Text

The Benefits of Ono Sokki's Sound Testing

In today's noisy world, where loud sounds are everywhere, finding moments of peace and quiet isn't just a nice idea—it's really important. Companies, engineers, and researchers are always looking for ways to reduce noise, not just to make people more comfortable but also to keep our communities and environment healthy. This is where Ono Sokki comes in. We're leaders in creating testing solutions that bring a lot of benefits to anyone who wants to achieve top-notch sound quality.

Understanding the Essence

Sound measurement is all about measuring how loud things are in different places. It's super important for lots of industries like cars, airplanes, building stuff, and making things. The main aim is simple: make sure things follow the rules, make products better, give people a good experience, and lessen how noise affects people and nature.

With many years of experience, we are a top provider of testing tools and solutions, especially for sound and vibration inspection. Let's explore the many advantages their advanced technologies offer.

Precision and Accuracy

We focus on being very precise and accurate with what we offer. Our instruments are designed using the newest technologies, which means you can rely on them to give consistent and trustworthy measurements. Whether you're checking how loud a car engine is, testing how well building blocks sound, or keeping an eye on vibrations in machines, our tools give engineers and researchers the exact data they need.

Comprehensive Solutions for Diverse Needs

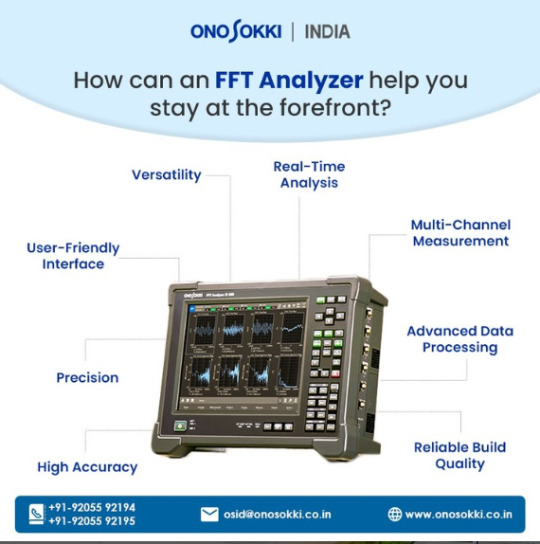

Every testing need is different, and we understand that. That's why we provide a variety of tools and solutions designed for different industries. Whether you need a simple handheld sound level meter for quick checks on-site or a more advanced FFT analyzer for detailed frequency analysis, our range of products covers a wide range of requirements. This means that no matter if you're doing basic noise checks or complex acoustic research, we have the perfect tool for you.

Efficiency in Testing Processes

In any industry, time is really important, and we've made sure that our solutions are all about being efficient. Our tools are easy to use, so engineers and technicians can run tests quickly and precisely. This efficiency not only saves time, but it also helps boost productivity. This means faster decision-making based on test results.

Ensuring Regulatory Compliance

In lots of businesses, it's really important to follow the rules about how much noise things can make and how well we block sound. If you don't follow these rules, it can lead to big problems like getting into trouble with the law, having to pay fines, and even damaging your reputation. Our sound solutions are really useful here because we help companies check everything properly to make sure their products and buildings meet the rules.

Optimizing Product Design and Performance

For companies that make things, knowing how their products sound is really important. Our tools help engineers really get into the details of how their creations sound. We can find ways to make them better and more innovative. Whether it's making a car sound just right, making a household appliance quieter, or making a building more comfortable for the people inside, our tools are the key to making products really great.

Enhancing User Experience

In today's world filled with noise, having a quieter space usually means a better quality of life. The constant buzz of home gadgets or the loud sounds of engines can be really irritating and stressful. When companies use our sound solutions, we can make products that focus on making users feel more comfortable and relaxed. Whether it's making HVAC systems quieter, adjusting the volume of electronic devices, or enhancing the sound quality of buildings, these efforts help create calmer and more pleasant places to live and work.

Environmental Stewardship

Testing is not only important for our own comfort but also for taking care of our environment. Loud noises can really harm animals and their homes, messing up the balance of nature and changing how animals act. When companies use our ideas to make less noise from things like factories, cars, and building sites, we're helping keep our planet healthier for everyone.

Innovative Research and Development

The study of sounds is always changing, with new problems and chances coming up all the time. Our dedication to creating new ideas means that our solutions always use the latest technology. This doesn't just help industries now; it also sets the stage for amazing research and progress in the future. Whether it's making better noise-cancelling technology or finding new ways to block sound, there's a lot we can do.

Efficiency and Time-Saving

One big benefit of our products is that we make things run smoother and better. These tools are designed to make testing much faster without sacrificing accuracy. We have a wide range of products for all kinds of testing needs, including sound testing.

Industry-Leading Expertise

Since 1954, Ono Sokki has been a top manufacturer in the measurement and testing equipment industry. We are known for their high-quality products, especially in the automotive engineering sector, showing their dedication to providing excellent tools and systems.

Considerations for Sound Evaluation

Real-Time Frequency Analysis: This feature allows you to see and analyze the frequency of sounds as they happen. You can observe how the sound changes across different pitches instantly.

Customizable Test Parameters: You have the ability to adjust and tailor the testing settings according to your specific needs. This means you can set up the tests exactly as required for your project or research.

Data Logging Capabilities: With this feature, all the results and findings from the tests are recorded and saved automatically. This makes it easy to review past tests, track changes over time, and compare different scenarios.

Conclusion

In the world of sound, we are proud to be known for our excellence. Our precise tools, all-encompassing solutions, and dedication to innovation bring numerous advantages to various industries, researchers, and communities globally. Whether it's ensuring that rules are followed, improving product designs, making user experiences better, or helping with environmental protection, the impact of our Sound and Vibration Analyzer is felt far and wide.

As we live in a world full of sound, the need for accurate, dependable, and efficient testing is incredibly important. In this mix of noise and quiet, our instruments play a crucial role, blending industry, innovation, and environmental care.

By embracing the benefits of testing, we not only create more peaceful and comfortable spaces for ourselves but also set the stage for a better, more harmonious relationship with the world around us. In our pursuit of acoustic perfection, we stand as a steadfast partner, magnifying the advantages of testing for a future that's both brighter and quieter.

