#Precision Engineering

Text

Excellence in Flow Control: Butterfly Valve Manufacturers

Hf Valve specializes in crafting precision-engineered flow control devices. They produce a variety of butterfly valves, ranging from resilient-seated to high-performance designs, to suit diverse applications. These manufacturers adhere to industry standards, ensuring quality, reliability, and efficiency in managing fluid flow across industries such as oil and gas, water treatment, and HVAC systems.

#Butterfly Valve Manufacturers#Precision Engineering#Flow Control Devices#Resilient-Seated Valves#High-Performance Valves#Diverse Applications

2 notes

·

View notes

Text

Premier SS Angle Manufacturer: High-Quality Stainless Steel Angles

Elevate your structural projects with top-tier SS angle manufacturer, stainless steel angles, structural steel, corrosion-resistant angles, high-quality SS products, durable metal angles, precision engineering, structural fabrication, stainless steel fabrication, industrial applicationsfrom our leading company. Crafted with precision and durability in mind, our SS angles offer superior strength and corrosion resistance, ensuring long-lasting performance in diverse applications.

#SS angle manufacturer#stainless steel angles#structural steel#corrosion-resistant angles#high-quality SS products#durable metal angles#precision engineering#structural fabrication#stainless steel fabrication#industrial applications

0 notes

Text

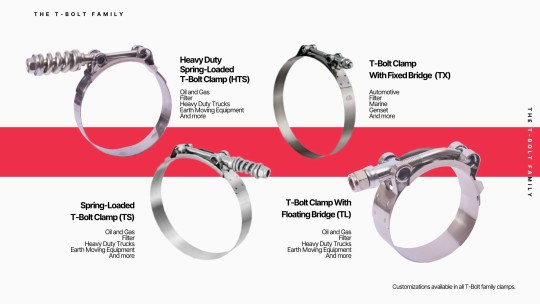

Mastering Precision: The Engineering Marvel of T-Bolt Clamps

In the dynamic world of engineering and technology, precision and reliability reign supreme. At Jolly Clamps, we understand the pivotal role that quality clamping solutions play in ensuring the seamless operation of various industrial processes. That’s why we take immense pride in manufacturing the highest quality T-Bolt Clamps adhering to the stringent SAE standards.

The Epitome of Engineering Excellence

Our T-Bolt Clamps are more than just components; they are the epitome of engineering and technology. Crafted with precision and tested for performance and durability, our T-Bolt Clamps stand as a testament to our commitment to excellence. Designed for the long haul, they find applications in automobiles, heavy trucks, duct connections, industrial machinery, radiators, irrigation systems, and various other industries.

Unraveling the Mechanism

A T-Bolt Clamp derives its name from its unique construction. It features a stainless steel band securely fastened by a forged T-Bolt. This robust assembly ensures the restraint and stability of components even in high-vibration environments. Engineered with the highest quality stainless steel, our T-Bolt Clamps offer unmatched durability and flexibility, making them the preferred choice for discerning customers.

Why Choose Jolly T-Bolt Hose Clamps?

As one of the leading T-Bolt Clamp manufacturers in India, Jolly Clamps stands as a beacon of trust and reliability. Our unwavering commitment to precision and perfection drives us to provide the highest quality clamping solutions tailored to our customers’ unique requirements. Whether it’s Spring Loaded T-Bolt Clamps, Heavy-Duty variants, or those with fixed or floating bridges, we offer a comprehensive range to meet diverse industry needs.

At Jolly Clamps, we understand that every application is unique. That’s why we offer customized T-Bolt Clamping solutions designed to excel in various industries. From Spring Loaded to Heavy-Duty variants, our diverse range ensures that our customers receive tailor-made solutions that deliver unmatched performance and reliability.

In the realm of precision engineering, T-Bolt Clamps stand tall as indispensable components ensuring the seamless operation of critical systems. At Jolly Clamps, we take pride in crafting these engineering marvels that epitomize quality, reliability, and precision. With our commitment to excellence and customer satisfaction, we continue to lead the way as pioneers in the realm of T-Bolt Clamp manufacturing, setting new standards of quality and performance with every innovation.

