#ethylene

Text

Ethylene is sometimes called the most important chemical in the petrochemical industry because it serves as the feedstock for a huge range of everyday products. It's used in the production of antifreeze, vinyl, synthetic rubber, foam insulation, and plastics of all kinds.

Currently, ethylene is produced through an energy- and resource-intensive process called steam cracking, where extremes of temperature and pressure produce ethylene from crude oil in the presence of steam -- and in the process, emit tons of carbon dioxide into the atmosphere. Another way in which ethylene can be produced, however, is through a process called oxidative coupling of methane (OCM). It has the potential to be a greener alternative to steam cracking, but until recently, the amount of ethylene it yields did not make the process economically viable.

Read more.

#Materials Science#Science#Ethylene#Chemistry#Materials processing#Core shell structures#Catalysts#Oxides#Rare earth elements#Lehigh University

10 notes

·

View notes

Text

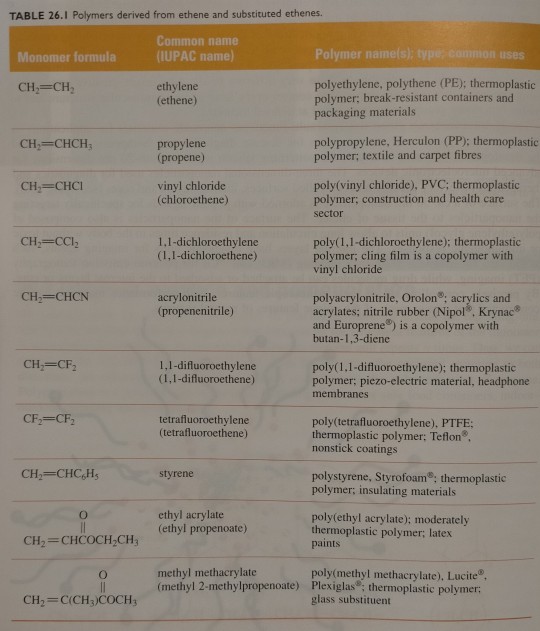

Table 26.1 gives some examples of polymers formed from compounds related to ethene, along with their common names and most important uses.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#polymers#ethene#ethylene#propene#propylene#chloroethene#vinyl chloride#dichloroethene#dichloroethylene#propenenitrile#acrylonitrile#difluoroethene#difluoroethylene#tetrafluoroethene#tetrafluoroethylene#styrene#ethyl propenoate#ethyl acrylate#methyl methylpropenoate#methyl methacrylate

2 notes

·

View notes

Text

#Ethylene#Ethyleneprices#Ethylenemarket#Ethylenenews#Ethylenedemand#Ethylenepricetrend#Ethylenemarketprice#priceofEthylene

2 notes

·

View notes

Video

youtube

Today’s song is Squirrel Gulf by Ethylene featuring the Synthesizer V voicebank Eleanor Forte

#synthesizer v#synthesizer v original#eleanor forte#eleanor forte lite#ethylene#ethylene (composer)#synth v#synthv#squirrel gulf

2 notes

·

View notes

Text

Ethylene: From Cracking Open the Basics to Shaping Our World

From the plastic bottles you use every day to the antifreeze in your car and even the soft fabric of your pajamas, a surprising common thread exists: Ethylene. This essential molecule, with the chemical formula C2H4, forms the backbone of countless products we use every day. In this blog, we'll uncover the secrets of Ethylene, how it's made, and its surprising impact on our modern world. We'll even explore some of the exciting ways it might be used in the future. Get ready to dive into the world of the most significant industrial organic compound around!

Introduction

Ethylene, a colorless gas with a hint of fruitiness, is a major player in the industrial world. Through a process called steam cracking, manufacturers turn ethane and naphtha (petroleum liquids) into valuable chemicals, including ethylene. This process involves intense heat (around 750°C) to break down the hydrocarbons. Ethylene itself is flammable, but it's the foundation for numerous essential chemicals. From polyethylene (the plastic in many everyday items) to ethylene oxide (used in antifreeze) and even ingredients for PVC and polystyrene, ethylene is a versatile building block. Interestingly, this same gas also helps speed up fruit ripening in large-scale agriculture. Polyethylene production currently dominates ethylene use, but its applications extend to refrigeration and even fuel gas for industrial cutting and welding.

