#high quality aluminium windows

Text

#aluminium doors and windows#windows & doors company#window door company#windows and doors installation#best aluminium windows uk#high quality aluminium windows#aluminium double glazed windows#best aluminium sliding doors uk#exterior double sliding patio doors#double sliding patio doors#aluminium sliding doors london#bi fold doors internal#best bifolding doors#glass roof panels uk#glass roof in london#glass roof systems uk#glass roofs uk#front door aluminium#aluminium door panels#corvision sliding patio doors#cortizo aluminium windows uk#cortizo doors and windows#roof lantern uk#conservatory roof solutions#heritage doors and windows#heritage aluminium windows and doors#heritage aluminium windows#internal heritage doors#heritage doors uk#aluminium casement windows

1 note

·

View note

Text

0 notes

Text

#luxury aluminium sliding doors london#best double sliding patio doors#best sliding door for home#best doors and windows uk#exterior double sliding patio doors#top quality aluminium door panels#front aluminium panel doors london#corvision sliding patio doors#durable aluminium sliding doors uk#affordable aluminium bi folding doors#best bifold doors uk#glass roof panels uk#glass roof in london#high quality aluminium windows#best aluminium clad windows#cortizo aluminium windows uk#best windows and doors service in uk#aluminium sliding doors london#best aluminium glass doors#cortizo doors and windows#top aluminium windows uk

0 notes

Text

#luxury aluminium sliding doors london#best double sliding patio doors#best sliding door for home#best doors and windows uk#exterior double sliding patio doors#top quality aluminium door panels#front aluminium panel doors london#corvision sliding patio doors#durable aluminium sliding doors uk#affordable aluminium bi folding doors#best bifold doors uk#glass roof panels uk#glass roof in london#high quality aluminium windows#best aluminium clad windows#cortizo aluminium windows uk#best windows and doors service in uk#aluminium sliding doors london#best aluminium glass doors#cortizo doors and windows#top aluminium windows uk

1 note

·

View note

Text

Sixaluminium - Devasa+

Aluminum extrusion is a process used to create parts with specific cross-sectional profiles by pushing heated alloy material through a die. This process allows for the creation of various shapes and sizes, making it a versatile method for manufacturing aluminum profiles. Despite its importance, many people may not even notice the prevalence of aluminum extrusions in their homes. In Turkey aluminium manufacturer, companies like Aluminance Aluminum Industry and Trade Inc. and Ş. are leading manufacturers of aluminum extrusion profiles and composite panels. These companies play a crucial role in providing high-quality aluminum extrusion products for various industries, including construction. The construction industry greatly benefits from the use of aluminum extrusion profiles. Aluminum construction are lightweight, strong, and corrosion-resistant, making them ideal for construction applications. They are commonly used in windows, doors, and other architectural elements due to their structural integrity and cost benefits. Additionally, aluminum extrusions offer sustainability advantages as they are recyclable and can be repurposed for other projects . The use of aluminum extrusions in construction also contributes to faster construction timelines, as they can be easily fabricated and installed. Overall, aluminium systems profiles have become an essential component in the construction industry, offering a range of benefits for architects, builders, and homeowners alike. In Turkey aluminium extrusion manufacturers like Ş. have played a significant role in supplying the construction industry with high-quality aluminum profiles. These profiles are used in various applications, including aluminum systems for windows, doors, and facades . The 40-Series Aluminium Extrusion Profile produced in the EU is a popular choice for construction pr aluminium veranda ojects due to its quality and durability. The use of aluminum extrusion profiles in construction not only enhances the aesthetics of buildings but also provides structural stability and longevity. With the continued advancements in aluminum extrusion technology, the construction industry can expect further innovation and development in the utilization of aluminum profiles for various architectural and structural applications.

