#floating ball valve

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

Trunnion Ball Valve

When you're thinking to start a production business then most probably you will need to think about needs that might arise. Some of the most common products that almost every factory or industry needs are valves, so finding the best Ball Valve Manufacturer and maintaining good relations is important. If you want to buy the right Trunnion Ball Valve for your business can consider shopping it from "CWT Valve". We are a leading manufacturer and supplier of valve products to meet its customer's needs. Shop it now!

0 notes

Text

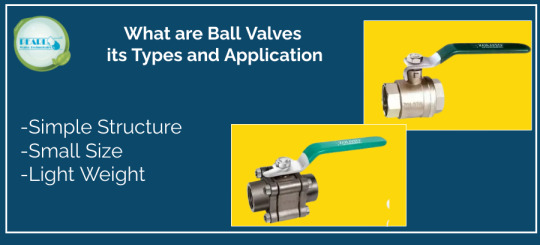

What are Ball Valves its types and application

A ball valve is a flow control device that uses a clean, perforated, and rotating ball to control the flow of fluid. It opens when the ball hole meets the door and closes when it is rotated 90 degrees with a valve handle, preventing flow. The handle lies on the floor facing the flow when it is open, and in the closed position, making it easy to visualize the position of the valve. 1/4 turn lock can be on either side of the clock or opposite the clock.

The basic components of Ball valves include the following:

If you want to know more about Ball Valves and its type and application read out our latest blog- What are Ball Valves its types and application (pearlwater.in)

#ball valves#8 mm ball valve#water tank float valve#brass ball valve#ball valve price#floating ball valve

0 notes

Text

Floating Ball Valve: A Comprehensive Guide to Optimal Fluid Control

Floating Ball Valves are essential components in fluid control systems, offering reliable shut-off and excellent sealing capabilities. In this comprehensive guide, we will explore the features, benefits, and applications of floating ball valves, providing valuable insights to help you make informed decisions for your fluid control needs.

Section 1: Understanding Floating Ball Valves

Floating ball valves are designed with a Floating Ball that is not fixed to the valve stem. This unique design allows the Ball to float and move with the fluid pressure, ensuring optimal sealing and minimizing the risk of leakage. These valves are commonly used in various industries for their versatility and reliable performance.

Section 2: Advantages of Floating Ball Valves

Excellent Sealing: Floating ball valves provide exceptional sealing performance due to the pressure exerted on the ball by the fluid, ensuring tight shut-off and preventing leakage.

Wide Range of Applications: Floating Ball Valves are suitable for a wide range of applications, including oil and gas, petrochemicals, chemical processing, water treatment, and many more. Their versatility makes them a popular choice in various industries.

Easy Operation and Maintenance: Floating Ball Valves are designed for ease of operation and maintenance. The simple structure and fewer components contribute to quick and efficient maintenance, reducing downtime and overall costs.

Section 3: Types of Floating Ball Valves

Two-Piece Design: This type of floating ball valve consists of two main parts—the body and the Ball. It offers ease of maintenance and is commonly used in low-pressure applications.

Three-Piece Design: Three-piece floating ball valves feature a detachable body, allowing easy access to the internals for maintenance. They are suitable for high-pressure and high-temperature applications.

Section 4: Selecting the Right Floating Ball Valve

Consider the following factors when choosing a Floating Ball Valve:

Material Compatibility: Ensure that the valve materials are compatible with the fluid being handled, considering factors such as corrosion resistance and temperature limitations.

Pressure and Temperature Rating: Select a valve with the appropriate pressure and temperature ratings to ensure optimal performance and safety.

End Connection Type: Choose the correct end connections (flanged, threaded, or welded) based on your piping system requirements.

Section 5: Maintenance and Safety Tips

Proper maintenance and safety practices are crucial for the optimal performance and longevity of floating ball valves. Regular inspection, lubrication, and adherence to safety guidelines are essential to ensuring reliable and safe operation.

Floating Ball Valves are reliable and versatile components for fluid control applications. Their excellent sealing capabilities, a wide range of applications, and ease of operation make them a popular choice in various industries. By understanding the advantages, types, and selection criteria for floating ball valves, you can make informed decisions and optimize your fluid control systems for efficient and reliable performance.

2 notes

·

View notes

Text

Ball Float Steam Trap Supplier in Morocco

Looking for a reliable supplier of Ball Float Steam Trap in Morocco and other African countries? Look no further than African Valve! Our high-quality valves are designed to maintain flow and provide effective protection for your industrial processes. It helps to remove condensate liquid from steam lines and stop the loss of valuable steam, industrial systems often use these valves.