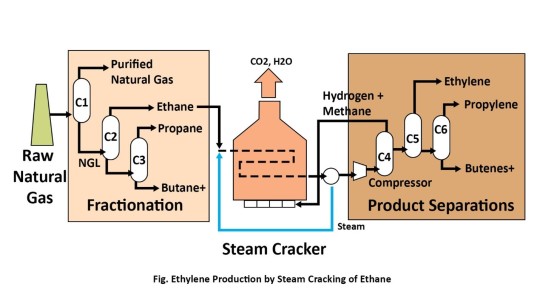

Manufacturing Processes

Ethylene, a very common organic compound, is essential for the petrochemical industry. Made from various oil-based materials in factories that use high-temperature steam, it serves as the starting point for many other important chemicals.

Cracking and quenching

Cracking and quenching are fundamental processes in ethylene production. Initially, an ethane-propane blend undergoes high-temperature cracking in furnaces, yielding ethylene, propylene, and additional byproducts. To halt undesirable reactions and byproduct formation, the resultant stream is swiftly cooled in a water-based quench. Downstream, a decanter removes heavies, condensed dilution steam, tar, and coke, ensuring product purity. The cracked gas is then guided to compression and separation stages, enabling the isolation of ethylene and propylene for further refinement and utilization. These sequential steps are integral to the efficient production of ethylene, a cornerstone chemical in numerous industrial applications.

Compression and drying

Compression and drying are crucial stages in gas processing. The cracked gas undergoes compression across five stages, ensuring optimal pressure levels for subsequent processing. Following the third compression stage, caustic soda and water washes in a caustic scrubber effectively eliminate carbon dioxide and sulfur impurities from the cracked gas stream. Subsequently, the compressed gas is cooled and subjected to molecular sieves for drying, effectively removing residual water content. This meticulous drying process ensures the purity and quality of the gas, preparing it for further refinement and utilization in various industrial applications.

Separation

• After drying, the cracked gas goes through a special chamber (cold box) to remove hydrogen and other small, light hydrocarbons. This process is designed to take out these unwanted elements without losing much of the valuable ethylene.

• At this stage, the condensed substances from the cooling process are directed into a sequence of separation columns. Initially, in the first column known as the demethanizer, methane is separated at the top and utilized further within the cold box, while the lower portion is directed into a second column, the deethanizer.

• The upper portion of the deethanizer, primarily containing ethylene and ethane, is sent through an acetylene converter before undergoing fractionation in the C2-splitter. Within this column, lighter components are removed from the overheads and returned to the compression system, while ethylene suitable for polymer-grade applications is extracted as a side stream. Ethane from the bottom of the C2-splitter is recycled back to the cracking furnaces.

• The lower portion of the deethanizer is channeled into a depropanizer, which separates out C3 (propylene fractionation tower/distillation tower) components in the overheads. This overhead stream is subjected to catalytic hydrotreatment to remove methyl acetylene and propadiene before being directed to the C3-splitter. Within this column, lighter components are extracted from the overheads and recycled to the compressors, while propylene suitable for polymer-grade applications is extracted as a side stream. Propane from the bottom of the C3-splitter is recycled back to the cracking furnaces, while a C4+ stream is obtained from the bottom of the depropanizer.

Technologies used by Major Players

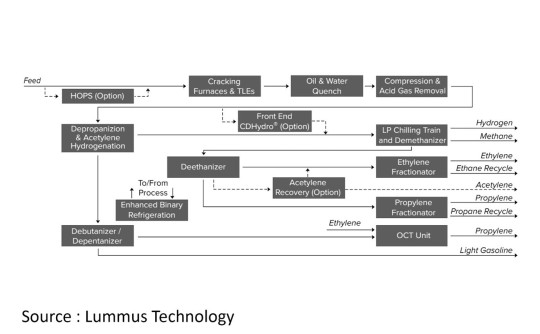

Lummus Technology

• The raw materials utilized in the production of ethylene by Lummus Technologies encompass a variety of hydrocarbons, such as ethane, propane, butane, naphtha, kerosene, diesel, gasoils, or hydrocracked vacuum gasoils.

• Initially, a mixture of fresh feed and recycled ethane and propane undergoes thermal cracking with steam in pyrolysis furnaces. The resulting gas is progressively cooled through steam generation and direct contact with oil and/or water.