2K notes

·

View notes

Photo

Alfa Romeo Disco Volante by Touring Superleggera

The Disco Volante is a two-seater Gran Turismo. It is based on the Alfa Romeo 8C Competizione coupé with its front-central mounted 4.7 litre V8 engine and a transaxle rear drive with unmodified specifications. Each unit, of which the construction requires 4,000 hours of manual work.The present Disco Volante celebrates the myth of the 1952 style icon. The new design briefing required to blend ingredients as innovation, emotion and aerodynamic properties into a timeless and essential shape.During the development stage, Head of Design Louis de Fabribeckers and his team cooperated with the engineers on an almost daily basis. “We focused on the preservation of the design essence. – says de Fabribeckers – Once the design frozen, we had to understand the manufacturing problems and solve them right away without compromising the design.”In consistency with the car’s design philosophy the interior has a ‘science fiction’ feel to it. Part of this ‘spaceship’ atmosphere was created by elements like the red LED interior light profiles. Also, aeronautics has been the inspiration for parts like the dashboard, instruments and seat adjustment lever.The Alfa Romeo 8C Competizione chassis was chosen for its light and rigid structure and its outstanding dynamic properties. Therefore it forms the perfect basis for the coach-built bodywork of the Disco Volante, integrally conserving the rolling chassis and drive train.The Alfa Romeo 8C’s steel space-frame and other structural elements were retained to guarantee torsion stiffness, high performance and the quality standard. The frame members and the central carbon cell remained unchanged. Elements of the underpinning and the body, such as the engine bay and firewall, the windscreen and cowl, the a-pillar and the locks and hinges have been retained too, just as the dashboard and instruments, the pedals and the steering wheel. Parts like doorframes, the roof frame and the c-pillar have been modified to match with the new shape.The layout of a front-central mounted engine, a transaxle transmission and rear-wheel drive offers an optimal weight distribution of 49-51% between the front and rear axles. To ensure excellent handling the front and rear double-wishbone suspension scheme is combined with hub carriers of forged aluminium and additional trailing arms for the rear suspension.The lightweight and compact 4.7 litre V8 engine delivers 450HP and 480Nm peak torque. It is coupled with a six-speed sequential transaxle gearbox with electronic control and paddle-shift gear selection. Together with a limited-slip differential and a state-of-the-art braking system with large diameter, ventilated discs a precise, dynamic and proactive drive is ensured. The Disco Volante can accelerate from 0 to 100 km/h (0-62 mph) in 4,2 seconds and has a top speed of about 290 km/h (181 mph).

All new and modified components of the Disco Volante have been CAD designed. In this process, which covers feasibility, safety, homologation, aerodynamics and structural analysis, the most advanced IT tools and simulation techniques have been used.

Since torsion stiffness and noise reduction are of critical importance, special attention has been paid to the under-body structure and its elements, like the tubular frames supporting the rear wings and bumper, and the roll bar joining the c-pillars. Other complex design issues were the tailgate hinges, the 3d-cambered door window, and the front wheel covers.

The Disco Volante was then submitted to a CFD aerodynamic study to enhance the airflow and ensure optimal downforce in the rear section. After that, FEM calculations were run to assess resistance and rigidity of all parts subject to homologation.

Touring Superleggera is synonymous with the manufacture of lightweight bodywork. The weight advantage of aluminium is one of the assets of Touring Superleggera’s construction methods. Nowadays however, the craft of hand-beating aluminium panels is combined with the use of carbon fibre reinforced plastic (CFRP). For the Disco Volante, Touring decided to use this combination of aluminium and CFRP. This has been the result of a study conducted to define optimal use of materials for the bodywork in terms of weight, resistance, precision, finish and quality, and ease of repair in case of damage.

The CFRP is used for specific components like the front bumper and grille, the bonnet, the skirts, the boot lid and the integrated rear-window frame. The bonnet and the boot lid are sandwich-built with Nomex filler in-between to obtain a better stiffness/weight ratio and to dampen vibration and noise.

The aluminium panels are hand-beaten using an epoxy mould. Since the inner frames of most parts of the bodywork are made of CFRP, this requires gluing of aluminium on carbon fibre. This technique adds to the rigidity as the glue has structural properties.

The body panels are pre-assembled on a laser measurement platform using a jig. This ensures that the strict tolerance required is respected. After adjustment, the panels are either welded or glued. The body-in-white is then used to preassemble and fit all trim components, brightware and moulding.

