#cnc router software

Note

ouughh cnc machines my beloved!! i've not even touched one in years bc i went down the coding path, not the engineering path, but man do i miss them sometimes. i wish i could have one but honestly what would i even make with it

truth! my biggest weakness is that im an artist and not an engineer sooo. that does complicate things. but im good as fuck at toolpathing/general troubleshooting so i mostly help other people with projects. when i do design for the cnc i do a lot of text engraving (not dissimilar to signmaking) and some flatpack furniture type stuff. ive also been experimenting with making triptychs with cnc cut bases. we also have a 3d printed pen holder for our big shopbot LOL so i want to try toolpathing it to write stuff for me sometime soon. because why not

#answers#m#not to flex but we also have a cnc plasma cutter that ive messed w here and there#but the software for that thing is really annoying so i still suck at running it but oh well#since i work with mostly found/scavenged stock its hard to find decent sheet steel so cnc router it is

1 note

·

View note

Text

I think everyone has heard the term “supply chain crisis” at this point. Manufacturing centers were first hit in late 2019 and most to the global lockdowns were in effect by the second quarter of 2020. It is now third quarter of 2022 and we are into year three of this “interruption”, it is time to discard this outdated and frankly wrong from the start system of manufacturing and distribution. Americans in particular were already caught in a state of duality in which much of the public laments that nothing is made domestically, while also discarding anything made by local shops as “overpriced hipster gear”. I have previously stated that for true domestic production to return to America there would need to be enough demand for the products to cause more competition and drive the prices down as domestic supply increased.

That is the current situation as I see it, so now what do we do about it? In the last decade one particular technology has taken off, once a novelty and hyper expensive tool for industrial prototyping, 3D printers have become affordable, commonplace, and surprisingly capable. While still used by many to produce novelty items and in industrial roles, this technology is akin to the movable-type printing press of the mid-1400s in that it represents an upset to the established order if utilized effectively. Now before this is dismissed I am aware of the limitations of what can be printed at home. More exotic and expensive versions are used to produce high strength items. But this is where it gets interesting, because it isn’t about everyone having a printer. It’s about everyone using home printers to get a head start on skills, hobbies, and trades they couldn’t afford to break into otherwise and then using those skills to work with each other.

Lathes or milling machines are both often said to be machines that make machines. 3D printers should be included in that list. Now there is nothing made on this machine that can’t be done with other tools and methods, but few that allow the low cost of entry and ease within a home settings. Open source software and thousands of free files allow anyone and everyone to make tons of tools, dies, forms, jigs, stencils, etc. as needed. I've seen sheet steel stamped on dies made from common PLA on a cheap press from Harbor Freight, or even just stuck with hammers. My cousin makes brackets for electronics with an entry level printer while his wife makes custom cookie cutters for various events on the same machine.

And that’s the thing about this, the broad range of applications combined with people’s varied and personal interests. With the addition of a chop saw and drill for extruded or tubular metal you can make strong supports for printed pieces to form a much larger machine. If you can make a drill press or milling machine, you can make a lathe, manually operated or CNC. I’ve seen people make large format CNC router tables that can quickly and efficiently cut and trim an entire sheet of plywood for assembly. If within a community most people have the ability to make their own simple plastic or resin tools and utensils, while someone has a garage metal shop, another a carpentry shop, a couple down the road a leather shop and sewing studio, someone else a pottery studio, even a small foundry for smelting and casting, you would have a far more self-reliant community than anything seen in a hundred years in much of the western world.

I was originally going to link a bunch of videos showing the possibilities and I still might add some later on about specific applications. But I really want everyone to give this some serious thought on their own. Is there a hobby or trade you are interested in but you’re concerned about the investment? Look at what the essential components are. Can the more complex ones be found used? The cheaper ones made at home? We, as in all of us, are in a massive web of unsustainable distribution and centralized manufacturing. I don’t believe the key is to change where that center is, but to replace it with local and regional decentralized networks of skilled individuals whom own their own tools and shops.

#self reliance#sustainability#decentralisation#3d printer#trades#hobbies#skill set#new skills#casting#welding#machining#carpentry#pottery

38 notes

·

View notes

Text

250 Models for CNC Routers. Love sayings for love occsaions like weddings, love presents for girlfriends and more. Download 240+ CNC vector files of love sayings and images perfect for laser cutting projects. Includes wedding, anniversary, Valentine’s Day designs. Features: – File type: CDR – Compatible software: CorelDRAW, Inkscape, Adobe Illustrator – 250+ love saying […] https://tinyurl.com/299hlm46

0 notes

Text

Why CNC Machines Are Essential for Modern Woodworking - Squickmon's Perspective

CNC machines have revolutionized the woodworking industry by providing efficiency and precision that traditional equipment just cannot match. CNC technology can transform your approach to woodworking, regardless of your level of experience or type of work: hobbyist, skilled craftsmen, or large production team member.