• Subsequently, the effluent undergoes compression in a three-stage centrifugal compressor, followed by the removal of acid gases using amine solution and/or caustic soda. Dehydration of the gases is achieved using a molecular sieve. Product recovery is carried out under cryogenic conditions in refrigerated fractionation systems.

• Acetylene compounds undergo hydrogenation in catalyst systems, and hydrogen is purified through Pressure Swing Adsorption (PSA) or methanation.

• Polymer-grade ethylene and propylene are obtained via highly integrated super-fractionation towers aimed at minimizing energy consumption. Simultaneously, mixed C4 products and pyrolysis gasoline are coproduced and recovered. The C4s can serve as feed for an OCT or CPT unit, facilitating the production of propylene, butene-1, or hexene-1. A unified mixed refrigeration system fulfills all refrigeration needs. Essential utilities like steam, cooling water, and fuel are fully integrated to optimize overall efficiency.

• An additional feature involves potentially integrating a gas turbine generator with the pyrolysis furnaces to generate electrical power and extra super-high-pressure steam. The hot exhaust gases from the turbine are directed back to the furnaces to provide hot combustion air.

Applications of Ethylene

Ethylene, a crucial building block in chemical manufacturing, plays a pivotal role in the production of various essential compounds. One prominent application is in the synthesis of Polyethylene, a versatile plastic widely used in packaging, construction, and other industries. Additionally, Ethylene Oxide, valued for its role as a sterilizing agent and in the manufacture of ethylene glycol, finds extensive use in the medical and automotive sectors. Ethylene Dichloride serves as a precursor in the production of vinyl chloride, a key ingredient in the manufacturing of PVC pipes and other products. Ethylene Benzene is utilized in the synthesis of styrene, employed in the production of plastics, rubber, and resins. These and other derivatives highlight the diverse applications of ethylene across various industrial sectors.

1. Polyethylene

Polyethylene, a ubiquitous plastic, finds extensive application in diverse industries. Its versatility makes it a preferred choice for food packaging, ensuring the preservation and safety of food products. Additionally, it is utilized in the production of bottles, providing lightweight and durable containers for beverages, household products, and personal care items. Polyethylene's flexibility and strength make it ideal for manufacturing bags, facilitating storage, transportation, and disposal of goods. Its widespread use in these applications underscores its importance in modern society, contributing to convenience, efficiency, and safety in various aspects of daily life.

2. Ethylene dichloride (EDC)

Ethylene dichloride (EDC), recognized for its lead scavenging properties, is a common additive in leaded fuels, effectively reducing engine knocking and enhancing combustion efficiency. Beyond its role in fuel formulations, EDC has found diverse industrial applications. It served as an extraction solvent, facilitating the separation of desired compounds in various processes. Moreover, its solvency properties made it suitable for textile cleaning and metal degreasing applications. EDC's inclusion in certain adhesives contributed to their adhesive strength and durability.

3. Ethylene Benzene

Ethylbenzene serves as a fundamental precursor in the synthesis of styrene and synthetic polymers, playing a pivotal role in various industrial processes. Widely recognized as a solvent, it facilitates the dissolution of substances in applications ranging from paints and inks to carpet glues and varnishes. Additionally, ethylbenzene finds utility as a constituent of asphalt and naphtha, contributing to their formulation and performance characteristics. Its presence in synthetic rubber and fuels underscores its versatility across multiple sectors. Moreover, ethylbenzene is incorporated into tobacco products and insecticides, adding to its diverse range of applications. It also serves as a component in automotive and aviation fuels, enhancing their combustion properties.

4. Food & Beverages

Ethylene provided in cylinders are employed to regulate the ripening of fruits, particularly bananas, with a concentration of a few ppm being utilized in warehouse atmospheres.

Market Outlook

The driving force behind the global Ethylene market is its use in making Polyethylene plastic. No wonder it's everywhere, from food packaging and grocery bags to toys, cable insulation, and even household items like squeeze bottles. There are different types of Polyethylene, with two major players being LDPE (Low-Density) and HDPE (High-Density). Interestingly, HDPE goes a step further – it's also used to create other plastics like PET (Polyethylene Terephthalate), commonly found in water bottles, food containers, and packaging. But Ethylene's uses extend beyond plastics. It's also a key ingredient in producing Ethylene Oxide, a precursor for chemicals like ethanol amines and monoethylene glycol, further boosting the demand for Ethylene.

