#Trunnion Ball Valve

Link

Most people make use of the Butterfly Valve that will also control the flow of liquid as well as you can enjoy a lot of benefits from their side. If you want to buy them can consider to shopping it from “CWT Valve”.

0 notes

Text

Trunnion Ball Valve - How They Work

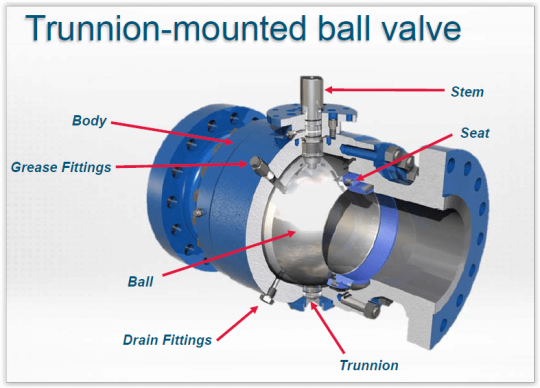

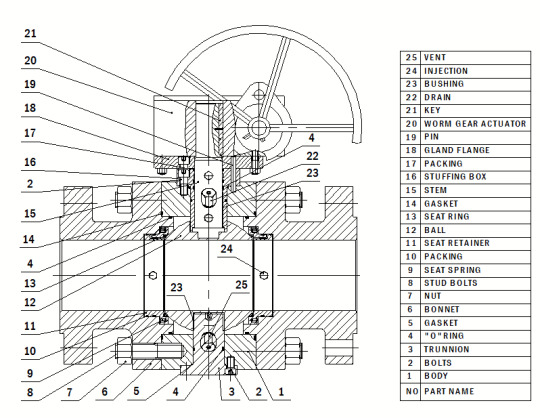

Trunnion ball valves are quarter-turn valves used to stop or begin the progression of a media in a line. The most widely recognized kind of ball valve has a "free drifting" plan, so the trunnion type is a plan change. Inside a trunnion ball valve, the ball interfaces with the stem toward one side, and on the opposite end, a shaft called the trunnion. Because of this plan change, the ball is held immovably set up. In a drifting ball valve, the ball is simply associated with the stem and is in this way called drifting.

Trunnion ball valves enjoy a wide range of upper hands over free-drifting valves, they are reasonable for low, and high-pressure applications, and proposition lower functional costs than free-drifting ball valves.

Trunnion ball valve benefits

High strain applications

For high strain applications, a trunnion ball valve is the ideal ball valve configuration type. In the drifting ball valves, the ball has some opportunity for development. During use, the ball drifts somewhat downstream against the seat ring and makes a fixing just on one side of the valve. What's more, the force on the stem is additionally expanded.

Here the trunnion configuration offers an answer. In the trunnion valve plan, the ball isn't drifting as it is associated with the trunnion. This is profitable since it will keep a legitimate seal on the two sides and there is no additional force to the stem. Consequently, for higher strain applications a trunnion ball valve will give better fixing and require less force to turn.

Spring-Loaded Seats

Trunnion-mounted ball valves are fitted with spring-stacked seats. In a drifting ball valve the tension powers the ball against the seats, which makes a seal. Tragically the ball valve will require high strain to make a compelling seal, which would deliver them incapable in low tension frameworks.

Trunnion-mounted ball valves are compelling in both low and high tension circumstances. In low or no-pressure circumstances the spring-stacked seats will make a seal, while likewise working for high tension applications.

Lower functional expenses

A trunnion-mounted ball valve gives lower functional expenses because of the way that any extra strain on the valve is consumed by the trunnion and the stem. This prompts a lower working force and hence dispenses with the requirement for an enormous actuator.

Trunnion-mounted ball valve weight

A trunnion ball valve is planned by API608 or API 6D and conforms to a few other industry principles. Programming interface 6D gives essential plans, aspects, and testing guidelines for the trunnion valve. The API 6D standard likewise gives the standard loads of trunnion ball valves relating to various drag sizes and body aspects.

Trunnion twofold block and drain (ebb) ball valves

Twofold block and drain (DBB) is the method involved with closing a line segment on the two sides of the valve as opposed to only one. Consequently, a trunnion ball valve can impede both the upstream and downstream sides of the functioning region and afterward vent (drain) any strain that remaining parts in the channeling and valve. A twofold block and drain (DBB) are frequently utilized for stricter detachment of cycle liquid from other hardware. It normally comprises two trunnion ball valves that go about as block valves and a drain valve (generally ball or needle valve) to a protected area, reliable with nearby natural guidelines.

A DBB valve is a side-section ball valve intended for downstream, halfway, and upstream gas and oil applications with either a welded or blasted body. The valve has two seats, each giving a seal against pressure independently. One seat seals the liquid from upstream, and the other seat seals the liquid from downstream. For a DBB trunnion-mounted ball valve, when the valve is in the shut position, and the liquid comes from upstream, it pushes the seat against the ball to deliver the fixing.

At the point when the pipeline is feeling the squeeze, the trunnion ball valve is shut. The liquid remaining parts are caught inside the ball, which makes a resultant tension in the ball. The strain inside the ball climbs when the temperature in the ball becomes higher. It is important to vent/drain the tension when the strain in the ball turns out to be sufficiently high. For a trunnion ball valve with a drain capability, the strain in the ball pushes the seat back as the spring behind the seat packs, and there is vent/draining between the fixing surfaces. As per API 6D details, the venting/draining is expected at a strain of under 1.33 times the planned pressure rating for the ball valves. Be that as it may, a few basic undertakings need to vent at a tension under 1.1 times the initially planned pressure.