What Are CNC Machines?

Computer-controlled movements are used by CNC (Computer Numerical Control) machines, such as routers, mills, and lathes, to precisely cut, carve, and shape wood. They work with digital design files, which guarantees correct and consistent outcomes each and every time.

Why Use CNC Machines?

1. Precision and Accuracy: CNC machines are great at producing finely detailed cuts and removing human mistakes, all while guaranteeing superior quality.

2. Efficiency and Productivity: These devices boost output and speed project completion by automating tool changes, accelerating manufacturing, and operating constantly.

3. Versatility and Flexibility: CNC machines can perform a wide range of tasks with ease, enabling endless inventiveness, from simple furniture items to intricate architectural elements.

4. Waste Reduction and Material Optimisation: CNC machines reduce waste and maximise material utilisation, which makes them economical and eco-friendly.

Streamlining Production with CNC

Automated Operation: CNC Plasma Cutters handle repetitive tasks, freeing up woodworkers to focus on design and supervision, reducing errors and rework.

Batch Production: Produce identical or similar parts in large quantities with consistent quality, ideal for items like chair legs or cabinet doors.

Just-In-Time Manufacturing: Components are produced as needed, reducing inventory costs and enhancing flexibility.

Integration with CAD/CAM Software: Design files can be easily created and modified, accelerating prototyping and production planning.

Diverse Woodworking Tasks with CNC

Cutting and Profiling: CNC routers excel at making straight cuts, curved shapes, and intricate designs with precision.

Carving and Engraving: Create detailed patterns and artistic designs with CNC mills and routers.

Joinery and Assembly: Achieve perfect joints like dovetails and mortise and tenon with automated accuracy.

3D Sculpting and Modeling: Bring digital designs to life with detailed 3D sculptures and reliefs.

Conclusion

In the field of woodworking, CNC machines are cutting-edge because they improve accuracy, increase output, and foster creativity. Embrace CNC technology to elevate your craft and achieve remarkable results. For high-quality CNC equipment, trust Squickmon's Engineering & Automation, a leader in the industry with over 15 years of expertise.

Unlock the future of woodworking with CNC machines and experience unparalleled precision and efficiency!

Check Out: Reasons to Use CNC Machines in Woodworking - Squickmon's

#CNCPlsmaTableManufacturer.#cnc plasma#cnc plasma table manufacturer#plasma table#cnc plasma table#woodworking

0 notes

Text

How to Create Gorgeous Wood Art with CNC | Step-by-Step Guide

youtube

How to Create Gorgeous Wood Art with CNC | Step-by-Step Guide

Welcome to our detailed step-by-step guide on creating gorgeous wood art using CNC (Computer Numerical Control) technology. Whether you're a woodworking enthusiast or a tech-savvy creator, this guide will walk you through the process of turning raw wood into intricate pieces of art with precision and ease.

Step 1: Designing the Artwork

The journey begins with designing your artwork. Using CAD (Computer-Aided Design) software, you can create intricate patterns and designs. The gentle clicking of the mouse and the rhythmic tapping of the keyboard as you sketch out your ideas set the stage for the creative process. Ensure your design is saved in a format compatible with CNC machines, such as DXF or SVG files.

Step 2: Preparing the CNC Machine

Next, prepare your CNC machine. The soft hum of the machine powering up and the whirring as it calibrates create a sense of anticipation. Secure the wood onto the machine bed, ensuring it is firmly in place. The gentle clamping sounds assure you that the wood won’t move during the cutting process.

Step 3: Setting Up the Cutting Parameters

Input the cutting parameters into the CNC machine. This includes specifying the cutting depth, speed, and tool type. The quiet beeping and clicking as you enter these settings ensure that everything is precisely configured. Double-check your settings to avoid any errors during the cutting process.

Step 4: Cutting the Wood

Initiate the cutting process and watch as the CNC machine brings your design to life. The rhythmic buzz of the router cutting through the wood and the steady movement of the machine are both mesmerizing and satisfying. Each pass of the tool removes excess material, gradually revealing the intricate design.

Step 5: Cleaning and Detailing

Once the cutting is complete, remove the wood from the CNC machine. The soft brushing sounds as you clean off sawdust and debris reveal the crisp lines and details of your design. Use fine sandpaper to smooth any rough edges, enhancing the tactile quality of the piece.

Step 6: Applying a Finish

To protect and enhance the beauty of your wood art, apply a finish. The brush’s soft swishing as it spreads oil, varnish, or lacquer over the surface adds a rich, protective layer. This step brings out the natural grain and color of the wood, making your design truly stand out.

Step 7: Final Inspection and Display

The final step is a thorough inspection. Run your hands over the piece, checking for smoothness and ensuring all details are perfect. The subtle creaks and tactile feedback assure you that the piece is ready for display. Choose a suitable spot to showcase your artwork, where it can be admired for its intricate design and craftsmanship.