Ethylene Major Global Players

Significant players in the Global Ethylene market are Sinopec, LyondellBasell, DowDupont, Exxon Mobil Corporation, INEOS, Chevron Phillips, Braskem, Zhejiang Petrochemical, PTT Global Chemical, Formosa Plastics Group (Formosa Petrochemical Corp.), PetroChina, Arabian Petrochemical Company, Yeochun NCC Co. Ltd., Royal Dutch Shell, Kavian Petrochemical, and Others.

Conclusion:

Ethylene is a colorless gas with a distinctive fruity odor. Widely utilized in agriculture, ethylene expedites the ripening of fruits such as tomatoes, bananas, and mangoes. Moreover, ethylene serves as a vital precursor in chemical synthesis, contributing to the production of Polyethylene, Ethylene Oxide, Ethylene Dichloride, and Ethylene Benzene. Additionally, it finds application as a refrigerant in petrochemical industries and as a fuel gas for welding and cutting processes. The global ethylene market is forecasted to witness substantial growth, primarily driven by increasing demand for ethylene as a feedstock in chemical manufacturing, particularly for Polyethylene, renowned for its durability, flexibility, and lightweight nature, essential for food and beverage packaging and various other industries. This anticipated market expansion reflects the continuous evolution of ethylene-based products and their pivotal role in meeting diverse industrial needs, paving the way for innovation and growth opportunities in the chemical sector.

0 notes

Text

pet1 ? dangereux

0 notes

Text

#styrene#scalemodel#scale#scratchbuild#vr#scratchbuilt#scalemodels#modelmaking#scratchbuilding#plasticmodel#ethylene#polystyrene#styrenejunkie#styrenemonomer#propyleneglycol#coroplast#volkswagenmk#miniatures#turbo#modelbuilding#mk#revell#golf#glycolpeople#ethyleneglycol#printshop#chemicalindustry#plasticmodels#indianchemicalindustry#styrenemonomerplant

0 notes

Text

1-Methylcyclopropene MCP – Ức chế sự già hóa, kéo dài thời gian bảo quản nông sản

1-MCP đã được sử dụng rộng rãi trong ngành nông nghiệp và thực phẩm để cải thiện chất lượng và tuổi thọ của sản phẩm n ông nghiệp.

1. Thông tin sản phẩm

- Tên tiếng anh: 1-MCP 1-methylcyclopropene

- Ngoại quan: bột màu trắng

- Độ ẩm: <5%

- Hàm lượng 1-methylcyclopropene: > 3.5%

- Độ tinh khiết thế thôi: 95%

2. Cơ chế hoạt động của 1-MCP - ức chế sự già hóa, kéo dài thời gian bảo quản nông sản.

Khi các cơ chất thực sự bước vào giai đoạn trưởng thành, ethylene, một loại hormone trưởng thành hợp hợp, sẽ được sản xuất và kết hợp với protein thụ thể ethylene bên trong tế bào để thúc đẩy quá trình lão hóa nhanh hơn và cái chết của cây trồng. 1-Methylcyclopropene, có cấu trúc phân tử tương tự ethylene, cũng có thể liên kết với các thụ thể protein ethylene này, ngăn không cho thụ thể liên kết với ethylene, đồng thời ngăn chặn các phản ứng sinh lý và sinh hóa gây trưởng thành, chậm trễ xuất hiện phản ứng lão hóa sinh lý ở thực vật.

Do đó, trước khi giải phóng ethylene nội sinh trong thực vật, việc áp dụng 1-MCP sẽ liên kết trước với thụ thể, làm giảm tác động tiêu điểm c cực của ethylene sẽ liên kết với thụ thể của chúng, làm quá chậm quá trình trưởng thành và đạt được hiệu quả bảo quản.

2. Ứng dụng của sản phẩm 1-Methylcyclopropene

Đối với rau:

Chế độ quá trình chuyển màu (màu xanh qua màu vàng), chuyển éo, giảm cường độ hô hấp, làm chậm quá trình suy giảm chất dinh dưỡng của rau, duy trì, cải thiện mùi của rau, kéo dài thời gian sử dụng, bảo quản, vận hành rau củ.