0 notes

Text

The Feline One: Unveiling the World's Most Expensive Motorcycle

https://gob.stayingalive.in/revving-up-knowledge-unveil/the-feline-one-unveiling.html

Discover Feline One, the world’s most expensive motorcycle crafted with precision engineering and unparalleled luxury. Explore the tradeoffs, challenges, and impact of using titanium, carbon, and aerospace aluminum. #LuxuryMotorcycle #Innovation #EngineeringExcellence #RevolutionaryRide #FelineOne…

View On WordPress

#Aerospace aluminum motorcycle#automotive#Carbon Motorcycle#cars#Environmental impact#Expensive motorcycle#Feline Motorcycles#Feline One#Good Old Bandit#Gud Ol Bandit#luxury#Luxury engineering#Luxury motorcycle#Motorcycle design#Motorcycle engineering#Motorcycle innovation#Motorcycles#News#Performance motorcycles#Precision engineering#Sanjay K Mohindroo#Sanjay Kumar Mohindroo#Sanjay Mohindroo#Sustainable materials#Titanium Motorcycle

0 notes

Text

The Ultimate Stainless Steel Cleaning Guide: Secrets to a Spotless Finish

Stainless steel: a symbol of modern elegance and durability. But even the most glamorous surfaces can succumb to fingerprints, watermarks, and grime. Fear not! With the right approach, you can achieve a mirror-like shine on your stainless steel appliances, fixtures, and décor. Here are 10 secrets to unlock the ultimate stainless steel cleaning guide:

1. Know Your Finish: Not all stainless steel is created equal. Brushed finishes hide minor imperfections better, while polished finishes require a touch more TLC. Identify your steel's finish to choose the gentlest yet most effective cleaning method.

2. Less is More: Ditch the harsh chemicals! Abrasive cleaners can scratch your stainless steel, leaving a dull and damaged surface. Opt for mild dish soap, white vinegar, or baking soda mixed with water – these natural solutions are powerful enough to cut through grime without causing harm.

3. The Microfiber Marvel: Your best friend in the fight against fingerprints is a microfiber cloth. This soft yet effective fabric lifts dirt and smudges without leaving streaks or scratches. Microfiber cloths are reusable and environmentally friendly too!

4. The Power of Prevention: The key to a spotless finish is preventing dirt and grime buildup in the first place. After cleaning your stainless steel, buff it with a dry microfiber cloth to remove any watermarks and leave a protective layer that minimizes fingerprint smudges.

5. Fight Watermarks Head-On: Stubborn watermarks can be a nuisance. For mild cases, a solution of white vinegar and water can work wonders. For tougher marks, make a paste of baking soda and water, apply it to the affected area, and gently buff it off with a damp microfiber cloth.

6. Banish Grease Stains: Fingerprint magnets fade in comparison to greasy splatters on your stainless steel stovetop. Tackle greasy stains with a paste of baking soda and water. Let it sit for a few minutes, then wipe it clean with a damp microfiber cloth. For stubborn stains, repeat the process or consider using a commercial stainless steel cleaner specifically designed for grease.

7. Tackle Tough Stains with Care: If you encounter a particularly stubborn stain, resist the urge to grab a scouring pad. These can scratch the surface. Opt for a gentle abrasive like a nylon scrub pad with your cleaning solution. Always test the cleaning method on an inconspicuous area first.

0 notes

Text

Introducing the NR-4032 Damper Assembly (Shocker) by SBJ Nirmal, meticulously engineered to enhance the performance of your Sonalika Challenger machinery. Crafted with precision and designed for seamless integration, our Damper Assembly ensures smooth and stable operation, even in the most challenging terrains.

At SBJ Nirmal, we prioritize excellence in every aspect of our products. The NR-4032 Damper Assembly exemplifies our commitment to providing the best service, quality, product, and price to our valued customers. With a focus on superior craftsmanship and durability, you can trust in the reliability of our products to meet and exceed your expectations.

Experience the SBJ Nirmal difference today and elevate the performance of your Sonalika Challenger with our NR-4032 Damper Assembly.

Visit us:- https://sbjnirmal.com/

E-mail:- [email protected]

#rotavatorparts#sbjnirmalproducts#rotavator#harvesterparts#agriculture#sbj#business#culture#exporter#IMPORTER#FARMERS#Damper Assembly#Shocker#SBJ Nirmal#Sonalika Challenger#Performance enhancement#Precision engineering#Seamless integration#Smooth operation#Stable operation#Challenging terrains#Excellence#Best service#Quality#Product#Price#Craftsmanship#Durability#Reliability#Customer satisfaction

0 notes

Text

Driving Efficiency and Precision: Exploring the Metering Pumps Market

In the intricate landscape of industrial processes, where accuracy and efficiency are paramount, metering pumps play a pivotal role. These precision instruments are designed to deliver fluids with absolute consistency, making them indispensable across various sectors such as chemical processing, water treatment, and pharmaceuticals.

