Text

CNC laser cutting

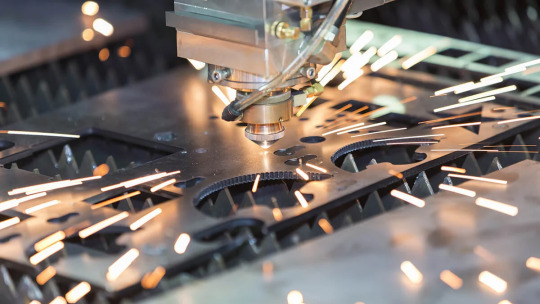

Aqua Technologies employs CNC laser cutting technology to precisely fabricate various materials, including metals, plastics, and composites. This advanced method allows for intricate designs, accurate dimensions, and clean edges. Aqua Technologies' CNC laser cutting services provide efficient and high-quality solutions for diverse industrial applications.

1 note

·

View note

Text

3D WaterJet Cutting Service

Several different types of materials can be cut using 3D waterjet services. Basic material is utilised optimally with no distortion, discoloration, or change in the structure. services for CNC water jet cutting, Cut intricate forms, including welded edges, in a single process.

1 note

·

View note

Text

waterjet cutting

Aqua Technologies is a leading provider of waterjet cutting services, employing a highly efficient and precise cutting method. Our company boasts cutting-edge equipment and a team of skilled technicians, delivering innovative solutions across various industries and materials. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive particles. This powerful combination enables us to effortlessly cut through a wide range of materials, including metal, stone, glass, and composites. Notably, our process eliminates the risk of heat-affected zones or rough edges, ensuring clean and accurate cuts. Aqua Technologies' waterjet cutting services are renowned for their versatility, speed, and cost-effectiveness, guaranteeing exceptional results for our clients' diverse cutting requirements.

0 notes

Text

CNC laser cutting

Aqua Technologies, a renowned industry leader, employs state-of-the-art CNC laser cutting technology to provide precise and efficient solutions. With their cutting-edge equipment and expertise, they deliver exceptional accuracy and intricate designs, meeting the diverse needs of their clients. The advanced CNC laser cutting process enables Aqua Technologies to work with a wide range of materials, including metals, plastics, and composites, ensuring versatility and adaptability in their manufacturing processes. By leveraging this technology, Aqua Technologies ensures faster production cycles, reduced material waste, and unparalleled precision, resulting in superior quality products. With a commitment to innovation and the utilization of CNC laser cutting, Aqua Technologies stands at the forefront of delivering cutting-edge solutions to industries worldwide.

1 note

·

View note

Text

CNC laser cutting

CNC laser cutting is a highly precise and efficient cutting method that utilizes a laser beam to cut through various materials with exceptional accuracy. This advanced technology offers numerous benefits and is widely used in various industries.

One of the key advantages of CNC laser cutting is its versatility. It can cut through a wide range of materials, including metals, plastics, wood, acrylics, and more. With the ability to handle different thicknesses and complexities, CNC laser cutting allows for the production of intricate designs and precise cuts.

The process is computer-controlled, ensuring consistent and repeatable results. The CNC (Computer Numerical Control) system precisely directs the laser beam to follow a programmed path, eliminating human errors and ensuring high accuracy. This makes CNC laser cutting ideal for producing complex shapes, sharp corners, and fine details.

CNC laser cutting is a non-contact process, meaning there is no physical contact between the cutting tool and the material. This reduces the risk of material damage, deformation, or contamination, resulting in clean and high-quality cuts.

1 note

·

View note

Text

Waterjet Cutting

Aqua Technologies offers waterjet cutting services that utilize high-pressure water streams to cut through various materials such as metal, plastic, composites, and stone. Waterjet cutting is a versatile and precise cutting method that allows for complex shapes and intricate designs to be cut with ease.

Our waterjet cutting machines use advanced technology that allows for precision cutting with minimal material waste. The process involves pressurized water being forced through a small nozzle, creating a concentrated stream of water that can cut through materials with up to 60,000 psi of pressure.

One of the benefits of waterjet cutting is that it does not generate heat, which can be a concern with other cutting methods. This means that the material being cut does not experience heat-related distortion or warping, resulting in a cleaner and more accurate cut. Additionally, waterjet cutting does not produce harmful fumes or dust, making it a safer and more environmentally friendly cutting method.