Đối với trái cây:

Thực tế chậm, cứng, quản lý thời gian kéo dài, làm chậm quá trình suy giảm chất lượng của trái cây.

Bảo quản hoa cắt:

Giảm hiện tượng vàng lá, tàn rụng hoa, rụng lá. Ức chế tacục hóa của Ethylene đối với hoa tươi, giảm cường độ hô hấp giúp hoa tươi lâu, kéo dài tuổi thọ, thời gian sử dụng và bảo quản.

Một số thử nghiệm đã chỉ ra rằng sau khi hoa cẩm thạch được xử lý bằng 1-MCP, thời gian ra hoa được kéo dài hơn 2 lần và hiệu quả rõ ràng rõ ràng.

Có một phương pháp xử lý nông sản sau thu hoạch, thời hạn sử dụng của nông sản được xử lý bằng 1-MCP thường được kéo dài kể từ. Nó có thể làm giảm cường độ hô hấp của nông sản, nhờ đó nông sản có thể kéo dài thời gian bảo quản ngay trong môi trường có nhiệt độ thấp cao hơn một chút so với nhiệt độ bảo quản tối ưu. Không thể giảm bớt thất bại nhưng có thể cải thiện chất lượng. Đặc biệt phù hợp với các loại nông sản cần bảo quản lạnh hoặc vận chuyển trên quãng đường dài.

Đường uống: LD50 uống cấp tính cho chuột cống 966, chuột cái 807 mg/kg.

Thực tế: LD50 tối đa là > 4000, > 2000 mg/kg.

Không khó chịu với da và mắt. Không phải là một chất nhạy cảm với da.

Căng thẳng phải: LC50 (4 Phân) đối với chuột> 5,2 mg/l không khí.

https://damtom.vn/san-pham/1-methylcyclopropene-mcp-uc-che-su-gia-hoa-keo-dai-thoi-gian-bao-quan-nong-san/

Website: https://damtom.vn/

#ethylene#Giảm hiện tượng vàng lá#ngăn rụng hoa#kéo dài tuổi thọ#methylcyclopropene#kéo_dài_thời_gian_bảo_quản#ức_chế_sinh_trưởng

0 notes

Text

The Laminating Adhesives Market size is estimated to reach US$3.1 billion by 2027 after growing at a CAGR of 5.9% during the forecast period 2022-2027. There are several laminating processes that are generally classified as either wet or dry laminating processes. The basic categories of laminating adhesives used are water-based, solvent-based, ultraviolet curable and hot melt adhesives. The basic resin systems widely used in the laminating adhesives industry are polyurethane, acrylic, ethylene, vinyl acetate, silicone and polyolefins. Most of the water-based adhesives are acrylics or acrylic hybrids and polyurethane dispersions. These laminating adhesives dominate the market owing to their Food and Drug Authority (FDA) compliance which makes them the preferred choice for food packaging applications. As per the World Packaging Organization (WPO), the turnover of the global packaging industry is more than $500 billion, in which food packaging is an important area. The growth of flexible packaging drives the Laminating Adhesives market.

0 notes

Text

Global Ethylene Market Is Estimated To Witness High Growth Owing To Increasing Demand for Consumer Goods and the Trend of Technological Advancements

The global ethylene market is estimated to be valued at USD 166,520 million in 2019 and is expected to exhibit a CAGR of 5.6% over the forecast period 2020-2027, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

The ethylene market refers to the production and consumption of ethylene, a petrochemical that is widely used in various industries. Ethylene is primarily used as a raw material in the production of consumer goods such as plastics, packaging materials, automotive components, and textiles. It is also used in the manufacturing of chemicals, solvents, and resins. The increasing demand for these products across different sectors is driving the growth of the ethylene market.

B) Market Dynamics:

Two drivers are contributing to the growth of the global ethylene market. Firstly, the rising demand for consumer goods, especially in emerging economies, is fueling the growth of the ethylene market. With increasing disposable income and changing lifestyles, there is a higher demand for products such as plastics, packaging materials, and textiles. This is driving the production of ethylene as it serves as a key raw material in these industries.

Secondly, the trend of technological advancements is also boosting the growth of the ethylene market. Continuous research and development efforts in polymerization technology and catalysts have led to improved production processes and higher yields. This has resulted in increased production efficiency and reduced manufacturing costs, further driving the growth of the ethylene market.

