminum nitride#titania#titanium dioxide#stainless steel#steel#aluminum

0 notes

Text

天元介绍氮化铝陶瓷基板

天元航材是一家拥有50余年的生产技术工艺沉淀的化工原料厂家,主营产品有六方氮化硼(HBN、白石墨烯)等硼系列化工原料产品。今天,小编给大家介绍下关于氮化铝陶瓷基板的相关知识,我们的六方氮化硼可用于制备氮化铝陶瓷基板过程中吗?那么氮化铝陶瓷基板如何制备呢?一起来看看吧!

ps:天元航材不提供氮化铝陶瓷基板,以下仅对氮化铝陶瓷基板相关制作工艺进行简单介绍!

陶瓷基板产品问世,打开散热应用领域行业发展,陶瓷基板指的是铜箔高温下直接键合到氮化铝(AlN)或氧化铝(Al2O3)陶瓷基片表面(单层或双层)上面的新工艺板。按材料来区分可以分为Al2O3、BeO、AlN等多种。具备可靠性高、结合力强、高强度、高导热率、高绝缘性等优质性能指标。主要应用于汽车电子、大功率电力半导体模块、航天航空及军工用其他电子元件、LED照明等领域中。

近年来,随着大规模集成电路及其电子设备朝着高速化、多用途、微型化、大功率的方面发展,各种各样应用领域对性能卓越、高密度电路的需求将增长。在其中A1N陶瓷的应用领域尤为突出。

A1N是III-V族半导体化合物,其晶体是以[A1N4]四面体为结构单位的共价键化合物,25℃时晶格常数a0=3.1172,c0=4.9816,属六方晶系。A1N陶瓷是新型无机非金属材料,最高可稳定到2473K,具备可靠的电绝缘性能、相对较低的介电损耗、低介电常数、出色的热导率等出色的性能指标,并且具有与Si相近的热膨胀系数等等一些列出色的特性,被视作高集成度半导体基片和电子器件封装的理想材料。因而有关于A1N功能陶瓷材料的研究受到了广泛关注。

然而,电路密度和功能的不断提升造成电路工作温度不断攀升,为了避免元件因热聚集和热循环的作用造成损坏,对基板材料的低介电常数、低热膨胀系数、高热导率等方面提出的问题更加严格的。

为了解决以上出现的难题,下面给大家介绍一种氮化铝陶瓷基板的制备工艺方法

1、将比例为(1~5):1的六方氮化硼粉体和氨硼烷改性剂分散在第一溶剂(丁醇、乙酸乙酯、丙醇或乙醇)中,获得氮化硼混合溶液,再将混合溶液倒进砂磨机中,在转速为700~1200rpm下,快速加工处理30~60min后,空气干燥粉碎碾磨后获得改性氮化硼;

2、将改性氮化硼、小于3μm的氮化铝超细粉、多元烧结助剂(YF3-CaF2、Y203-Ca0、Y203-Ca0-Li20、Y203-CaF2或Y203-Ca0-Li203)、粘接剂(聚乙醇缩丁醛、聚乙二醇或聚氨酯)及其第二溶剂利用高分子混料设备搅拌均匀后获得烧结浆料;

3、将流程二的烧结浆料通过真空脱泡机脱泡处理之后,利用流延机,获得一定的厚度的流延带;

4、将流程三的流延带经冲切、层压、排胶和烧结后获得细密的氮化铝陶瓷基板。

5、将氮化铝陶瓷基板用等离子体处理表面,然后再把铜箔贴到上述氮化铝陶瓷基板上,基通过1000~1100℃处理之后获得所需要封装材料。

来源:

https://www.ty1971.cn/Article/dhltcjb.html

0 notes

Text

Boron in Industrial Applications

At present, china use low temperature rapid reaction, self-propagating high temperature reduction, combustion synthesis technology to prepare ultrafine high purity boron powder. For rocket solid fuel, nuclear reactor control rods, explosives the catalyst, automotive airbag triggered agent, boron-containing superconductors, high-quality special steel and other defense industry.

