#reinforced concrete

Text

All right if you see this post put in the tags a list of all the Wikipedia pages you have open in your tabs no matter how long they've been there

#Neutron bomb#The Maltese Falcon (1941 Film)#Angular diameter#Patriots' Day#Dodo#Mark of the Vampire (1935 Film)#Reinforced concrete

2K notes

·

View notes

Photo

Miskolc, Look-out tower on Avas (Miskolc-Avas TV Tower). Photo: Béla Bakonyi. Postcard, Képzőművészeti Alap Kiadóvállalata, Budapest.

Designed by Miklós Hófer and György Vörös, built in 1966.

(Megkezdődött a modern építészet fontos oszlopa, a miskolci Avasi kilátó felújítása)

301 notes

·

View notes

Photo

Marco Miehling - A Tree is a Big Plant with a Stick Up in the Middle, 2017

´´

#Marco Miehling#A Tree is a Big Plant with a Stick Up in the Middle#art#artist#contemporary art#sculpture#Reinforced Concrete#London Plane#Platanus x hispanica#Dyneema Rope#Swivel Eye Bolt

58 notes

·

View notes

Text

Heritage Listed mainline sewer viaduct (1898-99). Built to bring the first sewerage to the Inner West as a job creation project near the end of almost a decade of economic depression, but a wide network of sewers didn't become a reality until the 1930’s. A fancy design of brick and cast iron latticing was rejected, in favour of this - the first instance of steel reinforced concrete employed in Sydney architecture as a cost saving measure. 990 feet long. Constructed over almost two years, it's required only minor repairs since and remains operational. Annandale.

#sewer#viaduct#heritage#vintage#mainline#late victorian era architecture#reinforced concrete#streetscape#parkland#sewerage#urban shit#inner west sydney

100 notes

·

View notes

Text

In the realm of construction, the choice of building materials and techniques plays a pivotal role in determining the durability, strength, and overall quality of a structure. One such method that has stood the test of time is cast-in-situ concrete, also known as cast-in-place concrete. This construction technique involves pouring concrete directly into the formwork at the construction site, where it is allowed to set and cure, forming a seamless and robust structure.

Understanding Cast-In-Situ Concrete

Cast-in-situ concrete is a construction method that involves pouring fresh concrete into a specific mould or formwork at the construction site.

Unlike precast concrete, which is cast and cured in a controlled environment before being transported to the construction site, cast-in-situ concrete is mixed and poured on-site. This method offers a high degree of flexibility, allowing for customization and adaptability to the unique requirements of each construction project.

#construction#construction news#civil engineering#building construction#structural engineering#civil#engineering#reinforced concrete#civil construction#concrete

2 notes

·

View notes

Text

Enhance Structural Integrity with Gsource Technologies' Concrete Detailing

https://www.gsourcedata.com/reinforced-concrete-detailing-services

#gsourcetechnolgies#reinforced concrete#inforceddetailing#inforcedservices#architectureservices#engineeringservices

2 notes

·

View notes

Text

Did you know? 🧐

Anghel I. Saligny, an academician, engineer, construction engineer, minister and teacher, is considered to be one of the pioneers of world technology in the designing and construction of bridges and silos with metal structure and reinforced concrete, one of the founders of Romanian engineering.

Between 1884 and 1889 he worked on the construction of the docks and warehouses in Galaţi and Braila, giving total original solutions, including: the construction of foundations on fascination layers and pile drivers, the connection basins with the Danube for silos and the use, for the first time in the world, reinforced concrete in silos construction.

Based on his own inventions, Anghel Saligny built for the first time the reinforced concrete silos from Braila (1888) and Galaţi (1889), only two decades after the French Joseph Monier (1823-1906) obtained in 1867 , the first patent for building elements (beams, slabs, pillars) of reinforced concrete, this material little studied at the time. The silos designed and executed, under the direct guidance of Anghel Saligny, could contain over 25,000 tonnes of grain (30 m x 120 m at the base and over 18 m tall). The hexagonal cell walls of the silos have been made, for the first time in the world, by plate-shaped pieces made to the ground. Prefabrication of floorboards, stiffening and junction corners, metal strip welding and assembly-based assembly are other global priorities.

His most important work is the design in 1888 and the construction of the Cernavoda Danube Bridge, which at that time was the longest in Europe and among the most important metallic openings in the world, between 1890 and 1895. Saligny's project brought two major innovations in the construction of bridges: the new beam system with consoles for the bridge superstructure and the use of soft steel instead of puddle iron as building material for bridge bridges.

Between the years 1889 and 1909 he headed the Constanta harbor works, introducing for the first time in Romania pilots and artillery dredgers in the port constructions and designing the grain silos and the oil station.

