#concrete pan mixer

Text

concrete pan mixer manufacturer

hardic engineering is pan mixer, pan mixer machine, laboratory concrete pan mixer, paver block machine, manual concrete block machine manufacturer and suppliers in india, ahmedabad. we are quality manufacturer of pan mixer, castable pan mixer, refectory pan mixer, sand mixer muller, and industrial mixer.

#pan mixer#pan mixer machine#refectory pan mixer#paver block machinery#laboratory concrete pan mixer#sand mixer muller#industrial mixer#manual concrete block machine#foundry sand muller#concrete pan mixer#paver block machine#fly ash brick machine#pan mixer in Ahmedabad#pan mixer manufacturers#pan mixer manufacturers in Ahmedabad#pan mixer machine manufacturers

0 notes

Video

youtube

30cuM/hr Compact Bin Concrete Batching Plant | Navya Equipments

Compact Concrete Batching Plant | Manufacturers | Navya Equipments

#concrete batching plant#pan mixer#compact concrete batching plants#automatic concrete plants#navya concrete plants#navya batching plants#mobile concrete batching plant#inline concrete batching plants#concrete batching plant manufacturers#manufacturer of compact concrete batching plants in India#construction equipment manufacturers#30cuM/hr batching plant

0 notes

Text

Mobile Concrete Batching Plant(INLINE BINS)

Fully Automatic Mobile Concrete Batching & Mixing Plant.

Available in 20/30/45/60 Cu.M. Per Hour Capacity.

Turbo Pan Mixer with spring based arms & blades. /SICOMA (Italy) Twin Shaft Mixer.

Inline Bins.

Large Mixer Platform for ease of Maintenance.

Easy & fast installation, commissioning & erection.

Flexible in adopting to different design mix.

Dual/Double conveyor Belts reduces cycle time and helps in achieving maximum output.

Tyres & tow bar provides mobility to the plant.

Added safety with limit switches in mixer.

Built on single Frame Structure/Chasis.

High accuracy weighing system.

Less Foundation required.

Consistent & uniform mixing.

Plant only require power supply.

Easily movable.

0 notes

Text

Concrete batching plant with pan mixer - Atlas Equipments

Ready mix concrete plant from leading Indian manufacturer of road and civil construction machinery. Buy quality products at reasonable rates.

0 notes

Photo

We are one of leading #manufacturer of #laboratory #pan #mixer for the #trialmix of #concrete Visit : http://setestindia.com/laboratory-concrete-pan-mixture-machine.html (at Delhi, India) https://www.instagram.com/p/CiNpd4Wq9bi/?igshid=NGJjMDIxMWI=

0 notes

Link

DURAPAN’s commitment to safety, quality, and leak-proof containment pans are designed and certified for rigging. Engineered & fabricated in North America leveraging regulatory & manufacturing relationships to create the Best Available Technology.

#Containment pans#Portable job-site containment pans#Paint And Drywall Washout#Super heavy lift#Truck ramp#Dewatering roll off container#Concrete slurry dewatering#Concrete mixer truck washout

1 note

·

View note

Text

Rosehip & Almond Torte

This is the cake I make every year for Christmas Eve. It is a ridiculous beast that is frankly, absurdly expensive to make due to the ingredients but it is so, so worth it, and it's the perfect light, not-too-sweet finale for the monument to excess that is the traditional Ukrainian Christmas Eve dinner as made by my family.

The base of the sponge recipe is from Savella Stechishin's Traditional Ukrainian Cookery, but I've made so many changes over the years that it is no longer recognizable as such. A Torte of Theseus, if you will. The frosting is completely my own invention, with thanks to Deb Perelman of Smitten Kitchen for the idea to stabilize the whipped cream with sour cream.

Sponge

16 eggs, separated

2 cups powdered sugar

3 cups almond flour

1/2 cup all purpose or gluten-free 1-for-1 flour (whichever you like, does not affect texture or taste at all)

2tsp grated lemon rind

2tsp grated lemon rind

2tbsp lemon juice

Pinch salt

Line 3 8-9" circular cake pans with parchment paper (one circle on bottom, and then a strip around the sides, leaving enough to overlap. Use a plain metal paperclip to hold the ends together if necessary). Preheat oven to 350F degrees.