Description:

Body: Carbon Steel, Stainless Steel, Ductile Iron

Float ball: SS304

Bolt: SS304

Bracket: SS304

Pin: SS304

Bonnet: Carbon Steel, CF8

Disc: 2Cr13, SS304

Seat: 2Cr13, SS304

Gasket: Graphite+SS304

Nominal Diameter: DN15 to DN100

Nominal Pressure: PN10 to PN64

1 note

·

View note

Text

Discover the perfect solution for maintaining optimal water levels in your tank with our innovative float valve for water tanks! Our reliable and efficient float valves ensure a seamless water management system, preventing overflow and wastage. Say goodbye to manual monitoring and hello to worry-free water control.

1 note

·

View note

Text

106X electromagnetic remote control floating ball valve

106X electric remote control floating ball valve is installed on the often open (often closed) solenoid valve electric control device on the basis of 100X remote control floating ball valve, make the valve has double insurance effect, even if the power failure or electric floating ball failure, also can control the water level, never let the water level exceed the specified position, the electric floating ball valve can set the open and closing water level, solve the main valve frequent open and close.

0 notes

Text

Floating Ball Valve

UTMOST, a floating ball valve manufacturer, offers different floating ball valve types at a good float ball price. The floating ball valve has a simple structure and good sealing performance, but the load of the working medium on the sphere is all transmitted to the outlet sealing ring. Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the sphere medium. When subjected to higher pressure impact, the sphere may shift. This valves and controls structure is generally used for medium and low-pressure ball valve and float.

Floating Ball Valve Application of Norms

Flange dimensions to ANSI B 16.5

Face to face dimensions to ANSI B 16.10

Floating ball valve design and Manufacture in accordance with API 6D

Valve tested to API 598

Floating Ball Valve Datas

Materials of Water Tank Ball Float Main Parts

Main Performance Specification of SS Ball Float Valve

Main Connection Dimensions of Floating Ball Valve

Applicable Temperature

- 196Ps550°c (Different Materials for Different Operating Temperatures)

Applicable Medium

Ordinary type

Water, Steam, Petroleum, LPG, Natural gas, etc.

Antisulphur type

Natural gas containing H2S and CO, petroleum, etc

https://www.utmostvalve.com/products/floating-ball-valve/

1 note

·

View note

Text

Talking to someone who is interested in fixing things is very nice, so I’ve been talking with Scott about the weird plumbing and things in the house.

He saw my post about the shower and was asking some questions and giving ideas and omg it’s just really, really nice to be heard.

Anyway. Since I’ve been telling you all about the weirdness, too:

So here are the shut offs for the shower, way overhead where my short ass can’t reach without a step stool which seems like a bad idea in an emergency, but whatever...

So they are accessible-ish. AFAIK it doesn’t matter which way it’s turned (they can only go one way but there’s a little barrier so you can tell which way that is. I couldn’t see it before) because it’s just a little ball with a tunnel and it’s either tunnel lines up with pipe so water can get through, or ball covers pipe and water can’t get through.

I can’t turn them, though. I don’t know if they’re stuck or if it’s my weakness and messed up shoulder. I am very weak in the hands anymore. No grip, lots of pain.

I do have a plumber’s wrench thing that I can probably use to turn them. Haven’t tried, yet.

Also yes, those pipes are crooked AF.

The previous homeowners did it. I’m guessing the extensions over the ceiling there are for the toilet and sink.

The leak is probably in the.... I keep forgetting what this is called. It’s probably in this thing here which I could likely disassemble and fix or replace no problem, I just don’t want to. Nobody uses this shower.

Really, the entire basement needs torn out and redone professionally.

I’ve had to fix EVERY. SINGLE. POWER OUTLET. because they’re ALL mounted wrong.

Anyway.

You know how I’ve said that I’m not stupid but I’m slow; I’ll get there eventually?

I finally had the smart idea to go outside and measure the distance from the window to the spigot.

14 inches.

Then I came inside and measured from the window again and the spigot is, I shit you not....

right there.

Right where those walls meet. That corner is 13.5 inches from the window.

Which begs the question: Where the fuck is the pipe, then, if there is wall framing there???

Also this means there’s a void behind there. The foundation is a little past the spigot, maybe another 10 inches, and the bathroom isn’t that deep. There’s a good...

guestimating...

1ft by.... maybe 4ft area that’s covered. For some reason.

So I’m wondering if I cut like....

here? if I’d be able to reach in and access the shut off valve (and then install a little access door cubby thing). Or maybe cut all the way out and install a people-size door.