160 notes

·

View notes

Note

can you guys chill lmao. just trying to help

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminium oxide (α-Al2O3) with trace amounts of elements such as iron, titanium, cobalt, lead, chromium, vanadium, magnesium, boron, and silicon. The name sapphire is derived from the Latin word sapphirus, itself from the Greek word sappheiros (σάπφειρος), which referred to lapis lazuli. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. Red corundum stones also occur, but are called rubies rather than sapphires. Pink-colored corundum may be classified either as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs. Sapphire is the birthstone for September and the gem of the 45th anniversary. A sapphire jubilee occurs after 65 years.

Sapphire is one of the two gem-varieties of corundum, the other being ruby (defined as corundum in a shade of red). Although blue is the best-known sapphire color, they occur in other colors, including gray and black, and also can be colorless. A pinkish orange variety of sapphire is called padparadscha.

Significant sapphire deposits are found in Australia, Afghanistan, Cambodia, Cameroon, China (Shandong), Colombia, Ethiopia, India Jammu and Kashmir (Padder, Kishtwar), Kenya, Laos, Madagascar, Malawi, Mozambique, Myanmar (Burma), Nigeria, Rwanda, Sri Lanka, Tanzania, Thailand, United States (Montana) and Vietnam. Sapphire and rubies are often found in the same geographical settings, but they generally have different geological formations. For example, both ruby and sapphire are found in Myanmar's Mogok Stone Tract, but the rubies form in marble, while the sapphire forms in granitic pegmatites or corundum syenites.

Every sapphire mine produces a wide range of quality, and origin is not a guarantee of quality. For sapphire, Jammu and Kashmir receives the highest premium, although Burma, Sri Lanka, and Madagascar also produce large quantities of fine quality gems.

The cost of natural sapphires varies depending on their color, clarity, size, cut, and overall quality. Sapphires that are completely untreated are worth far more than those that have been treated. Geographical origin also has a major impact on price. For most gems of one carat or more, an independent report from a respected laboratory such as GIA, Lotus Gemology, or SSEF, is often required by buyers before they will make a purchase.

9 notes

·

View notes

Text

The Importance of Aluminium Ingots in Various Industries

Aluminium is a lightweight and versatile metal that is widely used in many different industries, including construction, automotive, aerospace, and packaging. Aluminium ingots are an essential part of the manufacturing process for producing high-quality aluminium products. In this blog, we will discuss the importance of aluminium ingots and their use in various industries.

What are Aluminium Ingots?

Aluminium ingots are rectangular or trapezoidal blocks of pure aluminium metal that are used to produce various aluminium products. They are produced by smelting raw aluminium ore and then pouring the molten metal into a mould. Once the metal has cooled and solidified, it is removed from the mould and processed further to create a wide range of aluminium products.

Uses of Aluminium Ingots

Construction Industry: Aluminium is widely used in the construction industry due to its lightweight and corrosion-resistant properties. Aluminium ingots are used to produce various building materials such as window frames, roofing sheets, and structural components.

Automotive Industry: Aluminium is also extensively used in the automotive industry due to its lightweight, high strength, and durability. Aluminium ingots are used to produce car parts such as engine blocks, wheels, and chassis.

Aerospace Industry: Aluminium is a critical material in the aerospace industry due to its lightweight and high strength-to-weight ratio. Aluminium ingots are used to produce aircraft parts such as wings, fuselages, and landing gear.

Packaging Industry: Aluminium is widely used in the packaging industry due to its excellent barrier properties and ability to preserve the freshness and quality of food and beverages. Aluminium ingots are used to produce various types of packaging such as cans, foils, and containers.

Advantages of Using Aluminium Ingots

Lightweight: Aluminium is one-third the weight of steel, which makes it an ideal material for applications where weight reduction is crucial.

Corrosion Resistance: Aluminium is highly resistant to corrosion, which makes it ideal for outdoor applications and harsh environments.

High Strength-to-Weight Ratio: Aluminium has a high strength-to-weight ratio, which makes it suitable for applications where high strength and low weight are required.

Aluminium ingots are a critical component in the manufacturing process for producing high-quality aluminium products. They are widely used in various industries such as construction, automotive, aerospace, and packaging. Aluminium offers numerous advantages over other materials, such as its lightweight, corrosion resistance, and high strength-to-weight ratio, making it an ideal material for a wide range of applications.