Elemental boron fiber and composite materials: It is reported that the high-strength boron fibers produced by boron fiber manufacturers, high melting point, light weight, good thermal stability. Its strength is 3 times of steel. The E modulus is almost equal. And the weight is only 1/40 of the steel. As the metal powder supplier predict, the era of boron fiber instead of carbon fiber and titanium alloy is coming. An epoxy resin or a polyamide resin as a boron fiber composite material of the base body and metallic aluminum, titanium, cobalt, boron-containing fibers of the matrix material also has good performance. Boron nitride fiber modulus and high functional fibers, high-temperature structural materials can be used as aerospace. The non-metallic borides apply in the field of aerospace defense are boron carbide, boron nitride, and phosphide boron and its composite.

1. Boron carbide, the hardness of boron carbide is only second to diamond and cubic boron nitride. Because of its high strength, high hardness, low density, good wear resistance and chemical properties of stable and neutron absorption properties, it have a wide range of applications in the aerospace, military protection, nuclear power plants, machinery and chemical industry. Because of its hard cast military can protect board for warships, tanks, armored vehicles, bulletproof layer. Its light and hard coated can paint on the aircraft, submarines, or on the vehicle brakes to make it more robust. Also be used as a lightweight body armor, bulletproof vests, or coated on the jewelry and watches to prevent them from being worn. For spacecraft because of its high wear resistance, mechanical seals clever submarines. Its neutron absorption feature can be used for nuclear shielding materials and nuclear reactor core block.

2. Boron nitride, boron nitride is inorganic polymers. Different crystal structure, it has three allotrope: hexagonal boron nitride, close-packed hexagonal boron nitride, cubic boron nitride. Hexagonal boron nitride has the same crystal structure and graphite, commonly known as white graphite. Hardness (Mohs) 2.0; 3000 ~~ ℃ sublimation; 3300 ~ 3400 ℃ melting. The high temperature wear resistance of HBN is excellent, a graphite more resistant to heat than the solid, corrosion resistance, thermal stability is better than diamond, and good dielectric insulating properties and high thermal conductivity. Through microwave and infrared light, radiation-resistant, has a strong neutron absorption capacity, and therefore can be used as a high-temperature electrical insulation materials in the field of aerospace defense, anti-neutron shielding material, the radar the transfer window, the radar antenna medium and rocket engine group and other items.

3. Phosphide Boron, phosphide Boron is also a super-hard, anti-wear, heat-resistant, corrosion-resistant of new inorganic materials. Preparation method: phosphine method, boron trichloride, iodide, boron, the metal phosphide method and the metal flux method. Because of its different system of law, can present as dark red crystals, brown or gel form. Phosphide Boron has chemical stability and strong resistance to oxidation and corrosion resistance, insoluble in acid and organic solvents. Hardness than SiC, the structure has a large energy gap, in the air of 800 to 1000 ° C can not oxidize. Can be used for high-temperature semiconductors, synthetic gem materials; can also be used for optical instruments, precision instruments, be applied in the field of defense high-tech.

Visit Here For More Details:

https://thermic-edge.com/products/ceramics/boron-nitride-ceramics/

0 notes

Text

Cubic Boron Nitride (CBN) Wheels Market | Analysis Report | 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Cubic Boron Nitride (CBN) Wheels Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Cubic Boron Nitride (CBN) Wheels Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cubic Boron Nitride (CBN) Wheels Market?

The Cubic Boron Nitride (CBN) wheels market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Cubic Boron Nitride (CBN) Wheels?

Cubic Boron Nitride (CBN) wheels are abrasive tools employed for grinding and cutting tasks, renowned for their remarkable hardness, thermal conductivity, and chemical stability. These wheels consist of synthetic crystalline CBN particles adhered to a substrate, typically aluminum or steel, offering superior performance and durability compared to conventional abrasive materials such as silicon carbide or aluminum oxide. Widely applied in precision machining, CBN wheels excel in grinding hardened steels, superalloys, and other challenging materials where high material removal rates, precision, and surface finish quality are essential. Valued for their ability to maintain sharp cutting edges, resist wear, and efficiently dissipate heat, CBN wheels enhance productivity and cost-effectiveness across various industrial applications.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1932

What are the growth prospects and trends in the Cubic Boron Nitride (CBN) Wheels industry?