For any clarifications or queries, please feel free to contact us:Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Sound and Vibration Inspection#Sound Testing#Sound and Vibration Analyzer#FFT Analyzer#Vibration Analyzer#ono sokki india#db meter#class 2 sound level meter#class 1 sound level meter#noise level meter#sound level meter

0 notes

Text

Harnessing Ono Sokki's Linear Gauge Sensor for Accurate Data

Precision and reliability are crucial factors in the measurement of displacement, particularly in today's dynamic industrial environment. Our Linear Gauge Sensor are recognized as leading-edge tools for obtaining precise data across diverse applications. Let's explore the exceptional features of these sensors and their effective utilization.

Our device is meticulously engineered to deliver unparalleled accuracy in displacement measurement. The sensor utilize cutting-edge technology to ensure precise readings, making them indispensable in industries where even the slightest deviation can have significant repercussions.

Features of the sensor

High Precision: It's boast high precision, allowing for precise measurement of displacement with minimal margin for error.

Reliability: Built to withstand demanding industrial environments, these sensor offer consistent and reliable performance under various conditions.

Versatility: With a range of models available, Ono Sokki caters to diverse applications, ensuring that there's a sensor suitable for every need.

Digital Interface: The GS series Digital Linear Gauges feature advanced digital interfaces, enabling seamless integration with modern measurement systems.

Applications of the Device

The versatility of the sensor makes it ideal for a wide array of applications across industries. Here are some key areas where these sensor excel:

Manufacturing and Quality Control

In manufacturing processes where precision is paramount, our sensor play a crucial role in ensuring product quality. From automotive to aerospace industries, these sensor help maintain tight tolerances and uphold stringent quality standards.

Automotive Testing

In automotive testing applications, such as chassis testing and suspension analysis, linear variable differential transducer provide precise displacement measurement, enabling engineers to fine-tune vehicle performance and safety parameters.

Research and Development

In research and development environments where innovation thrives on accurate data, further facilitate groundbreaking discoveries by providing researchers with reliable displacement measurements.

Harnessing The Power

To harness the full potential, it's essential to employ best practices in sensor installation, calibration, and data interpretation. Here are some tips for maximizing the effectiveness of these sensor:

Proper Installation

Ensure that the sensor is installed securely and aligned correctly with the target object to obtain accurate measurements consistently.

Calibration

Regular calibration is crucial to maintaining the accuracy of the sensor over time. Follow the manufacturer's guidelines for calibration procedures and frequency.

Data Analysis

Invest in software tools or systems that allow for a thorough analysis of the data collected by the sensor. Extract valuable insights to optimize processes and improve overall efficiency.

Quality Assurance

Ono Sokki's sensor represents the pinnacle of precision and reliability in displacement measurement technology. With their advanced features and versatile applications, these sensor empower industries to achieve new heights of accuracy and efficiency. By harnessing the capabilities of LVDT sensors and implementing best practices, businesses can unlock a world of possibilities and stay ahead in today's competitive landscape.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Linear Gauge Sensor#LVDT#Linear Variable Differential Transducer#sound level meter#noise level meter#class 2 sound level meter#class 1 sound level meter#db meter#ono sokki india

0 notes

Text

The Power of Hand-Held Tachometer in Industry

Every moving part, every revolution, and every rotation counts towards the smooth operation and optimal performance of equipment. This is where hand-held tachometers step in as unsung heroes, offering a myriad of benefits that can significantly enhance productivity and streamline operations across various sectors.

Understanding the Essence of Hand-Held Tachometers

The HT-6200 Hand-Held Tachometer, proudly offered by Ono Sokki, represents the pinnacle of precision instrumentation for measuring rotational speed. Crafted by a renowned Japanese company specializing in high-quality measurement tools, this compact and portable device is engineered to excel in various industrial and laboratory settings.

Designed with utmost user convenience in mind, the HT-6200 boasts a user-friendly interface coupled with a large, easy-to-read digital display. This intuitive design ensures that engineers and technicians can effortlessly obtain RPM (Revolutions Per Minute) measurements of engines, motors, and other rotating machinery, even in demanding environments.

Versatility Across Industries

One of the defining features of tachometers is their versatility, making them indispensable tools across a wide range of industries. From manufacturing plants and automotive workshops to aviation maintenance facilities and agricultural settings, these devices find application wherever rotational speed monitoring is essential.

Automotive Industry

In the automotive sector, it plays a crucial role in diagnosing engine issues, tuning performance, and ensuring compliance with safety standards. Mechanics rely on tachometers to measure engine RPM during maintenance tasks such as tuning, timing adjustments, and troubleshooting engine misfires.

Manufacturing Sector

Within manufacturing plants, digital engine tachometer, another name for the device, aid in quality control by verifying the speed of production line machinery. By accurately measuring RPM, operators can detect deviations from specified speeds, identify potential malfunctions, and prevent costly downtime associated with equipment failures.

Aviation Maintenance

In aviation maintenance, precision is non-negotiable. Device enable technicians to assess the rotational speed of aircraft components such as propellers, turbines, and auxiliary power units (APUs). This facilitates routine maintenance checks, enhances safety, and ensures compliance with rigorous aviation regulations.

Agricultural Applications

Even in the agricultural domain, it proves their worth. Farmers utilize these devices to calibrate equipment such as tractors, harvesters, and irrigation pumps, optimizing their performance for maximum efficiency. By monitoring RPM, farmers can fine-tune machinery settings to achieve optimal output while minimizing fuel consumption and wear and tear.

Advantages Over Traditional Methods

Compared to traditional methods of RPM measurement, these tachometers offer several distinct advantages that elevate their utility and effectiveness.

Portability and Convenience

The portability of them allows operators to perform on-the-spot measurements without the need for bulky or fixed equipment. This portability is particularly advantageous in scenarios where mobility is essential, such as field inspections or remote maintenance tasks.

Real-Time Feedback

With these devices, operators gain immediate feedback on machinery performance, enabling prompt decision-making and proactive maintenance interventions. Real-time RPM data empowers operators to identify issues swiftly, minimizing downtime and optimizing workflow efficiency.

Accuracy and Precision

Accuracy is paramount in industrial settings, where even minor deviations in rotational speed can have significant consequences. The tachometers deliver precise RPM measurements, ensuring that machinery operates within optimal parameters and reducing the risk of performance-related issues or product defects.

Conclusion

With Ono Sokki's cutting-edge technology at their fingertips, engineers and technicians can trust the HT-6200 to streamline their workflow and optimize equipment performance. By swiftly identifying potential issues and ensuring machinery operates within optimal parameters, users can enhance productivity, minimize downtime, and extend the lifespan of critical assets.