57 notes

·

View notes

Text

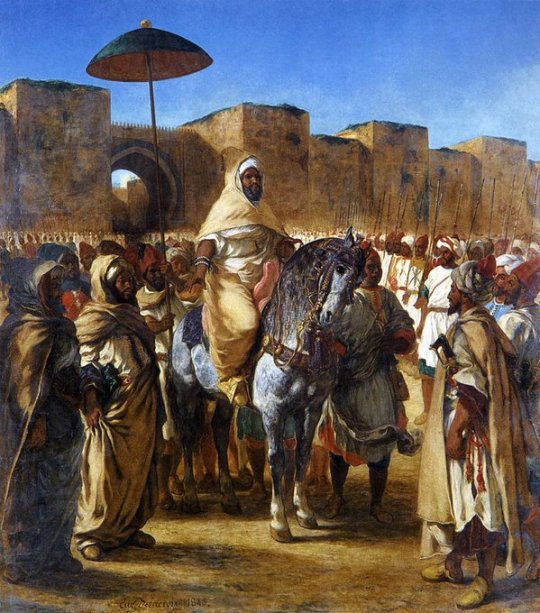

THE MOORS

During the European Dark Ages, between the 7th and 14th century AD, the Moorish Empire in Spain became one of the world's finest civilizations. General Tarik and his Black Moorish army from Morocco, conquered Spain after a week-long battle with King Roderick in 711 AD. (The word tariff and the Rock of Gibraltar were named after him). They found that Europe, with the assistance of the Catholic Church, had returned almost to complete barbarism. The population was 90% illiterate and had lost all of the civilizing principles that were passed on by the ancient Greeks and Romans.

The Moors reintroduced mathematics, medicine, agriculture, and the physical sciences. Arabic figures including the zero and the decimal point replaced the clumsy Roman numerals. As Dr. Van Sertima says, "You can't do higher mathematics with Roman numerals." The Moors introduced agriculture to Europe including cotton, rice, sugar cane, dates, ginger, lemons, and strawberries. They also taught them how to store grain for up to 100 years and built underground grain silos. They established a world-famous silk industry in Spain. The Moorish achievement in hydraulic engineering was outstanding.

They constructed an aqueduct, that conveyed water from the mountains to the city through lead pipes from the mountains to the city. They taught them how to mine for minerals on a large scale, including copper, gold, silver, tin, lead, and aluminium. Spain soon became the world centre for high-quality sword blades and shields. Spain was eventually manufacturing up to 12,000 blades and shields per year. Spanish craft and woollen became world famous. The Moorish craftsman also produced world-class glass, pottery, vases, mosaics, and jewellery.

The Moors introduced to Europe paved, lighted streets with raised sidewalks for pedestrians, flanked by uninterrupted rows of buildings. Paved and lighted streets did not appear in London or Paris for centuries. They constructed thousands of public markets and mills in each city. Cordova alone had 5,000 of each. They were also introduced to Spain's underwear and bathing with soap. Their public baths numbered in the thousands when bathing in the rest of Europe was frowned upon as a diabolical custom to be avoided by all good Christians.

Poor hygiene contributed to the plagues in the rest of Europe. Moorish monarchs dwelled in sumptuous palaces while the crowned heads of England, France, and Germany lived in barns, lacking windows, toilets, and chimneys, with only a hole in the roof as the exit for smoke. Human waste material was thrown in the streets since no bathrooms were present. Education was made mandatory by the Moors, while 90% of Europe was illiterate, including the kings and queens. The Moors introduced public libraries to Europe with 600,000 books in Cordova alone. They established 17 outstanding universities in Spain.

Since Africa is a matriarchal society, women were also encouraged to devote themselves to serious study, and it was only in Spain that one could find female doctors, lawyers, and scientists. Moorish schoolteachers knew that the world was round and taught geography from a globe. They produced expert maps with all sea and land routes accurately located concerning latitude and longitude; while also introducing compasses to Europe.

They were such expert shipbuilders that they were able to use their geography expertise to import and export as far away as India and China. It was not by accident that a Moor named Pietro Olonzo Nino was the chief navigator for Christopher Columbus on the flagship Santa Maria.