At Aqua Technologies, we have a team of experienced professionals who can assist with all aspects of waterjet cutting, from design to final product. We can work with a wide range of materials and can cut pieces in various sizes and thicknesses. Our waterjet cutting services are suitable for a range of industries, including aerospace, automotive, and manufacturing.

If you're interested in learning more about our waterjet cutting services, please feel free to contact us for more information or to discuss your specific needs.

0 notes

Text

CNC Shearing and Bending

CNC shearing and bending are two critical processes in metal fabrication that help create precision parts and components for a variety of industries. At Aqua Technologies, we use state-of-the-art CNC shearing and bending equipment to deliver exceptional quality and accuracy in our fabrication services.

CNC shearing involves cutting large sheets of metal to size using computer-controlled blades. This process is ideal for creating straight cuts and is especially useful when working with large volumes of material. Our CNC shearing equipment can handle a wide range of materials and thicknesses, ensuring that we can produce high-quality parts to meet our customers' exact specifications.

CNC bending, on the other hand, involves using computer-controlled presses to form metal into specific shapes and angles. This process is highly precise and is used to create complex parts that require tight tolerances and consistent results. Our CNC bending equipment can handle a variety of materials, including steel, aluminum, and stainless steel, and can produce parts with a high degree of accuracy and repeatability.

At Aqua Technologies, we pride ourselves on our ability to deliver precision parts and components to our customers. Our team of experienced professionals works closely with each customer to understand their unique needs and provide tailored solutions that meet their specific requirements. We use the latest technology and techniques to ensure that every part we produce is of the highest quality, and we are committed to delivering exceptional results every time.

0 notes

Text

CNC laser cutting

CNC laser cutting is a highly precise cutting process that uses a laser beam to cut through various materials with accuracy and speed. At Aqua Technologies, we offer CNC laser cutting services using advanced laser cutting machines to create high-quality, precise cuts in a wide range of materials.

One of the primary advantages of CNC laser cutting is its ability to create complex designs with extreme precision. Our machines use advanced computer software to control the cutting process, allowing for highly accurate and consistent cuts that meet our customers' specifications.

Our CNC laser cutting services can be used for a variety of materials, including metals, plastics, composites, and more. This makes it a popular choice for a wide range of industries, including aerospace, automotive, and medical.

At Aqua Technologies, we have invested in the latest technology to ensure that we provide our customers with the highest quality cuts possible. Our experienced team of engineers and technicians works closely with our customers to understand their needs and provide customized solutions to meet their specific requirements.

In addition to its precision, CNC laser cutting is also a fast and efficient process. Our machines can quickly cut through materials, reducing production time and increasing efficiency. This also allows us to offer competitive pricing while maintaining high-quality standards.

Overall, CNC laser cutting at Aqua Technologies offers a reliable and efficient solution for cutting a wide range of materials with extreme precision. With our state-of-the-art equipment and experienced team, we are committed to providing our customers with the highest quality cuts and exceptional service.

0 notes

Text

CNC laser cutting

CNC laser cutting is a versatile cutting process that uses a laser beam to cut through various materials with high precision. Aqua Technologies is a company that offers CNC laser cutting services using state-of-the-art laser cutting machines to provide accurate and efficient cutting solutions.

Here are some benefits of CNC laser cutting at Aqua Technologies:

Precision: CNC laser cutting is a highly precise cutting method that can cut through materials with high accuracy and minimal tolerances. This makes it ideal for cutting complex shapes and designs.

Versatility: CNC laser cutting can cut through a wide range of materials, including metals, plastics, composites, and more. It can also cut through thick materials with ease.

Speed: CNC laser cutting is a fast cutting method that can cut through materials quickly and efficiently, reducing production time and costs.

No Tooling Required: Unlike other cutting methods, CNC laser cutting does not require any tooling or expensive set-up costs. This makes it a cost-effective solution for small and large production runs.

Minimal Material Waste: CNC laser cutting services in coimbatore is a precise cutting method that minimizes material waste. This is because the laser beam is narrow and can be positioned to optimize material usage.

Customization: CNC laser cutting is a highly customizable cutting method that can be used to create custom parts and components. This is ideal for industries that require unique or specialized parts.