#romania#proud to be romanian#romanian#engeneering#construction engineering#pioneer#world#technology#designing#construction#bridges#silos#metal#structure#reinforced concrete#dock#warehouses#consolas#port#did you know

13 notes

·

View notes

Text

History of Reinforced Concrete and Structural Design

History of Reinforced Concrete and Structural Design

The average person thinks that concrete has been in common use for many centuries, but such is not the case. Although the Romans made cement – called Pozzolana – before Christ by mixing slaked lime with a volcanic ash from Mount Vesuvius and used it to make concrete for building, the art was lost during the Dark Ages 5th century -15th century A.D. and was not revived until eighteenth and…

View On WordPress

#Ernest L. Ransome#Great Pyramid of Giza#Joseph Monier#Professor Hardy Cross#Reinforced Concrete#Structural Analysis#Structural engineering#Vitruvius

3 notes

·

View notes

Text

pettels - Reinforced Concrete

youtube

0 notes

Text

Concrete is something that is very smooth but extremely risky at times. It may give the best finishing touch to everything but may be the most dangerous thing if not used at the right way.

So there are some ways through which we should protect it not to become slippery to avoid any form of accidents.

Essential Steps to Make a Concrete Floor Slip Resistant

1. Concrete Of The Best Quantity

You should thereby use the best type of concrete possible so that there is no form of problems created at any level. In this way the durability of the structure will be thereby improved. Even sealer is used right hereand it should be used in the best way to have great advantages.

2. Anti-Slip Sealer

The best way to avoid slippery is to use a slip-resistant sealer. For example, penetrative sealers penetrate the pores, providing strength from within. Thus these are generally non slippery.

Thus, sealers generally will not only protect you from accidents but also from extreme weather conditions.

3. Finishing Touch Of Rock Salt

This is a form of finishing touch.Through this method salt is sprinkled on the wet concrete surface. That part is removed when the concrete surface is being cured which leaves a texture in it. Even other things are added such as alluminium oxide which grit the sealer to mark an extreme difference in it. This is the best thing used in concrete that is used wildly.

The best thing to notice here is that it is available in various colours giving us different options within a reasonable price rate.

4. Silica Sand

This procedure is about applying a part of silica over the area of the first coat in the concrete sealer. After the first part has dried, the next part should be applied right then.This way it will get a better texture and appearance.

Read more

0 notes

Text

JOHNS BRIDGE KILKENNY

A bridge 'designed for the Joint Committee of the Kilkenny County Council and the Kilkenny Borough Council by Mr. A.M. Burden

PHOTOGRAPHED IN AUGUST 2018

To be honest I did not get the opportunity to explore the immediate area in detail during my visit to Kilkenny in August 2018 but I hope to do so in 2024 when I visit in March.

A bridge ‘designed for the Joint Committee of the Kilkenny County Council and the Kilkenny Borough Council by Mr. A.M. Burden [Alexander Burden Mitchell (1864-1923)] County Surveyor of…

View On WordPress

#A7RIII#august 2018#Hennebique ferro-concrete#Ireland#John&039;s Bridge#kilkenny#Kilkenny Borough Council#kilkenny county council#Mr. A.M. Burden#reinforced concrete#river nore#Sony

0 notes

Link

What do you mean by Glass Fiber Reinforced Gypsum?

Various types of materials are used to construct modern buildings. It is extremely important for anyone involved in the construction industry, from builders to architects to engineers, to know the nuances of building materials.

The knowledge of numerous building material types, together with the specifics of their qualities and their many applications for diverse reasons, serves as a significant tool in the hands of the builders to achieve cost savings in the construction process.

Additionally, precise material use contributes to improved structural strength, aesthetic appearance, and functional efficiency.

What is a GFRG Panel?

Glass Fiber Reinforced Gypsum (GFRG) is also known as fast walls. Gypsum plaster is mixed with glass fibres and calcined before being moulded into these construction panels. It was created for the purpose of constructing massive structures for the first time by the GFRG Building System Australia in 1990. Now, India and other emerging nations are using these panels.

GFRG panels generally measure 12 meters long, 3 meters wide, and 0.124 meters deep. Gypsum, glass fibre, concrete slurry, and chemicals, including water-repellent emulsion, are the main components of these panels.

Classification of GFRG Panel

General Grade

The general-grade GFRG panels can be used both structurally and non-structurally in dry locations. Building external or internal walls using these types of panels is generally not recommended. Formwork for walls and floors should not be constructed with them.

Water Resistance Class

In wet areas, where water resistance is of the utmost importance, glass fibre-reinforced gypsum panels are often used. This type of GFRG panel is also used as formwork for concrete filling in floors and walls.