In essence, the HT-6200, a Laser Type Tachometer stands as a testament to Ono Sokki's commitment to excellence and innovation in the realm of rotational speed measurement. With its unparalleled accuracy, user-friendly design, and robust construction, this device empowers professionals to uphold the highest standards of efficiency and reliability across diverse industrial applications.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Hand-Held Tachometer#digital engine tachometer#Laser Type Tachometer#class 1 sound level meter#class 2 sound level meter#sound level meter#noise level meter#db meter#ono sokki india

0 notes

Text

Sound Level Meter in Pune | Sound Level Meter

Discover precise sound measurement solutions with Ono Sokki India, offering cutting-edge Sound Level Meter in Pune. Our advanced instruments ensure accurate and reliable sound monitoring for various applications. Trust us for top-notch Sound Level Meters designed to meet your specific needs in Pune and beyond.

For more information, contact us at:

Call: 9205592194

Email: [email protected]

Website: www.onosokki.co.in

#sound level meter#sound level meter in pune#noise level meter#class 1 sound level meter#class 2 sound level meter#db meter

0 notes

Text

Uses of Linear Variable Differential Transducer(LVDT)

Unleash LVDT Power for Unmatched Productivity and Seamless Processes.The Linear Variable Differential Transducer (LVDT) is an essential instrument in many industries, including manufacturing, research, aerospace and automotive engineering, because to its unmatched accuracy.For your crucial measurement requirements, put your trust in the performance and quality of the linear variable differential transducer from Ono Sokki INDIA.

0 notes

Text

Crucial Role of Sound Measurement

Sound measurement techniques are becoming increasingly sophisticated along with technology. As a result, we gain fresh and enhanced insights into our surroundings. To help businesses properly care for the environment, Ono Sokki India functions as a kind of guide, helping them to make sense of all the sounds around them.

0 notes

Text

Ono Sokki’s dB Meter: Transforming Noise Monitoring and Assessment

In an era defined by bustling industries and surging urbanization, the escalating concern of noise pollution has come to the forefront. The imperative for precise and dependable tools for noise monitoring and assessment has reached unprecedented heights. Enter Ono Sokki's dB Meter, a revolutionary solution that reshapes the landscape of noise measurement and analysis.

Unparalleled Precision and Dependability

The core of the dB Meter's extraordinary performance lies in its advanced technology. This device offers unrivalled precision and dependability because of its cutting-edge sensors and signal processing skills. Whether you're engaged in monitoring industrial noise, evaluating environmental soundscapes, or ensuring strict adherence to noise regulations, the Meter is engineered to furnish results that you can wholeheartedly rely on.

Key Advantages and Features

Real-time Data Insights

A standout attribute of the Ono Sokki Meter is its capacity to provide real-time data insights. With its user-centric interface and intuitive controls, users gain instantaneous access to noise levels and their analysis. This feature proves invaluable in scenarios necessitating prompt action or decision-making, allowing you to be proactive in mitigating noise-related challenges.

Customizable Reporting

Elevating data analysis to new heights, it offers customizable reporting capabilities. Users possess the flexibility to tailor the generated reports based on specific parameters, enhancing the efficacy of sharing information with stakeholders, regulatory bodies, or colleagues. This adaptability streamlines communication and facilitates more effective decision-making processes.

Remote Monitoring

In a digitally interconnected world, decibel meters remain at the vanguard by offering remote monitoring functionality. Leveraging wireless connectivity and seamless integration with smart devices, users can monitor noise levels from afar. This aspect proves particularly beneficial for large-scale undertakings or areas that are logistically challenging to access.

Endurance and Longevity

Precision-crafted for durability, noise level meters boast exceptional robustness and longevity. Engineered to withstand even the harshest environmental conditions, it confidently addresses both indoor and outdoor demands. Its sturdy construction ensures that the device consistently provides accurate results, irrespective of challenging operational environments.

Facilitating Compliance and Regulation

Industries and communities alike are bound by noise regulations and standards. They prove to be an indispensable asset by furnishing accurate measurements aligned with these regulations. This proactive approach not only safeguards against legal entanglements but also contributes to fostering a healthier and more harmonious soundscape.

Diverse Applications Across Industries

The versatility of dB meters is underscored by their extensive range of applications across various sectors.

Manufacturing and Industrial Settings

Within manufacturing and industrial landscapes, noise levels often escalate to hazardous thresholds. They empower continuous monitoring, facilitating early identification of noise-related hazards. By adopting this proactive stance, worker safety is prioritized, and operational processes are optimized for peak efficiency.

Construction and Infrastructure

Construction sites are notorious for generating high noise levels, which can adversely affect workers and nearby residents. Its real-time monitoring capacity equips construction managers with essential data to implement effective noise control measures. Consequently, enhanced community relations and adherence to noise regulations are achieved.

Environmental Conservation

Preserving the natural sound environment is pivotal for environmental conservation efforts. These meters empower researchers, conservationists, and policymakers to evaluate noise impacts on ecosystems. This knowledge informs endeavours to curtail human-induced noise pollution in ecologically sensitive regions.

Urban Planning and Development

In the realm of expanding urban areas, prudent urban planning assumes paramount importance. The sound level meter plays a pivotal role in gauging noise levels in urban contexts, empowering planners to make well-informed decisions that culminate in the creation of more liveable and harmonious cities.

The Culmination of Innovation

Ono Sokki's DB Meter, an example of innovation and accuracy, is unquestionably at the forefront of noise monitoring and assessment. Fusing technological sophistication, adaptable features, and far-reaching applications, it emerges as a transformative force in global industries and communities. By furnishing real-time insights, simplifying compliance efforts, and encouraging proactive noise management, the dB Meter enhances our capacity to foster a world where human activity coexists harmoniously with the environment.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Text

Harness the power of Ino Sokki's FFT analyzers with their high-speed data acquisition and real-time analysis. These cutting-edge capabilities empower researchers and industry experts to lead the way in swiftly changing industries.

For more information, contact us at:

Call: 9205592194

Email: [email protected]

Website: www.onosokki.co.in

0 notes

Text

Exploring the Advantages of Ono Sokki's Vibration Analyzer

In the field of engineering and industrial maintenance, accurate measurement and analysis of vibrations play a crucial role in ensuring the optimal performance and longevity of machinery. Ono Sokki, a renowned company specializing in precision measuring instruments, offers a cutting-edge solution known as the Vibration Analyzer. The objective is to delve into the advantages of Ono Sokki's Vibration Analyzer, unveiling its features, applications, and the benefits it offers to industries across diverse sectors.