He is said to have argued with Columbus as to who really discovered America. One of the worst mistakes the Moors made was to introduce gunpowder technology from China into Europe because their enemies adopted this weapon and used it to drive them out of Spain.

Europe then took the 700 years of civilization and education re-taught to them by the Moors and used this knowledge to attack Africa. While the Moors were re-civilizing Europe, great empires were thriving in Western Africa and frequently traded with the Moors.

These included the empires of Ghana, Mali, and Songhay, which prospered between 700 AD and 1600 AD. Africa was not a dark continent awaiting European civilization. In fact, Black African Egyptians and Black African Moors are credited with civilizing Europe."

18 notes

·

View notes

Text

The coolest commercial jet in the world??!!

INTRODUCTION

The days of the a380 and the humped 747 are gone and the 787 dreamliner is at the forefront of this revolution making it my favourite commercial airliner.

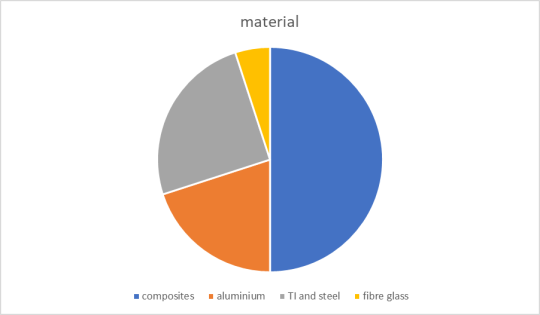

MATERIAL

About 50 percent of it is made of carbon fiber composite making it the first commercial jet in the world to be made up primarily of this material.

Composites are composed of 2 or more materials. Carbon reinforced plastics are composed of extremely strong carbon fibres bound together by plastic.

Carbon fibre is very strong and very light. It is 5 times stronger than steel and twice as stiff. Since they are very thin strands, thy can’t create solid structures, therefore, are bounded together by the plastic resin otherwise they would just form a strong but flexible fabric. Which is useful as it can be made into any shape required thus helping in forming the smooth curves of a jet.

Fun Fact- Boeing had to make customised ovens for the resin to heat in after it had been laid on the mould.

The 787 can also accommodate large windows on its fuselage as it is made up of composites. A hole this large on an aluminium jet would result in build up of stress around the window boundaries due to deviation of stress contours around the holes. Over a period of time, this would lead to damage on the body of the jet which will shorten the lifespan of the jet by a lot.

Aluminium based jets also pose another problem that has been solved by the use of carbon fibre composite. Use of joints and fasteners to rivet the pieces of aluminium together created small bumps and imperfections on the surface of the jet that created a lot of drag. Since the fuselage is now essentially a monolithic structure made of carbon composite, this drag is eliminated.

WINGS Wing Spar is the main structural component of a wing and its main job is to resist the upward bending force. In the 787 dreamliner, it is made up of carbon fibre composites and are structured by aluminium plates. This structure is hollow and acts as a space to store fuel in the jet. Carbon fibre composites have another quality that make them better for making wings. Carbon fibre composites can deform about 1.9% before entering the plastic region whereas aluminium can deform less than 1%.

(stress-strain graph depicting elastic and plastic regions. Source- https://www.smlease.com/entries/mechanical-design-basics/stress-strain-curve-diagram/)

Therefore, the wings can be super flexible. During the flight, the wingtips of a 787 dreamliner can move upward by about 3m.

The wings of a 787 are not the same as that of other aluminium jets. Due to its high flexibility, engineers designed the wings with a high aspect ratio. Aspect ratio is the ratio of the wing span to the mean chord of the wing. Gliders have high aspect ratio and the delta wings of a fighter jet have low aspect ratio. The 777 had an aspect ratio of 9 but the 787 has the aspect ratio of 11!

Thus even though composites are stiffer than aluminium, the wings of 787 bend more due to higher aspect ratio.