Conclusion

Thank you for following along on this detailed journey of creating gorgeous wood art with CNC technology. We hope this step-by-step guide has provided both inspiration and practical knowledge. Stay tuned for more woodworking tutorials and creative projects

0 notes

Text

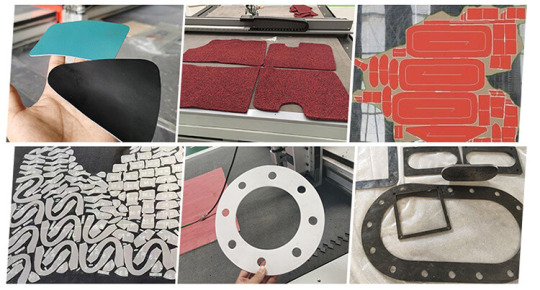

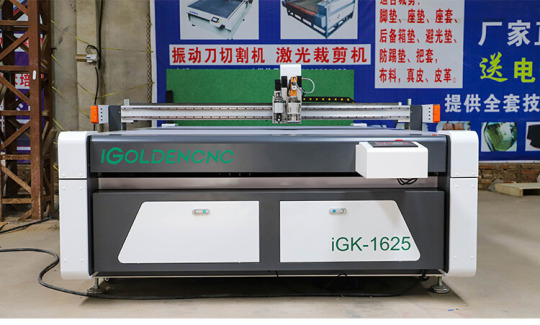

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

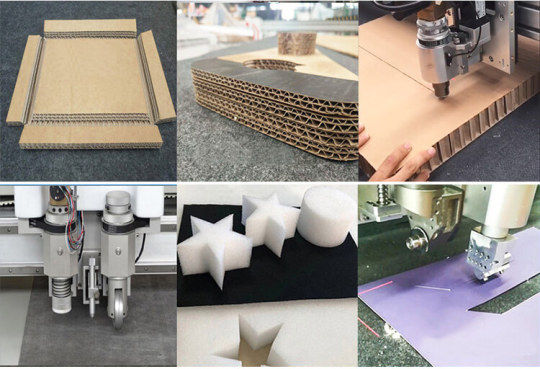

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

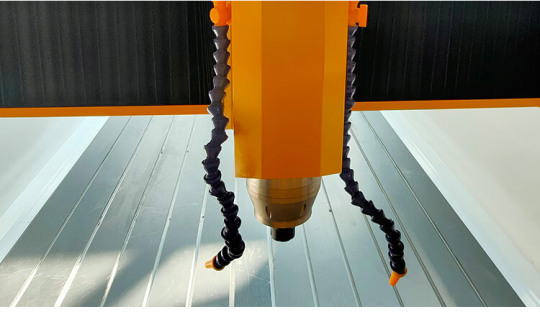

High-Performance CNC Router Machines for Sale

Unlock the full potential of your manufacturing capabilities with our state-of-the-art CNC router machines. Designed for precision, efficiency, and durability, our CNC routers are perfect for a wide range of industries including woodworking, metalworking, plastics, and more. Whether you're a small business looking to enhance your production line or a large-scale manufacturer seeking to upgrade your equipment, our CNC routers provide the perfect solution to meet your needs

Services

Consultation and Customization: Our experts offer personalized consultations to help you select the best CNC router machine tailored to your specific requirements. We also provide customization options to ensure the machine fits seamlessly into your production process.

Installation and Training: We provide comprehensive installation services and hands-on training for your team, ensuring a smooth transition and immediate productivity.

Maintenance and Support: Our commitment doesn't end with the sale. We offer ongoing maintenance services and 24/7 technical support to keep your CNC router running at peak performance.

Financing Options: To make your investment easier, we offer flexible financing plans that suit your budget and cash flow needs.

Key Features

Precision and Accuracy: Our CNC routers are equipped with high-precision components and advanced software, ensuring exceptional accuracy and repeatability for all your projects.

Versatile Functionality: From intricate designs to heavy-duty cutting, our machines can handle a wide variety of materials including wood, metal, plastic, foam, and composites.

Robust Construction: Built with high-quality materials and components, our CNC routers are designed for longevity and can withstand the rigors of continuous operation.

User-Friendly Interface: With intuitive controls and easy-to-use software, our CNC routers enable operators of all skill levels to achieve professional results.

High-Speed Performance: Maximize your productivity with our fast and efficient CNC routers, capable of handling high-volume production without compromising on quality.

Advanced Safety Features: Safety is our priority. Our machines come with integrated safety features to protect operators and ensure a secure working environment.

Invest in a CNC router machine today and take your manufacturing capabilities to the next level. Contact us now to learn more about our products, services, and financing options. Your journey to superior precision and efficiency starts here!