Advantages of Ono Sokki's Vibration Analyzer

1. High-Precision Measurement

Ono Sokki's Analyzer boasts exceptional accuracy in measuring vibrations. Equipped with advanced sensors and signal processing algorithms, it provides precise and reliable measurements, enabling engineers and technicians to identify and diagnose even the slightest abnormalities in machinery performance. With such high precision, maintenance teams can take prompt corrective actions, preventing potential breakdowns and minimizing downtime.

2. Comprehensive Vibration Analysis

One of the key advantages of its vibration analyzer is its ability to perform comprehensive vibration analysis. The analyzer offers a wide range of analysis functions, including time waveform analysis, frequency analysis, and phase analysis. These features allow users to gain deep insights into the characteristics of vibrations, identify specific fault patterns, and determine the root causes of issues. Consequently, engineers can develop effective maintenance strategies and optimize machinery performance.

3. Real-time Monitoring and Alarming

Further, the analyzer facilitates real-time monitoring of vibrations, ensuring continuous assessment of machinery conditions. By monitoring vibrations during operation, the analyzer can detect any sudden changes or abnormal behavior promptly. It also provides customizable alarm settings that notify maintenance personnel when vibration levels exceed predetermined thresholds. This proactive approach enables quick interventions and prevents potential damage, leading to enhanced equipment reliability.

4. User-friendly Interface and Intuitive Operation

The Ono Sokki analyzer is designed with a user-friendly interface and intuitive operation in mind. Ono Sokki has invested significant efforts in creating a system that is easy to navigate and operate, even for individuals with limited technical expertise. The analyzer's graphical display and intuitive controls enable users to access measurement data, perform analysis functions, and generate reports effortlessly. This user-friendly approach streamlines the entire vibration analysis process, saving time and improving overall productivity.

5. Versatile Applications

Ono Sokki finds applications in a wide range of industries. It is commonly utilized in manufacturing plants, power generation facilities, automotive production lines, and aerospace engineering, among others. The analyzer is compatible with various types of machinery, including motors, pumps, compressors, and turbines. Its versatility allows maintenance teams from different sectors to benefit from its advanced capabilities, ensuring the smooth operation of critical equipment.

The Key to Optimal Performance

Ono Sokki's Sound and Vibration Analyzer stands out as a powerful and reliable solution for analyzing vibrations in industrial machinery. With its high precision measurement, comprehensive analysis functions, real-time monitoring, user-friendly interface, and versatile applications, the analyzer empowers maintenance teams to proactively manage machinery health, prevent costly breakdowns, and optimize overall productivity.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Text

A Closer Look at the Ono Sokki Laser Type Tachometer

In the world of precision measurements and industrial applications, having accurate and reliable tools is essential. One such tool that stands out is the Ono Sokki Laser Type Tachometer. This advanced device offers precise speed and rotational measurements, making it a valuable asset in various industries. In the following sections, we will delve deeper into the features and benefits of the Laser tachometer by Ono Sokki.

The Laser Type Tachometer is a cutting-edge instrument designed to measure rotational speed with exceptional accuracy. It utilizes laser technology to provide non-contact measurements, eliminating the need for physical contact with the rotating object. This feature makes it ideal for delicate or high-speed applications where direct contact may not be possible or desirable.

Key Features and Benefits

1. Laser Accuracy and Non-Contact Measurement

The Ono Sokki Laser Type Tachometer, also known as a Digital Engine Tachometer, offers unparalleled accuracy due to its laser-based measurement system. By emitting a laser beam onto the rotating target, the Digital Engine Tachometer can precisely calculate the speed based on the reflected light. This non-contact measurement method ensures minimal interference with the object being measured and eliminates the risk of damage or disruption to the process.

2. Wide Range of Applications

With its versatile design, it finds application in a wide range of industries. Whether it's used in automotive, manufacturing, aerospace, or research and development, this tachometer delivers reliable and consistent results. It is suitable for measuring rotational speed in motors, turbines, conveyor belts, fans, pumps, and various other rotating components.

3. User-Friendly Interface and Data Management

Further, its features include a user-friendly interface, allowing for easy operation and quick measurements. Its digital display provides clear and readable readings, ensuring convenience and accuracy. The device also offers data storage capabilities, allowing users to save and retrieve measurement data for analysis and documentation purposes.

4. Compact and Portable Design

Portability is an essential factor in many industrial environments. The Laser Tachometer by Ono Sokki addresses this need with its compact and lightweight design. Its ergonomic structure enables easy handling and effortless transportation between measurement locations. This portability ensures flexibility and convenience, particularly in dynamic work environments.

5. Durability and Longevity

Built with durability in mind, the laser type tachometer is designed to withstand demanding conditions. It is constructed using high-quality materials that can endure rugged industrial environments and harsh operating conditions. This robust build ensures the device's longevity, making it a reliable long-term investment for businesses.

A Reliable Investment

The ono sokki's tachometer stands as a high-performing instrument in the realm of rotational speed measurements. Its laser accuracy, non-contact measurement capabilities, wide range of applications, user-friendly interface, compact design, and durability make it a valuable tool for industries requiring precise speed monitoring. Whether you're in manufacturing, automotive, or research and development, it offers the accuracy and reliability needed for critical measurements.

Investing in the Ono Sokki's Laser Type Tachometer equips professionals with a state-of-the-art device that can enhance productivity, improve quality control, and streamline operations. With its advanced features and benefits, this tachometer proves to be a smart choice for those seeking top-notch performance in rotational speed measurement.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Text

Why Sound and Vibration Measurement is Essential

Sound and vibration measurement is essential due to its many applications in ensuring workplace health and safety, environmental monitoring, product quality, structural integrity, research and development, and regulatory compliance. By understanding and quantifying sound and vibrations, we can improve judgement, boost productivity, and create a better, more harmonious environment for both people and the natural world. https://www.onosokki.co.in/sound-vibration-measurement/

0 notes

Text

Unlocking the Potential of Ono Sokki's Linear Variable Differential Transducer (LVDT)

Ono Sokki's Linear Variable Differential Transducer (LVDT) is a versatile sensor used for measuring linear displacement or position. Familiarize yourself with the working principles of LVDT. It consists of a primary coil and two secondary coils. As the core inside the coil moves, the voltage induced in the secondary coils changes proportionally, providing precise position measurements. Proper installation and calibration are crucial for accurate measurements. Follow the manufacturer's guidelines to mount the object securely and align it correctly with the measured object. Ensure that the LVDT is calibrated and zeroed appropriately before use. outputs an AC voltage that needs to be conditioned for further processing. Use a suitable signal conditioning circuit provided by Ono Sokki to amplify and filter the signal, eliminating noise and interference. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements. Python libraries like NumPy and SciPy can be helpful for signal processing tasks. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements.