UPVC Ball valve

UPVC Ball Valve manufacturers are additionally made by Aira Euro Automation, an industry chief in UPVC valve plan and assembling. Polyvinyl chloride (PVC) unplasticized ball valves have a characteristic propensity to oppose erosion and could be a decent ally to ranchers. These UPVC Ball Valve were made to battle the issues that ranchers and organizations experience while dealing with ranches. Water and development getting granules are conveyed to the remotest pieces of the ranch by the utilization of these valves, which make it feasible for both limited scope and enormous scope ranchers to offer water and supplements to far away places.

0 notes

Text

Trunnion Ball valve manufacturer in Mumbai

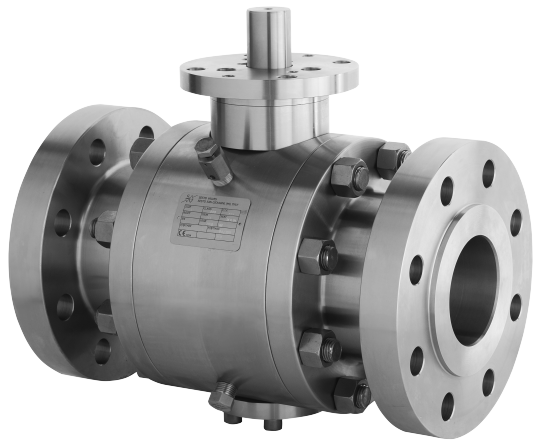

SpecialityValve is a reputed leading Trunnion Ball Valve manufacturer in Mumbai. The flow of a medium in a system is started and stopped using a Trunnion Ball valve. A ball is attached to the stem on one side and the trunnion on the other side of this type of ball valve. Both the stem and the trunnion keep the ball in place. This design gives the valve more strength, allowing it to work more efficiently. The lever or actuator must be turned to a 90 degree angle to start and stop the flow. This valve can be used in both low and high pressure situations. When compared to other valves, this one has a relatively low operating cost.

Top valve manufacturing company

Since 2013, SpecialityValves has been one of India's top manufacturers and global exporters of industrial valves. With a solid reputation for producing high-quality industrial valves and being a reliable provider of all varieties of valves, including some of the most popular and frequently used valves, we are a trusted supplier of all types of valves. Our service is entirely centred on the standard of offering customised valve design and production in accordance with our customers' needs and desires.

We are a world's largest producer of high-quality goods, and our well-integrated work environment is the key to our success. Our infrastructure is dispersed across a vast area and has plenty of room for expansion. We put a lot of money into leveraging current production techniques to improve our ability to reach a wider audience with our products in a fast-paced market. Our in-house production facilities are divided into highly advanced divisions for R&D, product testing, packaging, and distribution, each led by a skilled professional.

Advantages of Trunnion Ball Valve

Both high and low pressure applications are controlled

This valve has a lower operating cost.

Efficient

Industries that use trunnion ball valves:

Oil and gas industries.

Petrochemical industry.

Chemical industry

Marine Industries.

Description:

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Titanium, Stainless steel (SS316, SS304, F51, F55, CF8, CF8M).

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld Trunnion Ball Valve,

Socket weld Trunnion Ball Valve,

Threaded Trunnion Ball Valve,

Flanged Trunnion Ball Valve.

Operations:

Handwheel Operated,

Gear Operated,

Electric Actuated.

Pneumatic operated

For more visit: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

1 note

·

View note

Text

Trunnion Ball Valve

Trunnion ball valves are utilized in an assortment of uses, like water, gas and oil pipelines, synthetic plants and treatment facilities, and power plants. They are additionally utilized in farming, ranger service, and mining.

Trunnion ball valves are made of metal or steel and are normally round and hollow in shape. They have a handle and a ball that is held set up by a spring. At the point when the ball is delivered, it drops into an attachment on the valve body, permitting the progression of liquid.

Trunnion ball valves can be opened or shut by pivoting the handle. They are commonly fitted with a really look at valve to forestall reverse. Trunnion ball valves are solid and can deal with high strain and stream rates.

Trunnion Mounted Ball Valve

Trunnion mounted ball valves are commonly used to control the progression of liquid in pipelines, yet can be utilized in different applications too. These valves are made from a solid metal casing that is mounted on a metal roller that permits it to turn. At the point when the ball is turned, it moves the valve handle which can then be utilized to control the progression of liquid.

Trunnion mounted ball valves can be utilized in an assortment of utilizations, however are commonly utilized in pipelines. They are made from a solid metal casing that is mounted on a metal ball that permits it to pivot. At the point when the ball is pivoted, it moves the valve handle which can then

Trunnion Ball Valve Applications

A trunnion Ball Valve (TBV) is a kind of turning valve that utilizes a trunnion to pivot the valve body. TBVs are utilized in applications where a little, lightweight valve is required, like natural and modern applications. TBVs are likewise utilized in water dispersion and warming frameworks.

Trunnion Mounted Ball Valve Configurations

There are numerous setups for trunnion mounted ball valves. The most widely recognized setup is a solitary ball valve in the focal point of the valve body. Different setups incorporate a twofold ball valve, a quad ball valve, and a complex valve.

The upsides of a trunnion mounted ball valve are that they are conservative and simple to work. They are likewise flexible and can be utilized in an assortment of utilizations. The detriments of trunnion mounted ball valves are that they can be challenging to keep up with and they can be inclined to mileage.

For more data if it's not too much trouble, click here.