The cubic boron nitride wheels market growth is driven by various factors. The Cubic Boron Nitride (CBN) wheels market includes a variety of abrasive tools highly valued for their outstanding hardness, thermal conductivity, and chemical stability. Witnessing notable expansion propelled by growing demand for precise machining solutions across sectors like automotive, aerospace, and manufacturing, this market offers a diverse array of products tailored to specific cutting and grinding needs. Major players in the CBN wheels market provide cutting-edge solutions characterized by improved durability, cutting efficiency, and surface finish quality, effectively meeting the rigorous demands of contemporary machining processes. Furthermore, ongoing advancements in manufacturing techniques and materials drive continuous innovation within the market, ensuring its ongoing growth and widespread adoption of CBN wheel technology globally. Hence, all these factors contribute to cubic boron nitride wheels market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Resin CBN Wheels

Metal CBN Wheels

Ceramic CBN Wheels

Electroplated CBN Wheels

By Application:

Automotive Parts

Metal Grinding

Industrial

Others

Market Segmentation By Region:

North America

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Saint-Gobain Abrasives Inc.

ILJIN Diamond Co., Ltd.

Noritake Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Ehwa Diamond Industrial Co., Ltd.

Diametal AG

Tokyo Diamond Tools Mfg. Co., Ltd.

Zhengzhou Hongtuo Superabrasive Products Co., Ltd.

Sandvik AB

Engis Corporation

Karnasch Professional Tools GmbH

Nanjing Sanchao Advanced Materials Co., Ltd.

SuperAbrasives, Inc.

View Full Report: https://www.reportsandinsights.com/report/Cubic Boron Nitride (CBN) Wheels-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Cubic Boron Nitride (CBN) Wheels Market share#Cubic Boron Nitride (CBN) Wheels Market size#Cubic Boron Nitride (CBN) Wheels Market trends

0 notes

Text

Armor for steel: New method could enable advances in energy, electronics and aerospace

Researchers have demonstrated that stainless steel and other metal alloys coated with hexagonal boron nitride, or hBN, exhibit non-stick or low-friction qualities along with improved long-term protection against harsh corrosion and high-temperature oxidation in air. The work has been published in Advanced Materials Interfaces.

Metal alloys—mixtures of two or more metals—are created to be strong, durable and resistant to corrosion or oxidation. By adding coatings, or "armor," to make those materials even tougher, scientists could enhance existing products and enable the creation of new, innovative ones.

For example, armoring may boost the ability of solar panels to conduct heat and resist environmental factors. Additionally, it allows semiconductors to maintain proper operating temperature, and aerospace turbine blades to guard against wear, reduce friction and withstand hot conditions.

Read more.

27 notes

·

View notes

Text

Hexagonal boron nitride (h-BN) Overview

Hexagonal boron nitride (h-BN) is a kind of synthetic inorganic material with many excellent properties, which is more and more widely used in a variety of new technologies and products, improving the technical level of modern industry and promoting the development of new material industry to deeper and wider fields.

Definition of hexagonal boron nitride

Hexagonal boron nitride (h-BN) is a hexagonal network of layer structure crystals composed of nitrogen and boron atoms, and it is the only boron nitride physical phase structure that exists in all the physical phases in nature. Its appearance is a white powder with a soft texture, which is loose, smooth, and easy to absorb moisture, and it has a layer structure similar to that of graphene, and thus it is also known as "white graphite".

Structure of hexagonal boron nitride

From the molecular structure diagram, hexagonal boron nitride belongs to the hexagonal crystal system and has the same hexagonal crystal structure as graphene, consisting of multiple layers stacked together, with the different layers connected B-N-B by van der Waals forces, with lattice constants a=0.2506±0.0002 nm and c=0.667±0.0004 nm, and a density ρ=2.25 g/cm³.