What is an LVDT used for?

Industrial Automation: are used in industrial automation systems for precise positioning and control of machinery and equipment. They provide feedback on linear movements, allowing for accurate monitoring and adjustment of processes.

Quality Control and Metrology: It plays a crucial role in quality control and metrology applications. They are used for measuring dimensions, tolerances, and surface profiles in manufacturing processes, ensuring compliance with specifications, and maintaining product quality.

Material Testing: LVDTs are employed in material testing equipment to measure mechanical properties like strain, compression, or tensile strength. They provide accurate displacement measurements during mechanical testing and analysis.

Geotechnical Engineering: They are used in geotechnical applications to monitor ground movement and deformations. They help in measuring the settlement of structures, analysing soil behaviour, and providing early warnings for potential hazards.

Aerospace and Automotive: they are utilized in the aerospace and automotive industries for various applications, including flight control systems, suspension systems, fuel and hydraulic systems, and position feedback for movable components.

Research and Development: It finds applications in research and development projects across various scientific disciplines. They are used for precise measurements in areas such as material science, robotics, biomechanics, and more.

How does LVDT optimize measurement accuracy and precision for linear gauge sensors?

This is designed with high linearity, ensuring that the relationship between the measured linear displacement and the output voltage is consistent. Linear Gauge Sensor helps minimize measurement errors and deviations, enabling accurate and precise readings.

Excellent Signal-to-Noise Ratio: Provide a high signal-to-noise ratio, reducing the impact of external noise and interference on the measurement signal. This results in cleaner, more reliable data and enhances measurement accuracy.

Temperature Compensation: incorporate temperature compensation techniques. These compensate for temperature variations that can affect the performance of the sensor, ensuring accurate measurements even in changing environmental conditions.

Signal Conditioning: It offers dedicated signal conditioning circuits, or LVDT signal conditioners, to amplify and condition the LVDT output signal. These circuits help to minimize noise, enhance signal quality, and improve measurement accuracy.

Calibration and Linearity Correction: Ono Sokki provides calibration standards and techniques for their LVDTs, allowing users to perform regular calibration procedures. This ensures that it is accurately calibrated and enables correction for any non-linearities in the measurement output, further enhancing accuracy.

Mechanical Stability: They are designed to offer mechanical stability, minimizing mechanical vibrations or instabilities that could introduce measurement errors. Proper mounting and alignment techniques are employed to ensure reliable and repeatable measurements.

Data Acquisition: It can be easily integrated with various data acquisition systems, such as digital mustimeters or dedicated measurement instruments. These instruments offer high-resolution data acquisition capabilities, allowing precise capture of the LVDT output for accurate measurement analysis.

Where is LVDT applicable?

1. Manufacturing and industrial automation

2. Aerospace and defence

3. Automotive Industry

4. Civil Engineering and Structural Monitoring

5. Research and development

6. Medical Devices

7. Geotechnical Engineering

8. Quality Control and Metrology

9. Energy and power generation

Why is LVDT linear?

LVDTs are inherently linear due to their design and operating principles. The linear characteristic of an LVDT refers to its ability to provide a linear relationship between the physical displacement of its core and the output voltage it produces. They are constructed with a symmetrical arrangement of coils and a movable ferromagnetic core. This geometric symmetry ensures that the magnetic field generated by the primary coil is evenly distributed around the core. As a result, the induced voltages in the secondary coils are proportional to the core's position along the axis of motion. It uses a differential output configuration where two secondary coils are wound in opposite directions around the central primary coil. The voltages induced in the secondary coils are out of phase with each other. By taking the difference between these two outputs, a net voltage is obtained that is directly proportional to the core's displacement, resulting in a linear relationship.

Key to Reliable Linear Positioning

Ono Sokki's LVDT offers great potential for unlocking accurate and precise linear measurement capabilities. By understanding the principles of operation, properly installing and calibrating the sensor, implementing effective signal conditioning, and utilizing advanced techniques such as temperature compensation and linearity correction, users can optimize measurement accuracy and precision. It provides dedicated signal conditioning circuits, calibration standards, and expert support to ensure the optimal performance of their LVDTs. Additionally, maintaining mechanical stability, choosing appropriate data acquisition systems, and following quality assurance and maintenance practices contribute to unlocking the full potential. By leveraging the potential, users can obtain reliable and high-quality linear displacement measurements in various applications. Whether it's in manufacturing, automotive, aerospace, or research, the accuracy and precision offered empower users to make informed decisions, monitor critical processes, and achieve desired outcomes. Unlocking the potential involves continuous learning, staying updated with advancements in the field, and seeking support when needed. With proper implementation and utilization, LVDTs can be valuable tools for precise linear measurement and contribute to the success of diverse industries and applications.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Text

Optimizing Two-Wheeler Performance with Ono Sokki’s Chassis Dynamometer

Ono Sokki offers a specialized tool, the chassis dynamometer, that plays a crucial role in optimizing the performance of two-wheelers. The chassis dynamometer is a testing system designed to simulate real-world driving conditions and evaluate the performance characteristics of motorcycles and scooters. With Ono Sokki's chassis dynamometer, manufacturers, engineers, and enthusiasts can gather precise and reliable data to enhance the overall performance and efficiency of two-wheelers. The chassis dynamometer accurately measures the power and torque output of the engine. This data helps in evaluating the performance capabilities of the two-wheeler and identifying areas for improvement. Manufacturers can optimize engine design, intake and exhaust systems, and fuel delivery to maximize power and torque output. Ono Sokki's chassis dynamometer enables precise fuel efficiency and emissions testing. By simulating various road conditions and load scenarios, the dynamometer assesses the two-wheeler's fuel consumption and emission levels. This information allows manufacturers to develop more fuel-efficient and environmentally friendly vehicles while complying with emission standards.

What are chassis dynamometers useful for?

Performance testing allows for precise measurement of power output, torque, acceleration, and top speed, enabling performance comparisons between different models or modifications. This information helps optimize engine performance and evaluate the impact of changes made to the vehicle.

Fuel Efficiency and Emissions Testing: Chassis dynamometers simulate real-world driving conditions, allowing an accurate assessment of fuel consumption and emissions. This data helps manufacturers develop more fuel-efficient and environmentally friendly vehicles while ensuring compliance with emission standards.