1 note

·

View note

Text

Your One-Stop Solution for Trunnion Ball Valves in India

When it involves making sure seamless operations in various industrial packages, the choice of valves could make a large distinction. Trunnion ball valves, known for his or her sturdiness, reliability, and performance, have come to be an indispensable part of many industries. If you are trying to find the nice trunnion ball valves manufacturers in India, you have come to the proper vicinity. In this blog, they can explore why Instrument Fittings is your closing destination for pinnacle-notch trunnion ball valves and how they stand out as a leading dealer, supplier, and exporter inside the enterprise.

Understanding Trunnion Ball Valves

Before delving into why they are your ideal accomplice, permit first to apprehend what trunnion ball valves are. Unlike floating ball valves, trunnion ball valves have additional mechanical anchoring at the pinnacle and backside. This layout presents greater stability and control, particularly in high-pressure packages. The trunnion layout allows in decreasing the torque required to perform the valve, making it greater green and durable.

Why Choose Instrument Fittings for Trunnion Ball Valves?

They are dedicated to turning in top-notch fittings and furnishings to various industries, ensuring seamless connections and exceptional exceptional. Here’s why they are the desired preference amongst trunnion ball valves producers in India:

Exceptional Quality: Renowned for his or her incredible best and reliability, our trunnion ball valves have ended up synonymous with excellence within the marketplace. they ensure that every product meets stringent satisfactory standards, imparting our clients peace of mind and lengthy-lasting performance.

Comprehensive Range: they offer an extensive variety of trunnion ball valves to cater to diverse commercial desires. Whether you need a widespread valve or a custom designed answer, our massive product line guarantees that you discover exactly what you're looking for.

Expertise and Experience: With years of enjoyment within the industry, they've the know-how to apprehend the specific necessities of different sectors. Our information and experience allow us to offer solutions that are not most effective but also tailor-made to precise packages.

Sustainability Focus: Our aim is to decorate the fittings and fasteners sector with a focal point on first-rate and sustainability. They are devoted to putting new benchmarks within the enterprise, making sure lasting connections and a sustainable destiny for all our clients.

The Role of Trunnion Ball Valves in Various Industries

Trunnion ball valves play an important role in diverse industries due to their robust layout and dependable performance. Here are a few key packages:

Oil and Gas: These valves are essential in controlling the glide of oil and fuel, presenting protection and performance in high-stress environments.

Chemical Processing: The chemical industry calls for valves which can face up to corrosive materials and extreme temperatures. Trunnion ball valves are perfect for such situations.

Power Generation: In energy vegetation, reliable float manipulation is essential. Trunnion ball valves ensure smooth operations and minimal upkeep.

Water Treatment: These valves help in dealing with the float and stress of water in remedy plants, ensuring clean and safe water supply.

Your Reliable Trunnion Ball Valves Supplier

As main trunnion ball valves manufacturers in India, they take delight in our big community and sturdy supply chain. Here’s what sets us aside:

Wide Distribution Network: Our giant distribution network ensures that our merchandise is without difficulty to be had to customers throughout the u . S .. Whether you are in a metropolitan town or a far off vicinity, you may depend on us for they'll timed deliveries.

Customer-Centric Approach: they agree in constructing lasting relationships with our clients. Our purchaser-centric technique ensures that they provide personalized service and aid, helping you make the great choice to your particular desires.

Competitive Pricing: Quality no longer ought to come at an excessive price. They provide aggressive pricing on all our merchandise, making sure that you get a nice price for your investment.

Technical Support: Our group of experts is always equipped to assist you with any technical queries or troubles. They provide complete help to ensure that our valves perform optimally on your packages.

Trunnion Ball Valves Dealers: Partnering for Success

They apprehend the significance of strong partnerships. As depended on trunnion ball valves dealers, they collaborate with diverse stakeholders to ensure the seamless supply of first-rate valves. Here’s how they foster successful partnerships:

Reliable Inventory Management: they preserve a robust inventory to meet the instant necessities of our clients. Our efficient inventory management gadget guarantees that they can fulfill orders right away, fending off any downtime for your operations.

Training and Support: they provide education and guide to our companions, making sure that they're nicely-equipped to address our merchandise. This collaborative method guarantees that our valves are established and maintained correctly, maximizing their lifespan and performance.

Market Insights: they proportion precious marketplace insights with our companions, helping them stay in advance of industry traits and make informed choices. This proactive technique guarantees mutual growth and fulfillment.

Trunnion Ball Valves Stockist: Ensuring Availability

As a main trunnion ball valves stockist, they ensure that our merchandise are continually to be had to satisfy the needs of our clients. Here’s how they manage our inventory correctly:

Strategic Stock Locations: they have strategically located inventory points across the usa to ensure short and smooth entry to our merchandise. This community permits us to cater to urgent requirements without delays.

Advanced Inventory Systems: Our superior stock control systems help us song inventory tiers in real-time. This guarantees that they are able to manipulate our delivery chain correctly, lowering lead times and improving customer pleasure.

Diverse Product Range: they stock a diverse variety of trunnion ball valves to meet the varying wishes of different industries. Whether you want valves for high-strain programs or corrosive environments, they've the proper solution in inventory.

Trunnion Ball Valves Exporters in India: Reaching Global Markets

Instrument Fittings isn't always best a trusted name in India however additionally a famend exporter of trunnion ball valves. As main trunnion ball valve exporters in India, they reach global markets with our excellent merchandise. Here’s what makes us a favored exporter:

Global Standards Compliance: Our products follow global standards, making sure that they meet the requirements of global markets. This adherence to satisfactory standards makes our valves suitable for various international packages.

Efficient Logistics: they have a properly-installed logistics community that permits us to supply our products to clients around the sector. Our efficient logistics system ensures timely deliveries and minimum disruptions.

Custom Solutions: they recognize that one-of-a-kind markets have different necessities. Our ability to provide customized answers guarantees that they can meet the unique needs of our global clients.