Or is it on the other wall?

Like, does the framing for.....

Is the pipe RIGHT THERE and the framing is installed wrong and the drywall is just floating in the corner???? Or is it the other way so I’d be better off cutting into the window-wall?

Which way am I going to be blocked by boards?

Are BOTH sides floating?????

I wouldn’t put it past him. You should see how poorly he drywalled and framed the stairs.

What the fuck, Rolly. Why.

It would have been fixed by now if That Guy were willing to pay for the repairs or if I were able to. This has been driving me crazy for 16 years.

12 notes

·

View notes

Video

youtube

Jual Grating Steel AIS Surabaya | cv AIS | WA 082129846666

cv AIS telah lama men Jual Steel Grating dengan berbagai aplikasi sesuai kebutuhan Project. Tagline: #jualgratingsurabaya #daftarhargagrating #hargagratingperlembar #hargagratinggalvanizedjakarta #daftarhargagratinggalvanis #hargasteelgratingperm2 #hargagrating2018 #jualgratingsurabaya #ukurangratingplate #jualplatgratingsteelkotasbyjawatimur #daftarhargagrating #hargagrating2017 #hargasteelgratingperm2 #steelgratingsurabaya #hargagrating #hargagratingperlembar #daftarhargagrating #hargagratinggalvanizedjakarta #daftarhargagratinggalvanis #beratgratingperm2 #jualgratingjakarta #jualplatgratingjakarta #jualgratinggresik #jualgratingsidoarjo #jualgratingbalikpapan #pembuatangrating #platgrating #platgriting #gratinggalvanis #platgalvanis #grating2034 #agroindustrisurabaya #indobajasurabaya #ais2034 AGRO INDUSTRI SURABAYA LEBIH DARI 5 TAHUN BERKUTAT DALAM MELAYANI KEBUTUHAN INDUSTRI, MEMBUAT KAMI TERJUN LANGSUNG DALAM MEMENUHI SEGALA BENTUK KEBUTUHAN INDUSTRI. DEMI MEMBERIKAN KEMUDAHAN DAN MEMBANTU MELANCARKAN SEGALA KEBUTUHAN USAHA ANDA. wa.me/628212986666 KAMI TELAH TERHUBUNG DENGAN SEGALA IMPORTIR, PRODUSEN, DISTRIBUTOR YANG BERKAITAN DENGAN INDUSTRI. SEHINGGA DENGAN MUDAH KAMI DAPAT MEMBERIKAN PENAWARAN PRODUK DENGAN HARGA PALING COMPETITIF DAN BISA DIPERCAYA wa.me/628212986666 KAMI JUGA MENJUAL: FLANGE: BESI ( JIS, PN, ANSI) , FLANGE SUS FITTING: ELBOW, DOUBLE NIPPLE, DOP, PLUG, REDUCER, SOCK, TEE, VERLOP RING, WATERMOOR. wa.me/628212986666 KASA, SARINGAN, MESH: MESH JEPANG, MESH TEBAL, MESH LEBAR, MESH DOUBLE, MESH KUNINGAN, MESH NYLON, SCREEN BESI, SCREEN STAINLESS, WELDED MESH, LOKET, KNITTING MESH. wa.me/628212986666 KAWAT: KWAT STAINLESSH SOFT, KAWAT STAINLESS HARD, KAWAT BAJA. wa.me/628212986666 KAWAT LAS: KAWAT LAS STAINLESS, KAWAT LAS KUNINGAN, KAWAT LAS PERAK/ TEMBAGA. MANOMATER ( PRESSURE GAUGE) : MODEL PAYUNG, RAKET, ELEKTRIK, LOW PRESSURE, DIAFRAGMA, MODEL GLYSERIN. wa.me/628212986666 THERMOMETER: TERMO PAYONG, TERMO RAKET, TERMO CAPILER, TERMO GRAPH, TERMO GRAPH, TERMO GLASS, TERMO PIPA, TERMO DIESEL, TERMO ASPAL, TERMO BATANG, TERMO ELEKTRIK, TERMO POCKET, TERMOSTAT, TERMO KONTROL, TERMO COUPLE, TERMO MAGNIT. wa.me/628212986666 MISELANU: LANGSOL, ALUMINIUM FOIL, CIRCULAR GLASS, FLEXIBLE RUBBER, GLYSERIN MINYAK, GUNTING, GAUGE SAVER, KIKIR, KLINGER, KOPLING KUNINGAN, SIPHON, BRANSLANG. PACKING: PLAT KLINGRIT, KARET PLAT, RAMIE TEFLON, PURE TEFLON, ASBES TEFLON, KEVLAR TEFLON. METER METERAN BAILEY METER, BAROMETER, FLOW INDIKATOR, FLOW SWITCH, HIDROMETER, PRESSURE SWITCH, TACHOMETER, TRANSMITTER, WATER FLOWMETER. wa.me/628212986666 PLAT: PLAT SS 201, PLAT SS202, PLAT SS 304, PLAT LUBANG BESI, PLAT LUBANG STAINLESS, PLAT LUBANG CAPSUL. PIPA: PIPA ORNAMENT NIKEL 1, PIPA SS ORNAMENT NIKEL 4, PIPA KOTAK, PIPA SS SCHEDULE, PIPA TEMBAGA BATANG, PIPA TEMBAGA COIL. SIKU, STRIP STAINLESS DAN TEMBAGA. AS ( ROUND BAR) : AS STAINLESS STEEL, AS NYLON, AS TEMBAGA, AS TEFLON, AS NOVOTEK, AS POLY ETHELINE, AS POLY PROPHILENE. VALVE/ STOP KRAN: BALL VALVE, GATE VALVE, GLOBE VALVE, KNIFE GATE VALVE, BUTTERFLY VALVE, CHECK VALVE, STRAINER VALVE, TUESN, SOLONOID VALVE, SAVETY VALVE, COCK VALVE, FLOAT VALVE, PYL GLASS VALVE, NEEDLE VALVE, STEAM TRAP, PRV, SIGHT GLASS, AIR VENT, FOOT VALVE, DIAFRAM VALVE. wa.me/628212986666 WOOL: ROCKWOOL, GLASSWOOL, FELTWOOL, ROOFMESH, ALUMUNIUM FOIL BAIK SINGLE MAUPUN DOUBLE. wa.me/628212986666 MENGERJAKAN SESUAI KEBUTUHAN ANDA UNTUK PRODUK SBB: STEEL GRATING FRP GRATING PIPA CEMENT LINING KAWAT HARMONIKA KAWAT LOKET PLAT LUBANG SCREEN BAJA https://agroindustrisurabaya.com/ @cvAGROINDUSTRISURABAYA @AGROINDUSTRISURABAYA SALAM KENAL RAHMAT HIDAYAT wa.me/628212986666 ALAMAT WEB SITE AGRO INDUSTRI SURABAYA https://agroindustrisurabaya.com/ https://steelgratingsurabaya.com/ https://plattimah.com/ https://ProteksiKatodik.com/ ___ https://PlatExpanded.com/ https://AISProjectsite.com/ https://WoolInsulasi.com/ https://AISversa.com/ https://AIS2034.com/ ___ https://Indobajasurabaya.com/ http://flowmetersurabaya.com/ http://AgroIndustriSentosa.com/ http://AyahIBuSenang.com/ ___ https://insulationtoptrending.blogspo... https://gratingtoptrending.blogspot.com/ https://bublefoilsurabaya.blogspot.com/ https://jualtimbaltimahkacapb.blogspo... https://agroindustrisurabaya.wordpres...

