#CNC Machining process

Text

Get the Finest Precision with CNC Machining

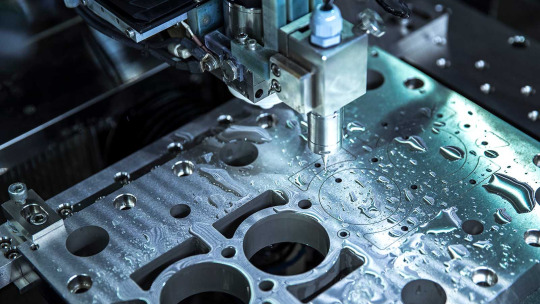

In a subtractive manufacturing technique known as CNC machining, materials are precisely shaped and cut into the necessary shapes. CNC machining automates the production process in contrast to conventional machining, which mainly depends on manual intervention, leading to improved precision, repeatability, and efficiency.

Using computer-aided design (CAD) software, a digital design is produced at the start of the process. The design acts as a guide for how the CNC machine should operate. The design is then transformed into a machine-readable format, often a G-code program, which gives instructions for the CNC machine after it is complete.

The ultimate product's needs are taken into consideration while selecting the material, which may be made of metals, polymers, or composites. By sawing the material into the required sizes, either manually or automatically, the material is prepared.

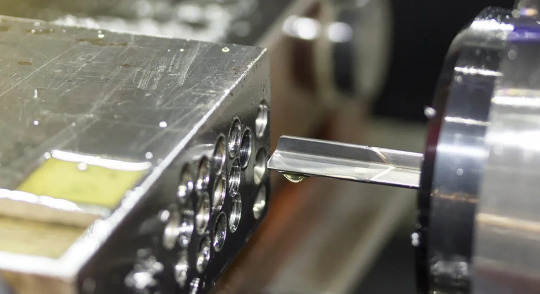

The prepared material is firmly secured to the work table of the CNC machine. The CNC program is entered into the machine's controller once the cutting tools, such as drills, mills, or lathes, are mounted during the CNC machining process.

After the machine is configured, the CNC controller reads the G-code program and gives precise instructions to the machine's motors to move the cutting tools. The cutting tools execute operations including drilling, milling, turning, and more to remove material in line with the design parameters.

Throughout the machining process, quality control procedures are used to make sure that the part's dimensions, tolerances, and surface finishes adhere to the necessary standards. To check accuracy, you could use measurement equipment like calipers, micrometers, or coordinate measuring machines (CMMs).

The advantages of CNC machining

The excellent precision and accuracy of CNC machining is well known. The process is computer-controlled, which guarantees consistent and dependable outcomes, making it perfect for applications that call for precise tolerances and complex geometries.

CNC machines can deal with a variety of materials, such as composites, metals, plastics, and wood. This adaptability makes it possible to produce a variety of components for different businesses.

Complex items may be produced fast and effectively using CNC machining. Once set up, the device can run alone with little assistance from a person. This shortens the production process and increases output in general.

It is possible to produce identical components with great repeatability using CNC prototype machining. Manufacturers can reliably make huge numbers of components because of the CNC program's ability to be stored and used again.

Main source: https://cneasteel.wordpress.com/

#CNC Machining#CNC Machining process#CNC Machining Techniques#CNC Prototype Machining#CNC Machining China

2 notes

·

View notes

Text

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Photo

For sale at our website www.ags.supply/

Timeless.

Brass is thousands of years old, yet used in some of the most sophisticated photographic instruments.

We chose to use brass for its lasting endurance and durability, its warm living character, and the direct connection to Leica’s history with this timeless material.

#analogous#process#Leica#leica camera#leicaq2#leicaq2monochrom#photography#photogear#Arca Swiss#brass#all brass#timeless#madetolast#lifetime goods#cnc machined#madeinportland#Adapt#Generate#Study

8 notes

·

View notes

Text

2 notes

·

View notes

Video

youtube

Customized cold heading parts #cnc machine #CNC customization #manufactu...One stop customization service for metal parts

#youtube#Cold heading processing#CNC Machining#Sheet metal processing#Casting processing#Metal parts supplier

1 note

·

View note

Text

Dellatecnica - Best Woodworking and Panel Processing Machines

DELLATECNICA provides best variety of Woodworking and Panel Processing Machines. We offer top quality woodworking equipments of Holzmac and Promac Brand having machines like Panel saw, Beam Saw, Curvilinear Edge Bander, Automatic Throughfeed edge banding Machine, CNC Nesting Machine and many more.