The metering pumps market is witnessing steady growth, fueled by the increasing demand for accurate and reliable fluid delivery systems. As industries strive for higher productivity and tighter quality control, the need for precise metering solutions becomes more pronounced.

One of the key drivers of metering pumps market is the expanding scope of applications. Metering pumps are not limited to a specific industry; rather, their versatility allows them to be deployed in diverse settings. Whether it's adding precise amounts of chemicals in industrial processes or delivering medications in healthcare settings, these pumps offer unmatched reliability and control.

Moreover, advancements in technology are further propelling the growth of the metering pumps market. Manufacturers are constantly innovating to enhance the precision, efficiency, and durability of these pumps. From sophisticated electronic controls to improved materials and designs, the latest generation of metering pumps sets new standards for performance and reliability.

Another factor driving market growth is the increasing emphasis on sustainability and resource optimization. Metering pumps enable precise dosing, minimizing wastage of chemicals, water, and energy. This not only reduces operational costs but also aligns with environmental regulations and sustainability goals.

Furthermore, the integration of automation and digitalization is transforming the metering pumps market. Smart metering solutions equipped with sensors and connectivity features enable remote monitoring, predictive maintenance, and real-time optimization. This enhances operational efficiency while minimizing downtime and maintenance costs.

In conclusion, the metering pumps market is poised for significant growth as industries continue to prioritize efficiency, precision, and sustainability in their operations. With ongoing technological advancements and expanding applications, metering pumps are set to play an increasingly indispensable role across various sectors, driving productivity and innovation.

Contact us for more information.

#Metering Pumps#Industrial Equipment#Chemical Processing#Precision Engineering#Fluid Dynamics#environmental sustainability#innovation#sustainability#technology#augmented reality#immersive experiences#additive manufacturing#ai#aiincelltherapy#compliance

0 notes

Text

Stainless Steel Screws Ahmedabad

Discover a wide range of premium stainless steel screws Ahmedabad at C P Fasteners. Our high-quality fasteners ensure durability and strength. Our durable and corrosion-resistant screws are perfect for various applications. Find the right stainless steel fasteners for your needs. Explore our collection now!

#stainless steel#stainless steel screws#stainless steel screws Ahmedabad#stainless steel nuts#precision engineering#reliable screws#durable fasteners#C P Fasteners

1 note

·

View note

Text

High precision metrology system - Viewmm

Viewmm is an advanced high-precision metrology system, revolutionizing measurements with unparalleled accuracy. Its cutting-edge technology ensures precise and reliable data acquisition, making it an indispensable tool for industries demanding utmost precision in their processes and product development.

For More Info Visit : https://viewmm.com/en/systems-software/

#High precision metrology system Metrology #Precision Measurement

#Optical Measurement #High-Accuracy #Precision Engineering #Measurement Technology

Address: 1711 W 17th St, Tempe, AZ 85281, United States

Hours: Closed ⋅ Opens 8 a.m.

Phone: +1 480-295-3150

0 notes

Text

Top Class Manufacturing Valve Company

Explore excellence with our top-class manufacturing valve company. We deliver top-notch quality, precision engineering, and cutting-edge technology. Elevate your industry standards with our reliable valves designed for optimal performance. Trust in our commitment to delivering excellence in every type of valve like Gate Valve, Globe Valve, Check Valve, Butterfly Valve, and Ball valve. For more details call us: 0086-731-88787784

0 notes

Text

Shaping the Future: Insights into the Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and…

View On WordPress

#advanced forming technology#advanced materials#aerospace industry#automotive components#ceramic components#engineering ceramics#high-pressure manufacturing#industrial manufacturing#industry trends#isostatic pressing#isostatic pressing applications#isostatic pressing process#manufacturing efficiency#market growth#material compaction#metal parts production#powdered metals#precision engineering

0 notes

Text

Reliable Flow Control: Fully-Weld Butterfly Valve in High-Pressure Applications

A fully-weld butterfly valve is a robust flow control device used in high-pressure and high-temperature applications. It features a fully welded construction, enhancing durability and minimizing leakage risks. With a compact design and excellent throttling capabilities, it's ideal for industries like oil and gas, petrochemicals, and power generation.