C) Market Key Trends:

One key trend in the Ethylene Market is the shift towards sustainability and bio-based alternatives. With growing environmental concerns and regulations on plastic usage, there is increasing interest in developing bio-based alternatives to ethylene and its derivatives. For example, bio-based polymers made from renewable resources are gaining traction in the packaging industry. This trend is driven by the increasing consumer demand for sustainable products.

D) SWOT Analysis:

Strengths:

1. Abundant availability of ethylene feedstock.

2. Growing demand for consumer goods.

Weaknesses:

1. Environmental concerns related to plastic usage.

2. Vulnerability to fluctuations in oil and gas prices.

Opportunities:

1. Development of bio-based alternatives.

2. Growing demand for ethylene oxide derivatives in the healthcare sector.

Threats:

1. Intense competition among key players.

2. Volatility in raw material prices.

E) Key Takeaways:

The global ethylene market is expected to witness high growth, exhibiting a CAGR of 5.6% over the forecast period.

The increasing demand for consumer goods and the trend of technological advancements are the primary drivers of market growth.

Asia-Pacific is the fastest growing and dominating region in the ethylene market, driven by the rapid industrialization and urbanization in countries like China and India.

Key players operating in the global ethylene market include Borealis, Chevron Phillips Chemical, Dow Chemical, ExxonMobil, INEOS, LyondellBasell Industries, Mitsubishi Chemical, SABIC, and Shell.

The global ethylene market is poised for significant growth due to the increasing demand for consumer goods and the trend of technological advancements. However, the industry also faces challenges related to environmental concerns and volatility in raw material prices. Despite these challenges, the market presents opportunities for the development of sustainable alternatives and increased demand in the healthcare sector. Overall, key players in the ethylene market need to focus on innovation and sustainability to maintain a competitive edge.

0 notes

Text

Ethylene glycol (see figure 19.2) and propylene glycol are synthesised from ethylene (ethene) and propylene (propene) respectively, hence their common names as shown below.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ethylene glycol#propylene glycol#ethylene#ethene#propylene#propene#synthesis#polarity#ethane#propane

4 notes

·

View notes

Text

#Ethylene#Ethyleneprices#Ethylenenews#Ethylenemarket#Ethylenedemand#Ethylenemarketprice#priceofEthylene

1 note

·

View note

Text

Ethylene appears to decrease the activity of auxin both by reducing its synthesis and transport and by increasing its destruction.

"Plant Physiology and Development" int'l 6e - Taiz, L., Zeiger, E., Møller, I.M., Murphy, A.

#book quote#plant physiology and development#nonfiction#textbook#ethylene#auxin#synthesis#transport#destruction

0 notes

Text

Bio-Based Ethylene Market was valued at US$ 414.34 Mn in 2019 and is projected to reach US$ 718.32 Mn by 2028 with a CAGR of 6.4% from 2019 to 2028 segmented into Raw Material and End-User Industry.

#Bio-Based Ethylene Market#Bio-Based Ethylene#Global Bio-Based Ethylene Market#Ethylene Market#Ethylene

0 notes

Link

Butyl Cellosolve là một chất hóa học, được tìm thấy trong một loạt các sản phẩm làm sạch – chất tẩy rửa kính, chất tẩy rửa lò, chất tẩy nhờn chung, tẩy tại chỗ, làm mát không khí, và chất tẩy rửa thảm, trong số những thứ khác. Nó là một chất lỏng không màu có vị ngọt, mùi ete. Nó cũng được biết đến như butyl glycol, Dowanol, và ethylene glycol monobutyl ether (EGBE). Butyl Cellosolve glycol ether tương thích với một loạt các loại nhựa và nó hòa tan 100% vào nước.

0 notes

Text

Using natural ethylene to ripen peepers🫑 and tommytoes🍎. --Loki💛😺

#cats#plushie#puppet#cat#stuffed animals#puppetry#plush animal#plush toys#puppets#plush cat#puppets of tumblr#puppet show#wholesome#sweet peppers#bell peppers#ripening#ethylene#plant hormones#growing tomatoes#roma tomatoes#tomatoes#tomato#apples#bananas#money saving tips#green pepper

0 notes