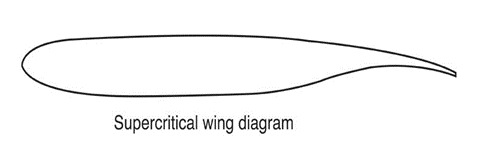

Higher aspect ratio means a larger wingspan as the vortex drags at the tip of wing, by spreading the area of wing over a longer wing, we minimize the pressure that drives vortices thus, the energy loss due to vortex drag is reduced. Another difference wings of the 787 dreamliner is the airfoil itself. The 787 uses a supercritical airfoil.

Tested in the early 1970s by NASA at the Dryden Flight Research Centre is now universally recognized by the aviation industry as a wing design that increases flying efficiency and helps lower fuel costs. Conventional wings are rounded on top and flat on the bottom. The SCW is flatter on the top, rounded on the bottom, and the upper trailing edge is accented with a downward curve to restore lift lost by flattening the upper surface.

THE PROBLEM WITH COMPOSITES

One of the things that stands out the most in the material composition of the 787 is the extensive use of titanium over aluminium since titanium is an expensive metal.

Aluminium on its own doesn’t corrode but when kept near carbon fibre, it oxidises rapidly. This is due to a phenomenon known as galvanic corrosion. When 2 materials with dissimilar electric potentials are kept in contact with each other with an electrolyte such as salt water, exchange of ions takes place.

Fun Fact- To reduce the cost of manufacturing Titanium, Boeing partnered with Norsk Titanium which 3-D print titanium parts thus eliminating the wastage of metal.

There is another issue with composites, even though carbon fibre is a good conductor of electricity, the plastic resin is an insulator and thus doesn’t allow electricity to conduct through it in case of lightning strikes. Thus, Boeing had to add strips of copper all around the fuselage to help it conduct lightning.

BIBLIOGRAPHY:

https://www.nasa.gov/pdf/89232main_TF-2004-13-DFRC.pdf

https://www.nasa.gov/centers/armstrong/news/FactSheets/FS-044-DFRC.html

https://www.smlease.com/entries/mechanical-design-basics/stress-strain-curve-diagram/

https://www.innovativecomposite.com/what-is-carbon-fiber/#:~:text=Carbon%20Fiber%20is%20a%20polymer,steel%20and%20twice%20as%20stiff.

https://www.sciencedirect.com/topics/engineering/boeing-787-dreamliner

https://www.aerospace-technology.com/projects/dreamliner/

https://www.boeing.com/commercial/787/by-design/#/advanced-composite-use

https://www.youtube.com/watch?v=lapFQl6RezA

#boeing#physics#science#aerospace#tech#aerodynamics#engineer#engineering#flights#airlines#pilotstuff#boeing 787#dreamliner#composites#wings

23 notes

·

View notes

Text

a followup to this post

(this is... not good. it’s a first draft where I just tried to write out as much of the dream as I could remember while badly trying to convey the atmosphere/vibes it had. the prose and structure and everything is really bad. Sorry)

I wake up. It’s nine o’clock.

I went to sleep at four hours past midnight.

I don’t feel like getting up yet, so for a while I think about things that don’t matter. What I think about during this time is not important.

Eventually I fall asleep. It’s eleven AM.

Waking up I put on a pair of black-fleece sweatpants and a black thermal shirt. In the back of my mind, I get the feeling something is off. The air is wrong. Too clean. The light is a pale, sickly yellow, with a faint shade of green in it.

I open my door. Resting on the opposite wall: a high-quality, well-made replica of an MA5B assault rifle from Halo. I do not own any halo merchandise.

I pick the rifle up. It’s mostly a thick and heavy plastic, but with aluminium plating in select areas that give it heft and a feeling of reliability.

Aiming at the wall, I breathe in, and squeeze the trigger. A barrage of blue plastic blasts out from the barrel and ricochets violently off the cold beige slab.

I walk through the main hall of my house. It’s a short walk, barely a couple seconds. Turning the corner, I walk through the door to the lounge.

I do not recognise the room I find myself in.

It holds no furniture. The back wall is solid, with no windows, and the faux-fireplace in the left wall is nowhere to be found. The room is larger than it should be. No hint exists of my old study, which is connected to the lounge by an open doorway.

There is one door, set into an area of the back wall that should not exist.

It feels familiar, like I’ve been here before, but I cannot place it in my memory. The walls have shifted from a pale, creamy beige to an ever so slightly yellower tinge.