#Fully Weld Butterfly Valve#Fully-Weld Butterfly Valve manufacturer#leading Fully-Weld Butterfly Valve manufacturer#trusted Fully-Weld Butterfly Valve manufacturer#High-Performance Butterfly Valve#Precision-Crafted High-Performance Butterfly Valve#Leading Butterfly Valve manufacturer#Knife Gate Valve#Valve Manufacturer#Cost-effective Solution#Chile-Based Company#Chile-Based Company for Knife Gate Valve#Butterfly Valve Manufacturers#Precision Engineering

0 notes

Text

Metal Manufacturing in Ontario

Dive into Ontario's metal manufacturing landscape: a hub of innovation, quality, and precision. Explore the industry's leaders and their contributions.

0 notes

Text

10 TON Indoor Gantry Cranes For Steel Factories

IntroductionCrafting the 10 TON Indoor Gantry CranesApplications of Double Girder Indoor Gantry Cranes in Steel IndustryDetermining the Price of Your Crane ProjectCONCLUSION

Introduction

Welcome to our blog, where we delight in sharing our engineering journey and recent achievements. Today, we are thrilled to spotlight a breakthrough project that has significantly impacted the steel industries…

View On WordPress

#10 ton indoor gantry cranes#cutting sizing factories#double girder cranes#gantry crane pricing#precision engineering#steel coil lifting#steel industry#steel sheet ironing#wimac crane

0 notes

Text

"Mastering Precision: Unleashing the Full Potential of CNC Milling Machines"

In today's rapidly advancing manufacturing industry, precision is key. Manufacturers are constantly seeking ways to enhance their production processes, reduce errors, and achieve impeccable accuracy. This quest for perfection has led to the rise of CNC milling machines, which have revolutionized the way we fabricate intricate and complex parts. By leveraging cutting-edge technology and advanced automation, CNC milling machines empower manufacturers to master precision and unleash the full potential of their operations.

The Power of CNC Milling Machines:

CNC milling machines utilize computer numerical control to automate the milling process, enabling unparalleled precision and repeatability. These machines are capable of executing highly intricate designs with incredible accuracy, ensuring consistency in every manufactured component. By eliminating human error and enhancing control, CNC milling machines deliver exceptional results that surpass traditional manual milling methods.

Unleashing Full Potential:

Mastering precision with CNC milling machines opens up a world of possibilities for manufacturers. Firstly, it allows them to push the boundaries of design complexity. Intricate shapes, intricate contours, and fine details that were once challenging to achieve are now within reach, thanks to the precision capabilities of CNC milling machines. This not only expands creative possibilities but also enables the production of high-quality parts with minimal defects.

Furthermore, CNC milling machines offer remarkable efficiency gains. These machines can operate continuously, 24/7, with minimal downtime and setup time. Once the design is programmed into the machine's computer, it can churn out parts with consistent precision, significantly reducing production time and costs. This increased efficiency allows manufacturers to meet tight deadlines, handle larger production volumes, and achieve higher profitability.

Additionally, CNC milling machines offer versatility. They can work with various materials such as metals, plastics, and composites, accommodating a wide range of manufacturing needs. Whether it's prototyping, small-batch production, or large-scale manufacturing, CNC milling machines provide the flexibility to adapt to diverse projects, making them indispensable tools in modern manufacturing facilities.

Conclusion:

Mastering precision with CNC milling machines unlocks a world of opportunities for manufacturers. The ability to achieve unparalleled accuracy and repeatability empowers them to tackle complex designs, improve production efficiency, and expand their capabilities. As technology continues to evolve, CNC milling machines will undoubtedly play a vital role in shaping the future of manufacturing, allowing us to push the boundaries of precision and innovation even further. By harnessing their full potential, manufacturers can take their operations to new heights and establish themselves as leaders in their respective industries.

1 note

·

View note

Text

uncle professor obrien is trying his best, god damn it

#dee s 9#garashir adoption au#idan is in the command track but he tries extra hard in engineering#so he can do right by his human professor uncle :)#you know lim is stoked about his brother learning a trade. Oh youre home for break! fix our generator.#miles is doing his best to be a loving parental figure! for julian's big goofy son!#whos like sooo much like his father its stupid. strong. confident. almost pathologic need to be loved#plus a deep deep deep feeling that they have and dont deserve an unfair advantage....#ANYWAYS CARDASSIANISM BE DAMNED MY BOY CAN TROUBLESHOOT A WARP CORE!#i have 1 hour almost precisely of free time a day and i spent it BANGING this out. god damn it

95 notes

·

View notes