Contact Us

OMNI CNC Technology Co.,Ltd

📍Business Address : No.27 Taiping Zhuang Industrial Park, Jinan, Shandong, China 250000

📞 Phone: 86 531 85938856

🌐 Website: https://www.omni-cnc.com

💼E-mail: [email protected]

🕘 Hours of Operation: 8:30-17:30

And don't forget to follow us on social media for the latest updates:

👍 Facebook: https://www.facebook.com/omnicncrouter

✅Twitter: https://twitter.com/omnicnc/status/907943103192956928

🔗 LinkedIn: https://www.linkedin.com/company/omni-cnc-technology-co-ltd

0 notes

Text

Exploring the Revolutionary World of CNC Machines

Introduction:

In the realm of modern manufacturing, few technologies have revolutionized production processes as profoundly as Computer Numerical Control (CNC) machines. These remarkable tools have transformed the landscape of manufacturing, offering precision, efficiency, and versatility that were once unimaginable. From intricate aerospace components to everyday consumer goods, CNC machines play a pivotal role in shaping the products we rely on every day. Let’s delve into the fascinating world of CNC machines to understand their significance and impact on various industries.

Understanding CNC Machines:

At its core, a CNC machine is a computer-controlled manufacturing device that operates with unparalleled accuracy and repeatability. Unlike conventional manual machines, which require human intervention to operate, CNC machines follow programmed instructions to execute precise machining tasks. This automation not only enhances productivity but also minimizes the margin of error, resulting in superior quality and consistency.

Key Components and Operation:

A typical CNC machine comprises several essential components, including a computerized control unit, motors, drive mechanisms, and cutting tools. The heart of the system is the control unit, which interprets digital instructions, often in the form of G-code, and translates them into precise movements of the machine’s axes. Motors and drive mechanisms then actuate these movements, guiding the cutting tools with utmost accuracy to sculpt raw materials into desired shapes.

Types of CNC Machines:

CNC machines come in various configurations, each tailored to specific machining applications. Some common types include CNC milling machines, lathes, routers, and plasma cutters. Each type offers unique capabilities, allowing manufacturers to perform a wide range of operations, from milling and drilling to turning and engraving. Moreover, advancements in technology have led to the development of multi-axis CNC machines, enabling even more intricate and complex machining tasks.

Applications Across Industries:

The versatility of CNC machines makes them indispensable across diverse industries. In aerospace and automotive manufacturing, CNC machines fabricate critical components with exceptional precision, ensuring optimal performance and safety. In the medical sector, they produce intricate surgical instruments and prosthetics with unparalleled accuracy, improving patient outcomes. Moreover, CNC machines play a crucial role in the production of consumer electronics, furniture, and custom-designed products, catering to diverse consumer demands.

Advantages of CNC Machining:

The adoption of CNC machining offers numerous advantages over traditional manufacturing methods. Firstly, it enhances productivity by reducing cycle times and enabling continuous operation through automated tool changes. Secondly, CNC machines facilitate rapid prototyping and iterative design processes, allowing manufacturers to bring products to market faster. Additionally, the digital nature of CNC programming enables seamless integration with Computer-Aided Design (CAD) software, streamlining the entire manufacturing workflow.

Challenges and Future Trends:

While CNC machining has revolutionized manufacturing, it is not without its challenges. High initial costs, complex programming requirements, and the need for skilled operators can pose barriers to adoption for some businesses. However, ongoing advancements in automation, robotics, and artificial intelligence are addressing these challenges, making CNC technology more accessible and cost-effective. Furthermore, the emergence of hybrid manufacturing systems, combining additive and subtractive processes, represents the next frontier in CNC machining, promising even greater efficiency and versatility.

Conclusion:

In conclusion, CNC machines have emerged as the cornerstone of modern manufacturing, empowering industries to achieve unprecedented levels of precision, efficiency, and innovation. From automotive giants to boutique artisans, businesses of all scales rely on CNC technology to bring their ideas to life with unparalleled quality and reliability. As we continue to push the boundaries of what is possible, CNC machines will undoubtedly remain at the forefront of technological advancement, shaping the future of manufacturing for generations to come.