With a stand- or hand-mixer, beat egg yolks until very light. Add sugar gradually and beat constantly until light and fluffy. Stir in the nuts, flour, lemon rind, lemon juice, and salt. Set aside.

With a meticulously clean and dry bowl and whisk attachments, beat egg whites into stiff peaks.

Transfer nut mixture to a large bowl. With a rubber spatula, gently fold in egg whites one large dollop at a time, being careful not to knock the air out. It will take a while as the nut and egg yolk mixture has the texture of wet concrete. Good arm work out!

Once all egg white is incorporated, evenly divide batter between the three pans. They will be quite thin layers. Bake for approximately 30 min or until golden on top and springy to the touch. They will be domed on the top when they are baked. The sponges will shrink back to flat once removed from the oven. This is normal and will not affect the texture of the sponge. Let stand a few minutes in the cake pans before removing to cool on a cake rack. Let cool completely before assembling.

Frosting

16oz heavy cream

1/8 cup sour cream

1/2 cup powdered sugar

2tsps rosewater

1/4c rosehip fruit spread (D'arbo brand)

NB: you could probably do this with any flavor profile and sub out the rosewater and the preserves but keep the measurements the same; just use seedless jam or fruit spread

Make whipped cream with the heavy cream and the powdered sugar. I use my stand-mixer for this but you could do it by hand. When it is fluffy, add the sour cream, the rosewater, and the rosehip spread. Do not overbeat or you will have very delicious butter.

When assembling the torte I usually add a layer of the rosehip spread to each layer of the torte before adding the frosting, just for some extra zing and moisture.

Ideally you'd refrigerate the cake if you have leftovers and then let come back up to room temp when you serve it, but to be perfectly honest I've left this cake covered in a cool room for a few days and neither I nor the cake suffered for it.

10 notes

·

View notes

Text

Laying Machines, Hydraulic Concrete Block Making Machines, Manufacturer

Laying Machines, Hydraulic Concrete Block Making Machines, Machinery, Turnkey Plant Projects, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India. Our hydraulic concrete block making machines provide easy, Eco-friendly and low cost to quicken the construction works.

Laying Machines, Hydraulic Concrete Block Making Machines, Fly Ash Brick Machines, Fly Ash Brick Machine, Turnkey Plant Projects, Automatic Fly Ash Brick Machines, Automatic Fly Ash Brick Machine, Semi Automatic Fly Ash Brick Machines, Semi Automatic Fly Ash Brick Machine, Interlocking Paver Block Machines, Interlocking Paver Block Machine, Paving Block Machines, Paving Block Machine, Pan Mixers, Pan Mixer, Belt Conveyors, Belt Conveyor, Box Feeders, Box Feeder, Press Feed Hoppers, Press Feed Hopper, Press Feeding Systems, Press Feeding System, Cellular Light Weight Concrete Machines, Cellular Light Weight Concrete Machine, CLC Concrete Machines, CLC Concrete Machine, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India.

0 notes

Text

How to Choose the Perfect Concrete Mixer for Sale?

Are you in the market for a concrete mixer for sale? Whether you're a DIY enthusiast tackling a backyard project or a professional contractor working on a construction site, choosing the right concrete mixer for sale is crucial for the success of your project. With a wide variety of options available, it's essential to know what factors to consider to make the best decision.

In this guide, we'll walk you through the process of selecting the perfect concrete mixer that suits your needs.

Understanding Your Needs

Before diving into the world of concrete mixers, it's essential to assess your requirements. Consider factors such as the volume of concrete you need to mix, the frequency of use, the size of the project, and the available space for the equipment. Understanding your needs will help narrow down your options and ensure you choose a mixer that can handle the job efficiently.

Types of Concrete Mixers

There are several types of concrete mixers available on the market, each with its own set of features and advantages. The most common types include:

Drum Concrete Mixers: These mixers have a rotating drum that mixes the concrete ingredients. They are available in both tilting and non-tilting designs, with varying capacities.