#Corner Rounding Machine#Dust Collectors#CNC Machines#High tech CNC Machines#Best Woodworking Machine Brands#Woodworking tools#Panel Processing Woodworking Machinery#Durable Woodworking Machines#Woodworking machine manufacturer#Woodworking machines in India#panel Processing Machine#woodworking Machine

1 note

·

View note

Text

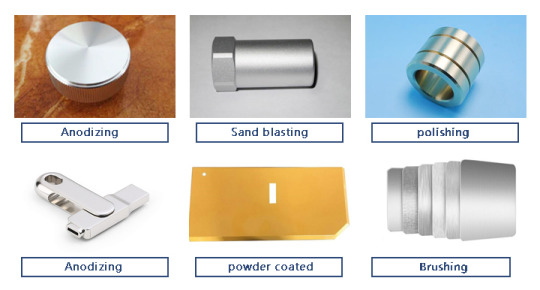

Explore the crucial role of surface finish in machined plastic parts, influencing visual appeal, functionality, and durability. This post delves into common causes of poor surface finish, such as design flaws and material selection, and provides practical tips for improvement. From selecting the right tools and materials to optimizing cutting parameters, discover the key factors in achieving a flawless surface finish. Gain insights into CNC machining, tool sharpness, cutting speed, feed rates, and finishing processes, ensuring a superior quality finish for plastic parts.

#Plastic Machining#Surface Finish Optimization#CNC Machining#Tool Selection#Material Selection#Cutting Parameters#Precision Machining#Finishing Techniques#Manufacturing Processes#Quality Improvement#Brogan & Patrick.

1 note

·

View note

Text

#cnc machined parts#injection Mold Plastic Manufacturer#cnc Machining Parts#parts for Cnc Router#cnc Parts Online#Plastic Injection Molding#Plastic Molding#Plastic Injection Molding Services#Metal Stamping Parts#Molding Abs Plastic#Abs Plastic Molds#Abs Plastic Injection Molding#Plastic Injection Molding Process#Cnc Machining Precision Components#Cnc Parts Supply#Custom Plastic Parts

0 notes

Link

#Molybdenum#tungsten#ioinimplanter#cnc machining#deep processing part#ionimplantation#semiconductorpart

0 notes

Text

Know About The CNC Machining In Details

Computer numerical control, or CNC, machines are becoming essential components of the manufacturing and production sectors, found in anything from small workshops to massive industrial complexes. The term numerical control was all that was used to describe CNC machining back then. This was an earlier system without computers that could be programmed.

CNC, which stands for “computer numerical…

View On WordPress

0 notes

Text

#Non-standard precision machining#precision#cnc swiss#precision parts#cnc turning#Precision machining manufacturer#shaft#The main processing methods of metal parts are: machining#stamping#precision casting (investment casting)#powder metallurgy#metal injection molding. Machining refers to the process of changing the dimensions or properties of a workpiece by means of a mechanical d#Stamping is a forming processing method that relies on press and die to exert external force on plate#strip#pipe and profile to produce plastic deformation or separation#so as to obtain the required shape and size of the workpiece (stamping parts). There are also special processing#laser processing#electric discharge processing#ultrasonic processing#electrolytic processing#particle beam processing and ultra-high speed processing. Turning#milling#forging#casting#grinding#CNC machining#CNC center all belong to machining.

0 notes

Text

An Efficient Processing Method For Complex Deep Holes, It Will Not Be Difficult For You After Reading The Hole Processing!

In fact, complex deep hole machining is becoming more and more challenging. Parts often require additional features such as very small hole finishes, internal chambers, hole diameter variations, contours, grooves, threads, and varying hole orientations. Efficiently obtaining such tight-tolerance holes requires not only extensive experience and R&D resources, but also engineering capability, application facilities, and substantial customer involvement.

Deep Hole Machining (DHM) is a machining field dominated by tools designed for existing applications. Many different industries are involved in deep hole machining, but the most widely used are the energy and aerospace industries. Certain deep-hole part features often seem impossible to form at first, but the non-standard cutting tool solutions designed by experts not only solve process problems, but also ensure that they are executed with high efficiency and error-free features to some extent. The ever-increasing demand for complex holes and the urgent need to shorten machining times have promoted the development of modern deep hole machining technology. Deep hole drilling has been an efficient machining method using carbide tools for decades, but bottom boring is starting to emerge as a bottleneck.