1 note

·

View note

Text

Waterjet Cutting

Waterjet cutting is a technology used by Aqua Technologies to cut a variety of materials such as metal, stone, glass, and composites using a high-pressure stream of water mixed with abrasive particles. The waterjet cutting process involves pumping water at a pressure of up to 90,000 psi through a small orifice to create a highly concentrated stream of water that is then directed onto the material to be cut.

The waterjet cutting process is highly precise and can create intricate shapes and patterns with minimal material waste. It is also a cold cutting process, meaning that there is no heat affected zone (HAZ) or thermal distortion, which can be a problem with other cutting methods. Additionally, waterjet cutting is an environmentally friendly cutting method as it does not produce any harmful byproducts.

At Aqua Technologies, we utilize state-of-the-art waterjet cutting machines that can cut materials up to 8 inches thick with a tolerance of ± 0.005 inches. Our experienced team of engineers and technicians work closely with our clients to ensure that their precise cutting needs are met, from design and material selection to the final product.

Overall, waterjet cutting is a highly efficient and precise cutting method that offers many benefits over traditional cutting methods. If you are looking for high-quality cutting services, Aqua Technologies is here to provide you with the solutions you need.

0 notes

Text

CNC laser cutting

A powerful laser is focused onto a tiny region of the material to be cut in order to produce the laser beam utilised in CNC laser cutting. The laser beam is commonly produced by a gas laser, such as a carbon dioxide (CO2) or neodymium-doped yttrium aluminium garnet (Nd:YAG) laser, which emits a focused beam of light capable of quickly and accurately cutting through a range of materials.

0 notes

Text

Hardox Extreme

Hardox steel has a high hardness, which is achieved through a specialised heat-treatment process. This makes it ideal for applications requiring high wear resistance, such as the manufacture of buckets, dump trucks, and other heavy machinery components. Hardox steel is also impact resistant and tough, making it a dependable choice for harsh working environments.

Overall, Hardox extreme steel is a dependable and adaptable material for heavy-duty applications requiring high wear and impact resistance. It is no surprise that it is a popular choice for companies in a variety of industries due to its exceptional durability, toughness, and environmental credentials.

0 notes

Text

Hardox

Hardox is a type of high-strength steel manufactured by the Swedish company SSAB. It is known for its exceptional toughness, wear resistance, and structural strength. Hardox steel is often used in demanding applications such as mining, construction, and recycling equipment, as well as in transportation vehicles and agricultural machinery.

Hardox steel is available in various grades, with different levels of hardness, strength, and toughness. The grades range from Hardox 400, which has a Brinell hardness of 400, to Hardox 600, which has a Brinell hardness of 600. There are also specialty grades available for specific applications, such as Hardox HiTemp for high-temperature environments, Hardox 500 Tuf for extreme impact resistance, and Hardox 500 tubes for cylindrical structures.

The manufacturing process of Hardox extreme involves quenching and tempering, which results in a steel with a microstructure that is hard but also tough and ductile. This makes Hardox steel highly resistant to wear and abrasion, while also allowing it to withstand impact and deformation without cracking or breaking.

Overall, Hardox steel is a versatile and reliable material that can withstand the toughest working conditions. Its high performance has made it a popular choice for industries that require durable and long-lasting equipment.

0 notes

Text

Hardox Extreme

Hardox Extreme is a type of abrasion-resistant steel produced by the Swedish steel manufacturer SSAB. It is designed to provide exceptional resistance to wear and tear, making it ideal for use in harsh and demanding environments where standard steel plates are not sufficient.

The key characteristic of Hardox Extreme is its ability to withstand extreme wear and impact forces. It is made from high-strength steel and is optimized for use in heavy-duty applications where impact and abrasion are constant. This makes it ideal for use in industries such as mining, construction, and quarrying, where equipment is subject to constant wear and tear.

The unique properties of Hardox Extreme are achieved through a specialized manufacturing process that involves precise control of the chemical composition and mechanical properties of the steel. The result is a plate that is significantly harder and tougher than conventional steel, with exceptional resistance to deformation and cracking.

Hardox Extreme is available in thicknesses ranging from 4mm to 130mm, and in widths up to 3,500mm. This range of sizes makes it suitable for a wide variety of applications, from small machine components to large industrial machinery.

In addition to its exceptional wear resistance, Hardox Extreme is also designed to be easy to work with. It can be cut, drilled, and welded using standard techniques, making it a versatile material that can be adapted to a wide range of applications.