Once again I fire the rifle, a stream of blue plastic exploding against the wall. Looking down, I find that instead of Nerf darts, as I expected, the ground is littered with an assortment of plastic missile rods from old Transformers figures, Lego axles, and d20 dice, all a deep and almost gemstone like blue.

I do not own any dice of any sort.

The door beckons, and I walk through, finding myself in a wide yet low-ceilinged hallway. This hallway should not exist. I should be standing on the brick floor of my backyard, under the old, rotting tree where the magpies sing and call.

The hallway doesn’t care what I think. It’s here, and I’m standing in it. That’s the only thing that matters.

The light has weight now; I can see the faint ghost of its body hanging in the air. The feeling of familiarity grows.

I reach a doorway on the side of the hallway and walk through.

I find myself in a room littered with objects of memory and familiarity. Transformers figures. Old train sets. Toy cars. An old aqua plastic table from when I was a child, which we threw out when we moved house. A mat depicting a cartoon map of a town, which I first think is something I used to own, but soon remember belonged to either my kindergarten or the after-school care program of my primary school. A counter, which is either of my old house or a counter from my kindergarten. Covering the ground in a sea of red and blue is a flood of Lego-like construction toy pieces from my primary school.

Looking up, I see another door.

I walk through it and into the memory of my kindergarten. A specific room, which I can recognise instantly. I do not know what it was for, or where it was located inside the kindergarten, but I remember this room often.

I move on quickly.

The dream changes as I walk through the next door. The light is colder now. Harsher. The yellow of the walls is stronger.

I turn around to see the door is gone, replaced with a mirror that stretches along the entire length of the wall, set from my waist to the ceiling in height. A counter extends out from the bottom of the mirror, a block of yellow-white laminated particle board.

The air feels heavy. I feel like I’m wreathed in a thin layer of oil, but the mirror shows no sign of that.

My hair is short. A buzzcut.

I feel a flash of fear: my hair hasn’t been that short for over a year.

I try to remember if I got a haircut that I’ve since forgotten about. I don’t remember getting one, but my memory isn’t great at the best of times and I can tell it’s not working right now.

I get the feeling that I have power here.

I reel my head back, breathing in, and whip my head forwards, hoping I’m right, and hoping it will work.

I look in the mirror. Is my hair longer? I can’t tell, but it feels like it is.

The oil feeling grows.

I repeat again. Once, twice, thrice.

My hair’s grown out a bit. It looks stupid, but now I know it’s working.

The oil feeling grows.

I shake my head and toss it forwards again, and my hair grows back to how it should be. I breathe a sigh of relief.

A thought crosses my mind. I wonder if it’s true.

The oil feels thicker now.

I reel back and whip my head forwards. It covers my eyes, obscuring my vision. Raising my head, I look in the mirror. My hair seems to brush itself aside to let me look.

I notice my acne’s gone, and I’ve got eyeliner on. My hair looks nicer, no longer just grown out for a year with no cut or styling. I smile to myself, feeling cute.

The oil is too strong to ignore. Heavy and thick and almost like it’s—

In the mirror, I see a pitch-black hand brush my hair away from my face and slink behind my head.

I should be scared, or cautious, I know. But I get the feeling that whatever it is, it’s helping me. Or at least, supportive of my actions.

I take a moment, sitting down on the bed that I’ve become aware is behind me.

Something to try. I’m not sure if it’ll work, but it can’t hurt. Unless I should fear the shadow-hand. I decide I don’t.

I lay down on the bed, losing sight of my reflection in the mirror, and will another wish into being.

The oil feeling pulses, and I rise from the bed, both by my own will, and by what feels like the oil lifting me.

I look in the mirror and —

My mother’s calls wake me from the dream.