Diagnostic and Troubleshooting: It assists in diagnosing and troubleshooting performance issues. By monitoring engine parameters, observing fuel consumption patterns, and analyzing power delivery, potential problems can be identified and addressed to optimize the vehicle's performance.

Research and Development: Chassis dynamometers serve as invaluable tools for research and development in the automotive industry. They allow for the testing and validation of new technologies, components, and vehicle designs, enabling engineers to optimize performance and improve overall efficiency.

Performance Validation and Certification: It provides a reliable platform for performance validation and certification. Manufacturers can ensure that their two-wheelers meet industry standards and performance criteria, instilling confidence in consumers regarding the quality and capabilities of the vehicles.

Suspension and Handling Optimization: Chassis dynamometers help assess the ride comfort and handling characteristics of two-wheelers. By simulating various road conditions, they enable manufacturers to optimize suspension systems, frame design, and tire selection, leading to enhanced stability, maneuverability, and rider comfort.

How does the use of a chassis dynamometer contribute to optimizing the performance of two-wheelers?

Precise Performance Measurement: It provides accurate and reliable measurements of power output, torque, acceleration, and top speed. These measurements help assess the current performance level of the two-wheeler and identify areas for improvement.

Performance Comparison: By conducting tests on different models or modifications of two-wheelers, a chassis dynamometer enables performance comparisons. This allows manufacturers and enthusiasts to evaluate the impact of changes and modifications on the overall performance of the vehicle.

Diagnostic Capabilities: Chassis dynamometers help diagnose and troubleshoot performance issues by monitoring engine parameters, fuel consumption patterns, and power delivery. Two-wheel chassis dynamometer, in identifying potential problems and optimizing the vehicle's performance.

Efficiency Optimization: With the ability to simulate real-world driving conditions, a chassis dynamometer assists in evaluating fuel consumption and emissions. This information helps manufacturers develop more fuel-efficient and environmentally friendly vehicles while ensuring compliance with emission standards.

Research and Development: Chassis dynamometers are valuable tools for research and development activities. They allow engineers to test and validate new technologies, components, and designs, leading to improvements in performance, efficiency, and overall quality of two-wheelers.

Performance Validation: It provides a reliable platform for performance validation, ensuring that two-wheelers meet industry standards and performance criteria. This enhances consumer confidence in the vehicle's quality and capabilities.

The use of a displacement sensor in a chassis dynamometer

A Displacement sensor in a chassis dynamometer provides precise measurements of the movement and displacement of various components of the two-wheeler, such as suspension systems, chassis flex, and wheel alignment. This accurate measurement allows for a comprehensive understanding of the vehicle's dynamics and performance characteristics.

By measuring the displacement of the suspension components, the sensor helps in tuning and optimizing the suspension system. It enables engineers and enthusiasts to fine-tune parameters such as spring rates, damping characteristics, and ride height, ensuring optimal handling, stability, and rider comfort.

The displacement sensor aids in analyzing the behavior of the frame and chassis under different load conditions.

It allows for the identification of any unwanted flex or deformations that can affect the overall performance and handling of the two-wheeler. This analysis helps in designing and refining the frame and chassis for improved rigidity and stability.

With the help of a displacement sensor, the chassis dynamometer can accurately measure the alignment and tracking of the wheels. This information is vital in ensuring that the wheels are properly aligned, minimizing tire wear, optimizing traction, and enhancing overall handling and performance.

The precise measurement of displacement provided by the sensor enables engineers and enthusiasts to fine-tune various parameters, such as suspension settings, frame stiffness, and wheel alignment, to achieve optimal performance. This optimization leads to improved stability, handling, and responsiveness, enhancing the overall performance of the two-wheeler.

Elevate Two-Wheeler Performance with Ono Sokki's Chassis Dynamometer

Ono Sokki's chassis dynamometer is a powerful tool that enables the optimization of two-wheeler performance. With precise measurement capabilities and advanced testing features, it allows manufacturers, engineers, and enthusiasts to elevate the performance of motorcycles and scooters. By utilizing Ono Sokki's chassis dynamometer, users can accurately measure power output, torque, acceleration, and top speed, enabling performance comparisons and fine-tuning engine settings. The dynamometer also facilitates fuel efficiency and emissions testing, ensuring compliance with environmental standards and promoting sustainable transportation. Furthermore, the chassis dynamometer aids in diagnosing and troubleshooting performance issues, leading to efficient problem-solving and improved overall performance. It serves as a valuable tool for research and development, enabling the testing and validation of new technologies and vehicle designs. Ono Sokki's commitment to precision, reliability, and innovation ensures that their chassis dynamometer meets the highest industry standards. With their expertise and cutting-edge solutions, Ono Sokki empowers users to unleash the full potential of two-wheelers, enhancing performance, fuel efficiency, and rider satisfaction.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Two-wheel chassis dynamometer#Displacement sensor#Linear Variable Differential Transducer#Sound Measurement#Vibration Measurement#Digital Fuel Flow Meter#On Road Fuel Consumption Meter#Linear Gauge Sensor#LVDT

0 notes

Text

Exploring the Depths of Sound Measurement

Ono Sokki is a renowned company specializing in sound measurement instruments and systems. With a rich history and expertise in the field, Ono Sokki offers a wide range of high-quality devices that enable precise and accurate sound measurement across various applications. Sound measurement plays a crucial role in several industries, including environmental monitoring, industrial noise control, product testing, and acoustic research. Ono Sokki's instruments are designed to meet the diverse needs of professionals in these fields, providing them with reliable tools for gathering and analyzing sound data. One of the fundamental parameters in sound measurement is sound pressure level (SPL), which represents the magnitude of sound waves. Ono Sokki offers sound level meters that allow users to measure SPL with precision. These meters often incorporate advanced features such as frequency weighting, time weighting, and octave band analysis to provide a comprehensive assessment of sound characteristics. In addition to sound level meters, Ono Sokki produces sound analyzers that enable in-depth analysis of sound signals. These analyzers typically offer a wide range of measurement capabilities, including spectral analysis, frequency response analysis, and sound intensity measurement. They are commonly used in fields like audio engineering, automotive testing, and architectural acoustics.

Significance of sound measurement

Environmental Monitoring: Sound measurement is essential for assessing and managing environmental noise pollution. It helps in identifying noise sources, evaluating their impact on communities, and implementing appropriate noise control measures.

Occupational Health and Safety: In workplaces, excessive noise levels can lead to hearing loss and other health issues. Sound measurement helps in determining and maintaining safe noise levels, ensuring the well-being of workers, and complying with occupational health and safety regulations.