Reputation for Excellence: Our recognition for handing over great pleasant and dependable merchandise has earned us the trust of customers internationally. They continue to uphold this reputation by constantly imparting top-notch trunnion ball valves.

Enhancing the Fittings and Fasteners Sector

Our intention is to decorate the fittings and fasteners sector with a focal point on fine and sustainability. Here’s how they're placing new benchmarks within the enterprise:

Innovation and Technology: they invest in modern technology and innovation to continuously enhance our merchandise. Our modern-day production facilities make certain that they stay at the leading edge of the enterprise.

Sustainable Practices: Sustainability is at the center of our operations. They undertake environmentally fine practices and use sustainable materials to minimize our effect on the environment.

Quality Assurance: Our stringent extraordinary assurance techniques make sure that each product that leaves our facility meets the highest requirements of extraordinary. They conduct thorough finds and inspections to guarantee the reliability of our valves.

Customer Satisfaction: they prioritize client pleasure specially. Our willpower to excellence and continuous development ensures that they exceed our clients’ expectancies each time.

Conclusion

When it involves trunnion ball valves, they are your one-stop solution in India. As main trunnion ball valves manufacturers, Trunnion ball valves suppliers, Trunnion ball valves dealers, Trunnion ball valves stockists, and Trunnion ball valves exporters in India, they are devoted to presenting top-notch services and products to our clients. Our consciousness on fine, sustainability, and consumer pleasure sets us apart within the enterprise.

Whether you're in need of reliable trunnion ball valves in your commercial applications or looking for a relied on associate to supply awesome valves, they are here to satisfy your desires. Explore our comprehensive range of trunnion ball valves and experience the distinction that sets us aside as a frontrunner inside the industry. Contact us these days to study more about our products and the way they can help you in accomplishing seamless operations and lasting connections.

#Trunnion ball valves manufacturers#Trunnion ball valves manufacturers in India#Trunnion ball valves suppliers#Trunnion ball valves dealers#Trunnion ball valves stockist#Trunnion ball valves exporters in india

0 notes

Text

instagram

Choose from floating or trunnion mounted designs, available in 1, 2, or 3-piece configurations and even 3-way L/T port options. We adhere to industry standards like API 6D, ISO 17292, ASME B16.34, and API 607, ensuring exceptional reliability. Select from soft or metal seated options, and choose manual, actuated (rack & pinion, scotch yoke, electric), or gear operated configurations for a perfect fit. Upgrade your flow control with Freture Techno's high-performance ball valves.

#API 6D#Ball Valve#Trunnion Mounted Ball Valve#ASME B16.34#Gear Operated#Rack and Pinion#freturetechno#manufacturers#mumbai#india#Instagram

0 notes

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

trunnion ball valves Manufacturer in India

If you are Looking for high-quality trunnion ball valves? We are a reputable manufacturer in India, offering reliable and durable trunnion ball valves for various industries. Trust our expertise for superior performance and excellent customer service. We are a trusted manufacturer in India, offering a wide range of reliable and durable trunnion ball valvess. Our products are designed to meet industry standards, ensuring efficient flow control and reliable performance. Contact us today for top-notch butterfly valves that cater to your specific needs. For more details visit here: https://avcvalves.in/

0 notes

Text

Trunnion Ball Valve

When you're thinking to start a production business then most probably you will need to think about needs that might arise. Some of the most common products that almost every factory or industry needs are valves, so finding the best Ball Valve Manufacturer and maintaining good relations is important. If you want to buy the right Trunnion Ball Valve for your business can consider shopping it from "CWT Valve". We are a leading manufacturer and supplier of valve products to meet its customer's needs. Shop it now!

0 notes

Text

The Importance of Testing and Certifications in Trunnion Ball Valve Manufacturing

Trunnion ball valves play a vital role in various industries, ensuring the safe and efficient control of fluid flow. These valves are widely used in oil and gas, petrochemical, power generation, and other critical applications. To guarantee their reliability and performance, rigorous testing and certifications are crucial during the manufacturing process. In this article, we will explore the significance of testing and certifications in trunnion ball valve manufacturer, highlighting their impact on quality assurance, safety, and industry standards.

Trunnion ball valves are essential components in various industrial applications where precise control over fluid flow is required. These valves offer reliable shut-off capabilities and excellent flow control, making them suitable for high-pressure and high-temperature environments. Trunnion ball valves are commonly used in pipelines, refineries, chemical plants, and power stations.

The Manufacturing Process of Trunnion Ball Valves

The manufacturing of trunnion ball valves involves several intricate steps to ensure optimal performance and longevity. The process includes designing the valve, selecting suitable materials, machining and assembling the components, and conducting thorough inspections at each stage. Testing and certifications are integral parts of this process, serving as checkpoints to ensure quality and compliance.

Importance of Testing in Trunnion Ball Valve Manufacturing

Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) techniques are used to assess the integrity and soundness of trunnion ball valves without causing any damage. NDT methods, such as ultrasonic testing, radiography, and magnetic particle inspection, are employed to detect potential defects, cracks, or imperfections in the valve components. These tests help identify any manufacturing flaws or material irregularities, ensuring that only high-quality valves proceed to the next manufacturing stages.

Pressure Testing

Pressure testing is a critical process that verifies the structural integrity and leakage performance of trunnion ball valves under simulated operating conditions. During pressure testing, valves are subjected to extreme pressures to assess their ability to withstand the expected working pressures without leakage or failure. This ensures that the valves can handle the demanding operational environments they are designed for, providing optimal safety and reliability.