0 notes

Video

youtube

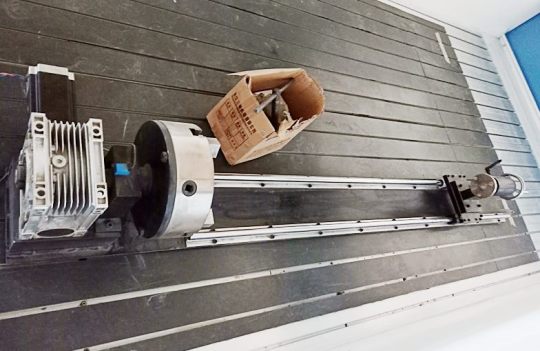

Check out WOODSTAR CNC Router 1325 spares @ https://www.woodstar.in/product/Looking for a CNC router machine in India? Check out our extensive range of CNC routers, including DIY kits, mini routers, woodworking routers, and more. Our CNC router machines are perfect for cutting, carving, and designing wood, metal, and other materials with precision and efficiency.Whether you're a hobbyist or a professional, our CNC routers are designed to meet your specific needs. Explore our selection of CNC router kits, bits, cutters, software, and other accessories to enhance your woodworking projects. From small desktop routers to industrial-grade machines, we have everything you need to take your craftsmanship to the next level.Browse through our collection of CNC router designs, tools, and projects for inspiration and ideas. Learn about the benefits of using a CNC router, how to set up and operate your machine, and discover the endless possibilities of CNC technology. Whether you're cutting intricate designs or creating 3D models, our CNC routers deliver precision and quality every time.Invest in a high-quality CNC router machine from a reliable manufacturer in India. Our machines are built to last and deliver exceptional performance for all your cutting and carving needs. Choose from a variety of sizes, features, and specifications to find the perfect CNC router for your workshop or business. Shop now and elevate your woodworking skills with our top-of-the-line CNC routers.Experience the power and precision of CNC technology with our cutting-edge routers. Whether you're a beginner or an experienced professional, our machines are designed to streamline your workflow and enhance your craftsmanship. Take your projects to the next level with a CNC router from our trusted range of products. Shop now and revolutionize the way you work with wood, metal, and more.

0 notes

Text

CNC Lathe Machine Manufacturer and Suppliers in India

The greatest prices on CNC Lathe Machine can be found at Indian Trade Bird. A CNC lathe(CNC lathe machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer. The full form of CNC is Computerised Numerical Control. CNC is a control system that controls devices running on electronic digital computers. It regulates, optimises, and records a machine moving objects. It can be a router, grinder, laser cutter, welder, milling machine, etc. Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

For More details clicks here - https://www.indiantradebird.com/product/cnc-lathe-machine

0 notes

Text

Crafting Efficiency: The Evolution of Door Making Machines

In the realm of woodworking, the evolution of technology has revolutionized the way we create everyday items. One such innovation that has significantly impacted the industry is the door making machine. These machines have streamlined the process of crafting doors, making it more efficient and precise than ever before.

The Birth of Door Making Machines

The history of door making machines dates back to the industrial revolution when manual labor was gradually being replaced by mechanized processes. Early versions of these machines were basic and required significant human intervention. However, as technology advanced, so did the capabilities of these machines.

Modern Marvels: Features and Functions

Today, door making machines come equipped with a plethora of features designed to enhance efficiency and precision. From automated cutting and shaping to intricate detailing, these machines can produce high-quality doors in a fraction of the time it would take using traditional methods.

Benefits of Door Making Machines

The advantages of using door making machines are manifold. Not only do they increase productivity by reducing production time, but they also ensure consistency in the quality of the doors produced. Additionally, these machines minimize waste and optimize material usage, making them a sustainable choice for woodworking businesses.

Choosing the Right Machine

When selecting a door making machine, it is essential to consider factors such as production volume, door size, and desired features. Whether opting for a CNC router for intricate designs or a panel saw for straight cuts, choosing the right machine can significantly impact the efficiency and output of your woodworking operations.

Future Innovations

As technology continues to advance, we can expect even more sophisticated door making machines to enter the market. From enhanced automation to integration with CAD software for seamless design-to-production workflows, the future of door making machines is bright and promising.

Conclusion

In conclusion, door making machine have revolutionized the woodworking industry, offering unparalleled efficiency and precision in the production of doors. By embracing these technological marvels, woodworking businesses can elevate their craftsmanship and stay ahead in a competitive market. As we look towards the future, the evolution of door making machines promises even greater innovations and possibilities for the industry.

0 notes

Text

Precision in Motion: Exploring the World of Metal CNC Machining

Share Post:

LinkedIn

Twitter

Facebook

Reddit

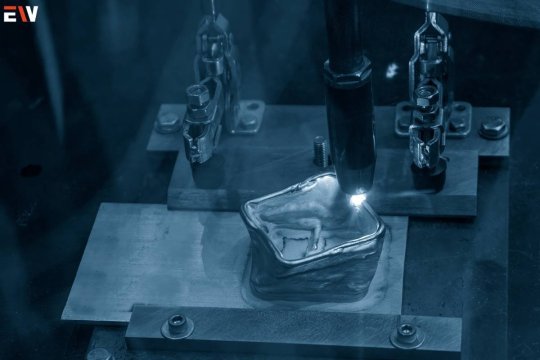

Metal CNC machining represents the pinnacle of precision engineering, offering unparalleled accuracy, efficiency, and versatility in the fabrication of metal components and parts. In this comprehensive overview, we delve into the intricacies of metal CNC machining, exploring its technology, applications, benefits, and the future of precision manufacturing.