Read more

#reinforcement#reinforced concrete#steel reinforcement#reinforced toes#construction#construction project#Construction Site#Residential Construction#new construction

0 notes

Text

SFRC Modelling and Non-Linear Analysis of Beam- Column Joint Under Cyclic Loading

Abstract

In this paper reinforced concrete beam column joint is modelled and analyzed using ABAQUS software to compare the simulated results with the experimental study. The joint is the most critical and most important part of the multi-story frames or multi-story buildings when they are subjected to earthquake loading. In this research the joint is analyzed for two different types of non-linear analysis that is non-linear static analysis and a part of non-linear dynamic analysis for the visual comparison with the experimental study.

Read More about this article: https://irispublishers.com/ctcse/fulltext/sfrc-modelling-and-non-linear-analysis-of-beam-column-joint-under-cyclic-loading.ID.000671.php

Read More about Iris Publishers Google scholar Articles: https://scholar.google.com/citations?view_op=view_citation&hl=en&user=LoZ6uCQAAAAJ&cstart=20&pagesize=80&citation_for_view=LoZ6uCQAAAAJ:hkOj_22Ku90C

1 note

·

View note

Text

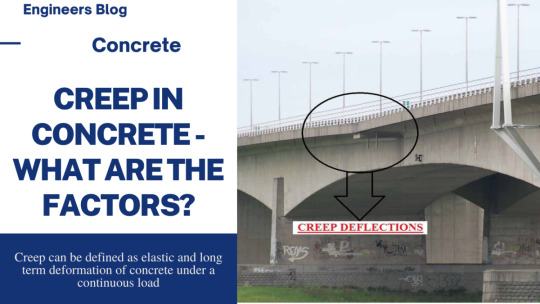

Creep in Concrete - What are the Factors?

Creep in Concrete – What are the Factors?

When concrete is loaded, the structure undergoes elastic and inelastic distortions. Elastic distortions do incontinently after the concrete is subordinated to a given cargo, according to Hooke’s Law. Inelastic distortions increase with time as the concrete gests a sustained cargo. This inelastic distortion, also known as creep, increases at a dwindling rate during the lading period. During the…

View On WordPress

#Civil Engineering#Concrete#concrete creep#concrete technology#creep#creep in concrete#creep in concrete measurement#creep of concrete#effects of creep on concrete#measure creep in concrete#reinforced concrete#what is creep in concrete ?

0 notes

Text

Concrete reinforced with reinforcing materials, usually steel, is known as reinforced cement concrete (RCC). Compressive strength is provided by concrete, and tensile strength is provided by steel. The combination of these materials produces a versatile, strong, and durable building material that can be used for a variety of purposes, including:

Buildings

Bridges

Dams

Tunnels

Roads

Parking structures

Other civil structures

RCC is a combination of compressive strength from the concrete and tensile strength from the reinforcement making it an ideal material for handling a wide range of loads and resisting cracking or failure.

#construction news#construction#civil engineering#building construction#reinforced concrete#civil construction#engineering

2 notes

·

View notes

Text

Gsource Technologies is at the forefront of delivering top-tier reinforced concrete detailing services that set the standard for precision and excellence in the construction industry. Reinforced concrete is a fundamental component of modern infrastructure and buildings, and our specialized detailing services ensure that every project is executed with the utmost structural integrity and efficiency.

Our team of experienced engineers and detailers possesses a deep understanding of reinforced concrete design principles, local building codes, and industry best practices. We leverage cutting-edge software and technology to create highly detailed and accurate reinforcement drawings and plans, tailored to the specific needs of each project.

Key highlights of our reinforced concrete detailing services:

Precision and Accuracy: We take pride in our commitment to delivering drawings that are error-free and in compliance with the most stringent industry standards.

Cost Efficiency: Our services optimize the use of materials, reducing wastage and ultimately saving you money on your construction project.

Compliance and Safety: We ensure that all designs meet local building codes and safety regulations, prioritizing the security of both workers and occupants.

Timely Delivery: We understand the importance of meeting project deadlines. Our team works efficiently to deliver detailed plans on time.

Customization: We tailor our services to suit a wide range of construction projects, from residential buildings to large-scale infrastructure.

Whether you're an architect, engineer, or construction professional, Gsource Technologies' reinforced concrete detailing services will streamline your project, ensuring durability and structural integrity while minimizing costs and risks. Partner with us for excellence in reinforced concrete detailing and take your construction projects to the next level.

#gsourcetechnolgies#architecturedesigns#engineeringdesigns#reinforced concrete#reinforceddetailing#reinforcedservices

1 note

·

View note