Flow Testing

Flow testing evaluates the valve's performance characteristics, including its flow capacity and pressure drop across the valve. By measuring flow rates and pressure differentials, manufacturers can assess whether the valve operates within the specified parameters. Flow testing also helps identify any flow restrictions or anomalies that may impact the valve's efficiency or cause operational issues. Ensuring proper flow performance is crucial for the overall effectiveness and functionality of trunnion ball valves.

Certifications and Industry Standards for Trunnion Ball Valves

Certifications and adherence to industry standards provide assurance that trunnion ball valves meet the required quality benchmarks. Some of the prominent certifications and standards in the valve manufacturing industry include:

API Certification

The American Petroleum Institute (API) sets industry standards for the design, manufacturing, and testing of valves used in oil and gas applications. API certification ensures that trunnion ball valves comply with rigorous specifications, including material selection, performance testing, and documentation requirements. Obtaining API certification demonstrates a manufacturer's commitment to producing valves that meet the highest quality and safety standards.

ISO Certification

International Organization for Standardization (ISO) certification certifies that the manufacturing processes of trunnion ball valves conform to internationally recognized quality management standards. ISO 9001:2015 is a widely recognized standard that ensures consistent quality, efficient production, and customer satisfaction. Manufacturers with ISO certification demonstrate their dedication to delivering reliable and compliant products.

ASME Certification

The American Society of Mechanical Engineers (ASME) certification verifies that trunnion ball valves meet the stringent standards set by ASME. ASME certification ensures that the valves are designed, manufactured, and tested according to the ASME Boiler and Pressure Vessel Code, guaranteeing their safety and performance. Valves with ASME certification provide an added level of confidence to end-users in various industries.

Ensuring Quality and Reliability through Testing and Certifications

The rigorous testing and certifications in trunnion ball valve manufacturing play a crucial role in ensuring the quality and reliability of the final products. By conducting thorough inspections, manufacturers can identify and rectify any defects or anomalies early in the production process. Testing verifies the valves' performance, structural integrity, and adherence to industry standards, providing assurance to end-users that they are investing in reliable and safe products.

Benefits of Third-Party Testing and Certifications

Third-party testing and certifications add an extra layer of credibility and impartiality to the manufacturing process. Engaging independent certification bodies and laboratories to conduct tests and validate compliance ensures that the testing process remains objective and unbiased. Third-party certifications also enhance customer trust, as they validate the manufacturer's claims and provide an external validation of quality and performance.

Conclusion

Testing and certifications are essential components of trunnion ball valve manufacturing. These processes ensure the quality, safety, and compliance of valves used in critical applications. By subjecting valves to rigorous tests and obtaining certifications from recognized bodies, manufacturers demonstrate their commitment to delivering high-quality, reliable, and industry-compliant products. The importance of testing and certifications cannot be overstated, as they provide end-users with the confidence and peace of mind they need when relying on trunnion ball valves for their operations.

0 notes

Text

Trunnion Ball Valve Manufacturer in USA

Being a valuable Trunnion Ball Valve Manufacturer in USA, SVR Global offers a wide range of Trunnion Ball Valves. Our Trunnion Ball Valves are tested to ensure they meet all of our clients’ requirements. We also offer customized Trunnion Ball valves that are tailored to specific industrial demands.

What is a Trunnion?

A trunnion allows you to mount a fixture to the surface allowing rotation of the fixture.

What is a Trunnion Ball Valve?

A short shaft like an extension called Trunnion is set in the body. The trunnion-mounted ball valve design features a trunnion anchoring at the top and bottom of the ball. The ball is supported by two floating or spring-loaded seats that remain in constant contact with the ball. Regardless of the pressure, this design guarantees a positive seal on both downstream and upstream seats.

A ball valve is a quarter-turn on/off valve with a rotational motion that controls the flow of a liquid or gas.

Ball valves are referred to as quarter-turn valves because the ball rotates 90 degrees between the fully open and fully closed positions. On/off valves either allow flow (on) or obstruct it completely (off). These valves are also known as isolation valves, because they can effectively shut down flow into a segment of a system, often for maintenance to be performed.

A ball valve comprises a valve housing, which is often a metal casting and a perforated ball. The flow is restricted by turning the ball 90 degrees around its axis using a stem.

Types of a Trunnion Ball Valve:

SVR Global is a valuable Trunnion Ball Valve Manufacturer in USA that offers trunnion ball valves:

Forged Trunnion ball valve

Casting Trunnion ball valve

Advantages of a Trunnion Ball Valve:

Appropriate for larger-bore and higher-pressure applications

Perfect for automated ball valve applications

Industries that use Trunnion Ball Valve

Oil and gas

Petrochemical

Synthetic industry

What is a Ball Valve?

A ball valve is a quarter-turn on/off valve with a rotational motion that controls the flow of a liquid or gas.

Ball valves are referred to as quarter-turn valves because the ball rotates 90 degrees between the fully open and fully closed positions. On/off valves either allow flow (on) or obstruct it completely (off). These valves are also known as isolation valves, because they can effectively shut down flow into a segment of a system, often for maintenance to be performed.

A ball valve comprises a valve housing, which is often a metal casting and a perforated ball. The flow is restricted by turning the ball 90 degrees around its axis using a stem.

Advantages of Ball Valves:

Compact in size

Corrosive environments aren’t an issue

Do not require lubrication

Easy to use

Fast-acting

Flexibility in design

Inexpensive

Long life expectancy

Low-pressure drop (flow is almost unrestricted)

Reduced chances of leakage

Requires little maintenance

Suitable for emergency power outages

Suitable for use in high-pressure environments

Disadvantages of Ball Valves:

Body cavity filled with fluid

Not suitable for high temperature

Not suitable for throttling

The partially exposed seat erodes quickly in a throttling position due to the impact of high-velocity flow.