5 notes

·

View notes

Text

Understanding the Functionality of Valves in Instrumentation Systems |Arcellor controls

The tricky global of instrumentation structures is predicated on a silent orchestra of additives working collectively to exactly control and monitor business strategies. Among these key players are device valves, regularly small but robust in their features. Let's discover the crucial role instrument valves play in making sure the easy operation of diverse commercial packages.

Instrument Valves: Masters of Control

Instrument valves, also called instrumentation valves or gauge valves, are specialized valves designed for specific regulation of float charges, pressures, and course of fluids (liquids, gasses, or slurries) inside instrumentation structures. Unlike their larger cousins in commercial piping, instrument valves usually address smaller glide charges and require an excessive diploma of manipulation.

Key Features of Instrument Valves:

Smaller Size: Ranging from 1/eight inch to one inch in length, device valves are nicely-applicable for tricky managed loops inside instrumentation structures.

High Precision: Their design prioritizes precise management over on/off float or throttling (gradually adjusting) to go with the flow prices and pressures.

Leak-Tight Performance: Tight close-off abilities are essential to save you leakage and keep gadget integrity.

Applications of Instrument Valves:

Instrument valves find software in a huge variety of industries relying on precise process manage:

Chemical Processing: Regulating the float of chemicals in reactors, pipelines, and analytical systems.

Oil and Gas Production: Controlling glide rates and pressures at some point of drilling, refining, and transportation.