Today, success in this machining area is often based on the use of a mix of standard and specialty tooling components that have been designed with experience as specialized deep hole machining tools. Equipped with extended high-precision shanks with support features and integrated reamers, these tools, combined with the latest cutting edge geometries and insert grades, and efficient coolant and chip control, allow for the highest penetration and Get the high-quality results you need with process security. In deep hole drilling, small diameter holes below 1mm are processed by carbide gun drills, but for holes of 15mm and above, welding edge drills are generally used, and for holes of 25mm and above, indexable drills are used. Insert drills are required for very efficient drilling. Modern indexable insert technology and drill tube systems are also opening up new possibilities for special tools for deep hole machining.

When the hole depth exceeds 10 times the hole diameter, the processed hole is generally considered to be very deep. Holes as deep as 300 diameters require specialized techniques and can only be drilled with single or dual pipe systems. The long run down to the bottom of these holes requires specialized kinematics, tool configurations and the correct cutting edge to complete the chambers, grooves, threads and cavities. Backer plate technology is another important area, also crucial in deep hole drilling, which is now also progressing considerably as part of deep hole machining technology. These include qualified drills for this field that offer higher performance.

1 note

·

View note

Text

QC12K Series CNC Shearing Machine Shearing Process

QC12K Series CNC Shearing Machine perfectly design for every metal Shearing aspect. Modern-day technology provides maximum safety, high accuracy, and unique ease of use.

DDM Machinery is one of the top worldwide shearing machine manufacturers in china. In this infographic, they described the shearing process of their machine. Visit our website for product pricing, customization, or other inquiries: https://www.ddm-china.com/shearing-machine/

0 notes

Text

Injection Mold Plastic Manufacturer: A Key Player in the Plastic Industry

Mold Plastic Manufacturer: A vital part of making plastic products is an injection mold plastic maker. An established technique for the mass manufacture of plastic components, injection molding uses molds that are created and produced by a professional business. These producers are working very hard to make sure that plastic parts are produced effectively, responsibly, and affordably for various industries. read more

Source:https://justpaste.it/injection-mold-plastic

#cnc machined parts#manufacturing plant#Plastic Injection Molding Services#Metal Stamping Parts#Molding Abs Plastic#Abs Plastic Molds#Abs Plastic Injection Molding#Plastic Injection Molding Process#Cnc Machining Precision Components#Cnc Parts Supply#Custom Plastic Parts

0 notes

Text

Four-process CNC cutting machine price

https://www.igolden-cnc.com/product/pneumatic-4-process-nesting-cnc-machine-for-furniture-making/

0 notes

Text

I'm very good at "professionalism" I was trained from a young age. If I get an interview, I'm getting the job. I sit upright in my chair and wear a collared shirt and my employer thinks, "wow! She has a lot of passion for this role!" Buddy, you don't know the start of it. You don't even know my gender.

I'm OSHA certified. I got my 24-hour GD&T training. They can see this. What they don't see is me waxing poetical about surface finish or some shit on this website. When I was in 6th grade, I was exposed to Autodesk Inventor and it changed me fundamentally as a person. Whenever I look at any consumer good (of which there are a lot) I have to consider how it was made. And where the materials came from and how it got here and really the whole ass process. It's fascinating to me in a way that can be described as "intense". I love looking at large machines and thinking about them and taking pictures of them. There are so many steps and machines and people involved to create anything around you. I think if any person truly understood everything that happened in a single factory they would go insane with the knowledge. But by god am I trying. My uncle works specifically on the printers that print dates onto food. There are hundreds or even thousands of hyperspecific jobs like that everywhere. My employer looks away and I'm creating an unholy abomination of R and HTML, and I'm downloading more libraries so I can change the default CSS colors. I don't know anything about programming but with the power of stack overflow and sheer determination I'm making it happen. Is it very useful? No. But I'm learning a lot and more importantly I don't give a fuck. I'm learning about PLCs. I'm learing about CNC machines. I'm fucking with my laptop. I'm deleting SQL databases. I'm finding electromechanical pinball machines on facebook marketplace. I'm writing G-code by hand. I'm a freight train with no brakes. I'm moving and I'm moving fast. And buddy, you better hope I'm moving in the right direction. I must be, because all of my former employers give me stellar reviews when used as a reference. I'm winning at "career" and also in life.

14 notes

·

View notes