Should be positioned upright and cannot be used for throttling because the valve handle has been rotated.

Description of a Trunnion Ball Valve:

SVR Global is a valuable Trunnion Ball Valve Manufacturer in USA offering an extensive range of valves in numerous sizes, styles, and designs.

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Titanium, Stainless steel (SS316, SS304, F51, F55, CF8, CF8M)

Class: 150-2500, PN25 – PN450

Size: 2” to 48”

Ends: Buttweld Trunnion Ball Valve, Socket weld Trunnion Ball Valve, Threaded Trunnion Ball Valve, Flanged Trunnion Ball Valve.

Operations: Gear Operated, Electric Actuated.

Visit us to know more about various valves provided by SVR Global - https://svrglobal.net/products/trunnion-ball-valve/

#Trunnion Ball Valve Manufacturer in USA#valve manufacturer#valve#valve supplier#ball valve manufacturer

0 notes

Text

Ensuring Hygiene with Trunnion Mounted Ball Valves

In the food and beverage industry, maintaining the highest standards of hygiene is paramount. Trunnion mounted ball valves are designed to meet stringent sanitary requirements, ensuring that no contaminants compromise product quality. Their robust design and ease of cleaning make them ideal for processing applications.

0 notes

Text

Trunnion Ball Valve Manufacturer in India

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturer in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valve and working?

Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints.

Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

Key Components:

Body: The main housing of the valve, providing structural support.

Ball: Spherical disk within the valve body, rotates to control fluid flow.

Trunnion: Shaft supporting the ball from below, ensuring secure attachment.

Seat: Machined surface where the ball makes contact to regulate flow.

Stem: Connects the actuator to the ball, facilitating its rotation.

Disk: Another term for the ball, referring to its spherical shape.

Actuator: Mechanism for operating the valve, such as handwheel or gear.

Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Advantages of Our Trunnion Ball Valves

Long Service Life: Built to withstand wear and tear, ensuring durability.

High Pressure and Temperature Handling: Capable of operating in demanding conditions.

Wide Range of Materials: Available in various materials to suit diverse applications.

Tight Shutoff: Ensures minimal leakage for precise flow control.

Easy Operation: User-friendly design for seamless valve operation.

Customizable: Can be tailored to specific requirements for optimal performance.

Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries:

Oil and Gas Industry

Petrochemical Industry

Chemical Industry

Power Generation Industry

Water and Wastewater Treatment Plants

Mining Industry

Description :

Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy(Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/ 5A, A352 LCC/ LCB (Casting)

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Threaded, Flanged

Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

0 notes

Text

Exploring the Different Types of Ball Valves and Their Applications

Ball valves are mechanical devices used to regulate the flow of fluids within a system by means of a spherical disc or "ball" contained within the valve body. The ball has a hole or port through its center, allowing fluid to pass through when aligned with the flow path and stopping the flow when rotated perpendicular to it. This simple yet effective design makes ball valves versatile and widely used in various industries for controlling the movement of liquids or gases.

The operation of ball valves is typically controlled by a lever, handle, or actuator, which rotates the ball within the valve body to open, close, or regulate the flow. This rotational motion offers quick and reliable shutoff, making ball valves suitable for applications where tight shut-off is required to prevent leakage or to control the flow rate precisely.

Ball valves are fundamental components in fluid control systems, offering efficient shut-off capabilities and reliable performance across a wide range of applications in industries such as oil and gas, petrochemical, water treatment, power generation, and more. Their simple yet effective design, coupled with their versatility and durability, makes them indispensable in modern engineering and industrial processes.

Types of Ball Valves

There are several types of ball valves, each designed to meet specific requirements and operating conditions. Here are some common types:

Floating Ball Valves:

Floating ball valves are a type of ball valve where the ball is not fixed in place but instead floats between the valve seats. Here's a more detailed explanation:

Description:

Floating ball valves consist of a spherical ball with a hole through its center, housed within a valve body. The ball is held in position by the valve seats, which are typically made of soft materials like PTFE (polytetrafluoroethylene) or elastomers. When the valve is in the closed position, the pressure of the fluid forces the ball against the downstream seat, creating a seal and preventing flow through the valve. In the open position, the ball rotates to align the hole with the flow path, allowing fluid to pass through.

Operation:

The operation of floating ball valves is relatively simple. When the valve handle or actuator is turned to the closed position, the ball is pushed by the fluid pressure against the downstream seat, creating a seal and stopping the flow of fluid. Conversely, when the valve is opened, the ball rotates within the valve body to align the hole with the flow path, allowing fluid to pass through.

Advantages:

Simple design: Floating ball valves have a straightforward design, making them easy to manufacture, install, and maintain.

Cost-effective: Compared to other types of ball valves, floating ball valves are often more affordable, making them a popular choice for general industrial applications.

Suitable for low to moderate pressure applications: Floating ball valves perform well in applications where the pressure requirements are not extremely high.

Disadvantages:

Less effective sealing at high pressures: Floating ball valves may experience reduced sealing effectiveness at higher pressures compared to other types of ball valves like trunnion-mounted ball valves.

Limited to smaller sizes: Floating ball valves are typically used in smaller sizes and may not be suitable for larger pipe diameters or higher flow rates.

Trunnion Ball Valves:

Trunnion ball valves are a type of ball valve designed to handle high-pressure and high-flow applications. Here's a detailed overview of trunnion ball valves:

Description:

Trunnion ball valves feature a fixed ball supported by trunnion bearings or pins at the top and bottom of the ball. Unlike floating ball valves, where the ball is free to move within the valve body, the trunnion-mounted ball remains stationary and is supported by the trunnion mechanism. This design provides additional support and stability, allowing the valve to handle higher pressures and larger pipe sizes with greater reliability.