Product Testing and Quality Control: Sound measurement is crucial for evaluating the acoustic performance of products such as speakers, headphones, and automotive components. By quantifying sound characteristics, manufacturers can ensure that their products meet desired standards and deliver optimal sound quality.

Architectural Acoustics: Sound measurement plays a vital role in designing spaces with appropriate acoustic properties. By measuring sound reflections, absorption, and transmission, architects and acoustic engineers can optimize room acoustics for enhanced speech intelligibility, reduced reverberation, and improved overall sound quality.

Audio Engineering and Music Production: Sound measurement tools are essential for audio professionals to calibrate and optimize audio equipment, monitor sound levels during live events, and ensure accurate sound reproduction in recording studios.

Sound measurement plays a crucial role

Environmental Monitoring: Sound measurement is vital for assessing and managing environmental noise pollution in industrial areas. It helps in identifying noise sources, evaluating their impact on nearby communities, and implementing noise control measures to comply with regulatory requirements.

Workplace Safety: Occupational health and safety regulations often require monitoring and controlling noise levels in industrial settings. Sound measurement helps in assessing and mitigating noise-related risks to protect workers from excessive noise exposure, which can lead to hearing loss and other health issues.

Product Testing and Quality Control: Sound measurement is essential in industries that produce acoustic equipment or components, such as audio systems, speakers, and automotive parts. By measuring sound characteristics and performance, manufacturers can ensure the quality, efficiency, and compliance of their products.

Machinery Diagnostics: It is used for diagnosing and monitoring the health of industrial machinery. By analyzing the sound signatures and vibrations of equipment, maintenance professionals can identify potential issues like bearing wear, misalignment, or unbalanced rotating parts, allowing for timely maintenance and preventing breakdowns.

Industrial Process Control: It is employed in process control systems to monitor and analyze acoustic signals for quality control and optimization purposes. By monitoring sound patterns, deviations, and frequencies, industrial processes can be adjusted and optimized for improved efficiency and productivity.

Structural Health Monitoring: Vibration measurement is used in structural engineering to assess the health and integrity of buildings, bridges, and other structures. By analyzing the acoustic emissions and vibrations, engineers can detect structural defects, cracks, or anomalies, enabling timely repairs and maintenance.

Emerging trends in sound measurement

Advancements in wireless technology have enabled the development of sound measurement systems that can be remotely operated and monitored. This allows for greater flexibility in data collection and monitoring in various applications and environments. The integration of Sound Testing devices with IoT technology has opened up new possibilities in data acquisition, analysis, and real-time monitoring. IoT-enabled sound measurement systems can provide continuous data streams, remote access, and enhanced connectivity for efficient monitoring and control. AI and machine learning algorithms are increasingly being utilized in sound measurement to enhance data analysis and pattern recognition. These technologies enable automated identification of sound sources, intelligent noise control systems, and advanced data processing for more accurate and efficient sound measurements. Virtual and augmented reality technologies are being applied to sound measurement, enabling immersive audio simulations and acoustic modelling. These advancements provide a more realistic and interactive approach to analysing sound environments and designing acoustic spaces. Sound measurement systems are now capable of simultaneously measuring multiple parameters, such as sound pressure level, sound intensity, frequency analysis, and reverberation time. This integrated approach allows for a more comprehensive understanding of sound characteristics and their interactions.

Plunge into the World of Sound Measurement

Ono Sokki is a leading provider of Sound Level Meter instruments and systems, offering a comprehensive range of tools that enable professionals to explore the depths of sound measurement. The significance of sound measurement lies in its ability to provide objective and quantitative data about sound waves and their characteristics, impacting various industries and applications. No Sokki's sound level meters, sound analysers, and vibration meters offer precise and reliable measurements, allowing professionals to gather comprehensive data and insights. These instruments incorporate advanced features such as frequency weighting, time weighting, and spectral analysis, empowering users to delve deeper into sound phenomena and make informed decisions based on accurate measurements. The industrial applications of sound measurement are vast and diverse. Ono Sokki's instruments find utility in environmental monitoring, occupational health and safety, product testing and quality control, machinery diagnostics, process control, structural health monitoring, and automotive testing, among others. By providing reliable measurement solutions for these applications, Ono Sokki contributes to enhancing environmental sustainability, ensuring workplace safety, optimizing product performance, and improving overall industrial processes.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

#sound measurement#Vibration measurement#Sound Testing#Sound Level Meter#Noise Level Meter#db Meter#Sound and Vibration Inspection#Sound and Vibration Analyzer

0 notes

Text

How to Choose the Right Motor and Compressor Tachometer

A Motor and Compressor Tachometer is a device used to measure the speed or rotational velocity of a motor or compressor. It provides valuable information about the performance and operational parameters of these machines. Tachometers are essential tools in various industries, including automotive, manufacturing, heating, ventilation, and air conditioning. Motors and compressors can produce different types of speed signals, such as voltage signals, current signals, or pulse signals. Verify that the tachometer you select can accurately measure and interpret the signal type generated by your motor or compressor. Some tachometers may offer multiple signal input options to accommodate various systems. Calibration is crucial to ensuring accurate measurements.

Check if the tachometer requires calibration, and consider the ease and frequency of calibration. Look for tachometers that provide high accuracy and reliable measurements to ensure precise monitoring of motor or compressor speed. Consider the user interface and ease of operation of the tachometer. An intuitive interface with clear displays and accessible controls can simplify the measurement process and enhance the user experience. Some tachometers may also offer additional features like memory storage, data logging, or configurable settings, which can be advantageous for data analysis and troubleshooting. Set a budget for your tachometer purchase and compare prices from different manufacturers or suppliers. Ensure that the tachometer comes with a warranty or guarantee to protect against any manufacturing defects or malfunctions.

How do I choose a tachometer?

Tachometer Type: There are various types of tachometers available, including contact, non-contact, optical, and digital tachometers. Determine the type that suits your application. Contact tachometers physically touch the rotating shaft, while non-contact tachometers use techniques like lasers or infrared to measure speed without physical contact.

Measurement Range: Identify the range of speeds you need to measure. Some tachometers have a limited range, so ensure the selected tachometer can measure the full speed range of your application.

Accuracy and Resolution: Check the accuracy and resolution specifications of the tachometer. Accuracy refers to how closely the tachometer's reading matches the actual speed, while resolution determines the smallest increment that can be detected. Consider the required precision for your application and select a tachometer that meets those requirements.

Display and Readability: Evaluate the display characteristics of the tachometer. It should have a clear and easily readable screen, especially in the environment where it will be used. Some tachometers offer additional features like backlit displays or large digits for improved visibility.