Understanding Metal CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to automate the operation of machine tools, such as lathes, mills, and routers. Metal CNC machining specifically focuses on the fabrication of metal components, utilizing specialized CNC machines equipped with cutting tools to shape and refine metal workpieces with exceptional precision.

Key Components:

1. CAD (Computer-Aided Design)

The design phase begins with the creation of a digital model of the desired part using CAD software. This digital model serves as the blueprint for the machining process.

2. CAM (Computer-Aided Manufacturing)

CAM software translates the CAD model into instructions for the CNC machine, generating tool paths and specifying machining operations such as milling, drilling, and turning.

3. CNC Machine

The CNC machine executes the programmed instructions, utilizing cutting tools to remove material from the workpiece and create the desired shape and features with high precision.

4. Cutting Tools

Various cutting tools, such as end mills, drills, and inserts, are used to remove material from the workpiece during the machining process. These tools are selected based on factors such as material type, geometry, and surface finish requirements.

What are its Applications?

CNC machining finds wide-ranging applications across industries and sectors, including:

1. Aerospace: Precision components for aircraft, spacecraft, and satellites, such as engine parts, structural components, and avionics.

2. Automotive: Engine components, transmission parts, chassis components, and precision tooling for automotive manufacturing.

3. Medical: Surgical instruments, implants, prosthetics, and medical device components require high precision and biocompatibility.

4. Electronics: Enclosures, heat sinks, connectors, and components for electronic devices and consumer electronics.

5. Industrial Manufacturing: Tooling, fixtures, molds, and production components for various manufacturing processes.

Benefits of Metal CNC Machining

1. Precision and Accuracy

CNC machining offers unparalleled precision and accuracy, with the ability to achieve tight tolerances and intricate geometries that are difficult or impossible to replicate with traditional machining methods.

2. Efficiency and Productivity

CNC machines operate with high speed and efficiency, allowing for rapid production of metal components with minimal downtime and waste. Automated tool changes, material handling, and process monitoring further enhance productivity.

3. Versatility and Flexibility

CNC machining can accommodate a wide range of materials, including metals such as aluminum, steel, titanium, and brass. Moreover, CNC machines are capable of machining complex shapes and features, making them highly versatile for diverse manufacturing applications.

4. Consistency and Repeatability

With CNC machining, each part produced is identical to the next, ensuring consistency and repeatability in quality and performance. This reliability is essential for industries with stringent quality standards and regulatory requirements.

Future Trends in Metal CNC Machining

1. Advanced Materials

As demand grows for lightweight, high-strength materials, such as titanium alloys and composites, metal CNC machining will continue to evolve to accommodate the machining challenges posed by these advanced materials.

2. Additive Manufacturing Integration

The integration of additive manufacturing (3D printing) with CNC machining processes, known as hybrid manufacturing, offers new possibilities for producing complex metal parts with enhanced efficiency and functionality.

3. Smart Manufacturing Technologies

Advancements in automation, robotics, artificial intelligence, and data analytics are transforming CNC machining into a smarter, more interconnected ecosystem, enabling predictive maintenance, real-time monitoring, and optimization of manufacturing processes.

4. Sustainable Practices

With a growing emphasis on sustainability and environmental stewardship, CNC machining will increasingly adopt eco-friendly practices, such as recycling metal chips and coolant, energy-efficient machining processes, and reduction of material waste.

Conclusion

Metal CNC machining stands at the forefront of precision manufacturing, offering unparalleled capabilities, efficiency, and versatility in the fabrication of metal components and parts. From aerospace to automotive, medical to electronics, CNC machining plays a critical role in driving innovation and advancement across industries. As technology continues to evolve and demand for high-quality, custom metal components grows, CNC machining will remain indispensable for delivering precision in motion and shaping the future of manufacturing.

Also Read: Industrial IoT: Transforming Manufacturing through Connected Intelligence

#metalcnc#PrecisionEngineering#manufacturing#Technology#cncmachining#metalfabrication#aerospace#medical#electronics#industrialmanufacturing

0 notes

Text

With 221 .STL type files included, this collection offers a wide variety of options for CNC routers, 3D printers, and other digital fabrication tools. Our STL files are compatible with popular software programs such as Artcam, Vectric Aspire, Cut3d, and more, ensuring that you can seamlessly integrate them into your workflow. If you have any […] https://tinyurl.com/2cm6e8ag

0 notes

Text

CNC routers and mills require regular maintenance and repairs. Using service and repair software can streamline these tasks and improve productivity. The software enhances reliability, reduces costs, and tracks work orders, spare parts, and service histories. It also allows you to manage your spare parts inventory effectively. AntMyERP's digital repair center provides a comprehensive solution for all your service and repair management needs, including creating digital invoices that you can send directly to customers and vendors via email. Invest in reliable service and repair management software today to maximize the potential of your CNC routers and mills.