Operation:

Trunnion ball valves operate similarly to other types of ball valves. When the valve is in the closed position, the ball is pressed against the downstream seat by the fluid pressure, creating a tight seal and preventing flow through the valve. To open the valve, the ball rotates within the valve body to align the hole with the flow path, allowing fluid to pass through.

Advantages:

Excellent sealing performance: The trunnion-mounted ball design ensures superior sealing performance, even under high-pressure conditions, compared to floating ball valves.

Suitable for high-pressure and high-flow applications: Trunnion ball valves are well-suited for applications where the operating pressures and flow rates are substantial.

Reduced operating torque: The trunnion-mounted ball design reduces the operating torque required to operate the valve, making it easier to open and close, particularly in larger sizes.

Disadvantages:

Higher initial cost: Trunnion ball valves typically have a higher initial cost compared to floating ball valves due to their more complex design and construction.

Limited flexibility: Trunnion ball valves may not be as versatile as floating ball valves and may not be suitable for low-pressure or smaller-sized applications.

Top-Entry Ball Valves:

Top-entry ball valves are a specific type of ball valve designed with accessibility and maintenance in mind. Here's a comprehensive overview:

Description:

Top-entry ball valves feature a design where the valve body can be disassembled from the top, allowing easy access to internal components such as the ball, seats, and stem. This design enables maintenance and repair work to be carried out without removing the valve from the pipeline, making it convenient and cost-effective.

Operation:

The operation of top-entry ball valves is similar to other types of ball valves. The ball within the valve body rotates to control the flow of fluid, with the valve opening and closing by aligning or misaligning the hole in the ball with the flow path. However, the unique feature of top-entry ball valves lies in their ability to be disassembled from the top for maintenance purposes.

Advantages:

Simplified maintenance: Top-entry ball valves allow easy access to internal components without the need to remove the valve from the pipeline, reducing downtime and maintenance costs.

Reduced risk of leakage: The top-entry design minimizes the risk of damage to the valve body or sealing components during maintenance, ensuring reliable performance and preventing leakage.

Suitable for applications requiring frequent inspection or maintenance: Top-entry ball valves are ideal for industries and applications where regular maintenance or inspection is necessary, such as oil and gas production facilities, chemical plants, and water treatment plants.

Disadvantages:

Higher initial cost: Top-entry ball valves may have a higher initial cost compared to standard ball valves due to their specialized design and construction.

Space requirements: The top-entry design may require additional space above the valve for maintenance access, which could be a consideration in tight or confined installations.

Fully Welded Ball Valves:

Fully welded ball valves are a type of ball valve known for their robust construction and ability to handle high-pressure and high-temperature applications. Here's an overview:

Description:

Fully welded ball valves feature a one-piece, welded body construction without any external leakage points, offering exceptional strength and durability. The valve body, end connections, and ball are welded together, providing a hermetic seal and eliminating potential leakage paths. These valves typically have a trunnion-mounted ball design for enhanced stability and sealing performance.

Operation:

The operation of fully welded ball valves is similar to other types of ball valves. The ball within the valve body rotates to control the flow of fluid, with the valve opening and closing by aligning or misaligning the hole in the ball with the flow path. However, the fully welded construction ensures a secure seal, even under extreme pressure or temperature conditions.

Advantages:

Superior sealing performance: Fully welded ball valves offer excellent sealing performance, minimizing the risk of leakage, even under high-pressure and high-temperature conditions.

Reduced risk of fugitive emissions: The welded construction eliminates potential leakage points, reducing the risk of fugitive emissions and ensuring environmental compliance.

Long service life: The robust construction and durable materials used in fully welded ball valves contribute to their long service life and minimal maintenance requirements.

Minimal maintenance: With fewer moving parts and no external leakage points, fully welded ball valves require minimal maintenance compared to other types of valves.

Disadvantages:

Limited access for maintenance or repair: The welded construction of fully welded ball valves can make it challenging to access internal components for maintenance or repair, potentially requiring specialized equipment or procedures.

Higher initial cost: Fully welded ball valves may have a higher initial cost compared to other types of ball valves due to their specialized construction and materials.

Applications of Ball Valves in Different Industries

Oil and Gas: In oil and gas extraction, ball valves are used in wellheads and pipelines to control the flow of crude oil, natural gas, and other fluids.

They are also employed in refineries for processes such as crude oil refining, gas processing, and product distribution.

Ball valves play a crucial role in storage facilities, tanker loading and unloading terminals, and transportation pipelines for oil and gas products.

Petrochemical: Ball valves are extensively utilized in petrochemical plants for controlling the flow of various chemicals and petrochemical products during manufacturing processes.

They are employed in handling fluids like acids, solvents, gases, and other raw materials crucial for producing plastics, rubber, fertilizers, and other petrochemical derivatives.

Ball valves are also integral in storage tanks, loading terminals, and distribution networks within the petrochemical industry.

Water and Wastewater Treatment: In water treatment plants, ball valves are used to regulate the flow of water, chemicals, and wastewater throughout the treatment process.

They are employed in filtration systems, sedimentation tanks, and chemical dosing units for precise control and management of fluids.

Ball valves are also utilized in wastewater treatment facilities for controlling the flow of sewage, sludge, and treated effluent.

Power Generation: Ball valves play a vital role in power generation plants, particularly in steam and water systems.

They are used to control the flow of water, steam, and various cooling fluids in boilers, turbines, condensers, and other power plant equipment.

Ball valves are also employed in fuel handling systems, such as those used in coal-fired, gas-fired, and nuclear power plants.