Hexagonal boron nitride is very stable in air, has a wide band gap (5.1 eV), can withstand high temperatures up to 2270°C, and sublimes only at about 3000°C. Hexagonal boron nitride also has good insulation, thermal conductivity, and chemical stability, low thermal expansion/shrinkage, and is non-reactive with both weak acids and strong bases at room temperature.

0 notes

Text

New Wearable Sensor Accurately Tracks Tiny Changes in the Breath Process - Technology Org

New Post has been published on https://thedigitalinsider.com/new-wearable-sensor-accurately-tracks-tiny-changes-in-the-breath-process-technology-org/

New Wearable Sensor Accurately Tracks Tiny Changes in the Breath Process - Technology Org

Manchester scientists have developed a new type of wearable sensor that can precisely track your breath, even the slightest changes in the exhaling and inhaling processes. This innovation, described in a recent study published in Advanced Materials, paves the way for improved monitoring of respiratory health and disease.

The sensor, based on a 2D material called hexagonal boron nitride (h-BN), is significantly more sensitive and accurate than previous designs. It can detect even subtle variations in breath patterns, such as those caused by asthma or sleep apnoea.

“Our sensor is like a highly accurate microphone for your breath,” says lead author Prof. Cinzia Casiraghi, a researcher at The University of Manchester. “It can pick up on the tiniest changes in airflow, providing valuable physiological information on an individual, for example related to their cardiac, neurological and pulmonary conditions as well as certain types of illness. “

How it works

The active material in the sensor is made of a hexagonal boron nitride ink, which has been designed by supramolecular chemistry to provide enhanced sensibility to water molecules. The ink is deposited between electrodes in the form of a thin film and then an alternating electric field is applied to the electrodes. When you inhale and exhale, the electrical signal of the film changes based on the local humidity, showing a characteristic “V shape” associated to the full breathing cycle. Changes in the V shape can therefore be attributed to changes in the exhaling-inhaling process, for example due to coughing, fever, runny and stuffy nose.

The new sensor has several advantages over existing technologies. It is more sensitive, meaning it can detect smaller changes in breath. It is also faster, with a response time of just milliseconds. And it is not affected by temperature or other environmental factors, making it more reliable for real-world use. Furthermore, it can be easily integrated onto face masks.

Potential applications

The researchers believe that their sensor has the potential to revolutionise the way we monitor respiratory health, and it could be used to track the effectiveness of respiratory treatments.

“This sensor has the potential to make a real difference in the lives of people with respiratory problems,” says Dr. Liming Chen, Postdoc in Casiraghi group who has worked on this project. “It could help us to diagnose diseases earlier, track the progression of diseases, and help making personalised treatment plans.”

The researchers are now working on extending the technology to achieve high sensitivity and selectivity towards selected biomarkers found in the breath that are associated to diseases, for example respiratory ammonia.

They hope to see their technology in the hands of patients and healthcare providers in the near future.

Source: University of Manchester

You can offer your link to a page which is relevant to the topic of this post.

#advanced materials#ammonia#applications#asthma#biomarkers#boron nitride#chemistry#Disease#Diseases#electric field#electrodes#Environmental#face masks#form#Full#Future#Hardware & gadgets#Health#Health & medicine news#healthcare#how#humidity#Ink#Innovation#it#Link#material#materials#Medical devices#microphone

0 notes

Text

The global hexagonal boron nitride (HBN) market size reached US$ 801.8 Million in 2023. Looking forward, IMARC Group expects the market to reach US$ 1,115.2 Million by 2032, exhibiting a growth rate (CAGR) of 3.62% during 2024-2032.

#Hexagonal Boron Nitride HBN Market#Hexagonal Boron Nitride HBN#Hexagonal Boron Nitride#Hexagonal Boron Nitride Market#Hexagonal Boron

0 notes

Text

Hexagonal Boron Nitride Market Size, Share, Forecast-2030

0 notes