Pan Concrete Mixers: Pan mixers feature a stationary pan with rotating blades that mix the concrete. They are suitable for small to medium-sized projects.

Twin Shaft Concrete Mixers: These mixers have two shafts with mixing arms that ensure thorough mixing of the concrete ingredients. They are ideal for large-scale projects and can handle various types of concrete mixes.

Capacity and Output

When choosing a concrete mixer for sale, pay attention to its capacity and output. The capacity refers to the volume of concrete the mixer can hold, while the output indicates the amount of concrete it can produce per batch. Ensure that the mixer's capacity and output align with your project requirements to avoid delays and inefficiencies.

Power Source

Concrete mixers are powered by different sources, including electricity, gasoline, and diesel. Consider the availability of power sources at your project site and choose a mixer that is compatible with the power source you prefer. Additionally, assess the mobility of the mixer if you need to move it around the site frequently.

Durability and Construction

Investing in a durable and well-constructed concrete mixer is essential for long-term performance and reliability. Look for mixers made from high-quality materials such as steel or cast iron, as they are more robust and resistant to wear and tear. Additionally, consider factors such as the design of the mixer's components and the reputation of the manufacturer for producing reliable equipment.

Features and Accessories

Consider the features and accessories offered with the concrete mixer, such as adjustable speed settings, safety features, and additional attachments like concrete vibrator that meet your specific need. These features can enhance the mixer's functionality and make your job easier and more efficient.

Budget Considerations

Lastly, consider your budget when choosing a concrete mixer for sale. While it's essential to invest in a quality mixer that meets your needs, you also want to ensure that it fits within your budget constraints. Compare prices and features from different manufacturers to find the best value for your money.

Conclusion

Choosing the perfect concrete mixer for sale requires careful consideration of your project requirements, the type of mixer, capacity, power source, durability, features, and budget. By taking the time to assess these factors and explore your options, you can select a mixer that will streamline your concrete mixing process and deliver excellent results. Whether you're tackling a small DIY project or managing a large construction site, investing in the right concrete mixer is key to success.

0 notes

Text

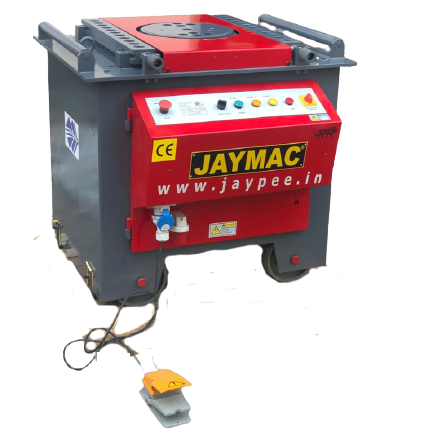

Types of Bending Machine

In the dynamic realm of construction, having reliable and efficient equipment is paramount. As a leading Construction Equipment Manufacturer ,Jaypee stands at the forefront, offering a diverse range of machinery tailored to meet industry demands across India. In this blog, we delve into the fascinating world of bending machines, a crucial component in construction processes.

Types of Bending Machines: Unveiling Precision and Power

1. Bar Bending Machine: Jaypee’s innovative bar bending machines play a pivotal role in shaping reinforced steel bars with precision. These machines are designed for accuracy, ensuring that the bent bars align seamlessly with project specifications.

2. Plate Compactor: Among Jaypee’s stellar offerings is the plate compactor, an indispensable tool for achieving a solid foundation. Ideal for compacting various surfaces, this equipment ensures that construction projects adhere to the highest quality standards.

3. Bar Shearing Machine: Jaypee’s bar shearing machines are engineered for efficiency in cutting steel bars, enhancing productivity on construction sites. These machines exemplify the company’s commitment to delivering robust solutions that stand the test of time.

4. Concrete Mixer Machine: When it comes to blending concrete consistently and efficiently, Jaypee’s concrete mixer machines shine. These machines are designed to handle the demanding mixing requirements of construction projects, ensuring uniformity and strength in every batch.