Power Generation: Maintaining the most reliable glide and stress of fluids in boilers, generators, and cooling structures.

Pharmaceutical Manufacturing: Ensuring sterile and precise go with the flow of fluids in production approaches.

Water Treatment Plants: Regulating glide prices of water and treatment chemicals.

Types of valves instruments:

A diverse variety of tool valves exist, each catering to unique manipulate wishes:

Needle Valves: Offer exceptional-tuned control over float quotes, perfect for low-flow applications.

Ball Valves: Provide short on/off waft management with a rotating ball detail.

Globe Valves: Offer correct throttling capabilities with a forestall-disc design.

Globe Valves: These valves are known for his or her tight close-off abilities and throttling ability.

Check Valves: Allow glide in one direction handiest, preventing backflow.

Butterfly Valves: Offer a fee-powerful alternative for on/off drift management in large traces.

Arcellor Controls: Your Partner in Industrial Control

Arcellor Controls, a globally recognized leader in business automation solutions, knows the crucial position of device valves in manner control. They provide a comprehensive range of amazing tool valves, catering to various industrial programs. Their valves are acknowledged for their:

Durability: Manufactured from high-grade substances to withstand harsh industrial environments.

Reliability: Built to perform consistently and dependably beneath disturbing situations.

Compliance: Adhere to industry requirements and specs for protection and performance.

Conclusion

By understanding the capability of tool valves, we benefit from a deeper appreciation for the problematic workings of instrumentation systems. These silent maestros make sure to manipulate over numerous commercial tactics, keeping them operating effectively and effectively. For dependable and awesome tool valves, Arcellor Controls may depend on associates in reaching the most desirable process manipulation.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments#valves in instrumentation

0 notes

Link

When it comes to finding a leading manufacturer and supplier that offers quality products to its customers can consider contacting "CWT Valve". Whether you want to buy Trunnion Ball Valve, Ball Valve, Floating Ball Valve, or another type, we are able to meet all your needs.

0 notes

Text

Exploring the Different Types of Ball Valves and Their Applications

Ball valves are mechanical devices used to regulate the flow of fluids within a system by means of a spherical disc or "ball" contained within the valve body. The ball has a hole or port through its center, allowing fluid to pass through when aligned with the flow path and stopping the flow when rotated perpendicular to it. This simple yet effective design makes ball valves versatile and widely used in various industries for controlling the movement of liquids or gases.

The operation of ball valves is typically controlled by a lever, handle, or actuator, which rotates the ball within the valve body to open, close, or regulate the flow. This rotational motion offers quick and reliable shutoff, making ball valves suitable for applications where tight shut-off is required to prevent leakage or to control the flow rate precisely.

Ball valves are fundamental components in fluid control systems, offering efficient shut-off capabilities and reliable performance across a wide range of applications in industries such as oil and gas, petrochemical, water treatment, power generation, and more. Their simple yet effective design, coupled with their versatility and durability, makes them indispensable in modern engineering and industrial processes.

Types of Ball Valves

There are several types of ball valves, each designed to meet specific requirements and operating conditions. Here are some common types:

Floating Ball Valves:

Floating ball valves are a type of ball valve where the ball is not fixed in place but instead floats between the valve seats. Here's a more detailed explanation:

Description:

Floating ball valves consist of a spherical ball with a hole through its center, housed within a valve body. The ball is held in position by the valve seats, which are typically made of soft materials like PTFE (polytetrafluoroethylene) or elastomers. When the valve is in the closed position, the pressure of the fluid forces the ball against the downstream seat, creating a seal and preventing flow through the valve. In the open position, the ball rotates to align the hole with the flow path, allowing fluid to pass through.

Operation:

The operation of floating ball valves is relatively simple. When the valve handle or actuator is turned to the closed position, the ball is pushed by the fluid pressure against the downstream seat, creating a seal and stopping the flow of fluid. Conversely, when the valve is opened, the ball rotates within the valve body to align the hole with the flow path, allowing fluid to pass through.

Advantages:

Simple design: Floating ball valves have a straightforward design, making them easy to manufacture, install, and maintain.

Cost-effective: Compared to other types of ball valves, floating ball valves are often more affordable, making them a popular choice for general industrial applications.

Suitable for low to moderate pressure applications: Floating ball valves perform well in applications where the pressure requirements are not extremely high.

Disadvantages:

Less effective sealing at high pressures: Floating ball valves may experience reduced sealing effectiveness at higher pressures compared to other types of ball valves like trunnion-mounted ball valves.

Limited to smaller sizes: Floating ball valves are typically used in smaller sizes and may not be suitable for larger pipe diameters or higher flow rates.