#My Writing#Probably gonna heavily edit or rewrite this at some point#there's a small but important bit I left out that I might put back in#because it's weird and I don't want anyone who knows me and finds this tumblr to ask questions#shadow-person-thing please take me back to your weird backrooms-esque-ish dream realm so I can finish the dream#also yeah basically everything here is what happened in the dream (though the rifle thing was sorta out of order)#I realised the ammo for it was dice and tf missile pieces when I opened the rifle up to check#but I don't remember when in the dream that happened#I think there were maybe a few more rooms between the hallway and the mirror but I don't remember them#might#delete later

2 notes

·

View notes

Text

#aluminium doors and windows#windows & doors company#window door company#windows and doors installation#best aluminium windows uk#high quality aluminium windows#aluminium double glazed windows#best aluminium sliding doors uk#exterior double sliding patio doors#double sliding patio doors#aluminium sliding doors london#bi fold doors internal#best bifolding doors#glass roof panels uk#glass roof in london#glass roof systems uk#glass roofs uk#front door aluminium#aluminium door panels#corvision sliding patio doors#cortizo aluminium windows uk#cortizo doors and windows#roof lantern uk#conservatory roof solutions#heritage doors and windows#heritage aluminium windows and doors#heritage aluminium windows#internal heritage doors#heritage doors uk#aluminium casement windows

0 notes

Text

#aluminium doors and windows#windows & doors company#window door company#windows and doors installation#best aluminium windows uk#high quality aluminium windows#aluminium double glazed windows#best aluminium sliding doors uk#exterior double sliding patio doors#double sliding patio doors#aluminium sliding doors london#bi fold doors internal#best bifolding doors#glass roof panels uk#glass roof in london#glass roof systems uk#glass roofs uk#front door aluminium#aluminium door panels#corvision sliding patio doors#cortizo aluminium windows uk#cortizo doors and windows#roof lantern uk#conservatory roof solutions#heritage doors and windows#heritage aluminium windows and doors#heritage aluminium windows#internal heritage doors#heritage doors uk#aluminium casement windows

0 notes

Text

#luxury aluminium sliding doors london#best double sliding patio doors#best sliding door for home#best doors and windows uk#exterior double sliding patio doors#top quality aluminium door panels#front aluminium panel doors london#corvision sliding patio doors#durable aluminium sliding doors uk#affordable aluminium bi folding doors#best bifold doors uk#glass roof panels uk#glass roof in london#high quality aluminium windows#best aluminium clad windows#cortizo aluminium windows uk#best windows and doors service in uk#aluminium sliding doors london#best aluminium glass doors#cortizo doors and windows#top aluminium windows uk

0 notes

Text

#luxury aluminium sliding doors london#best double sliding patio doors#best sliding door for home#best doors and windows uk#exterior double sliding patio doors#top quality aluminium door panels#front aluminium panel doors london#corvision sliding patio doors#durable aluminium sliding doors uk#affordable aluminium bi folding doors#best bifold doors uk#glass roof panels uk#glass roof in london#high quality aluminium windows#best aluminium clad windows#cortizo aluminium windows uk#best windows and doors service in uk#aluminium sliding doors london#best aluminium glass doors#cortizo doors and windows#top aluminium windows uk

0 notes

Text

Sixaluminium - Devasa+ (2)

The aluminum industry is a vital sector that plays a significant role in various industries, including construction, transportation, and manufacturing. Aluminium profile are widely used in these industries due to their lightweight, durable, and corrosion-resistant properties. These profiles are produced by aluminum profile manufacturers and aluminum extrusion companies, who are key players in the industry. Aluminium profile wholesalers play a crucial role in the distribution of aluminum profiles. They act as intermediaries between manufacturers and end-users, ensuring a smooth supply chain. These wholesalers offer a wide range of aluminum profiles, including standard profiles, conduit and trunking profiles, angle and corner profiles, and seamless aluminum extrusion . They provide a one-stop solution for customers, offering competitive prices and support throughout the purchasing process. By partnering with aluminum profile wholesalers, businesses can access a diverse range of profiles to meet their specific needs. Aluminium profile manufacturer and aluminum extrusion companies are responsible for the production and customization of aluminium manufacturer. They have the expertise and capabilities to design and manufacture profiles according to customer specifications. These manufacturers offer a wide range of profiles for architectural and industrial use, such as doors, windows, curtain walls, and other structural components. They utilize advanced techniques, including anodized aluminum, to enhance the appearance and durability of the profiles. By collaborating with aluminum profile manufacturers, businesses can obtain high-quality profiles tailored to their requirements.

1K notes

·

View notes