0 notes

Text

How many ways CNC machine tool systems can be classified?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes pre-programmed computer software to control the movement and operation of machine tools. These machine tools can include lathes, mills, routers, grinders, and other types of equipment used for precision cutting, drilling, shaping, and finishing of different materials.

Since its inception in the 1950s, CNC machining has revolutionized the manufacturing industry and has become an integral part of various industries such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One way to classify CNC machine tool systems is based on their motion control technology. This includes three main categories: 2-axis, 3-axis, and multi-axis systems. Let's take a closer look at each of these categories and their subcategories:

2-Axis Systems

2-axis systems are the most basic type of CNC machine tool system, with only two axes (X and Y) controlled by the computer software. These systems are typically used for simple operations such as drilling, facing, and boring. They are commonly found in manual milling machines that have been retrofitted with CNC controls.

3-Axis Systems

3-axis systems have three axes (X, Y, and Z) controlled by the computer software, allowing for more complex operations such as contouring, pocketing, and slotting. These systems are commonly used in modern CNC milling and turning machines.

Multi-Axis Systems

Multi-axis systems have additional axes, usually referred to as A, B, and C, controlled by the computer software. This adds more flexibility and complexity to the machining process, allowing for operations such as 3D surface machining and simultaneous five-axis milling. Multi-axis systems are commonly used in high-precision industries such as aerospace and medical manufacturing.

CNC machining has become an integral part of various industries in Canada, such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One major advantage of using CNC machining is its ability to produce complex and precise parts with high accuracy and repeatability. This is especially beneficial in industries where quality and precision are crucial, such as aerospace and medical manufacturing.

CNC castings in Canada also play a significant role in the manufacturing process. Casting is a cost-effective method for producing large quantities of identical parts with complex shapes and designs. With the use of CNC machining, these castings can be further refined and finished to meet specific requirements, resulting in high-quality end products.

Moreover, CNC machining offers a faster and more efficient production process compared to traditional methods. With the use of computer software and automated processes, CNC machines can produce parts with minimal human intervention, reducing the risk of errors and increasing productivity.

In Canada, there are various companies that specialize in providing CNC machining services. These companies not only offer machining services but also provide expertise in design, engineering, and prototyping. This allows for a seamless production process from concept to final product.

Another benefit of CNC machining in Canada is its ability to work with a wide range of materials such as metals, plastics, and composites. With the use of different cutting tools and techniques, CNC machines can effectively handle different materials, making it a versatile option for manufacturers.

In addition to its advantages, CNC machining in Canada also contributes to the country's economy. With the growing demand for precision and high-quality products, the need for CNC machining services continues to rise, creating job opportunities and contributing to economic growth.

Furthermore, with advancements in technology, CNC machining in Canada continues to evolve and improve. New techniques and software are constantly being developed, allowing for even more complex and precise parts to be manufactured. This not only benefits the manufacturers but also the end consumers who can enjoy high-quality products at competitive prices.

In conclusion, CNC machining in Canada is a crucial aspect of modern manufacturing. Its ability to produce high-quality, complex parts with efficiency and precision makes it an essential process for various industries. As technology continues to advance, we can only expect CNC machining in Canada to become even more advanced and integral in the manufacturing process. So whether it's for cnc castings or general machining needs, Canada has a wide range of reputable companies that offer top-notch CNC machining services. So if you're looking for quality and reliable manufacturing solutions, look no further than CNC machining in Canada. With its numerous benefits and constantly evolving technology, it's clear that CNC machining is here to stay and will continue to play a vital role in the growth of Canada's economy. So don't hesitate to utilize this advanced manufacturing process for your business needs, and experience the advantages it has to offer first-hand. Choose CNC machining in Canada and take your production to the next level. Happy machining! So, whether you're in need of CNC castings in Canada or general machining services in Canada, be sure to consider utilizing CNC machining for high-quality and efficient results. From its early origins to its current advancements, CNC machining has proven to be a valuable asset for many industries and will continue to do so in the future. So why not take advantage of this technology and see how it can benefit your business today? Give CNC machining in Canada a try and witness its power for yourself.

0 notes

Text

Stone CNC Engraving Tombstone Headstone Machine

A stone CNC machine is an automatic power tool with computer numerical controller for hobbyists and industrial manufacturer to make custom stone machining for artwork, decorations, souvenirs, gifts, crafts, tombstones and home improvement. It is capable of carving, engraving, cutting, polishing for basalt, granite, quartzite, limestone, marble, onyx, jade, travertine, alabaster, sandstone, slate, soapstone.