Trunnion Ball Valves:

Trunnion ball valves are a type of ball valve designed to handle high-pressure and high-flow applications. Here's a detailed overview of trunnion ball valves:

Description:

Trunnion ball valves feature a fixed ball supported by trunnion bearings or pins at the top and bottom of the ball. Unlike floating ball valves, where the ball is free to move within the valve body, the trunnion-mounted ball remains stationary and is supported by the trunnion mechanism. This design provides additional support and stability, allowing the valve to handle higher pressures and larger pipe sizes with greater reliability.

Operation:

Trunnion ball valves operate similarly to other types of ball valves. When the valve is in the closed position, the ball is pressed against the downstream seat by the fluid pressure, creating a tight seal and preventing flow through the valve. To open the valve, the ball rotates within the valve body to align the hole with the flow path, allowing fluid to pass through.

Advantages:

Excellent sealing performance: The trunnion-mounted ball design ensures superior sealing performance, even under high-pressure conditions, compared to floating ball valves.

Suitable for high-pressure and high-flow applications: Trunnion ball valves are well-suited for applications where the operating pressures and flow rates are substantial.

Reduced operating torque: The trunnion-mounted ball design reduces the operating torque required to operate the valve, making it easier to open and close, particularly in larger sizes.

Disadvantages:

Higher initial cost: Trunnion ball valves typically have a higher initial cost compared to floating ball valves due to their more complex design and construction.

Limited flexibility: Trunnion ball valves may not be as versatile as floating ball valves and may not be suitable for low-pressure or smaller-sized applications.

Top-Entry Ball Valves:

Top-entry ball valves are a specific type of ball valve designed with accessibility and maintenance in mind. Here's a comprehensive overview:

Description:

Top-entry ball valves feature a design where the valve body can be disassembled from the top, allowing easy access to internal components such as the ball, seats, and stem. This design enables maintenance and repair work to be carried out without removing the valve from the pipeline, making it convenient and cost-effective.

Operation:

The operation of top-entry ball valves is similar to other types of ball valves. The ball within the valve body rotates to control the flow of fluid, with the valve opening and closing by aligning or misaligning the hole in the ball with the flow path. However, the unique feature of top-entry ball valves lies in their ability to be disassembled from the top for maintenance purposes.

Advantages:

Simplified maintenance: Top-entry ball valves allow easy access to internal components without the need to remove the valve from the pipeline, reducing downtime and maintenance costs.

Reduced risk of leakage: The top-entry design minimizes the risk of damage to the valve body or sealing components during maintenance, ensuring reliable performance and preventing leakage.

Suitable for applications requiring frequent inspection or maintenance: Top-entry ball valves are ideal for industries and applications where regular maintenance or inspection is necessary, such as oil and gas production facilities, chemical plants, and water treatment plants.

Disadvantages:

Higher initial cost: Top-entry ball valves may have a higher initial cost compared to standard ball valves due to their specialized design and construction.

Space requirements: The top-entry design may require additional space above the valve for maintenance access, which could be a consideration in tight or confined installations.

Fully Welded Ball Valves:

Fully welded ball valves are a type of ball valve known for their robust construction and ability to handle high-pressure and high-temperature applications. Here's an overview:

Description:

Fully welded ball valves feature a one-piece, welded body construction without any external leakage points, offering exceptional strength and durability. The valve body, end connections, and ball are welded together, providing a hermetic seal and eliminating potential leakage paths. These valves typically have a trunnion-mounted ball design for enhanced stability and sealing performance.

Operation:

The operation of fully welded ball valves is similar to other types of ball valves. The ball within the valve body rotates to control the flow of fluid, with the valve opening and closing by aligning or misaligning the hole in the ball with the flow path. However, the fully welded construction ensures a secure seal, even under extreme pressure or temperature conditions.

Advantages:

Superior sealing performance: Fully welded ball valves offer excellent sealing performance, minimizing the risk of leakage, even under high-pressure and high-temperature conditions.

Reduced risk of fugitive emissions: The welded construction eliminates potential leakage points, reducing the risk of fugitive emissions and ensuring environmental compliance.

Long service life: The robust construction and durable materials used in fully welded ball valves contribute to their long service life and minimal maintenance requirements.

Minimal maintenance: With fewer moving parts and no external leakage points, fully welded ball valves require minimal maintenance compared to other types of valves.

Disadvantages:

Limited access for maintenance or repair: The welded construction of fully welded ball valves can make it challenging to access internal components for maintenance or repair, potentially requiring specialized equipment or procedures.