Overall, Hardox Extreme is a highly specialized steel plate designed to provide exceptional resistance to wear and tear in the most demanding industrial environments. Its unique properties make it an essential material for anyone looking to create equipment that can withstand extreme conditions and deliver reliable performance over an extended period.

0 notes

Text

Hardox Extreme

Hardox Extreme is a high-strength steel plate made by the Swedish company SSAB. It is designed to withstand extreme wear and tear in harsh environments, making it ideal for applications in industries such as mining, construction, agriculture, and transport.

Some of the key features of Hardox Extreme include:

Extreme wear resistance: Hardox Extreme has a high level of hardness and toughness, which makes it extremely resistant to wear and tear in abrasive environments. It can withstand impacts, scratches, and heavy loads, making it ideal for use in equipment that experiences high stress and wear.

Superior strength: Hardox Extreme has a minimum yield strength of 1000 MPa, making it one of the strongest steel plates on the market. This high strength allows it to handle heavy loads and extreme stress without deformation or cracking.

Lightweight: Despite its strength and durability, Hardox Extreme is relatively lightweight compared to other high-strength steel plates. This makes it ideal for use in applications where weight is a concern, such as in heavy-duty vehicles and equipment.

Versatile: Hardox Extreme is available in a variety of thicknesses and sizes, making it suitable for a wide range of applications. It can be used in everything from buckets and grapples to dump truck bodies and excavator booms.

Environmentally friendly: Hardox Extreme is made from recycled materials and is 100% recyclable. This makes it a more sustainable choice for companies looking to reduce their environmental impact.

Overall, Hardox Extreme is a versatile and durable steel plate that offers superior wear resistance and strength in harsh environments. Its unique properties make it an excellent choice for companies in a range of industries looking to improve the longevity and performance of their equipment.

0 notes

Text

Hardox

Hardox is a brand of wear-resistant steel produced by SSAB (Swedish Steel AB), a leading manufacturer of high-strength steel products. It is a multi-functional steel that is designed to deliver exceptional toughness and hardness, making it ideal for a wide range of applications, including heavy equipment, truck bodies, and construction machinery.

Hardox steel is made using a unique production process that results in a high-quality, uniform product. It is designed to withstand the most challenging environments, and its wear resistance has been tested under a variety of conditions, including abrasion, impact, and bending. The steel also features excellent structural integrity and maintains its strength even in harsh conditions.

One of the key benefits of Hardox steel is its versatility. It can be used in a range of applications, from heavy equipment to truck bodies, and it can be easily fabricated, drilled, and machined to meet the specific needs of each project. This versatility makes it a popular choice for many industries, including construction, mining, agriculture, and transportation.

Another advantage of Hardox Extreme steel is its durability. This steel has been proven to provide reliable performance for many years, even in harsh and demanding conditions. Its high level of toughness and hardness means that it can withstand significant wear and tear without losing its structural integrity, making it a cost-effective solution for many applications.

In conclusion, Hardox is a high-quality, versatile, and durable steel that offers a range of benefits for a variety of applications. Its unique production process, exceptional toughness, and wear resistance make it an ideal choice for a range of industries and applications, including heavy equipment, truck bodies, and construction machinery.

0 notes

Text

CNC Laser Cutting Services

CNC (Computer Numeric Control) Laser Cutting is a process of cutting materials using a high-powered laser beam. This process is often used in the manufacturing industry for cutting and shaping metal, plastic, wood, and other materials.

Some of the key features of CNC Laser Cutting services include:

Precision: The laser beam is highly accurate and precise, making it ideal for cutting intricate shapes and patterns with great detail.

Speed: The laser cutting process is much faster than traditional cutting methods, making it a cost-effective and time-efficient option.

Versatility: CNC laser cutting machines can handle a wide range of materials, including metals like steel, aluminum, and brass, as well as plastics, wood, and other materials.

Consistency: CNC laser cutting machines are programmed with computer software, ensuring consistent and repeatable cuts every time.

Automation: The entire cutting process can be automated, reducing the need for manual labor and increasing production efficiency.

CNC Laser Cutting services are commonly used in the automotive, aerospace, and electronics industries, as well as in the production of consumer goods and machinery. The process is also used in the creation of prototypes and custom parts, as well as in the production of signs and promotional materials.

Overall, CNC Laser Cutting is a highly efficient, cost-effective, and versatile method of cutting materials, and is an important tool in the modern manufacturing process.

0 notes