Pharmaceutical: In the pharmaceutical industry, ball valves are employed in various processes involving the production, storage, and distribution of pharmaceutical products.

They are used in manufacturing equipment for controlling the flow of ingredients, solvents, and cleaning agents during drug formulation.

Ball valves are also utilized in pharmaceutical cleanrooms, laboratories, and utilities for regulating the flow of purified water, gases, and other critical fluids used in pharmaceutical production.

Conclusion

In conclusion, exploring the different types of ball valves and their applications reveals the versatility and importance of these essential components across various industries. From floating ball valves, suitable for low to moderate pressure applications, to trunnion ball valves designed for high-pressure and high-flow systems, each type offers unique features and benefits to meet specific requirements.

0 notes

Text

Ball Valve FAQ: Everything You Need to Know

Ball valves are indispensable components in various industrial applications, offering reliable fluid control and shut-off capabilities. Here's a comprehensive guide to frequently asked questions about ball valves, tailored for professionals across industries.

What is a ball valve, and how does it work?

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluids. When the handle is turned 90 degrees, the ball's bore aligns with the flow path, allowing fluid to pass through, or it blocks the flow when turned perpendicular.

What are the main advantages of using ball valves?

Ball valves offer several advantages, including:

Quick and easy operation with a quarter-turn handle.

Excellent sealing capabilities, ensuring leak-proof performance.

Minimal pressure drop across the valve, enhancing efficiency.

Versatility to handle a wide range of fluids, including corrosive and abrasive media.

In which industrial applications are ball valves commonly used?

Ball valves find extensive use across various industries, including:

Oil and gas: Pipeline control, wellheads, and refining processes.

Petrochemical: Chemical processing, gas distribution, and storage.

Water and wastewater: Treatment plants, distribution networks, and pumping stations.

Power generation: Boiler systems, cooling towers, and steam lines.

Pharmaceuticals: Process control, sterile environments, and cleanroom applications.

What types of ball valves are available, and how do they differ?

There are several types of ball valves, including:

Floating ball valves: The ball is free to move within the valve body, allowing it to seat against the downstream seal under pressure.

Trunnion-mounted ball valves: The ball is supported by trunnions to handle higher pressure and larger sizes.

Multi-port ball valves: Designed with multiple ports for diverting, mixing, or isolating flows in complex systems.

V-port ball valves: Featuring a V-shaped ball orifice for precise flow control in throttling applications.

How can I select the right ball valve for my application?

Choosing the appropriate ball valve depends on factors such as fluid type, pressure, temperature, flow rate, and environmental conditions. Consulting with a knowledgeable supplier or engineer can help ensure the selection of the most suitable valve for your specific needs.

What maintenance is required for ball valves?

Ball valves generally require minimal maintenance due to their robust design. Periodic inspection for leaks, corrosion, and proper operation is recommended. Lubricating the valve stem and replacing seals as needed will help ensure long-term reliability.

In Conclusion

Ball valves are essential components in industrial fluid control systems, offering efficiency, reliability, and versatility across various applications. Understanding their features, types, and proper selection criteria is crucial for ensuring optimal performance and system integrity in diverse industrial settings.

#ball valves manufacturers#ball valve suppliers#freturetechno#industrial valves#manufactuers#mumbai#india

0 notes

Text

How to Choose the Right Motorized Ball Valve

Motorized ball valves are integral components in various industrial, commercial, and residential systems, offering precise control over fluid flow. Selecting the right motorized ball valve ensures optimal performance and longevity of your system. Here’s a comprehensive guide to help you make an informed decision:

Understanding Your Application: Begin by comprehensively understanding the requirements of your application. Consider factors such as fluid type, pressure, temperature, flow rate, and environmental conditions. This understanding will dictate the specifications needed for your motorized ball valve.

Valve Size and Compatibility: Choose a motorized ball valve that matches the size and compatibility requirements of your system. Ensure that the valve’s flow capacity aligns with your application’s demands to avoid inefficiencies or restrictions.

Material Selection: Material compatibility is crucial for ensuring the longevity and performance of your motorized ball valve. Common materials include brass, stainless steel, and PVC. Evaluate the compatibility of materials with the fluid being controlled and the environmental conditions of your application.

Actuator Type: Motorized ball valves come with various actuator types such as electric, pneumatic, or hydraulic. Electric actuators are popular due to their simplicity and ease of control. Consider factors like power availability, control method, and automation requirements when selecting the actuator type.

Control Options: Evaluate the control options available with the motorized ball valve. Depending on your application needs, choose between simple on/off control or more advanced modulating control for precise regulation of flow.

Sealing Mechanism: The sealing mechanism of a motorized ball valve significantly impacts its performance and reliability. Choose between options like floating ball, trunnion-mounted ball, or seat-sealed designs based on your application’s pressure and temperature requirements.

Voltage Compatibility: Ensure that the voltage requirements of the motorized ball valve align with the power supply available in your system. Opt for valves with voltage options compatible with your infrastructure to prevent compatibility issues.

Manufacturer Reputation and Support: Select motorized ball valves from reputable manufacturers known for producing high-quality, reliable products. Additionally, consider the availability of technical support, warranty coverage, and after-sales service from the manufacturer.

Budget Considerations: While quality should be a priority, consider your budget constraints when choosing a motorized ball valve. Balance the cost with the desired features and performance to achieve the best value for your investment.

Regular Maintenance and Inspection: Once installed, ensure regular maintenance and inspection of the motorized ball valve to prevent potential issues and prolong its lifespan.

By following these guidelines and considering the specific requirements of your application, you can confidently select the right motorized ball valve to meet your needs effectively. Remember, investing time in choosing the right valve upfront can save you from costly repairs and downtime in the long run.

0 notes