Higher initial cost: Fully welded ball valves may have a higher initial cost compared to other types of ball valves due to their specialized construction and materials.

Applications of Ball Valves in Different Industries

Oil and Gas: In oil and gas extraction, ball valves are used in wellheads and pipelines to control the flow of crude oil, natural gas, and other fluids.

They are also employed in refineries for processes such as crude oil refining, gas processing, and product distribution.

Ball valves play a crucial role in storage facilities, tanker loading and unloading terminals, and transportation pipelines for oil and gas products.

Petrochemical: Ball valves are extensively utilized in petrochemical plants for controlling the flow of various chemicals and petrochemical products during manufacturing processes.

They are employed in handling fluids like acids, solvents, gases, and other raw materials crucial for producing plastics, rubber, fertilizers, and other petrochemical derivatives.

Ball valves are also integral in storage tanks, loading terminals, and distribution networks within the petrochemical industry.

Water and Wastewater Treatment: In water treatment plants, ball valves are used to regulate the flow of water, chemicals, and wastewater throughout the treatment process.

They are employed in filtration systems, sedimentation tanks, and chemical dosing units for precise control and management of fluids.

Ball valves are also utilized in wastewater treatment facilities for controlling the flow of sewage, sludge, and treated effluent.

Power Generation: Ball valves play a vital role in power generation plants, particularly in steam and water systems.

They are used to control the flow of water, steam, and various cooling fluids in boilers, turbines, condensers, and other power plant equipment.

Ball valves are also employed in fuel handling systems, such as those used in coal-fired, gas-fired, and nuclear power plants.

Pharmaceutical: In the pharmaceutical industry, ball valves are employed in various processes involving the production, storage, and distribution of pharmaceutical products.

They are used in manufacturing equipment for controlling the flow of ingredients, solvents, and cleaning agents during drug formulation.

Ball valves are also utilized in pharmaceutical cleanrooms, laboratories, and utilities for regulating the flow of purified water, gases, and other critical fluids used in pharmaceutical production.

Conclusion

In conclusion, exploring the different types of ball valves and their applications reveals the versatility and importance of these essential components across various industries. From floating ball valves, suitable for low to moderate pressure applications, to trunnion ball valves designed for high-pressure and high-flow systems, each type offers unique features and benefits to meet specific requirements.

0 notes

Text

The Ultimate Guide to Understanding Floating Ball Valves: A Comprehensive Overview

Floating ball valves are pivotal components in fluid control systems, playing a crucial role in regulating the flow of liquids in various industries. In this comprehensive guide, we will delve into the intricacies of floating ball valves, exploring their design, functionality, applications, and the advantages they offer in fluid handling systems.

Section 1: The Basics of Floating Ball Valves

To comprehend floating ball valves, it's essential to start with the basics. We'll explore the fundamental design principles that distinguish floating ball valves from other valve types. From the freely moving ball to the sealing mechanism, readers will gain a solid understanding of the internal workings of these valves.

Section 2: Advantages of Floating Ball Valves

Why choose floating ball valves over other valve types? This section will highlight the distinctive advantages, including low torque requirements, bidirectional sealing, and suitability for a wide range of pressures and temperatures. Real-world examples and case studies will illustrate the practical benefits in different industrial applications.

Section 3: Applications in Various Industries

Floating ball valves find applications in diverse industries, from oil and gas to chemical processing. We'll explore specific use cases, detailing how these valves contribute to efficient fluid control in different settings. Whether it's managing corrosive substances or handling high-pressure environments, floating ball valves prove their versatility.

Section 4: Comparing Floating Ball Valves with Trunnion-Mounted Ball Valves

Readers often encounter the dilemma of choosing between floating and trunnion-mounted ball valves. This section will provide a side-by-side comparison, outlining the distinct features and suitability of each type. By the end, readers will have a clear understanding of when to opt for floating ball valves and when trunnion-mounted valves may be more appropriate.

Section 5: Maintenance Best Practices

Ensuring the longevity and optimal performance of floating ball valves requires proper maintenance. We'll offer practical tips and guidelines, covering routine inspections, lubrication, and troubleshooting common issues. A well-maintained valve contributes to the reliability of the entire fluid control system.

Conclusion:

As we conclude this ultimate guide, readers will have gained a comprehensive understanding of floating ball valves. From their internal mechanisms to real-world applications, the versatility and advantages of these valves make them indispensable in various industries. Whether you're a seasoned engineer or someone new to fluid control systems, this guide equips you with the knowledge to navigate the world of floating ball valves with confidence.