Types of Bending Machine — A Key Player in Construction Excellence

The phrase “Types of Bending Machine” resonates throughout the construction landscape, underscoring the significance of these tools in ensuring structural integrity. As a Construction Equipment Manufacturer, Jaypee’s commitment to excellence is evident in its array of bending machines, each designed to meet specific construction needs.

Navigating Construction Challenges with Jaypee’s Expertise

Whether it’s bending steel bars, compacting surfaces, or shearing reinforcements, Jaypee’s equipment proves instrumental in overcoming construction challenges. With a PAN India presence, Jaypee’s reputation for delivering top-notch machinery extends across the country, empowering construction projects with the tools they need for success.

In conclusion, the Types of Bending Machines offered by Jaypee not only exemplify precision and power but also embody the company’s dedication to advancing the construction industry. From plate compactors to bar shearing machines, each equipment type serves as a testament to Jaypee’s commitment to quality and innovation in construction equipment manufacturing.

0 notes

Text

concrete pan mixer machine manufacturer

hardic engineering is concrete pan mixer manufacturer in india. we also manufacturer of refectory pan mixer, castable pan mixer, laboratory concrete pan mixer in india.

#concrete pan mixer#concrete pan mixer manufacturer#concrete pan mixer in india#concrete pan mixer in ahmedabad#concrete pan mixer supplier in india

0 notes

Video

youtube

Concrete Batching Plants |Manufacturers|9855597851

#youtube#concrete batching plant#rmc plant#tractor transit mixer manufacturers#automatic concrete plants#pan mixer concrete plant#compact concrete plant#reversible drum batching plant

0 notes

Text

Precise Weighing: Digital weigh batcher ensures accurate measurement of materials like cement, aggregates, and water.

Efficient Mixing: Pan mixer facilitates thorough mixing of concrete ingredients, ensuring uniformity.

Automated Operation: Digital controls automate the batching process, reducing manual labor and minimizing errors.

Versatility: Suitable for various types of concrete mixes, including standard, lightweight, and specialty mixes.

Compact Design: Space-saving pan mixer setup ideal for constrained construction sites or mobile applications.

High Productivity: Faster batching and mixing cycles enhance overall construction project efficiency.

Quality Assurance: Consistent mix proportions lead to higher quality concrete and improved structural integrity.

Cost Savings: Optimized material usage and reduced wastage result in cost-effective concrete production.

User-Friendly Interface: Intuitive digital interface simplifies operation and monitoring of the batching process.

Integration Capabilities: Can be integrated with other construction equipment or computerized systems for seamless workflow management.

0 notes

Text

Pan Concrete Mixer in Madhya Pradesh

Akshar Precast Industries, a high-quality Manufacturer and supplier, specializes in Pan Concrete Mixer in Madhya Pradesh, India.

Akshar Precast Industries," established in 2018, stands out as a leading manufacturer of construction machinery. Their product range includes the Semi Automatic Fly Ash Brick Machine, Manual Bricks Making Machine, Block Making Machine, Paver Block Vibrating Table, Cement Brick Making Machine, and more.

A pan concrete mixer features a horizontal-axis drum with rotating blades around the center axis, ensuring thorough mixing. The distinctive pan-shaped drum enhances efficiency in material mixing and discharge.

Advantages of Pan Concrete Mixers:

Efficient Mixing: Ensures thorough and efficient mixing of concrete and various construction materials.

Versatility: Capable of handling a wide range of materials, making them suitable for diverse construction applications.

Consistency: Provides a consistent mix, ensuring uniform quality in the final product.

Ease of Cleaning: Designed for easy cleaning and maintenance.

Reduced Wastage: The efficient mixing process minimizes material wastage.

Compact Design: Compact and suitable for both stationary and mobile applications.

Service Coverage in Telangana:

Providing Pan Concrete Mixer in Madhya Pradesh Including Indore, Bhopal, Jabalpur, Gwalior, Katni, Ujjain, Dewas, Satna, Ratlam, Rewa, Sagar, Singrauli, Burhanpur, Khandwa, Bhind, Chhindware, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori.

For those interested, feel free to contact us, and we assure you of our best-quality products.

Read the full article

0 notes