CNC Tombstone Headstone Carving Machine

CNC stone craving machine offer great design flexibility. They can reproduce intricate patterns, decorative motifs, personalized messages, and even photo-realistic images with high accuracy. The software used in conjunction with the machine allows for precise control over the depth, width, and intricacy of the engravings.

CNC machines automate the engraving process, reducing the need for manual labor and increasing overall efficiency. Once the design is programmed, the machine can work autonomously, reducing production time and ensuring consistent quality.

A CNC stone engraving machine for tombstones and headstones is a specialized device used in the monument and memorial industry. These machines are designed to precisely engrave or carve designs, text, and other features onto stone surfaces like granite or marble.

CNC Tombstone Engraving Machine for Sale

Because the machine is a CNC stone engraver machine, in order to make the machine bear the weight of the stone, we adopted a T-type heavy machinery structure and the gantry is made of tubular steel, so this CNC tombstone engraver machine can bearing more than 2000kgs materials.and the Thick Aluminum & Hard PVC T-Slot Table makes the machine can easily fix the stone on the work table.

This stone CNC machine is equipped with an advanced 5.5kw water-cooled spindle, which can be controlled by a program, and the frequency range is from 6000 to 24000 RPM. It can meet the requirements of stone carving, cutting, lettering, polishing, and other operations. This ensures that this granite cutting tool can maintain high work efficiency

This Stone CNC Router utilizes brushless microstepper motors. These motors require no regular maintenance — therefore the machine can work efficiently. At the same time this CNC tombstone machining machine come standard with 5.5kw high frequency water cooling spindle, this spindle produces low noise and high cutting precision.

Even if you are a person who has never used CNC stone router machine, you can quickly learn how to operate this CNC tombstone machining machine.it has Automatic tool calibration which can easily and accurateily “Z” zero position for single and multiple tool changes.You can use the DSP hand controller to control this machine without connecting to the computer.

High Quality Cnc Granite Cutting Tools Engraving Machine

This Stone CNC Machine adopts an advanced machine tool construction concept and unique heavy-duty mechanical structure make our granite cutting tools not easy to deform and have excellent load-bearing capacity. At the same time, in order to improve the accuracy of stone relief, we have specially designed Zaxis, which not only improves the accuracy but also solves the problem of ball screw or Zaxis belt breaking. In terms of power, This stone design machine uses a motor with excellent performance to work, which ensures the accuracy and high speed of the stone design machine at work. This also makes granite router bits of granite cutting tools have greater momentum.

Advanced Stone CNC Machine Granite Cutting Tools

To make the service life of the stone CNC machine longer, The stone CNC machine has selected the advanced waterproof and dustproof system for the X Y Zaxis, which can protect all parts and reduce the number of product failures. The spindle adopts the famous water-cooled brushless spindle (5.5KW Powerful Water Cooling Spindle), which has the characteristics of strong cutting ability, low noise, and long working hours. At the same time, the stone design machine adopts Taiwan Hiwin square rail, XY axis German helical rack, and pinion, Z-axis high precision TBI ball screw, which are all durable stone CNC machine accessories and granite cutting tools.

Multifunctional Marble Granite Cutting Tools Machine

Our stone CNC cutting Machine is a stone design machine that can carry out multi-functional engraving on stone and can engrave a variety of stones, such as marble, granite, sapphire, quartz. And this stone CNC machine equipped with the advanced Mach 3 operating system, which can be used with all industry-standard CAD/CAM software to cut, drill, engrave and engrave the stone. It has a wide range of applications and can be used for carving memorial boards, furniture, bas-reliefs, tombstones, stone countertops, and other stone products. This granite letter cutting machine is a granite cutting tool machine very suitable for small and medium-sized stone processing plants.

Applications

Applicable Materials:

Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, crystal, glass, plastic, wood, bamboo and so on, it can do 3D embossment, line carving, bevelling and laser engraving.

Applicable Industries:

Stone Industry: Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, etc.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Wood crafts, gift box, jewelry box and other exquisite art crafts.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould; Artificial marble, plastic sheeting, PVC, wood, foam and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, signs of decoration, literal hole cutting etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox;

The laser head is available for engraving and cutting nonmetal materials, such as acrylic,color plates,ABS board,rubber,plastic,cloth toys,leather ,wool, crystal, glass, ceramic tile, jade, bamboo products, wood products.

Features and A dvantages of the Stone CNC Router

Automatic leveling function: It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

Stable table structure: The table adopts a high-quality steel structure and double beam design. And its gantry and work surface are respectively supported by reinforced beams. Therefore, the stone carving machine has the advantages of bearing load, no deformation, and high stability.

Super cutting ability: The stone carving machine has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive.

Longer service life: Use stainless steel sink, protection plate, and other parts to fully protect the transmission parts and electrical components. So that the CNC stone engraving machine has a long service life. Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

0 notes