#ball valve manufacturer#floating ball valves#ss floating ball valves#floating control ball valves#freture techno#india

0 notes

Text

How to Choose the Right Motorized Ball Valve

Motorized ball valves are integral components in various industrial, commercial, and residential systems, offering precise control over fluid flow. Selecting the right motorized ball valve ensures optimal performance and longevity of your system. Here’s a comprehensive guide to help you make an informed decision:

Understanding Your Application: Begin by comprehensively understanding the requirements of your application. Consider factors such as fluid type, pressure, temperature, flow rate, and environmental conditions. This understanding will dictate the specifications needed for your motorized ball valve.

Valve Size and Compatibility: Choose a motorized ball valve that matches the size and compatibility requirements of your system. Ensure that the valve’s flow capacity aligns with your application’s demands to avoid inefficiencies or restrictions.

Material Selection: Material compatibility is crucial for ensuring the longevity and performance of your motorized ball valve. Common materials include brass, stainless steel, and PVC. Evaluate the compatibility of materials with the fluid being controlled and the environmental conditions of your application.

Actuator Type: Motorized ball valves come with various actuator types such as electric, pneumatic, or hydraulic. Electric actuators are popular due to their simplicity and ease of control. Consider factors like power availability, control method, and automation requirements when selecting the actuator type.

Control Options: Evaluate the control options available with the motorized ball valve. Depending on your application needs, choose between simple on/off control or more advanced modulating control for precise regulation of flow.

Sealing Mechanism: The sealing mechanism of a motorized ball valve significantly impacts its performance and reliability. Choose between options like floating ball, trunnion-mounted ball, or seat-sealed designs based on your application’s pressure and temperature requirements.

Voltage Compatibility: Ensure that the voltage requirements of the motorized ball valve align with the power supply available in your system. Opt for valves with voltage options compatible with your infrastructure to prevent compatibility issues.

Manufacturer Reputation and Support: Select motorized ball valves from reputable manufacturers known for producing high-quality, reliable products. Additionally, consider the availability of technical support, warranty coverage, and after-sales service from the manufacturer.

Budget Considerations: While quality should be a priority, consider your budget constraints when choosing a motorized ball valve. Balance the cost with the desired features and performance to achieve the best value for your investment.

Regular Maintenance and Inspection: Once installed, ensure regular maintenance and inspection of the motorized ball valve to prevent potential issues and prolong its lifespan.

By following these guidelines and considering the specific requirements of your application, you can confidently select the right motorized ball valve to meet your needs effectively. Remember, investing time in choosing the right valve upfront can save you from costly repairs and downtime in the long run.

0 notes

Text

Titanium Ball Valve Supplier Egypt

African Valve is the trusted Titanium Ball Valve Supplier Egypt. It is a type of valve designed for controlling the flow of fluids or gases in various industrial applications. They are constructed using titanium materials which is lightweight, strong, and corrosion-resistant metal that is commonly used in various industrial applications, especially in environments where corrosion resistance and durability are critical factors.

Titanium Ball Valve has a ball inside the valve which can be rotated by a handle, actuator, or motor to control the flow rate. When the ball is turned perpendicular to the flow direction, it blocks the passage of the fluid, creating a tight seal. Due to their lightweight design they are widely used in various industries and applications where corrosion resistance, strength, and reliability are critical, including chemical processing, oil and gas, aerospace, and marine applications.

Types of Titanium Ball Valve we supply:

Floating Ball Valve

Trunnion Mounted Ball Valve

Top Entry Ball Valve

Fully Welded Ball Valve

Advantages:

Corrosion Resistance

High Strength-to-Weight Ratio

Biocompatibility

Excellent Temperature Resistance

Low Maintenance

Easy to operate & install

Industry:

Oil and Gas Industry

Chemical Processing

Marine and Shipbuilding

Power Generation

Desalination plants

Description:

Body: Titanium Grade 2, Titanium Grade 5, CF8, CF8M, Cast Iron, Carbon Steel

Ball: Titanium Grade 2, Titanium Grade 5, CF8, CF8M, Cast Iron, Carbon Steel

Stem: SS304, SS316

Gland Nut: SS304, SS316

Seat: PTFE, RTFE, PPL

Seal: PTFE

Packing: PTFE, Graphite

Nominal Size: 2 to 8

Nominal Pressure: Class 150 to Class 600, PN16 to PN63

End Connection: Flanged

Handle: Lever Handle, Locking Device Handle

Operation: Manual, Pneumatic, Electric Actuated

Visit our website for more detail:

0 notes