Signal Compatibility: Ensure the tachometer is compatible with the signal output of the system you want to measure. Common types of signals include analog voltage, current, or pulse signals. Check the tachometer's specifications to verify compatibility.

Environmental Considerations: Consider the environmental conditions in which the tachometer will be used. Factors such as temperature, humidity, and exposure to dust or moisture can affect the tachometer's performance. Choose a tachometer that is designed to withstand the specific environmental conditions of your application.

Additional Features: Some tachometers offer extra features that can be beneficial. These may include data logging capabilities, the ability to measure other parameters (e.g., temperature), or wireless connectivity for remote monitoring. Assess your specific needs and select a tachometer that provides the necessary features.

What are the types of tachometers?

There are several types of tachometers available, each with its own method of measuring and displaying rotational speed. Here are some common types of tachometers:

Contact Tachometer: A contact tachometer physically touches the rotating object or shaft to measure its speed. It typically uses a rubber or plastic wheel with a calibrated circumference that rolls along the surface of the rotating object. As the wheel turns, the tachometer measures the frequency or count of wheel revolutions to determine the rotational speed.

Non-Contact Tachometer: Non-contact tachometers measure speed without physical contact with the rotating object. They use various techniques, such as optical, laser, or infrared technology, to determine speed. These tachometers emit a beam of light signal towards a reflective surface on the rotating object and measure the frequency of the reflected signal to calculate the rotational speed.

Optical Tachometer: Optical tachometers utilize a light source and a photodetector to measure rotational speed. They work by detecting marks or reflective tape attached to the rotating object. As the marks or tape pass in front of the tachometer, the photodetector detects changes in light intensity and converts them into speed readings.

Laser Tachometer: Laser tachometers use laser beams to measure rotational speed. They emit a laser beam towards a reflective surface on the rotating object and detect the reflected light. By analyzing the frequency of the reflected light, laser tachometers calculate the rotational speed.

Digital Tachometer: Digital tachometers utilize digital technology to measure and display rotational speed. They often have a digital display that shows the speed reading in RPM (revolutions per minute). Digital tachometers can use various methods, such as contact, non-contact, or magnetic sensors, to measure speed.

Magnetic Tachometer: Magnetic tachometers employ a magnetic sensor to measure rotational speed. They use a magnet or a magnetic sensor probe placed near a gear or rotating component. As the gear or component moves, it creates a magnetic field disturbance that the magnetic sensor detects. The tachometer converts this information into rotational speed readings.

How to Choose the Right EV Tachometer for Motor and Compressor Applications

Ensure that the EV Tachometer you choose is compatible with the specific electric motor and compressor used in your EV system. Different motors and compressors may have varying signal outputs or require specific tachometer features to work properly. Check the compatibility specifications provided by the tachometer manufacturer to ensure a proper match. Determine the signal type and format used by your electric motor and compressor system to provide speed information. Some tachometers may require specific signal types such as analogy voltage, digital pulses, or CAN bus communication.

Ensure that the EV tachometer you select can accurately measure and interpret the signal type generated by your motor and compressor system. Identify the range of speeds you need to measure for both the motor and compressor. Consider the maximum and minimum RPM values to ensure that the selected EV tachometer can effectively measure and display the full range of speeds required for your application. Ensure that the chosen EV tachometer integrates seamlessly with the overall EV system. Check if it can communicate with the vehicle's ECU or other data logging systems to provide motor and compressor speed information for monitoring and diagnostics. Compatibility with onboard communication protocols such as the CAN bus can be essential for data exchange and integration.

How to Choose the Right Motor and Compressor Tachometer with a Non-Contact RPM Detector

Measurement Range: Determine the range of speeds you need to measure for your motor and compressor. Ensure that the tachometer you choose has a non-contact RPM detector that can accurately measure the full speed range of your application.

Accuracy and Resolution: Check the accuracy and resolution specifications of the tachometer. Accuracy refers to how closely the tachometer's reading matches the actual speed, while resolution determines the smallest increment that can be detected. Consider the required precision for your application and select a tachometer with a non-contact RPM detector that meets those requirements.

Non-Contact Technology: Recognize the specific non-contact technology that the tachometer uses. It can be optical, laser, infrared, or any other suitable technology. Ensure that the chosen tachometer employs a non-contact RPM detector that is suitable for your motor and compressor system.

Signal Compatibility: Verify that the tachometer with a Non-Contact RPM Detector is compatible with the signal output of your motor and compressor. Different tachometers may utilize various signal types, such as analogy voltage, current, or digital pulses. Ensure that the tachometer can accurately measure and interpret the signal generated by your motor and compressor system.

Display and Readability: Evaluate the display characteristics of the tachometer. The tachometer should have a clear and easily readable screen that provides RPM readings. Consider factors such as display size, brightness, and nonoptimal visibility, particularly in the environment where it will be used.

Environmental Considerations: Take into account the environmental conditions in which the tachometer with a non-contact RPM detector will be utilized. Ensure that it is designed to withstand factors like temperature variations, vibrations, and potential interference. Look for tachometers that are built to withstand the specific environmental conditions of your motor and compressor system.

Additional Features: Assess if the tachometer offers any additional features that would be beneficial for your application. This may include data logging capabilities, wireless connectivity for remote monitoring, or customizable settings. Determine if these features align with your specific requirements.

Culmination

Determine compatibility with your specific electric motor and compressor systems to ensure seamless integration. Verify the signal type and format used by your system, and select a tachometer that can accurately interpret and measure the signal. Consider the required measurement range, ensuring the tachometer can handle the full range of speeds needed for your application. Check the accuracy and resolution specifications to meet your precision requirements. Evaluate the display's readability, considering factors like size, brightness, and placement within your EV dashboard or control panel. Look for integration capabilities with your EV system, such as communication with the vehicle's ECU or data logging systems. The tachometer's ability to withstand environmental conditions like temperature variations, vibrations, and potential interference. Assess additional features like data logging, customizable settings, and connectivity options to enhance functionality and convenience.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Photo

Types of Digital Fuel Flow Meter | Ono Sokki India

Digital fuel flow meter from Ono Sokki India are available in a wide selection. They are made to precisely measure and track the flow of fuel in a variety of industrial applications. Because of their reputation for dependability, precision, and cutting-edge features, these digital fuel flow meters are a preferred option for companies operating in the automotive, aviation, marine, and energy industries. https://www.onosokki.co.in/product/fuel-flow-detector/

0 notes